Patents

Literature

75results about How to "Convenient itinerary" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

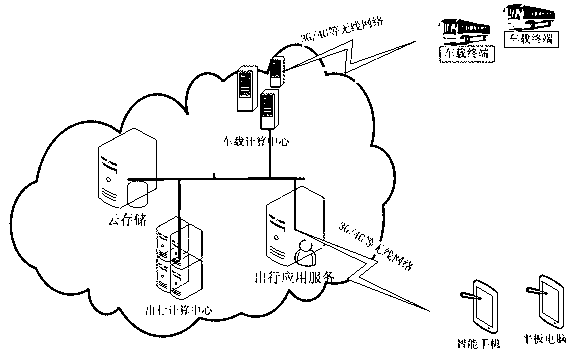

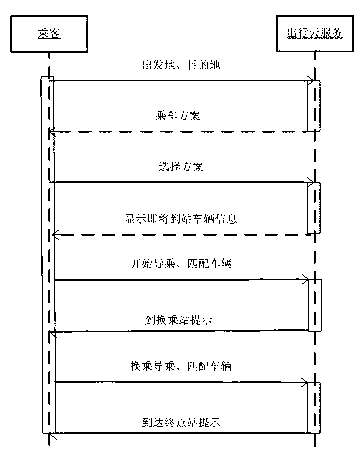

Bus trip service system based on cloud computing

ActiveCN103106702AEasy to scheduleEasy to travelRegistering/indicating working of vehiclesService systemCloud storage

The invention discloses a bus trip service system based on cloud computing. The bus trip service system comprises a vehicle-mounted terminal, a vehicle-mounted computing center, a cloud storage, a trip computing center, a trip application service and a trip application, wherein the trip application can be installed on mobile terminals such as a cell phone, a PAD and the like. A passenger can accomplish a trip plan by using the system, obtains a trip scheme and a latest real trip average time, so that convenience is brought to conduct the passenger to make a trip scheme. The system can provide an overall bus trip guide service, provides functions of bus station arriving prompting, station arriving and transfer prompting, so that people can go out more conveniently and simply and are prevented from missing the station or taking a wrong bus. Relevant service information is automatically prompted, so that convenience is brought for people to make a next scheme; and support is provided for public safety affairs, dispute, lost property finding and the like according to the trip track.

Owner:QINGDAO HISENSE TRANS TECH

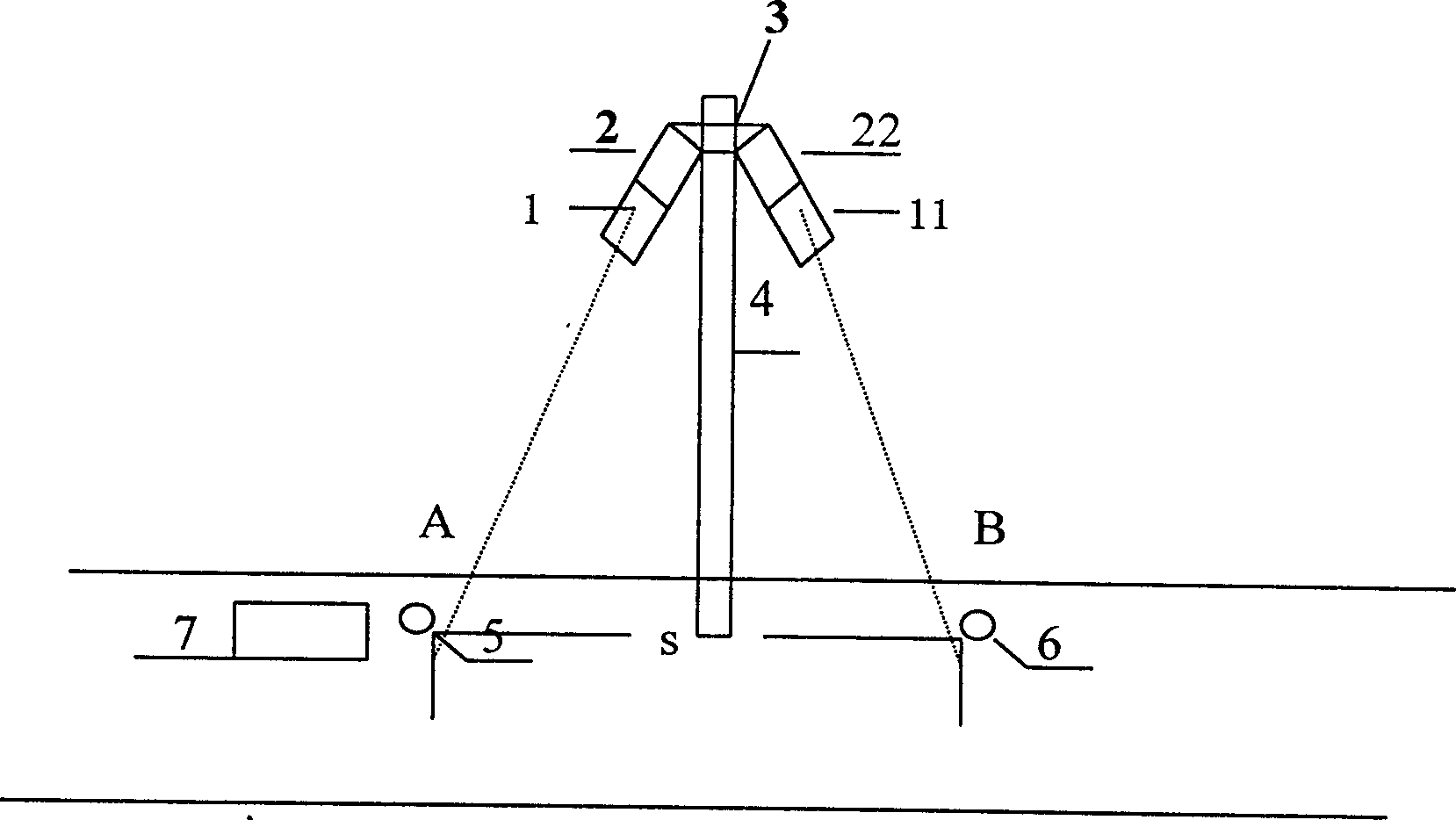

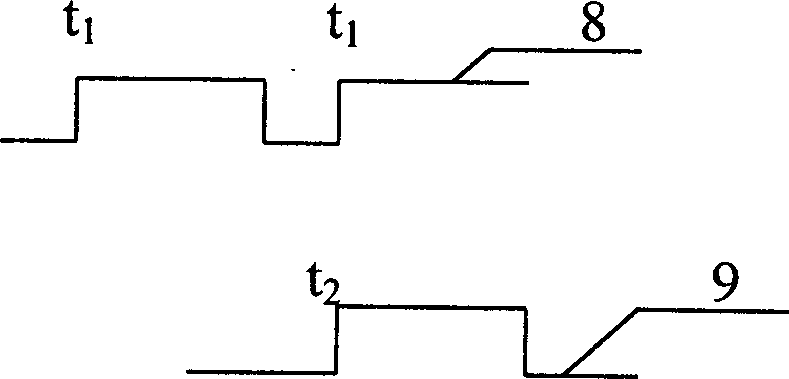

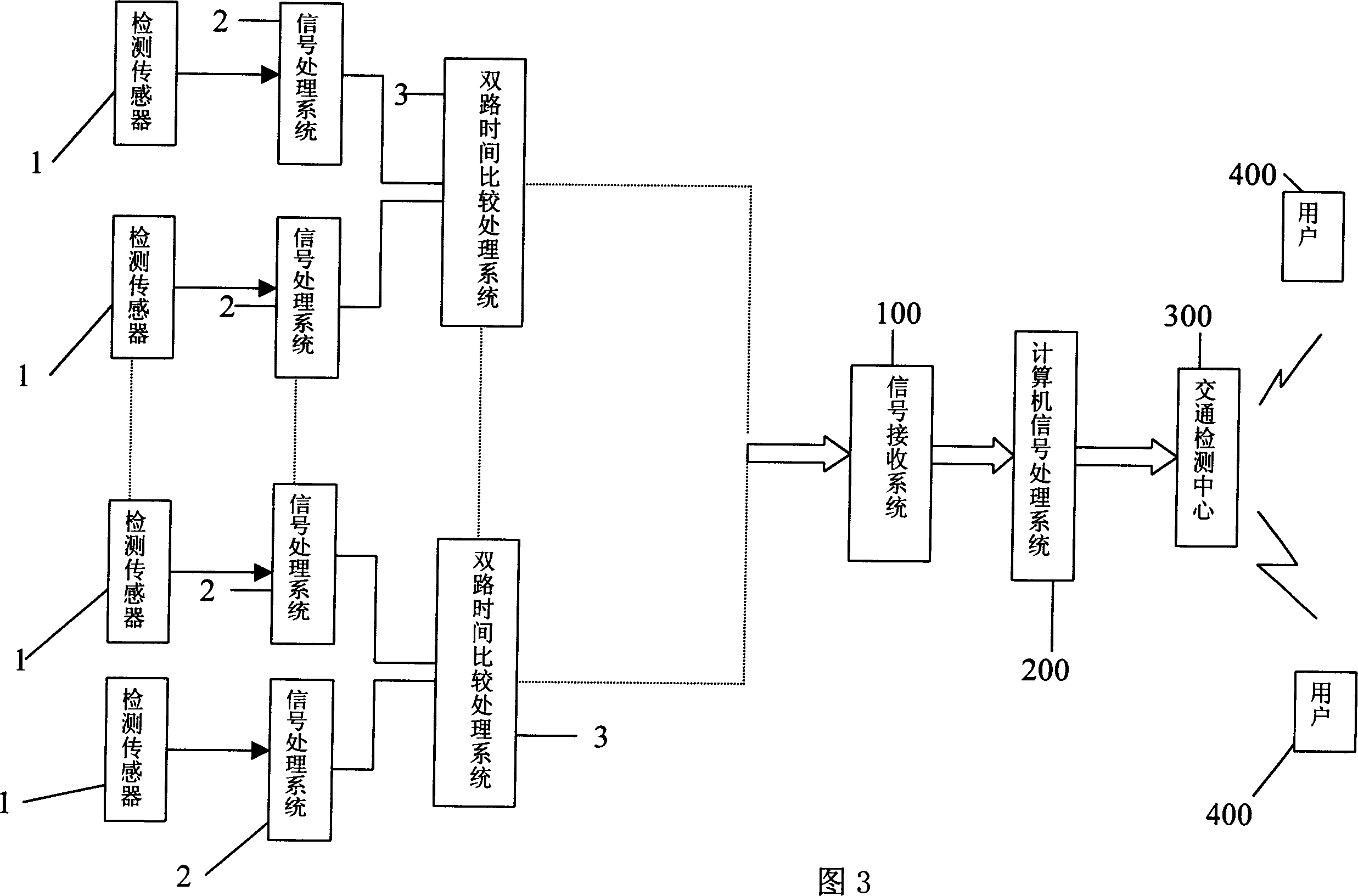

Road traffic status detecting method

InactiveCN1417756ASave transportation investmentConvenient itineraryDetection of traffic movementEngineeringHandling system

In the present invention, a set of sensors is regulated to proper length between detection points, two detecting sensors are used to detect the times for some automobile head to the detecting points separately, and thus the time difference for the automobile to pass through the distance between the detecting points and the automobile speed are calculated by the comparison and processing system while corresponding code number is given. Then, the code number is transmitted to the traffic detection center via available mobile communication network. The present invention makes it possible for thedrivers to understand the specific traffic state in every road.

Owner:陈少元

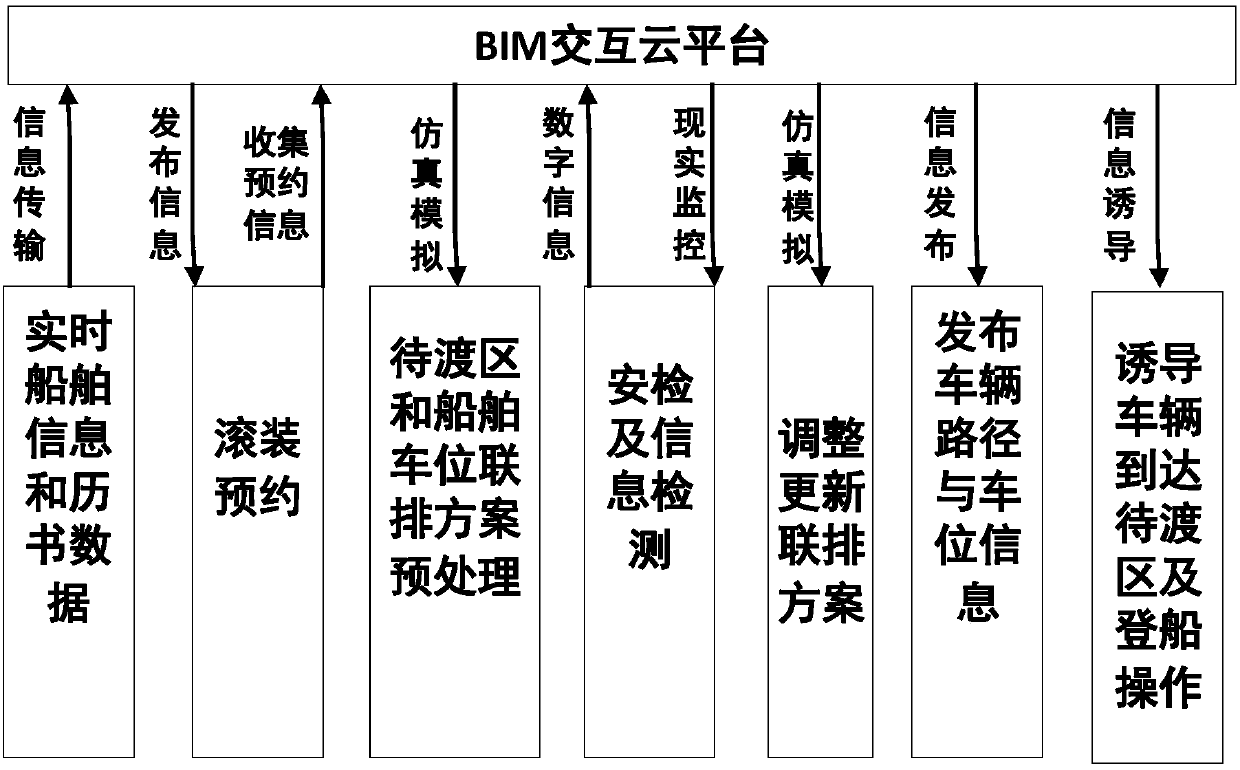

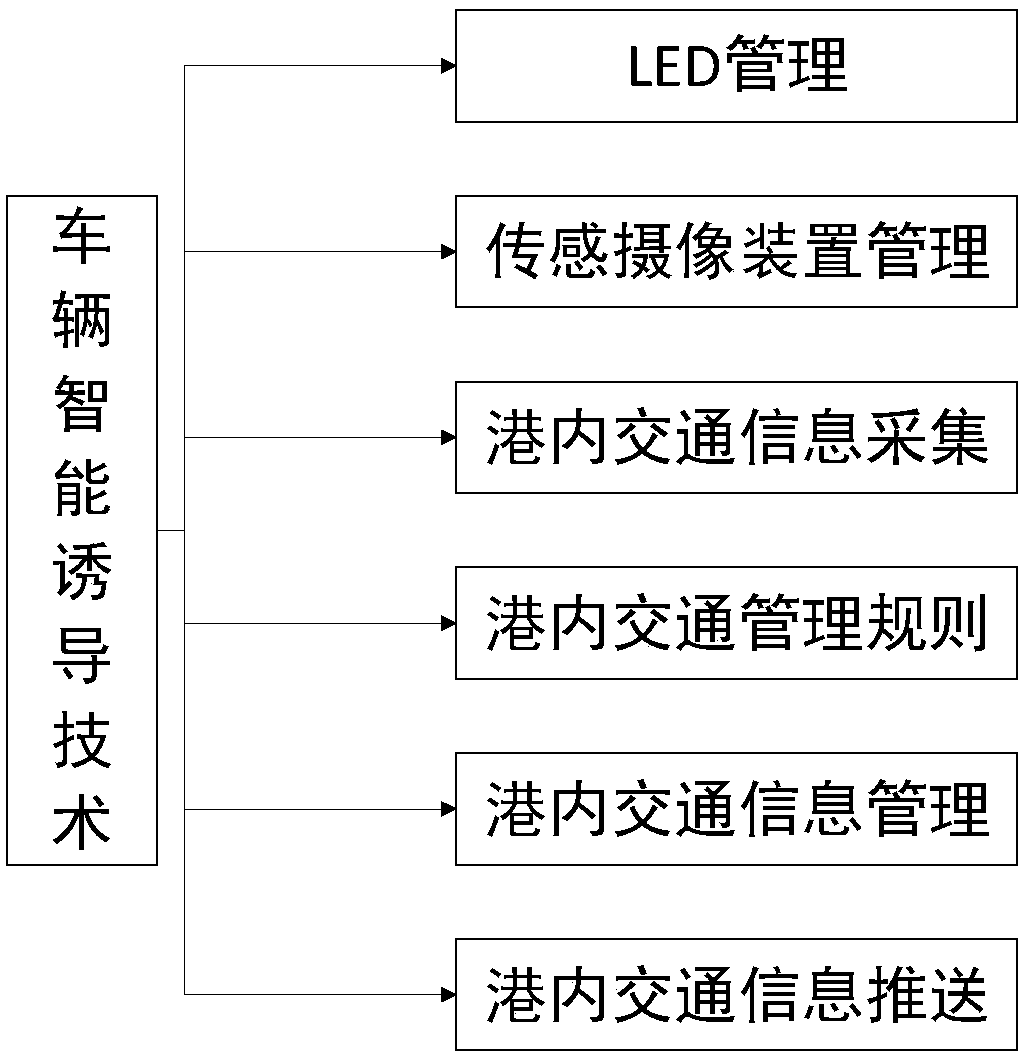

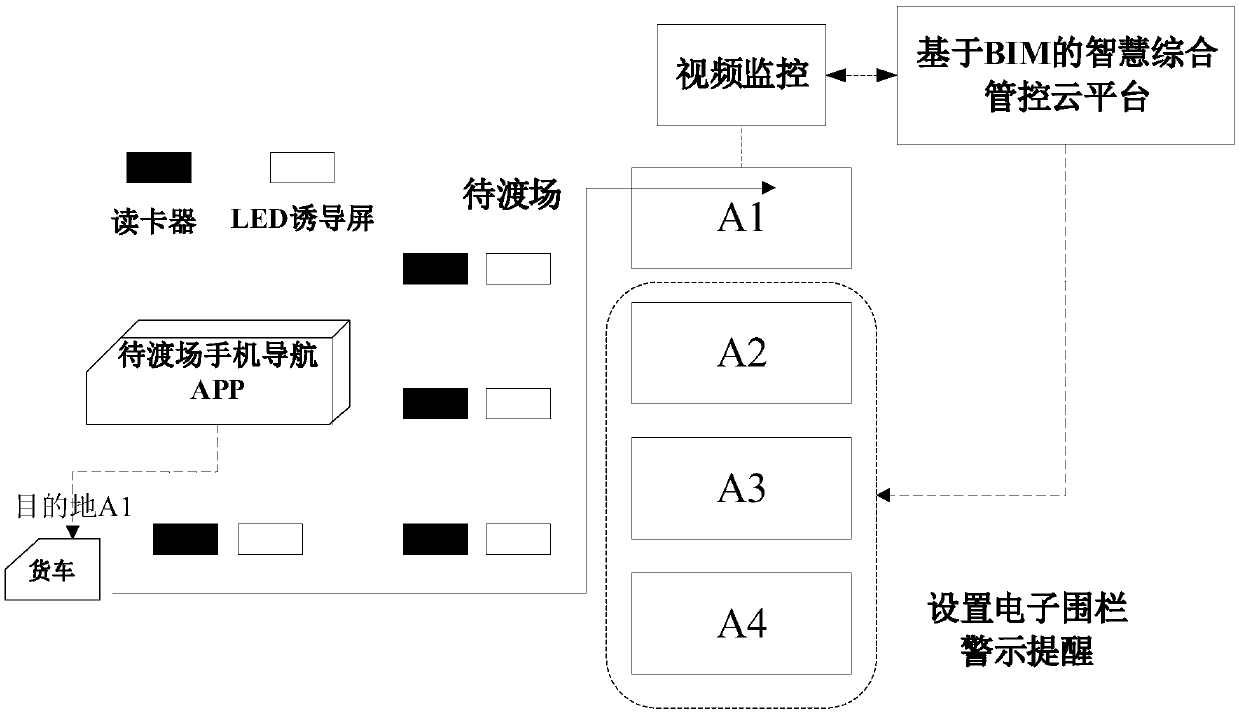

Passenger and freight roll-on and roll-off harbor to-be-transported field intelligent operation mode based on BIM technology

ActiveCN107705547ARealize side-by-side processingReduce wasteIndication of parksing free spacesMarine craft traffic controlParking spaceOperation mode

The invention discloses a passenger and freight roll-on and roll-off harbor to-be-transported field intelligent operation mode based on BIM technology. The passenger and freight roll-on and roll-off harbor to-be-transported field intelligent operation mode comprises steps of acquiring real-time ship information and historical information, issuing and collecting ticket buying reserving information,performing preprocessing on a combined solution of a to-be-transported area and a ship parking space, performing safety checking and information detecting, adjusting and updating the combined solution, issuing vehicle path and parking space information, inducing the vehicles arrive at the to-be-transported area, getting on the ship, etc. The passenger and freight roll-on and roll-off harbor to-be-transported field intelligent operation mode has advantages of automation and intelligence.

Owner:CCCC SECOND HARBOR CONSULTANTS CO LTD

Oil cylinder with adjustable piston stroke

The invention discloses an oil cylinder with adjustable piston stroke, which comprises a cylinder body, the front and the rear ends of the cylinder body are respectively provided with a front end cover and a rear end cover; the cylinder body is internally provided with a piston and a piston rod; the rear end cover is provided with a rear limiting seat which is internally provided with a limiting cavity which passes through a mounting hole on the rear end cover and is communicated with a rear cavity; the limiting cavity and the mounting hole are internally and movably provided with rear limiting rods, the front ends of which are matched with the bottom of the piston, and the rear ends thereof are positioned inside the limiting cavity; the rear limiting seat is provided with a screwed hole communicated with the limiting cavity; and the screwed hole is internally provided with an adjusting screw rod matched with the screwed hole, and the adjusting screw rod is provided with a locking nut matched with the adjusting screw rod. The oil cylinder has the advantages that the oil cylinder with the adjustable piston stroke can be used for conveniently adjusting the stroke of the piston and the piston rod as well as the length of the piston rod, thus leading the oil cylinder to be more conveniently and flexibly used and have wider application scope.

Owner:张家港和升数控机床制造有限公司

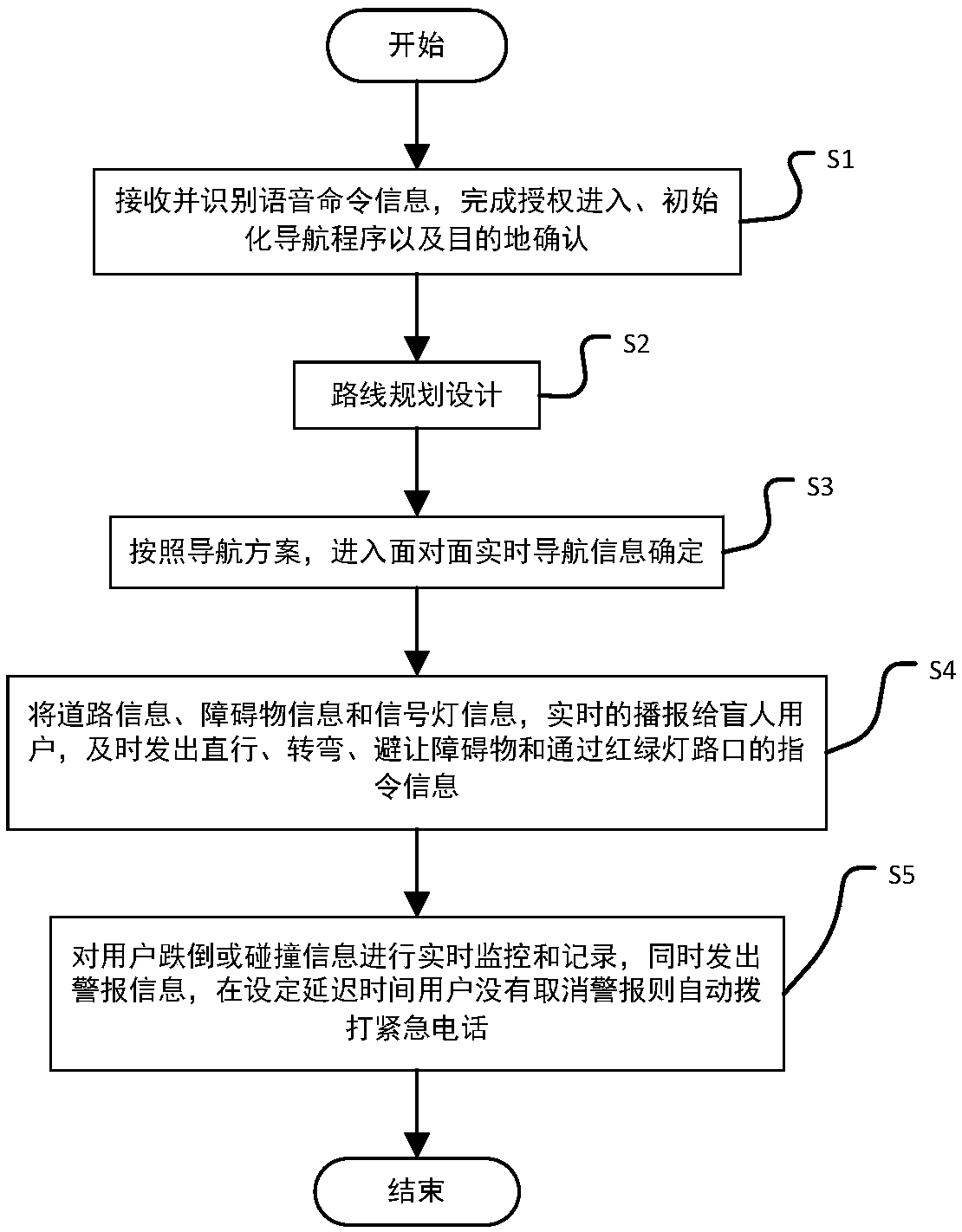

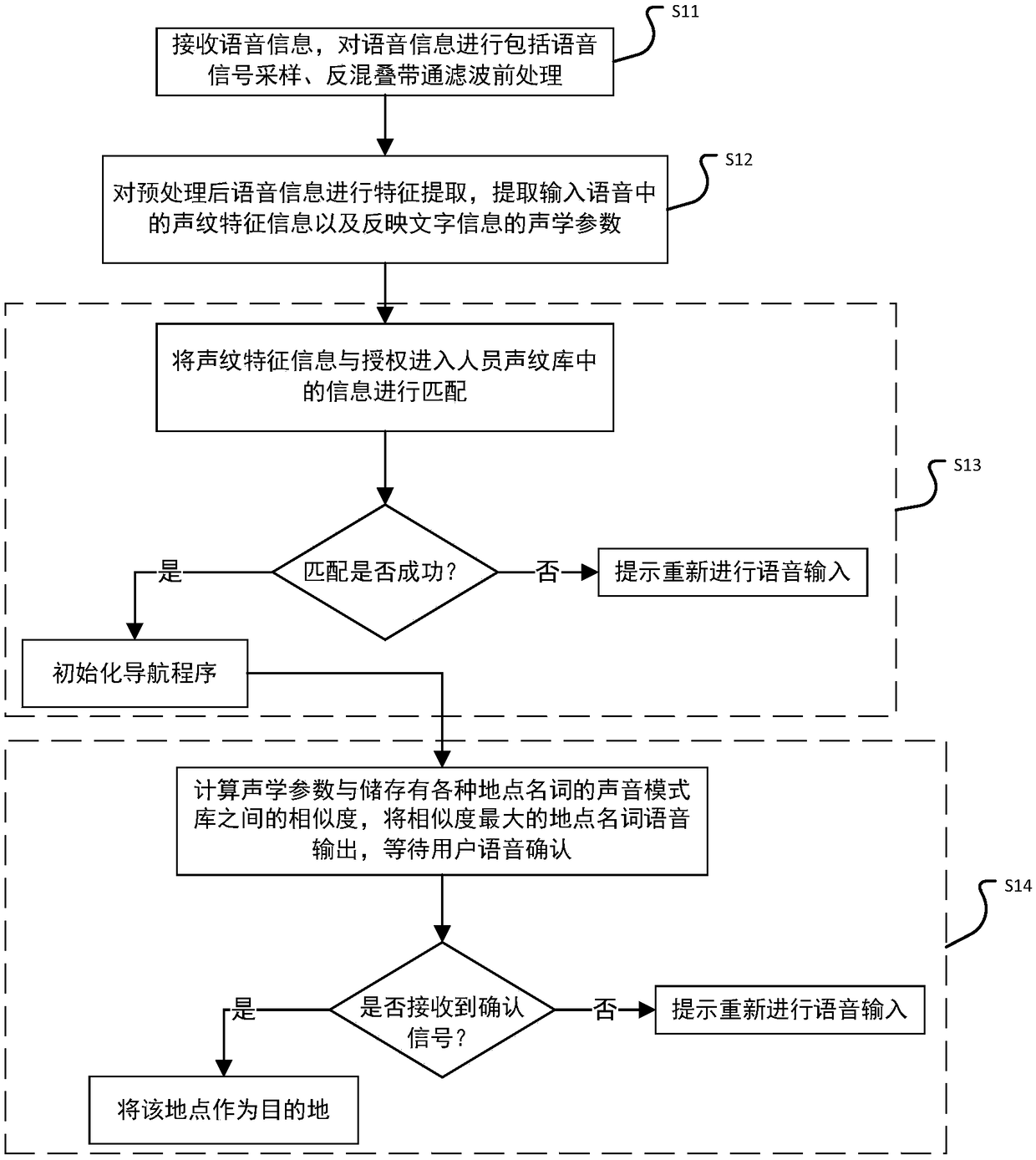

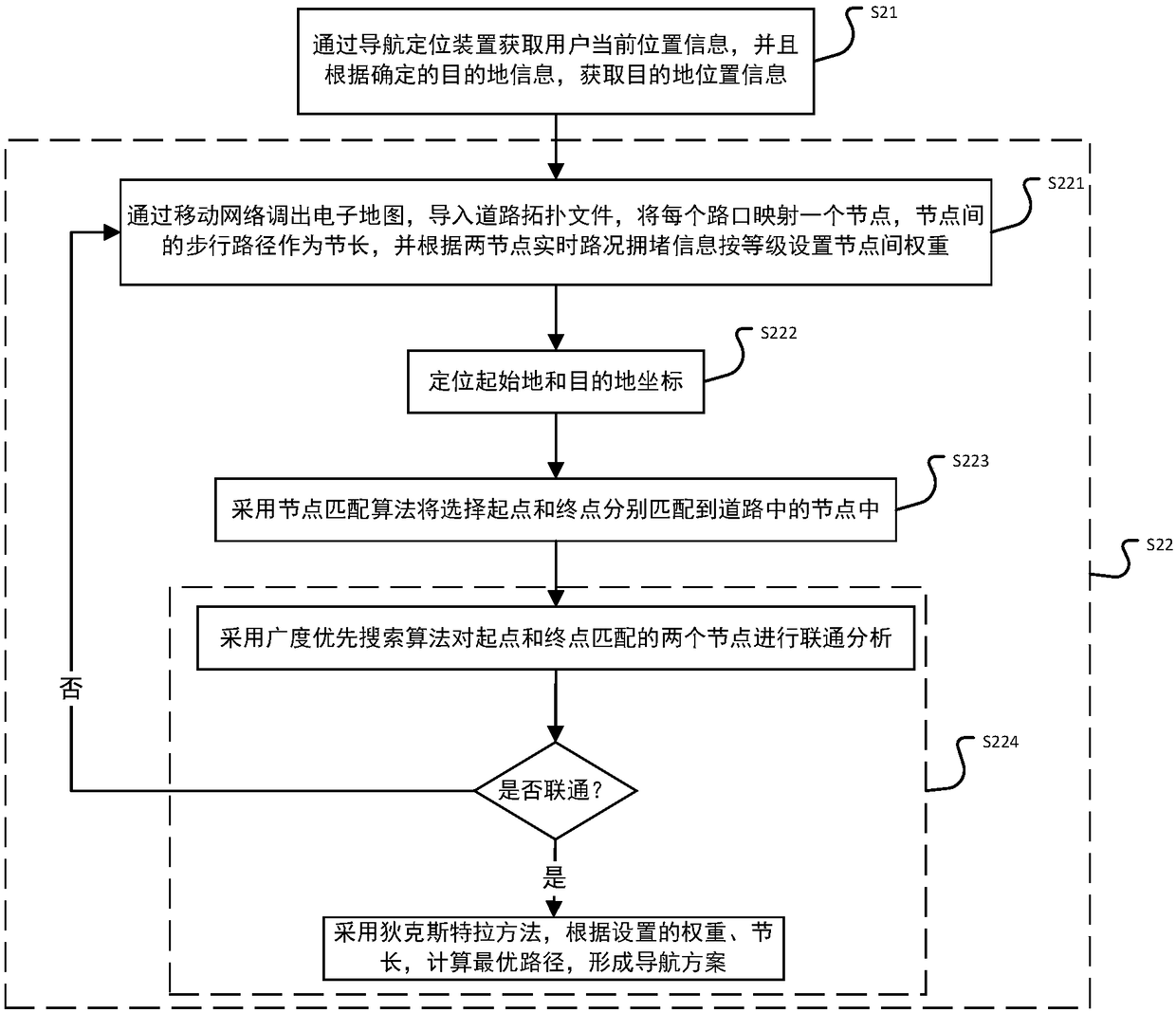

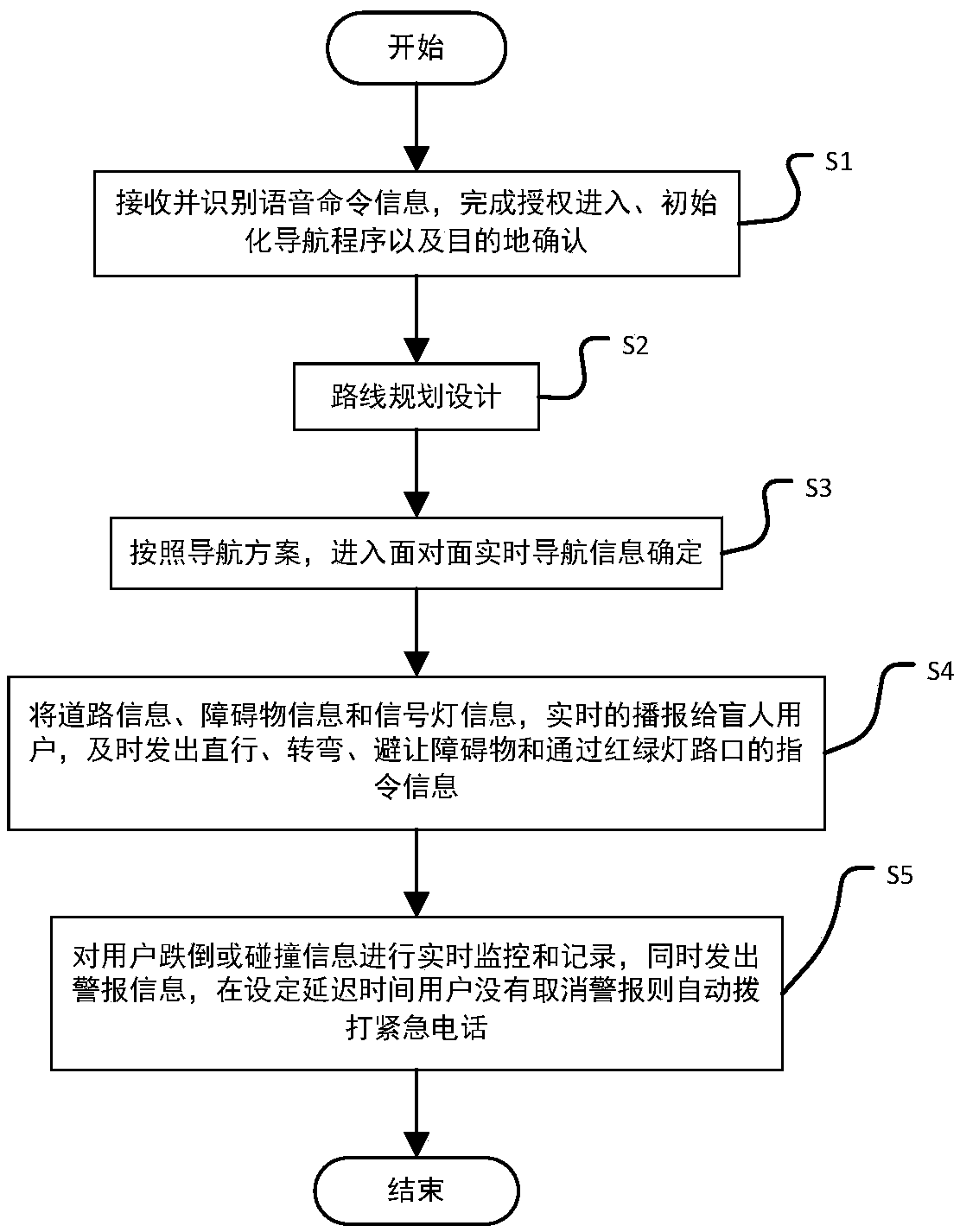

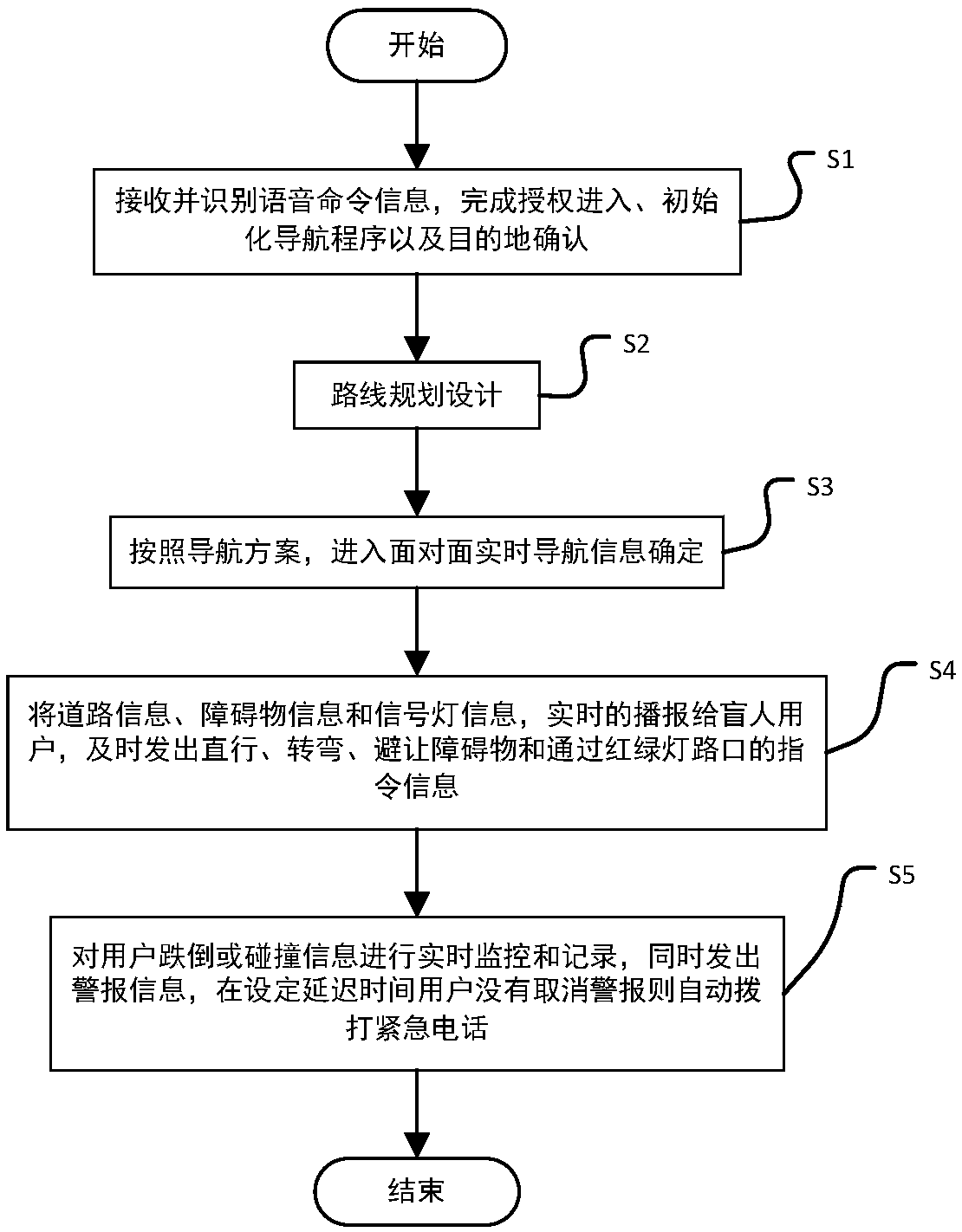

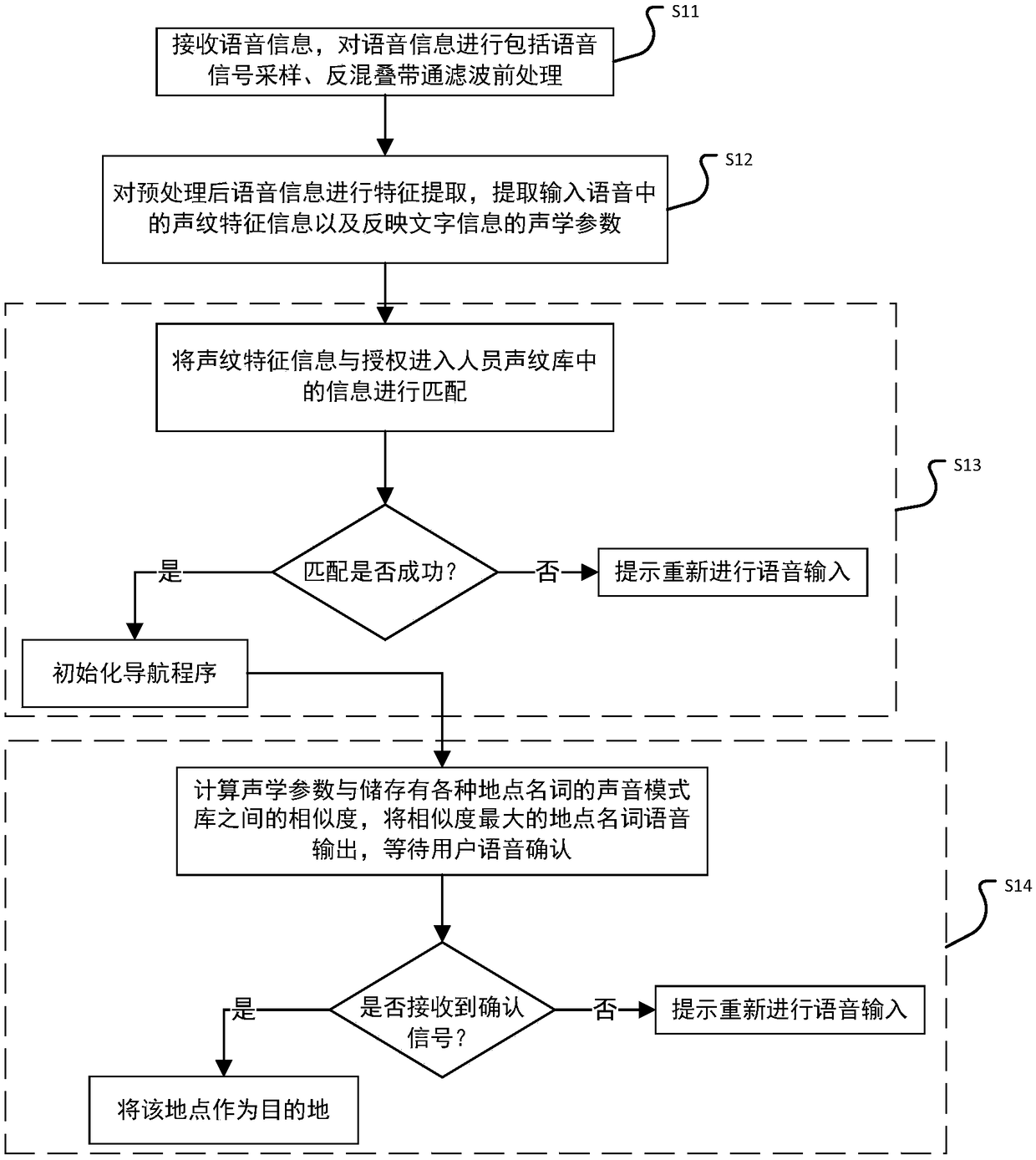

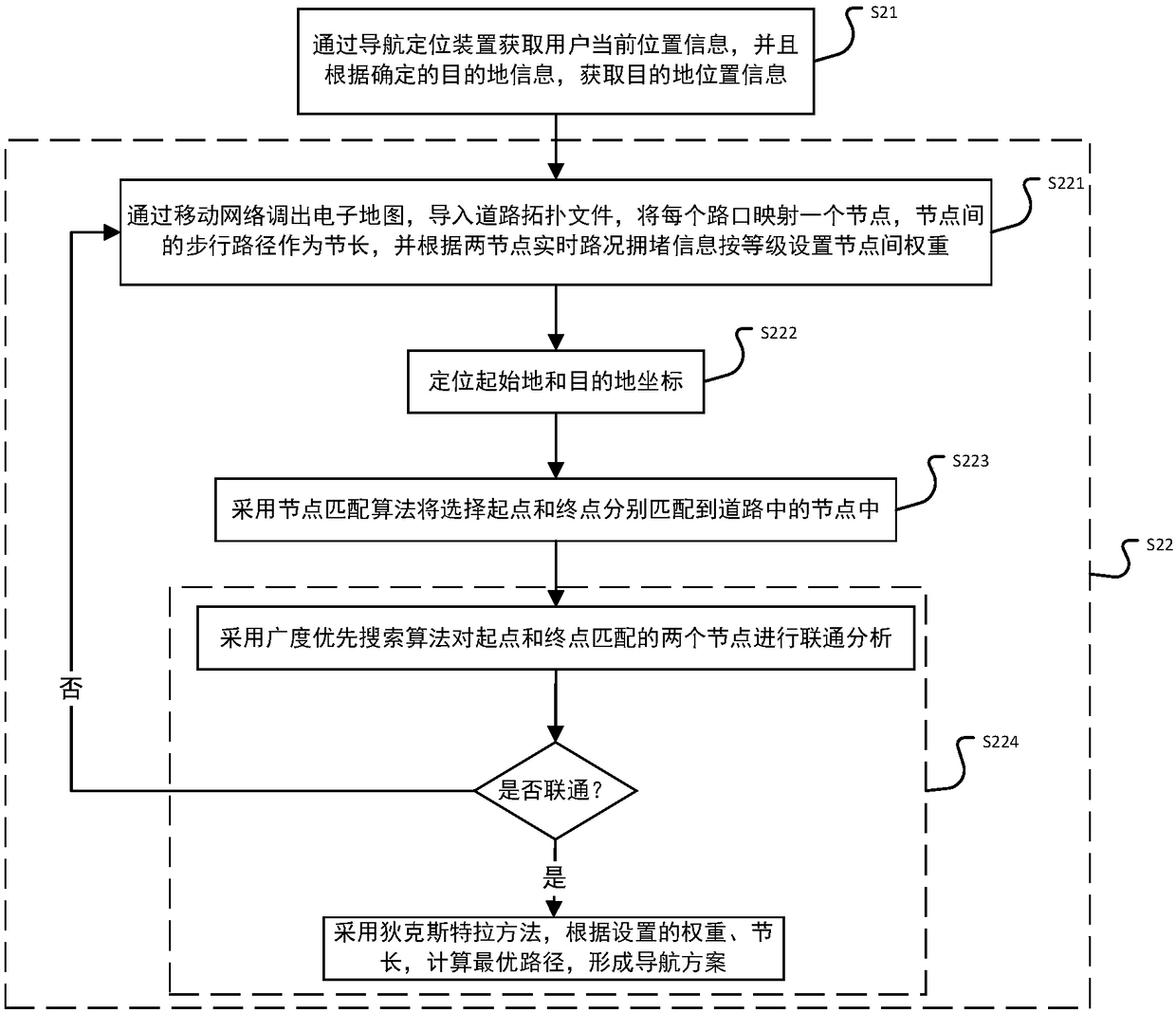

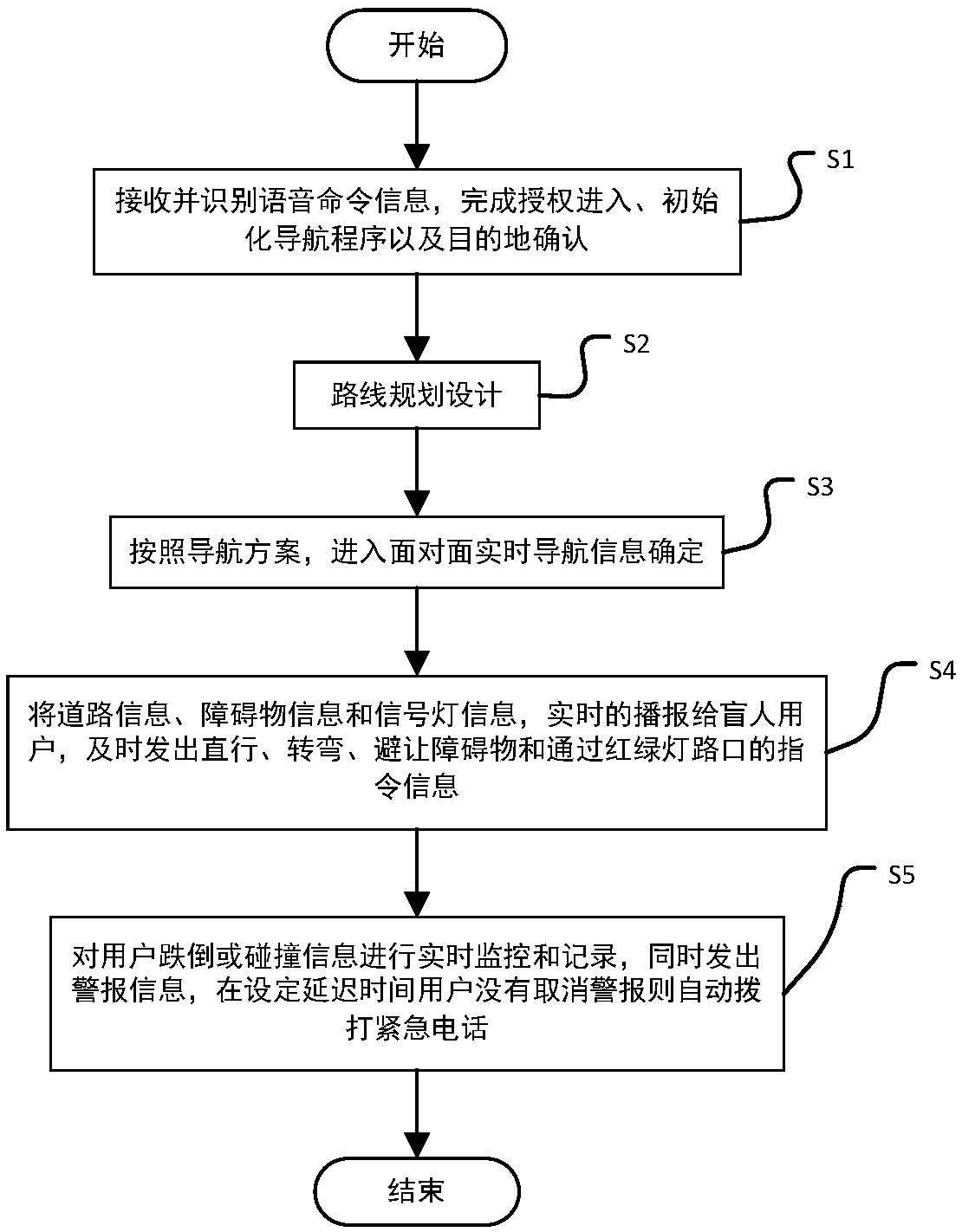

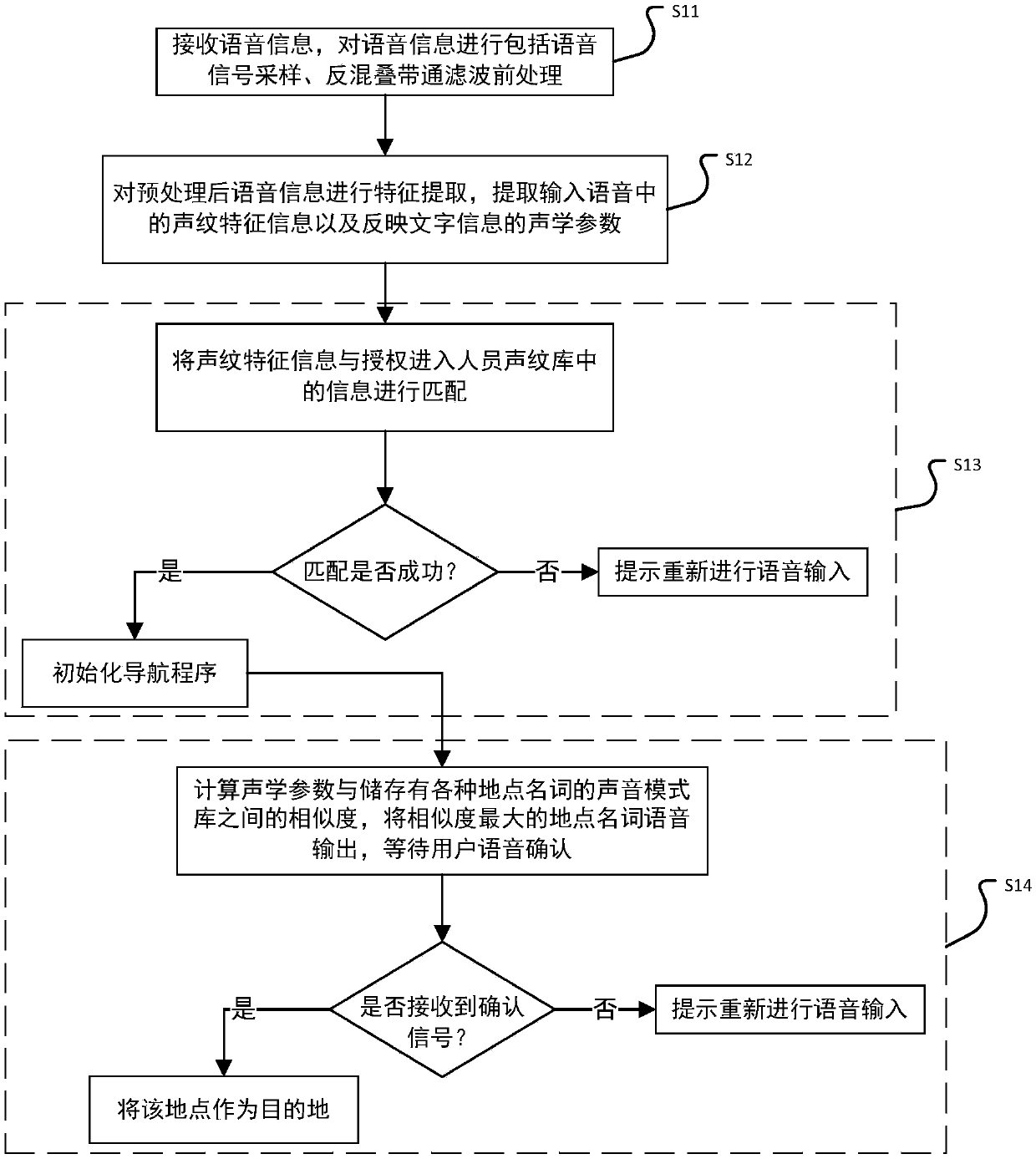

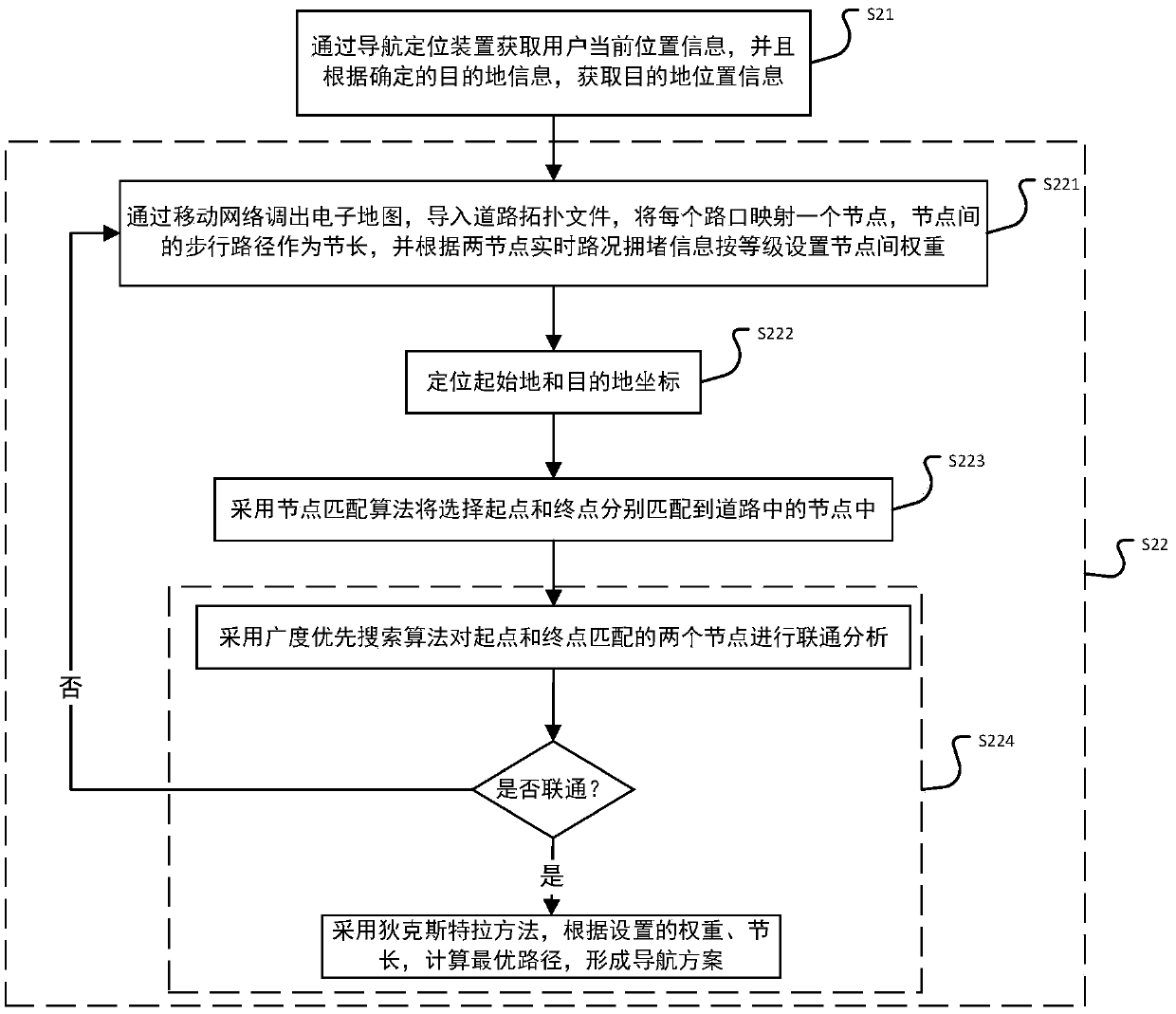

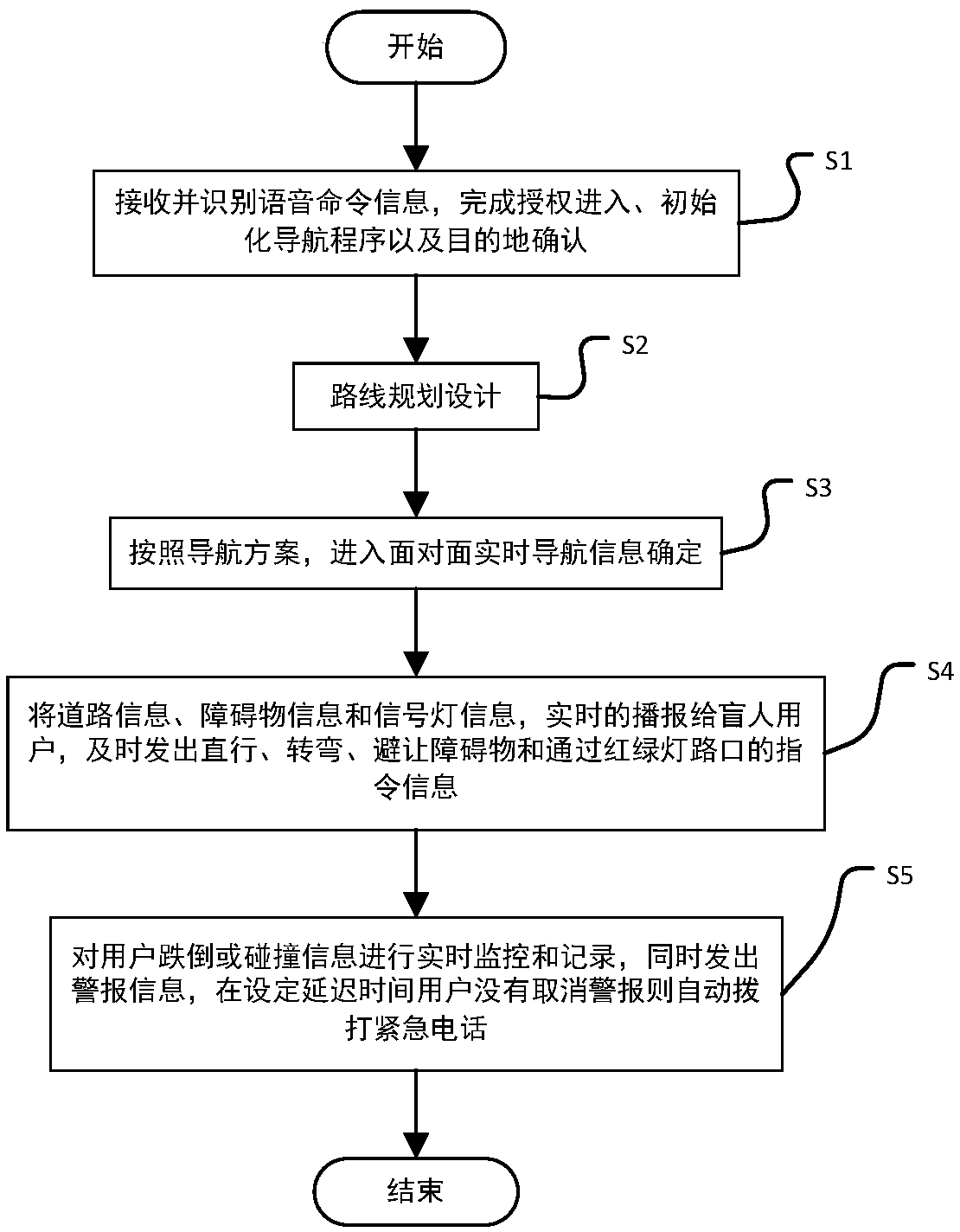

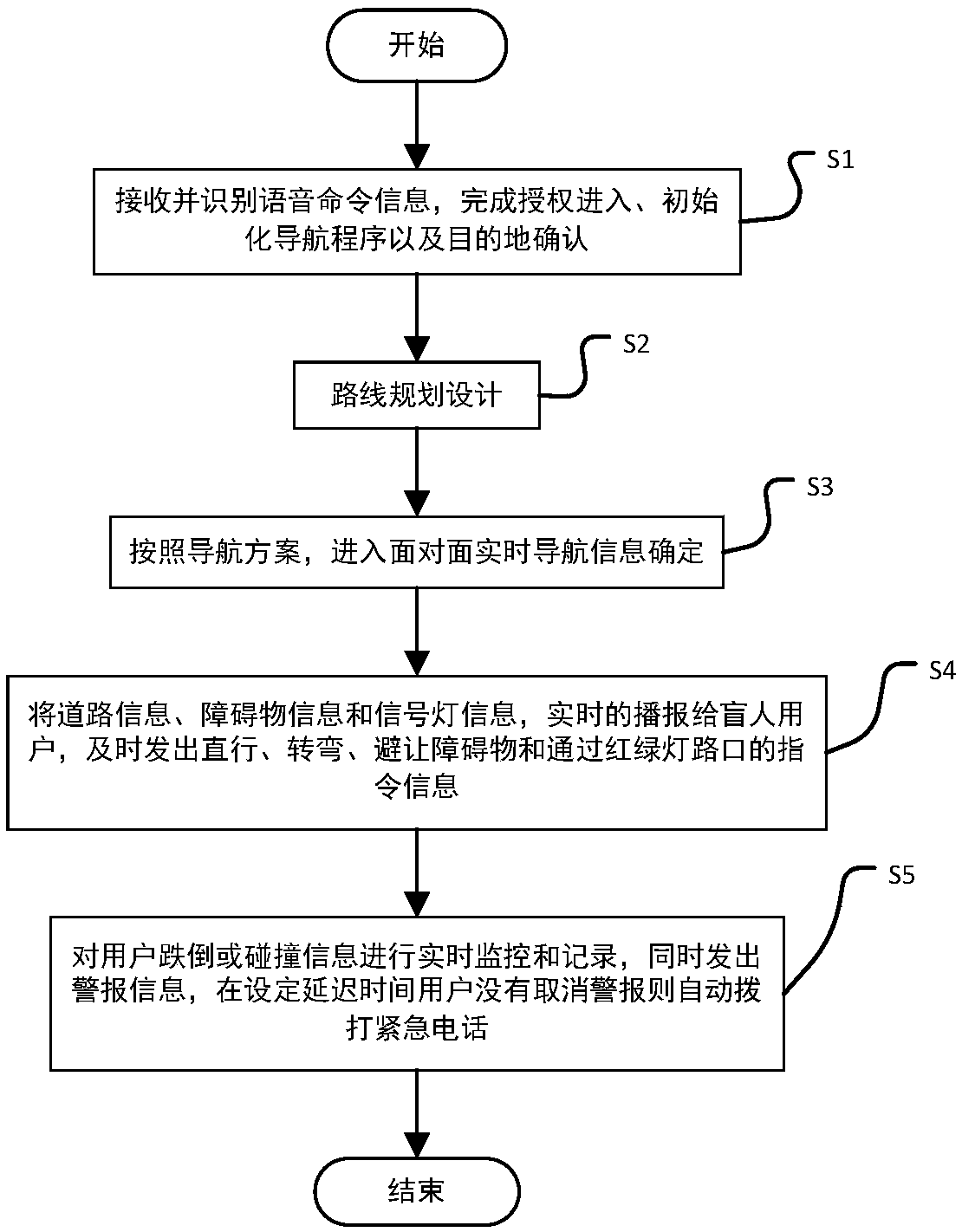

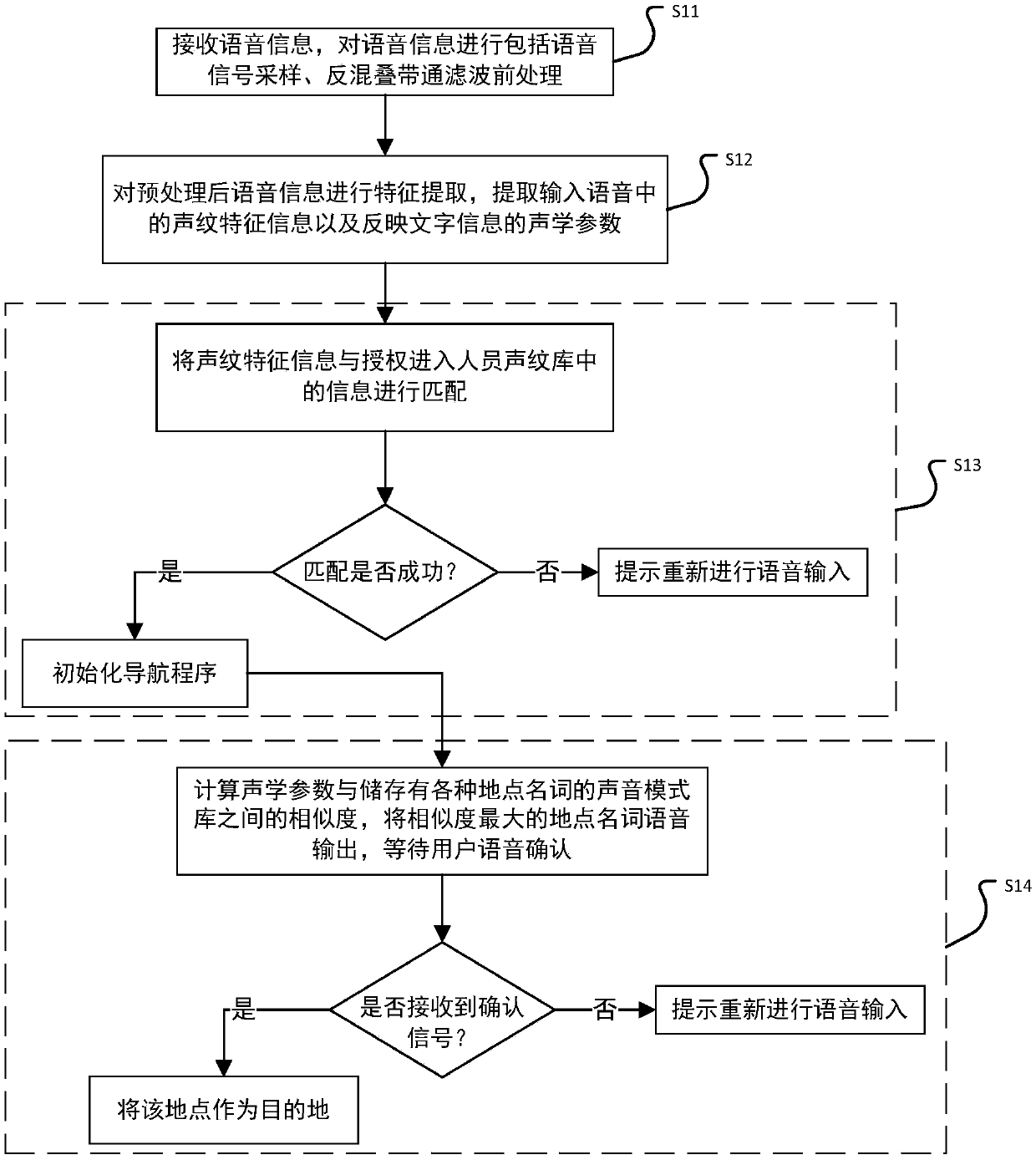

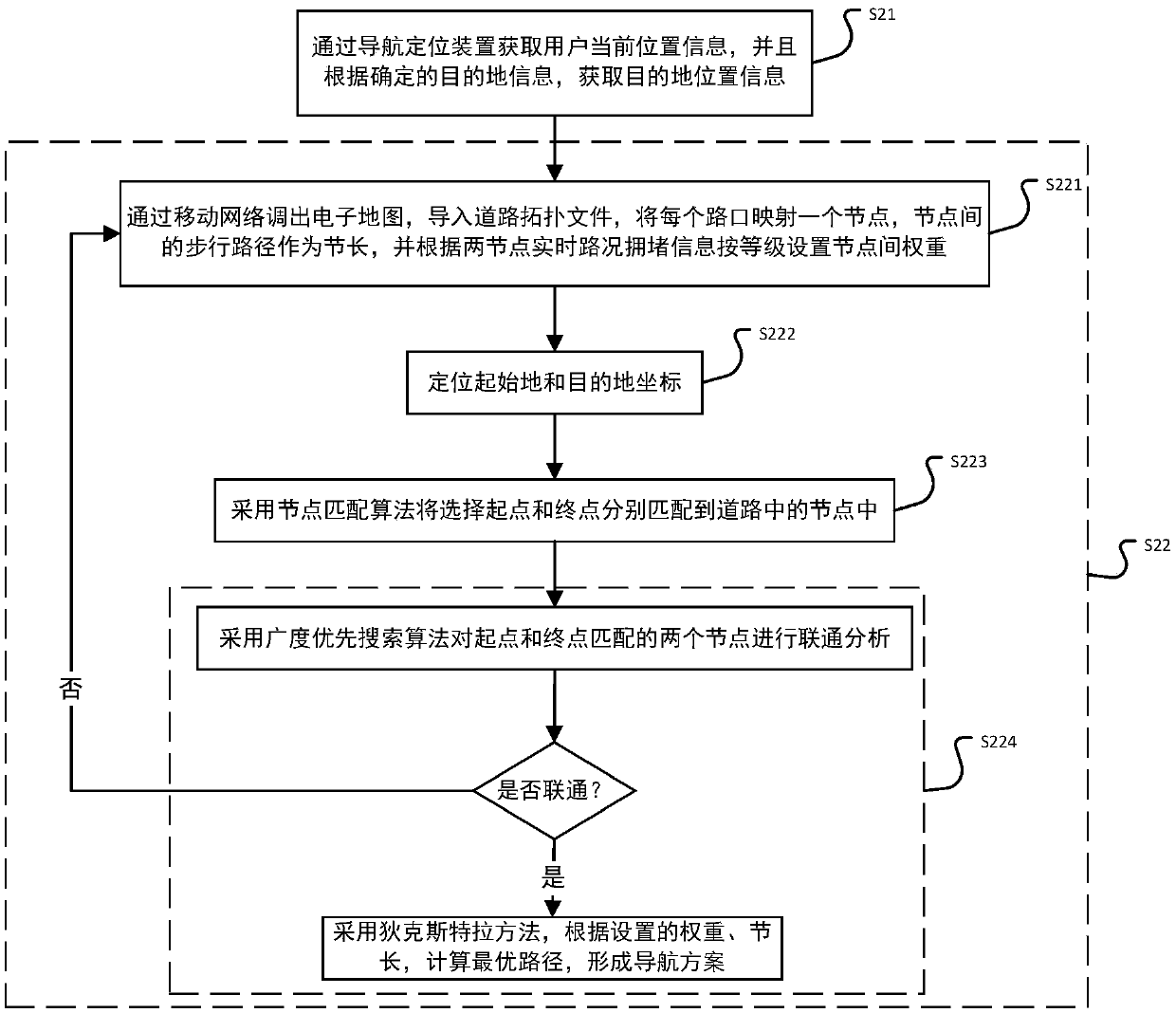

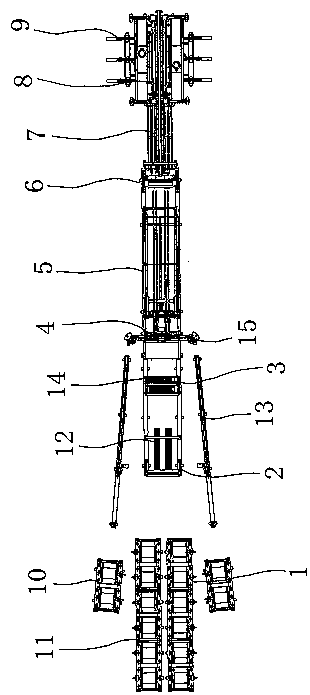

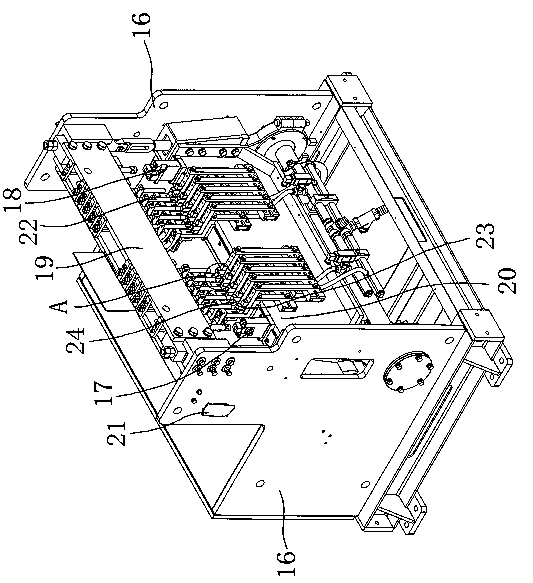

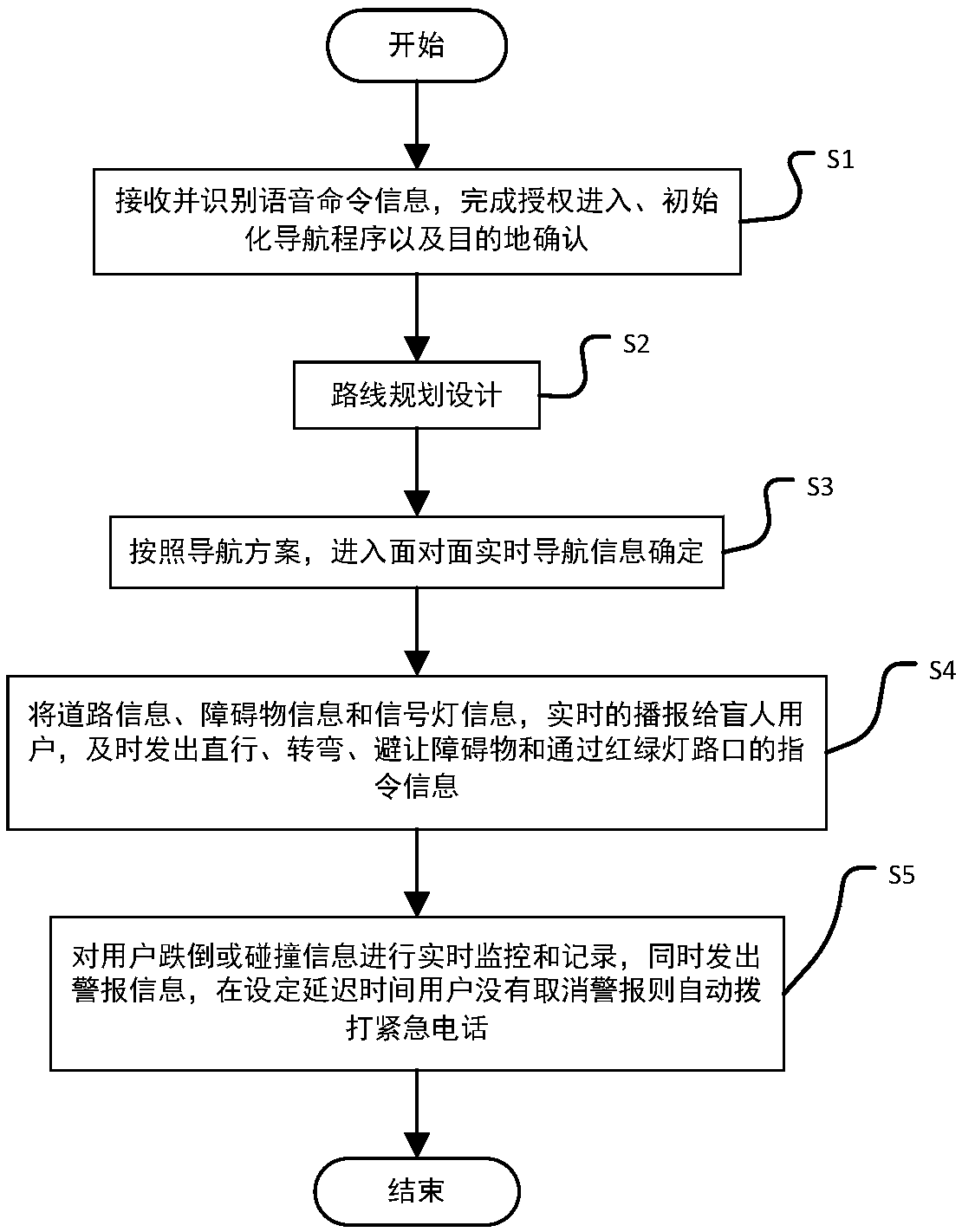

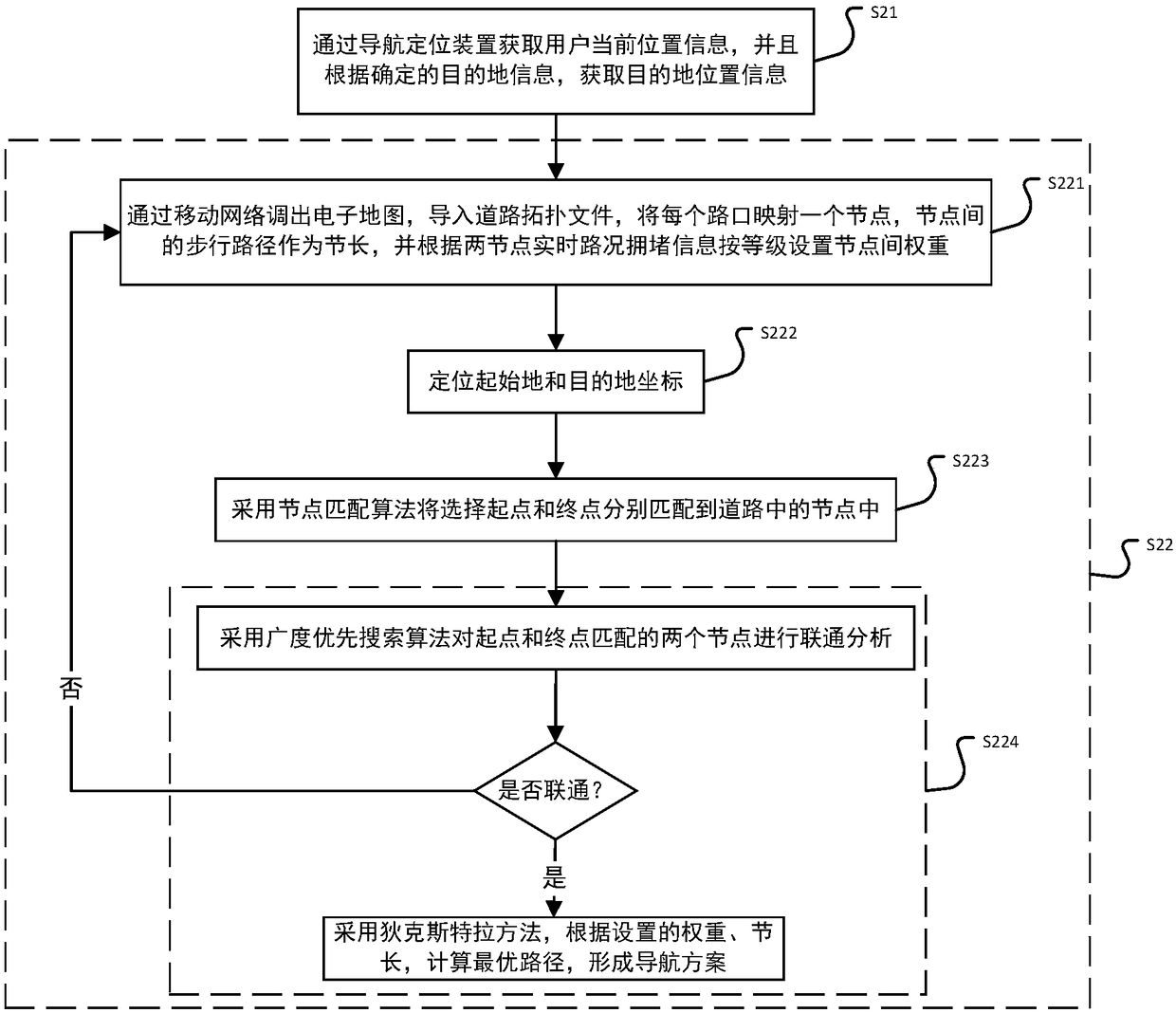

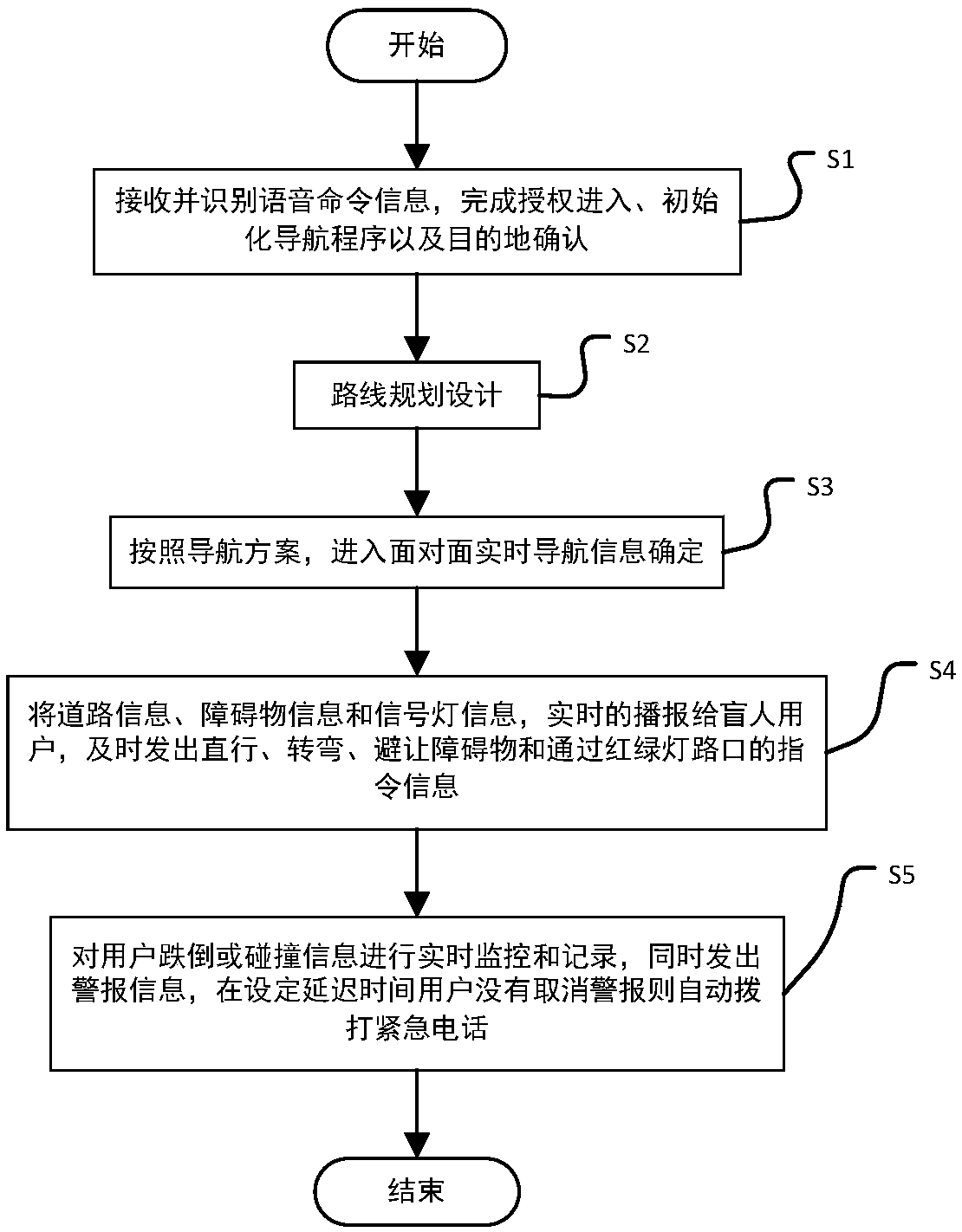

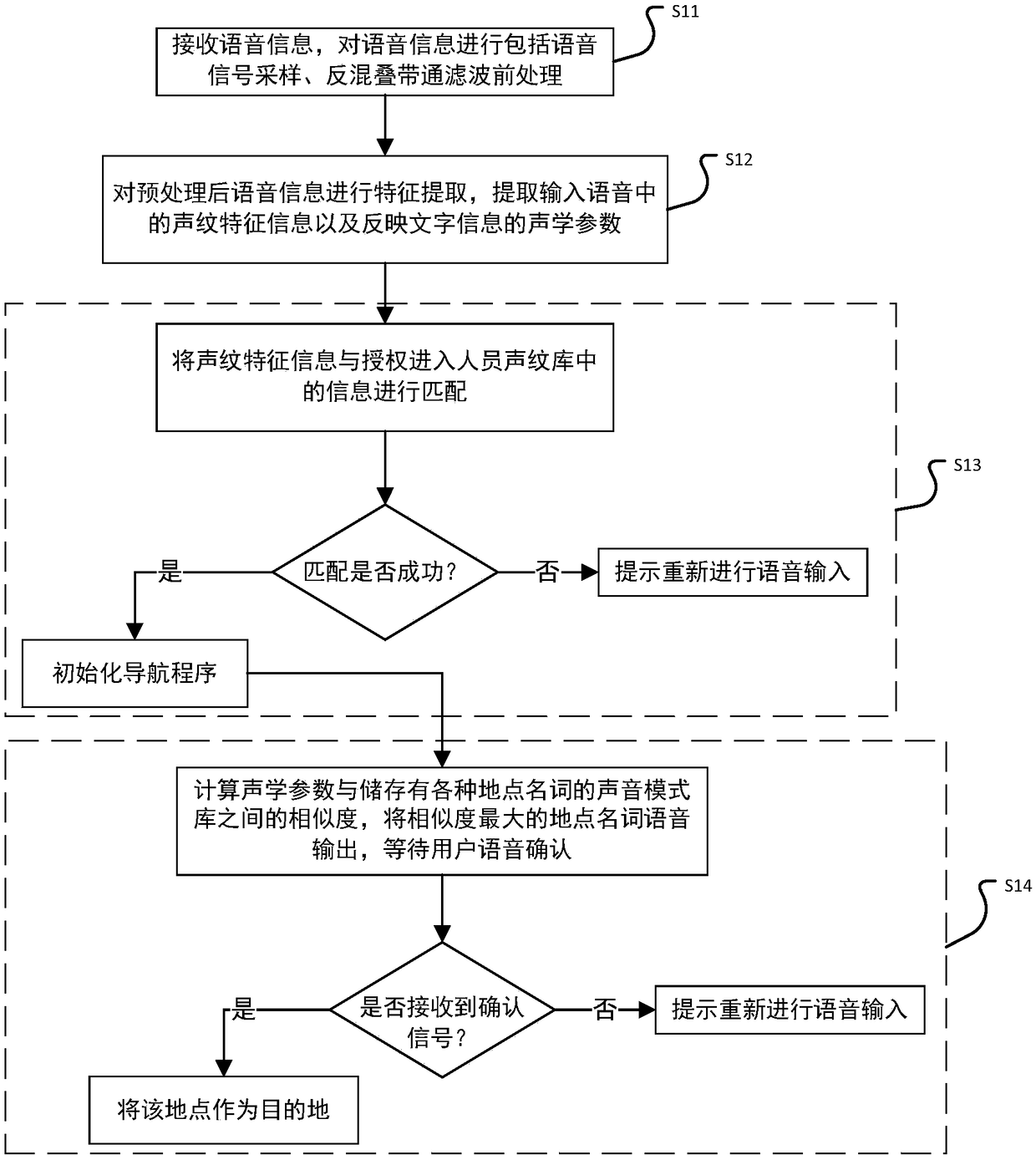

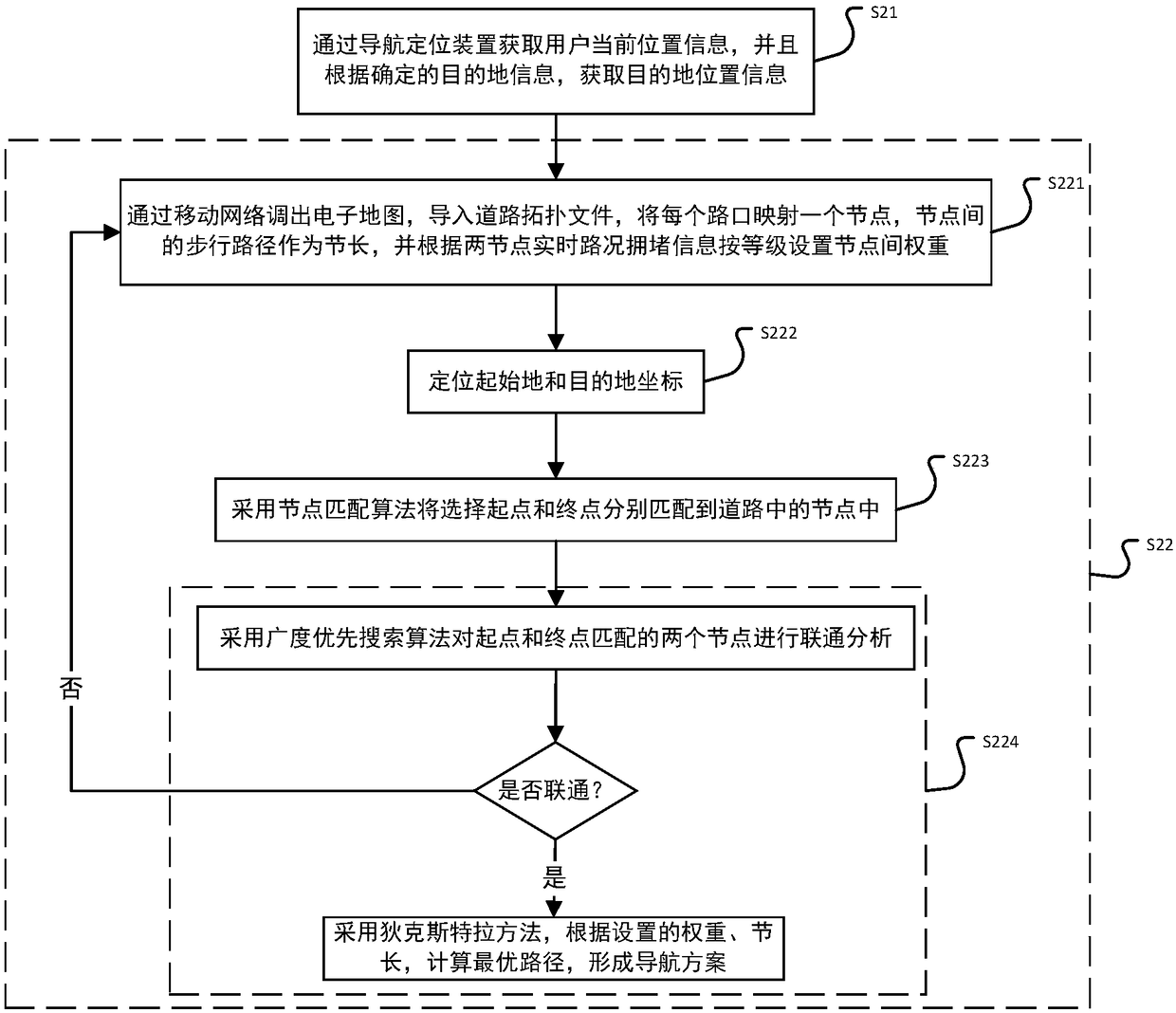

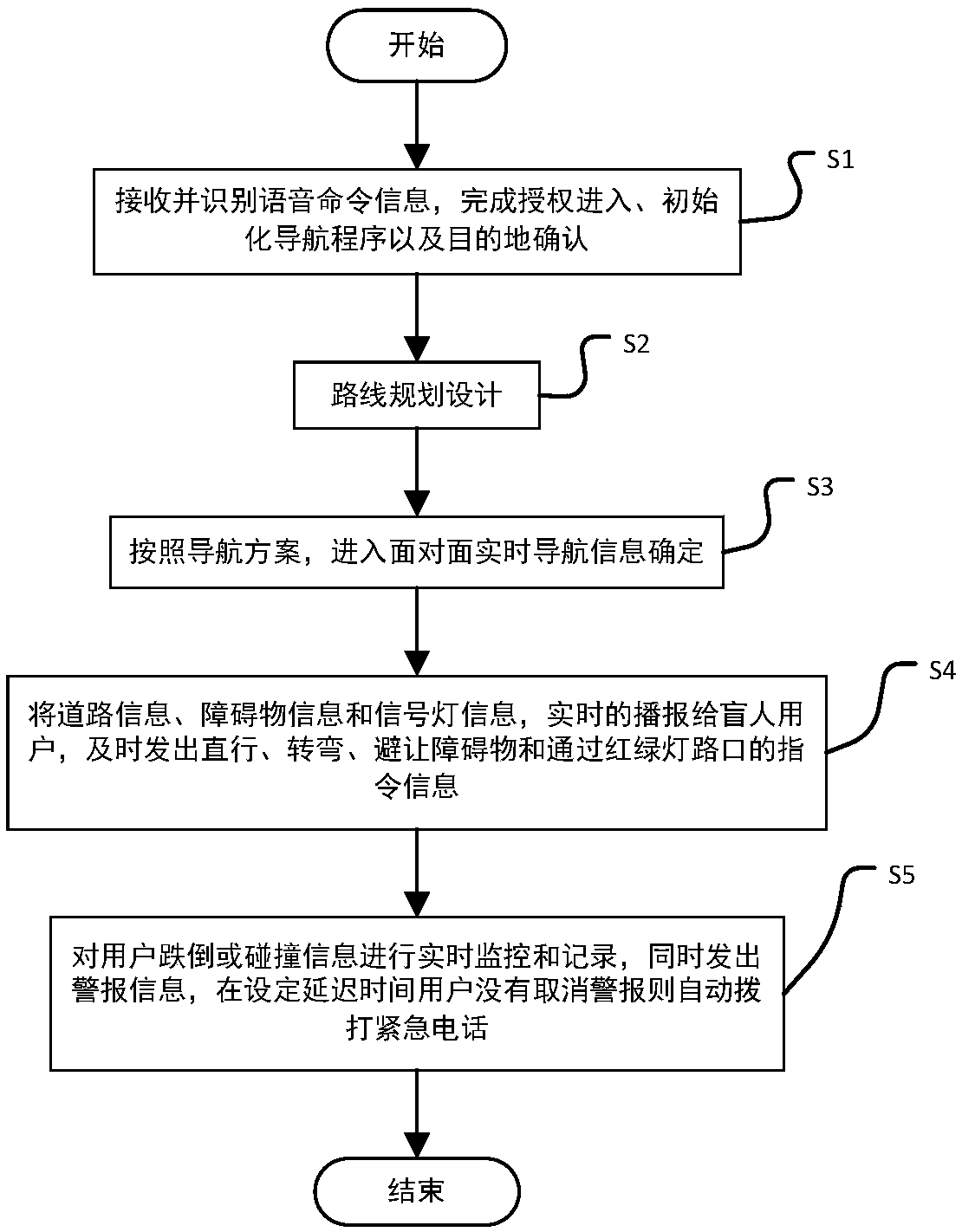

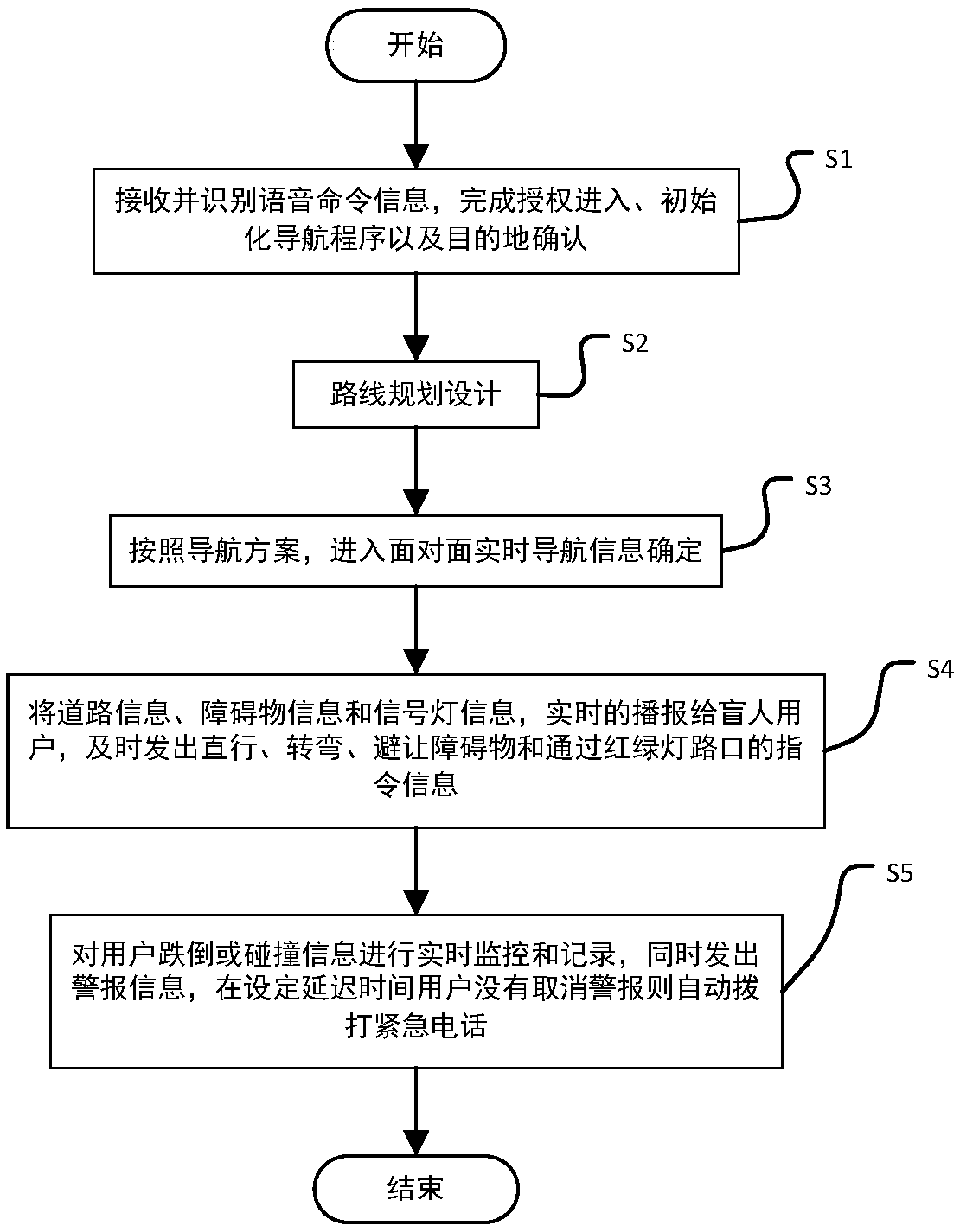

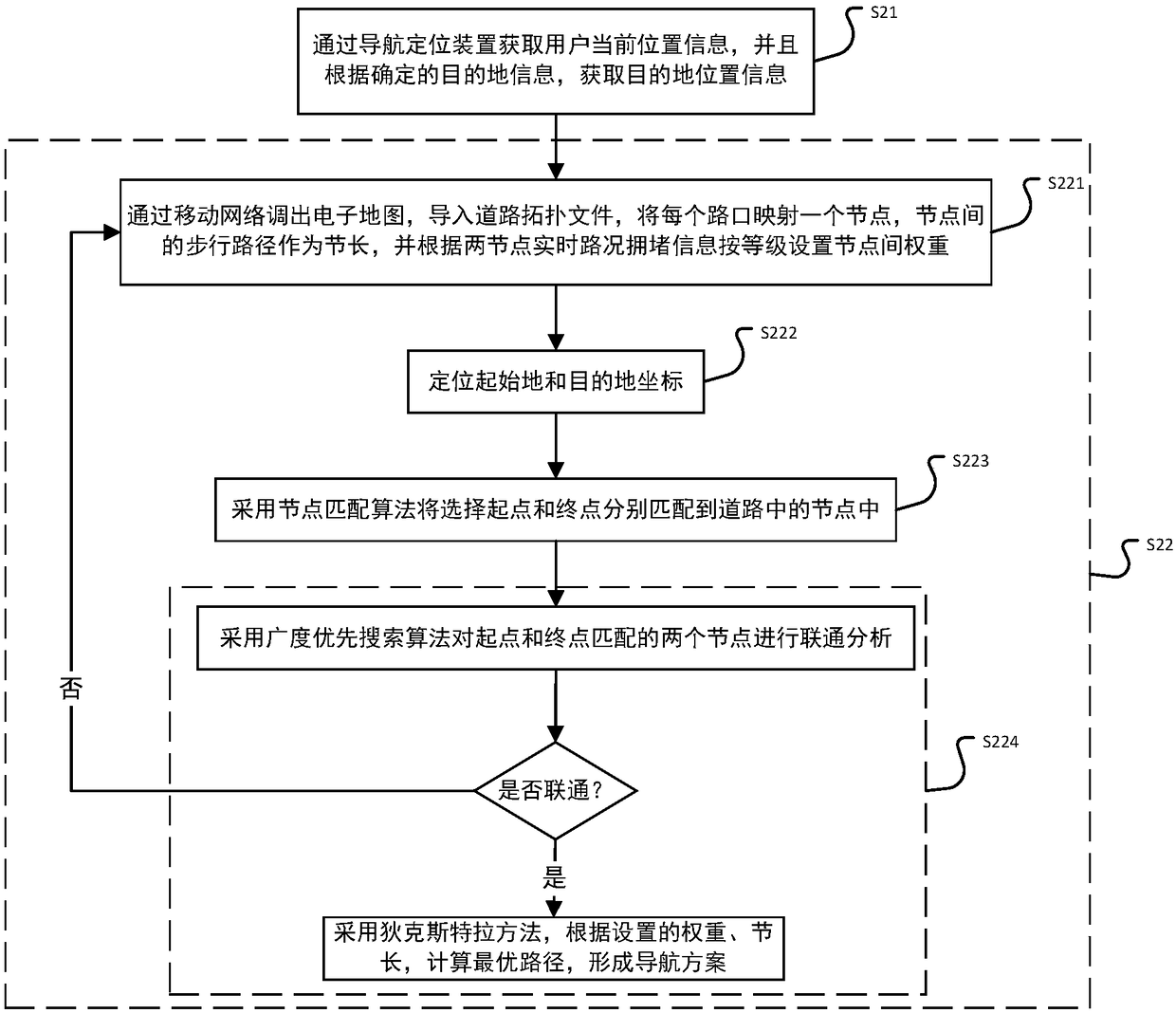

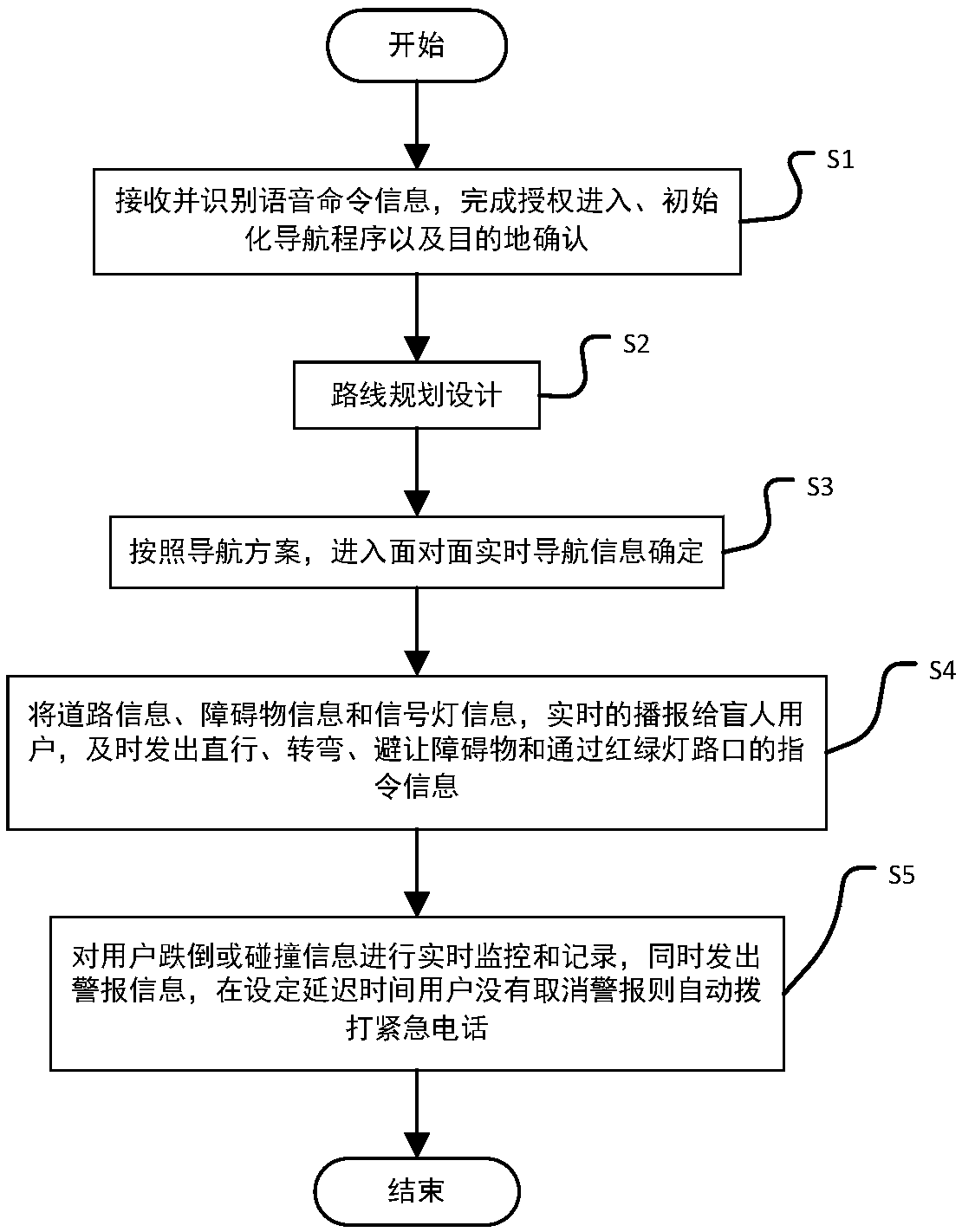

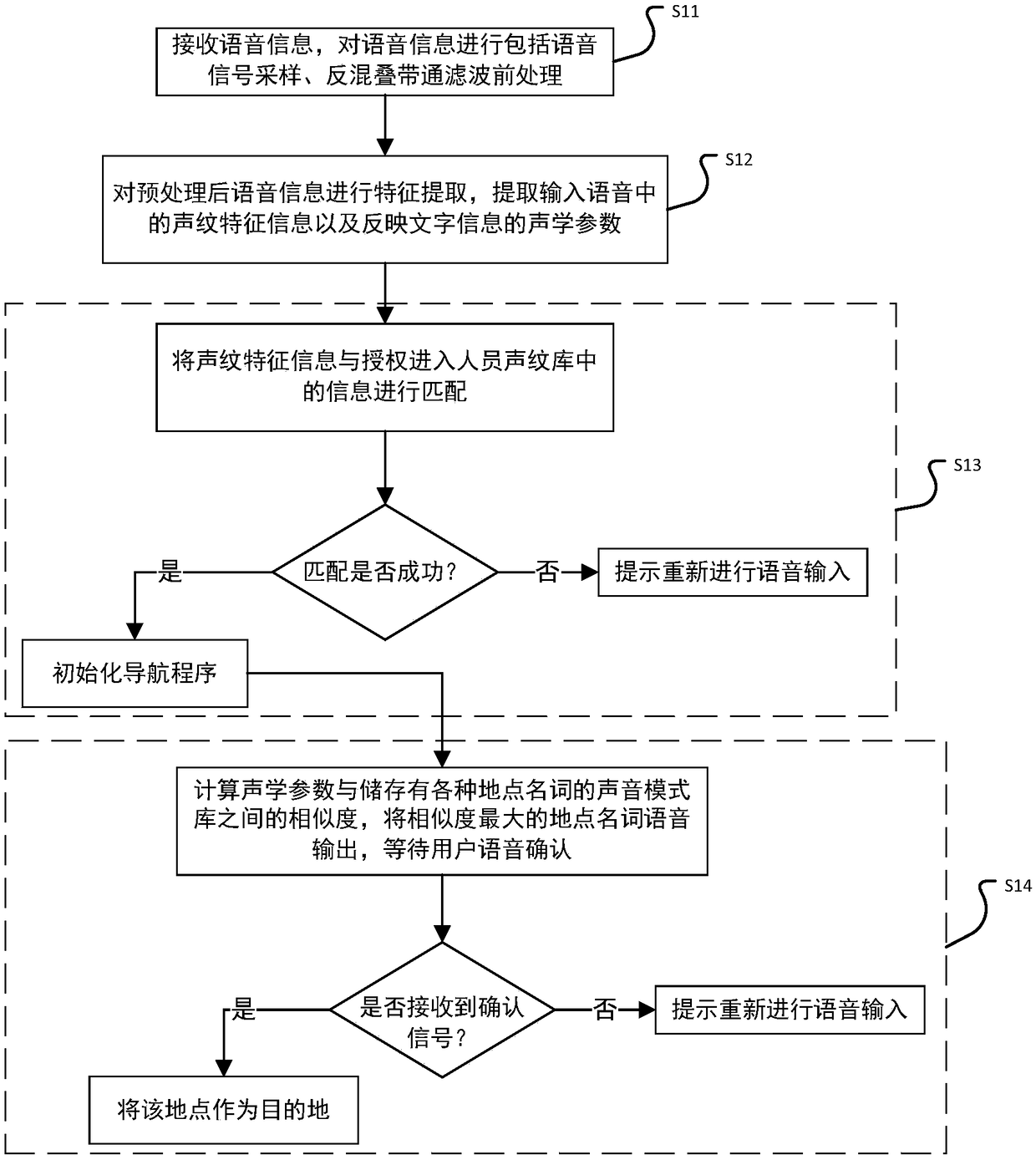

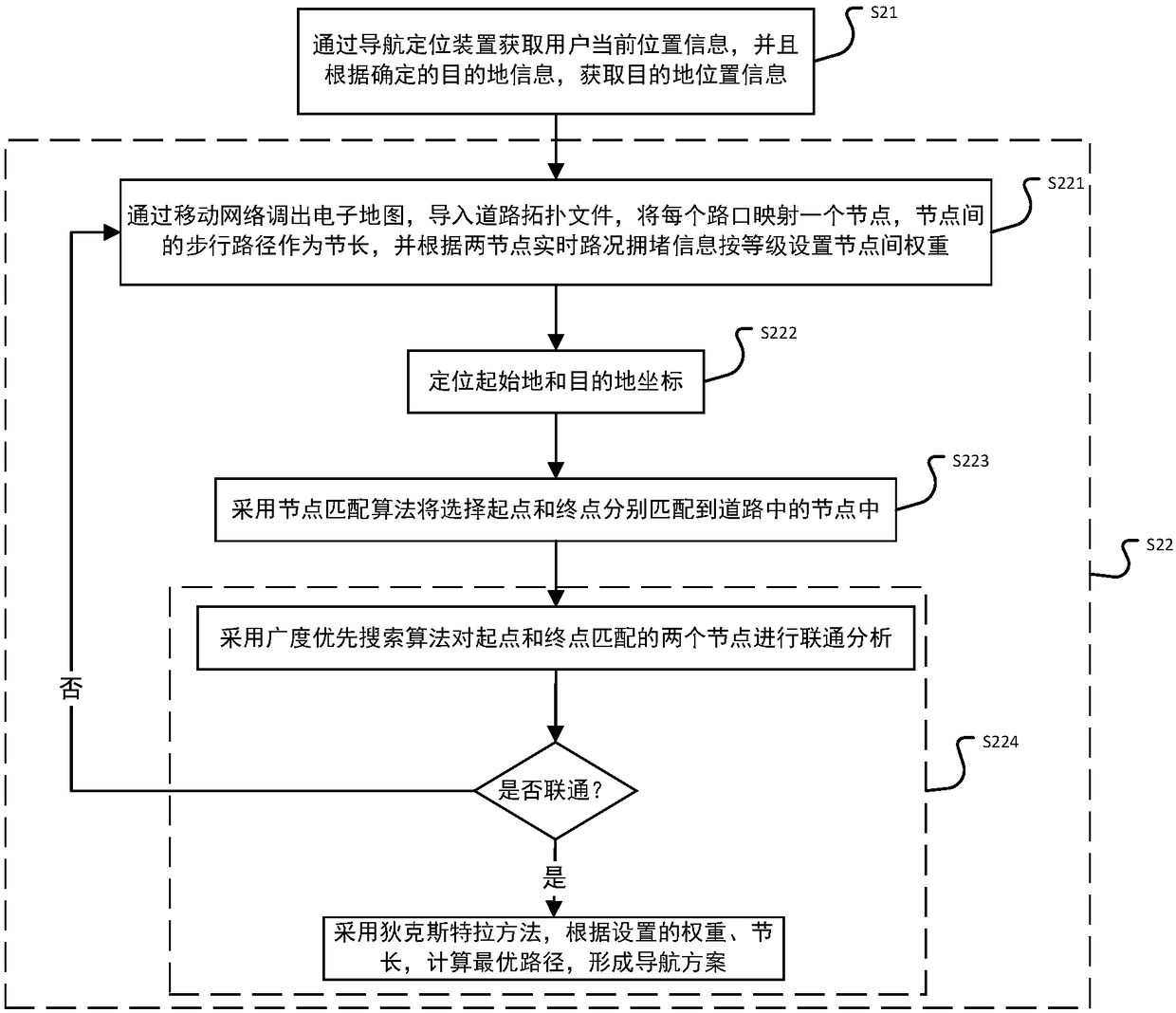

Intelligent navigation obstacle avoidance travel auxiliary method and system for blind person

InactiveCN108743266ATimely, efficient and accurate travelSafe and independent travelInstruments for road network navigationNavigational calculation instrumentsBroadcastingRoute planning

The invention discloses an intelligent navigation obstacle avoidance travel auxiliary method and system for a blind person. The method includes the steps of voice acquisition and analysis, path planning design, real-time navigation information determination, real-time navigation broadcasting and the like. The system comprises a storage module, a voice acquisition module, a voice data processing module, a positioning device module, a communication module, a path design determination algorithm module, a real-time navigation information determination module and an information transmission broadcasting module. The method and the system are stable, reliable, good in interference resistance and wide in applicable range, can conveniently and timely guide the blind person to advance in a complicated environment, and have the advantages of high system intelligence, advanced and scientific method, advancing path safety and accuracy and the like. Freedom of action of the blind person is greatly improved, and the method and the system have practicability, implementability, high practical values and wide application prospects.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

Auxiliary travel method and auxiliary travel system based on image recognition

InactiveCN108844545APersistent lockAccurate identificationNavigational calculation instrumentsNavigation by speed/acceleration measurementsReal time navigationAnti jamming

The invention discloses an auxiliary travel method and an auxiliary travel system based on image recognition. The method comprises the steps of speech acquisition and analysis, route planning and design, real-time navigation information determination, timely navigation broadcasting and the like; the system comprises a storage module, a speech acquisition module, a speech data processing module, apositioning device module, a communication module, a route design determination algorithm module, a real-time navigation information determination module and an information transmission broadcasting module. The method and the system disclosed by the invention have the advantages of stability and reliability, high anti-jamming performance, wide application range, capability of conveniently and timely guiding blind people to travel in complex environments, high system intelligence degree, advanced and scientific method, safe and accurate route and the like; the movement freedom of the blind people is greatly improved. The method and the system have practicality and feasibility, higher practical value and broad application prospect.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

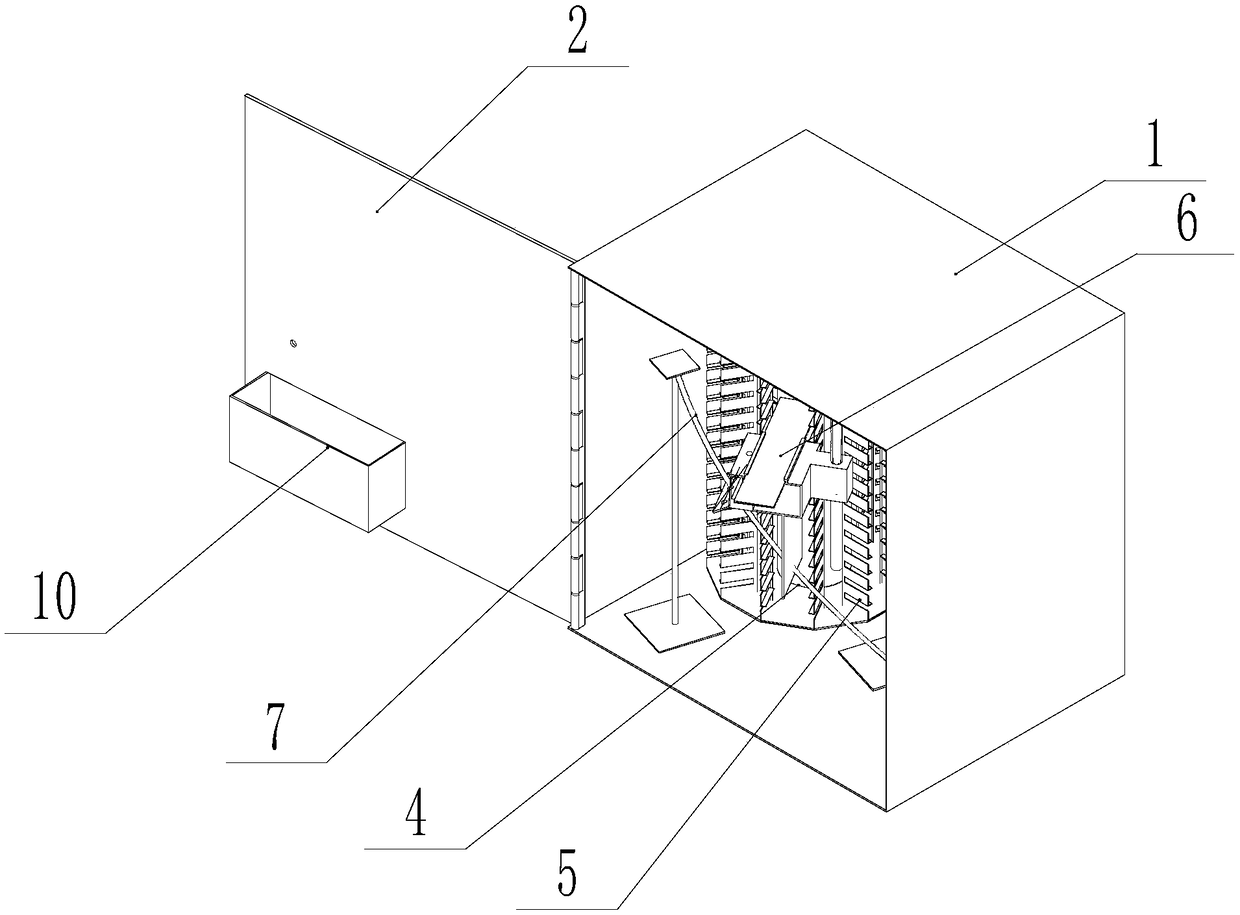

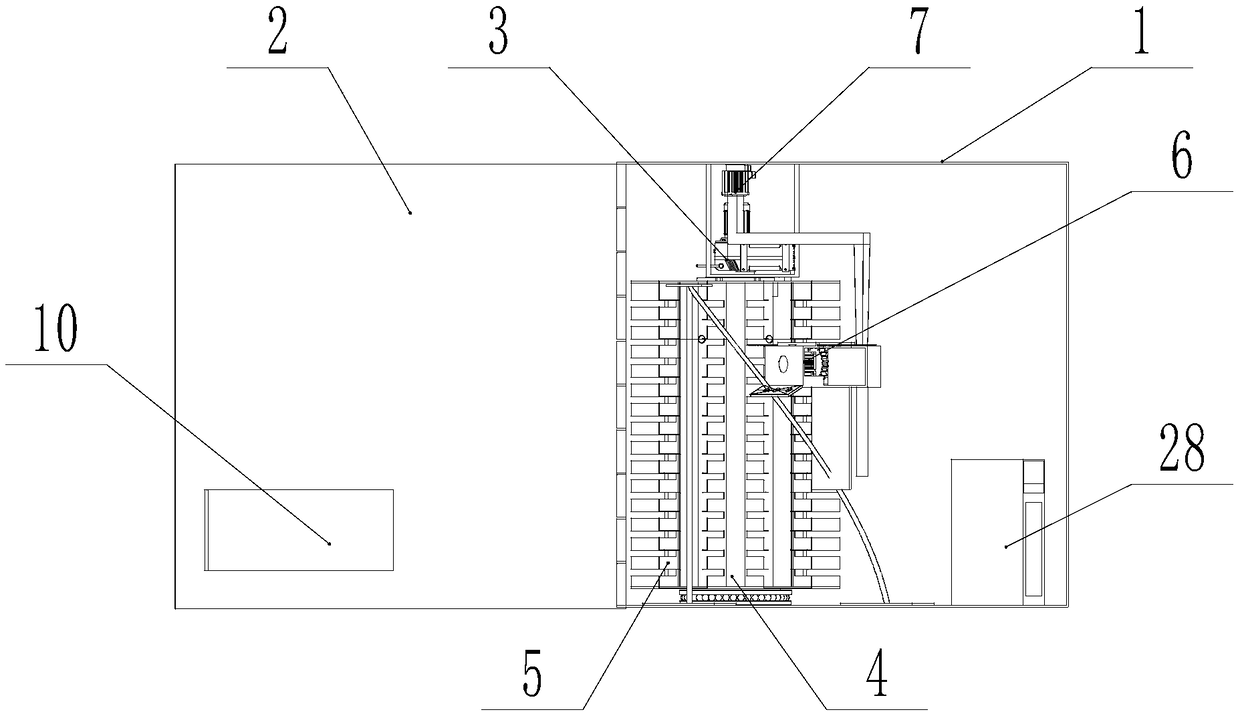

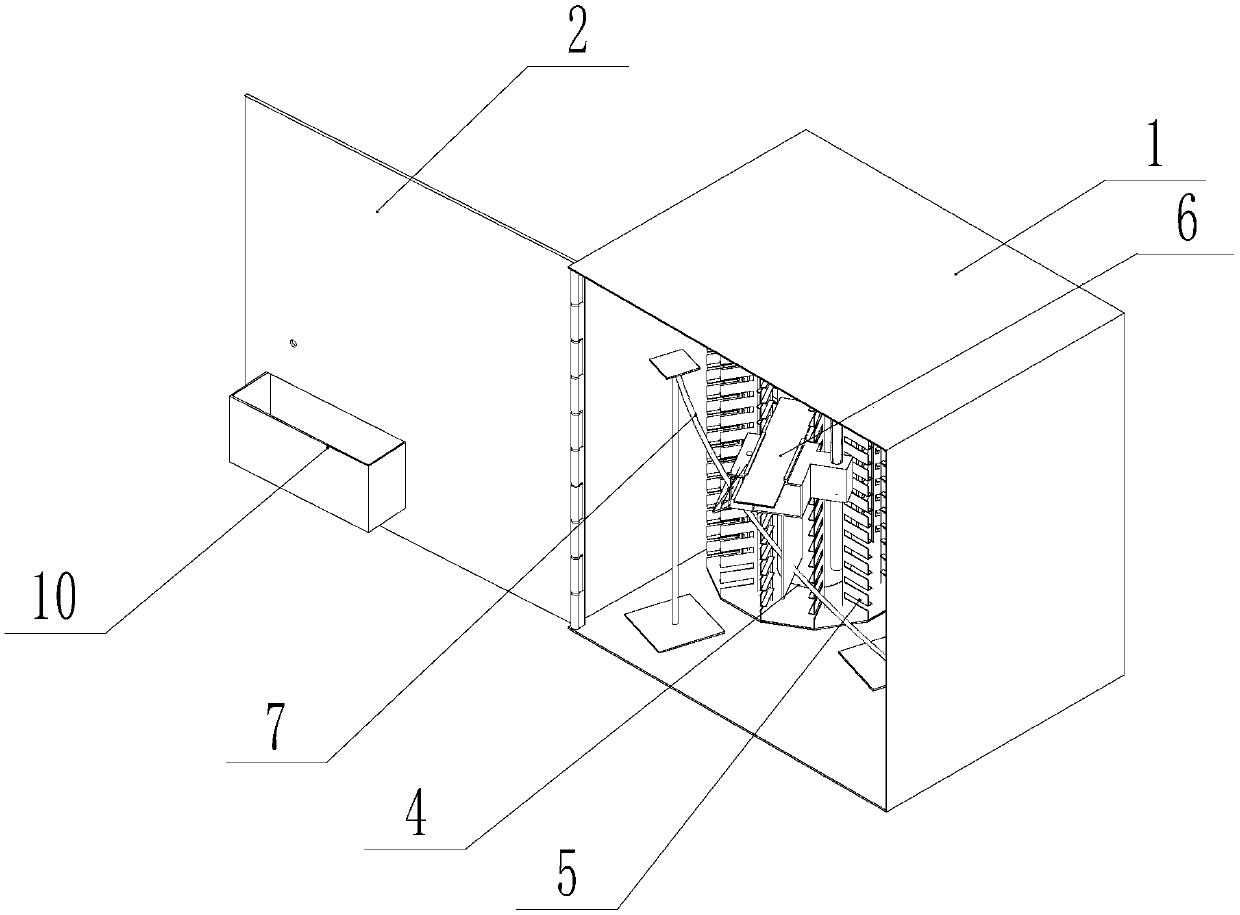

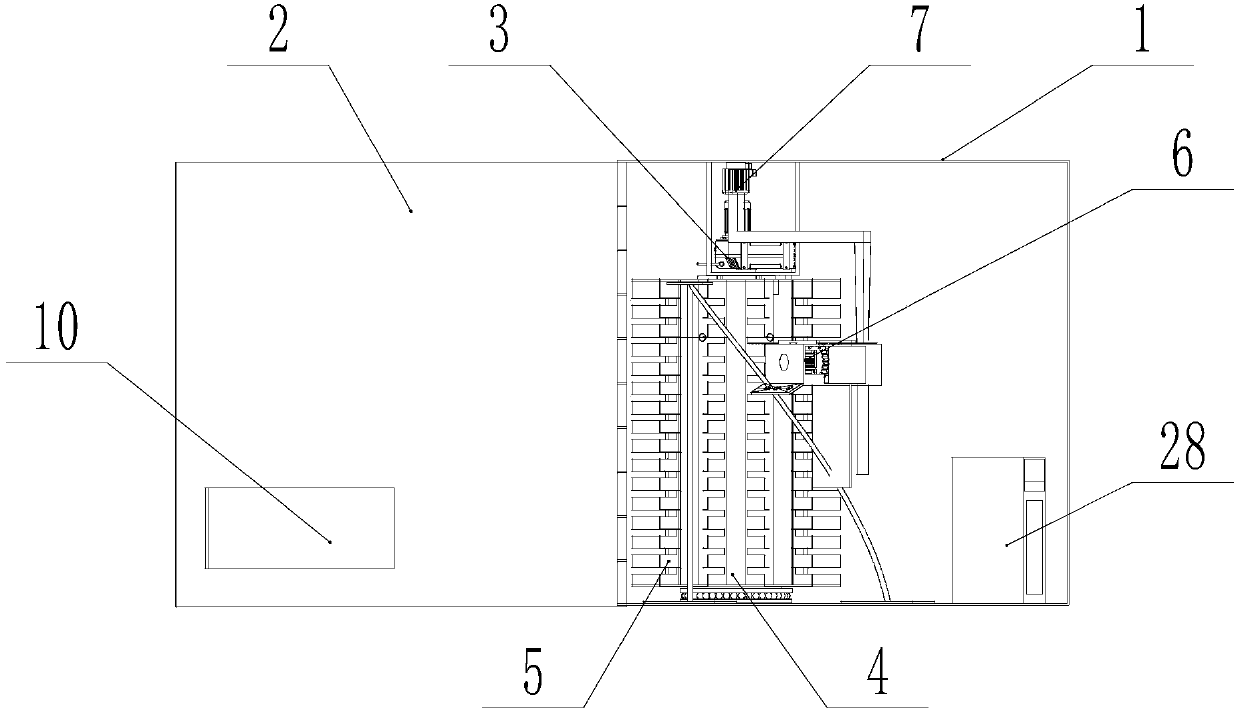

Vending system with overdue reminding rotary material-taking type storage type bento

ActiveCN109493512AEasy to take outTake out accuratelyCoin-freed apparatus detailsApparatus for meter-controlled dispensingHeating timeComputer terminal

The invention discloses a vending system with overdue reminding rotary material-taking type storage type bento, which comprises a user handheld terminal, a vending machine and a cloud server, whereinthe user handheld terminal is provided with a bento selling APP, the vending machine is provided with a code scanning mechanism, the user handheld terminal is connected with the cloud server through anetwork, and the vending machine is connected with the cloud server through GPRS. The vending machine comprises a shell, a door, a rotary driving device, an upright column, a storage bin, a material-taking device and a material-taking driving device, wherein the rotary driving device comprises a rotary motor and a grooved wheel mechanism, the material-taking device comprises an arc-shaped liftingtrack and the material-taking device. The vending system with overdue reminding rotary material-taking type storage type bento can make the user order the food in the vending machine on the APP. After the vending machine receives the order of the user, the food reserved by the user can be processed before the pick-up time reserved by the user. The user can directly take the processed food when taking the meal without waiting for heating time.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

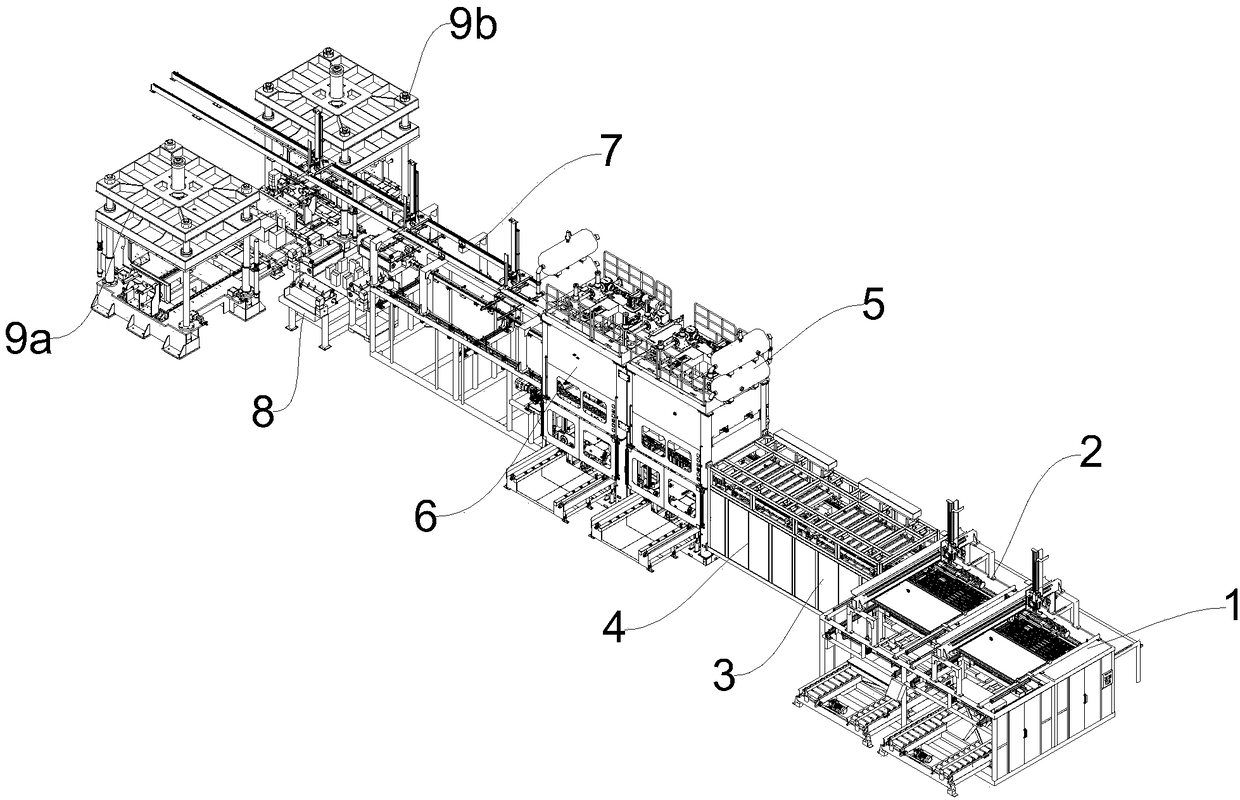

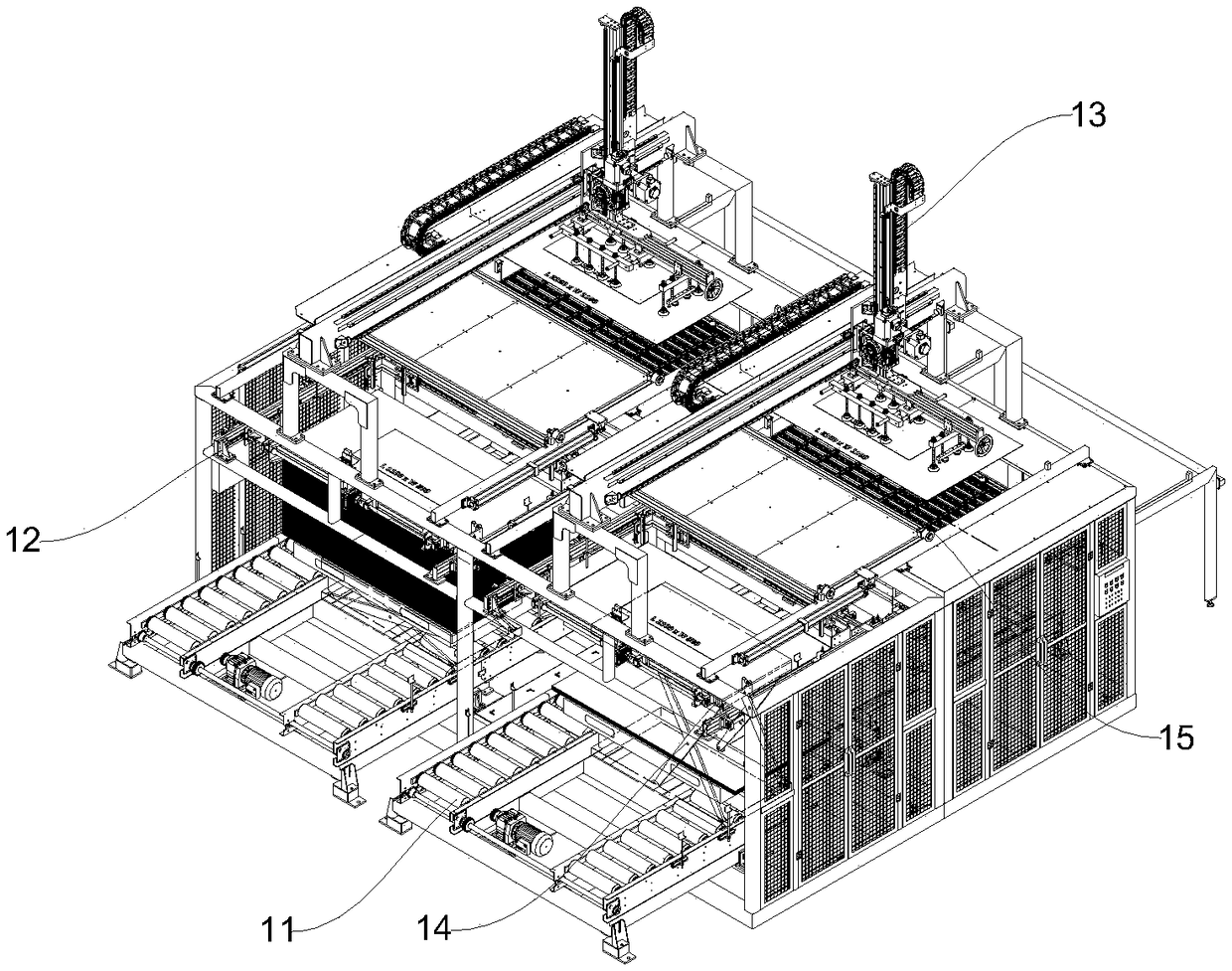

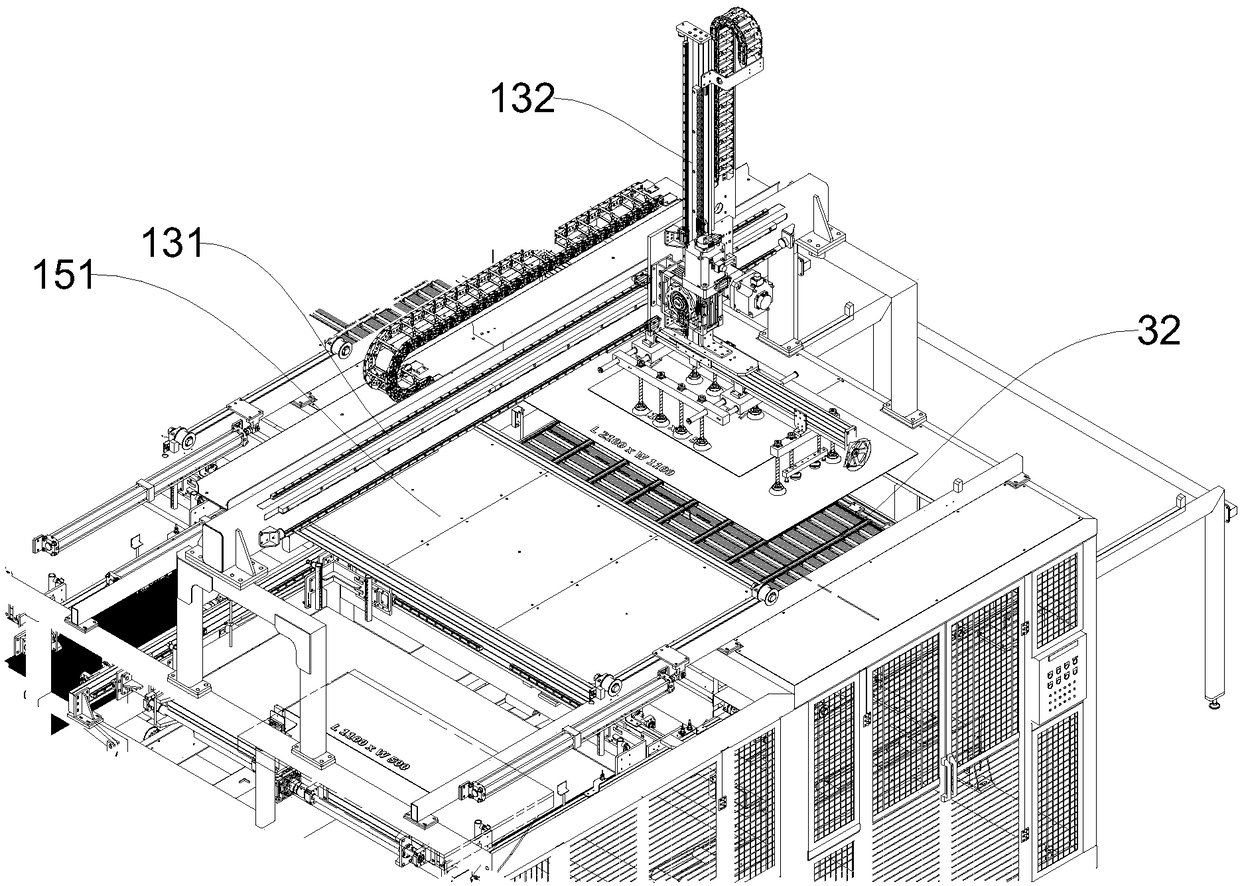

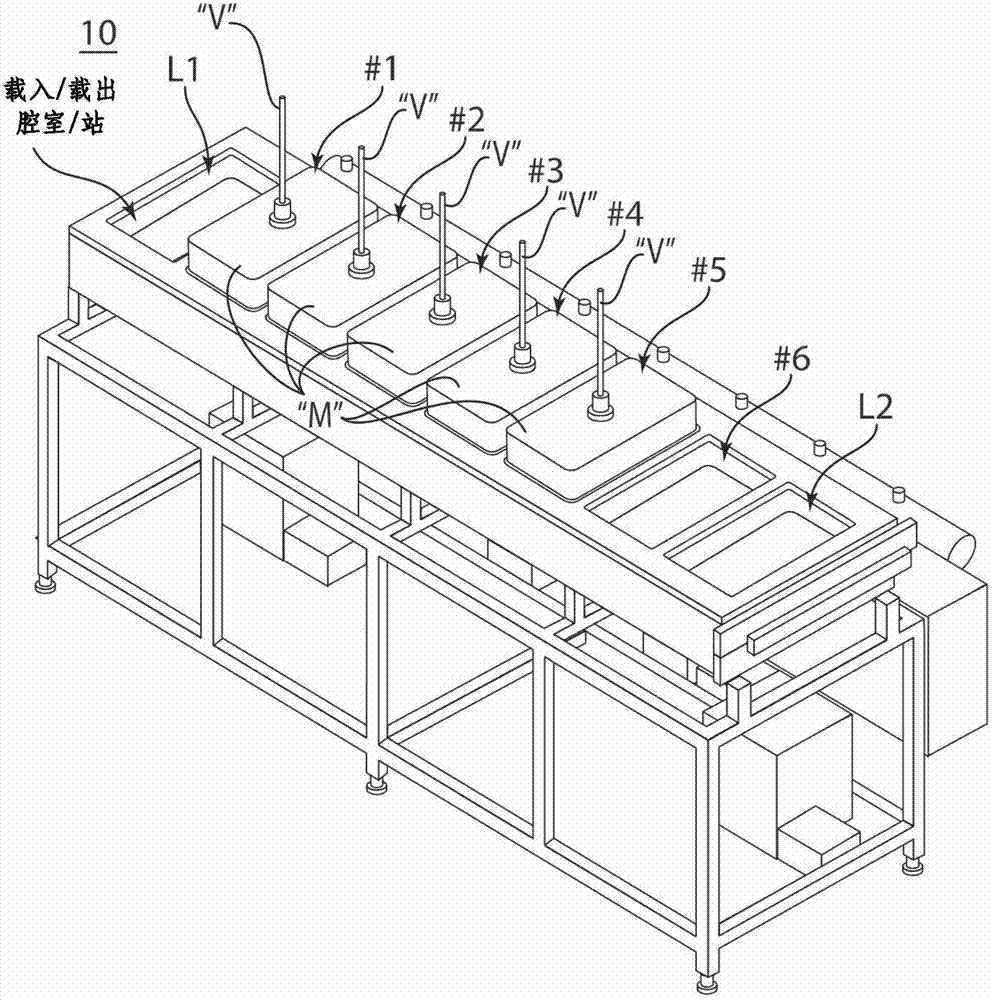

Double-liner concurrent vacuum plastic uptake molding machine

The invention discloses a double-liner concurrent vacuum plastic uptake molding machine. The machine includes a first feeding, aligning and preheating integrated device, a second feeding, aligning andpreheating integrated device, a first main heating device, a second main heating device, a first molding machine body, a second molding machine body, a discharging device, a bead cutter, a first punch press and a second punch press which are arranged in sequence, wherein the first punch press and the second punch press are arranged side by side; conveying chains are sequentially arranged in the first feeding, aligning and preheating integrated device, the second feeding, aligning and preheating integrated device, the first main heating device, the second main heating device, the first moldingmachine body, the second molding machine body and the discharging device; the discharging device is used for grasping products molded by the first molding machine body and / or the second molding machine body to the bead cutter, grasping products on the bead cutter to the first punch press and / or the second punch press and grasping products passing by the first punch press and / or the second punch press. The double-liner concurrent vacuum plastic uptake molding machine can achieve simultaneous processing of two kinds of products with different processing parameters on the same production line.

Owner:苏州云康机电有限公司

Navigation method and system for visually impaired people

InactiveCN109031306APersistent lockContinuous identificationNavigation by speed/acceleration measurementsRadio wave reradiation/reflectionVisually impairedReal time navigation

The invention discloses a navigation method and system for visually impaired people. The method comprises the steps of voice acquisition analysis, route planning design, real-time navigation information determination, timely navigation broadcasting and the like. The system comprises a storage module, a voice acquisition module, a voice data processing module, a positioning device module, a communication module, a route design determination algorithm module, a real-time navigation information determination module and an information transmission broadcast module. The navigation method and systemis stable and reliable, is good in anti-interference performance and wide in application range, can guide the walking of a blind person in a complex environment conveniently and timely, has the advantages of high intelligent degree of the system, advanced and scientific method, safe and accurate walking route and the like, greatly improves the action freedom of the blind person, has practicability and realizability, and has relatively high practical values and wide application prospects.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

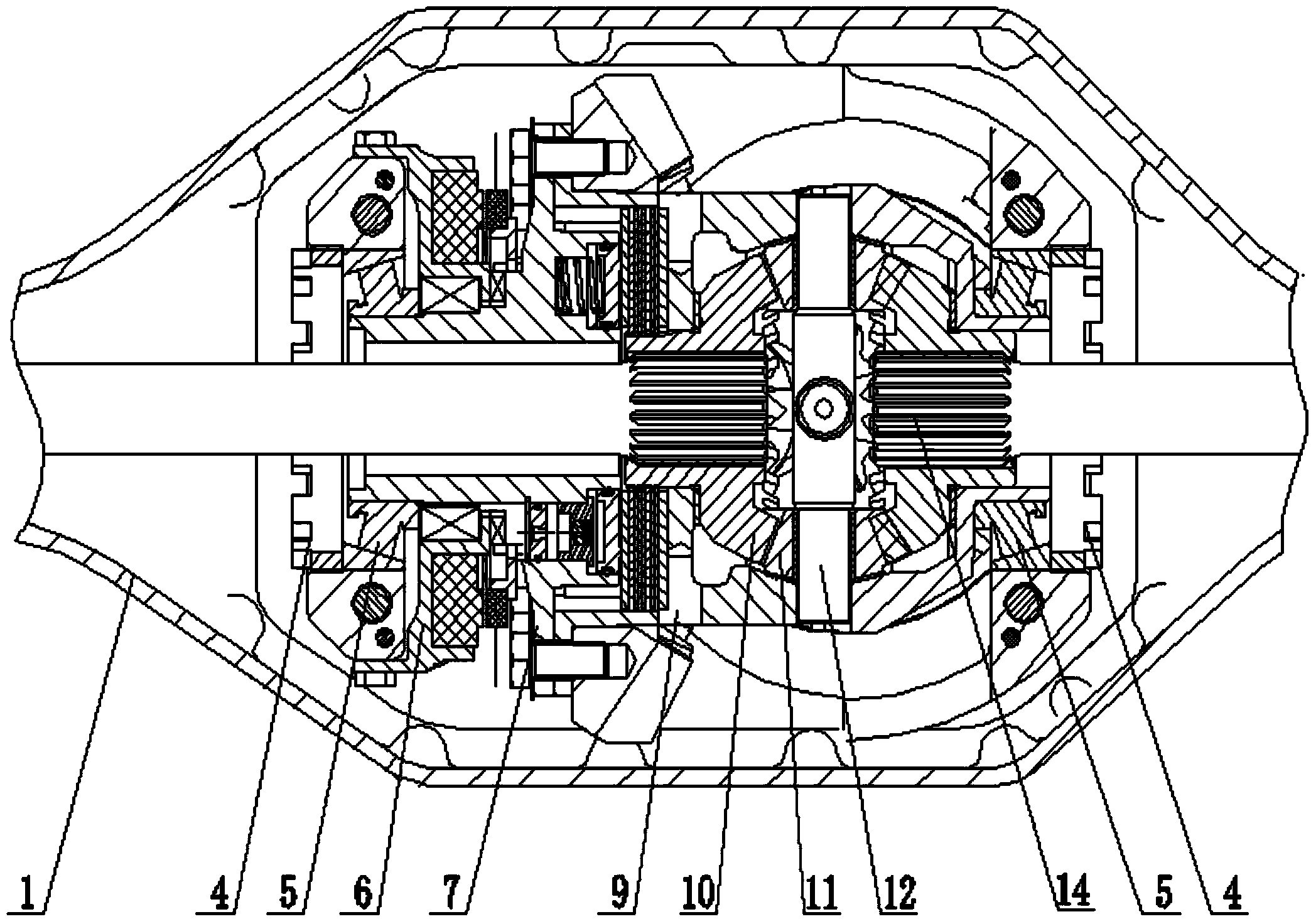

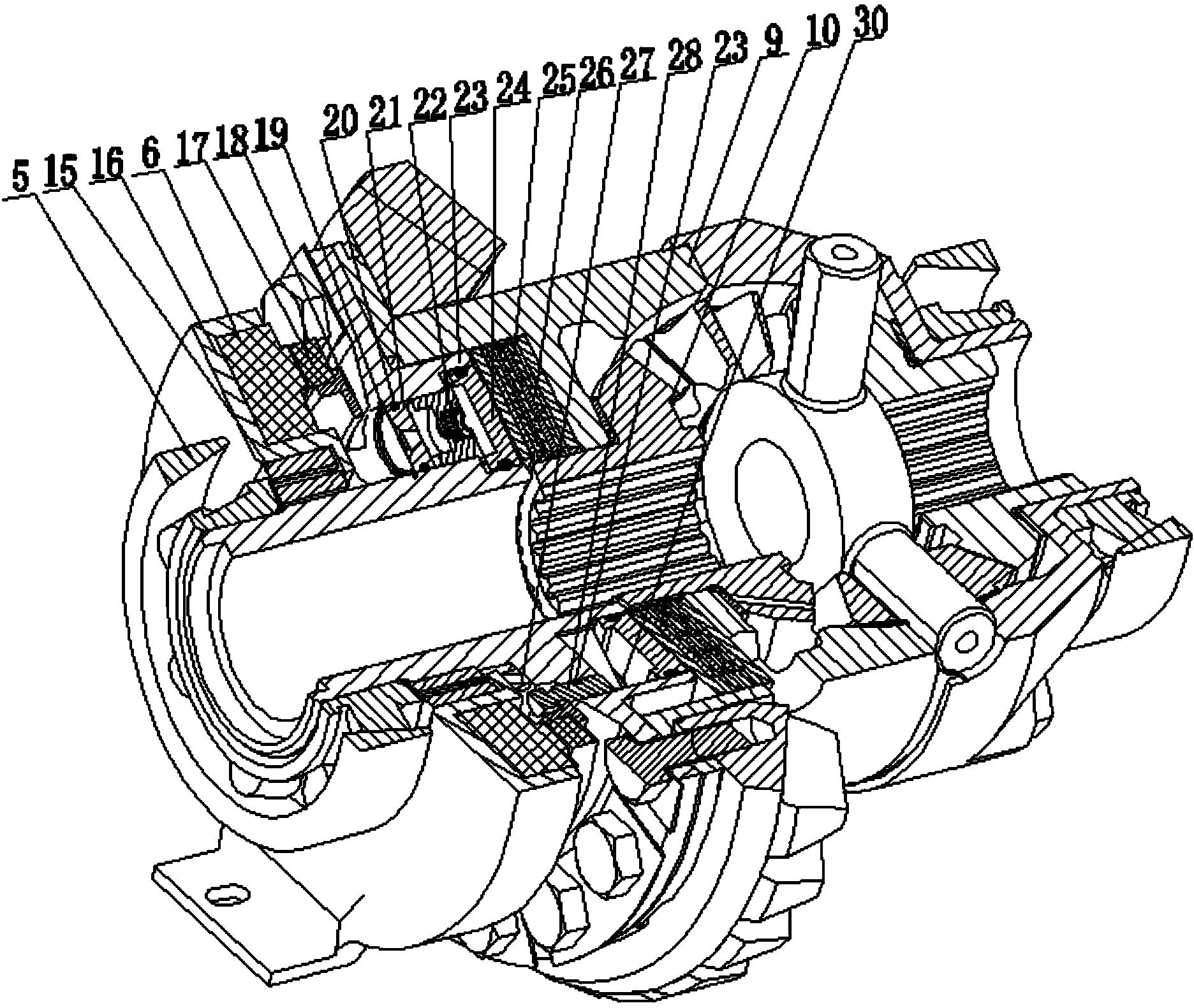

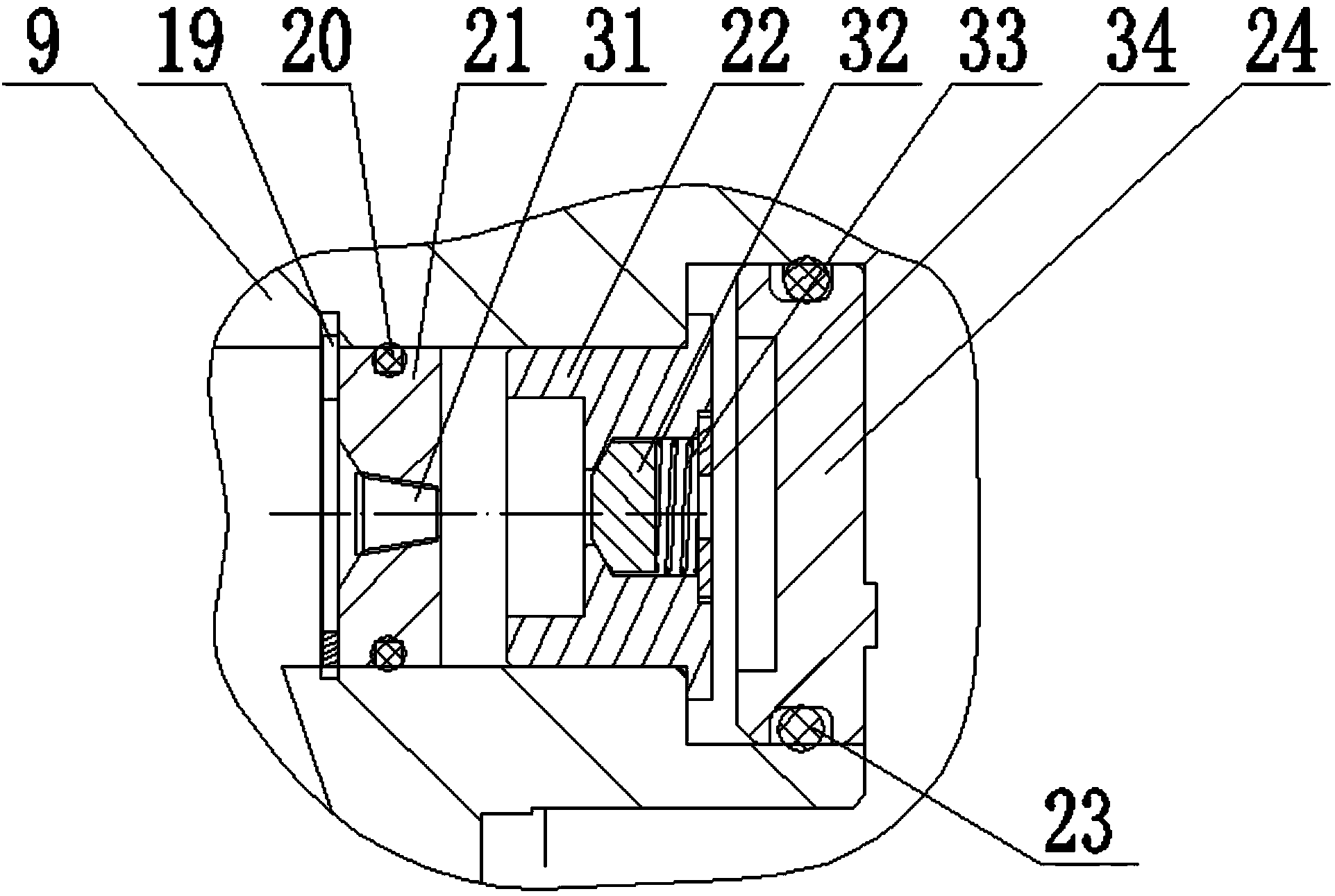

Electronic limited slip differential mechanism

ActiveCN104006139AGood limited slip effectShort tripDifferential gearingsNeedle roller bearingPiston

The invention relates to the technical field of differential mechanisms, particularly to an electronic limited slip differential mechanism. The electronic limited slip differential mechanism comprises a differential mechanism end cover, a needle bearing, an electromagnetic clutch support, an electromagnetic clutch, a magnet, a magnet support, a large piston, a small piston, an internal friction plate, an external friction plate, an air exhaust cock and a thrust unit. The electromagnetic clutch is arranged on the electromagnetic clutch support; the electromagnetic clutch support is mounted on the differential mechanism end cover through the needle bearing; the electromagnetic clutch support is mounted on the differential mechanism end cover through a thrust bearing; the magnet and the electromagnetic clutch are oppositely arranged, and the magnet is connected with the small piston through the magnet support; the large piston is arranged on the right of the small piston; the thrust unit is arranged on the left of the large piston; the right end surface of the large piston abuts against the external friction plate; the external friction plate and the internal friction plate are arranged inside a differential mechanism left casing in a crossed mode; the air exhaust cock is arranged inside the differential mechanism end cover. The electronic limited slip differential mechanism is simple in structure, good in slip limiting effects and short in slip limiting response time.

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST +1

Restocking method for food vending machine

ActiveCN109615779AEasy replenishmentTake it accuratelyCoin-freed apparatus detailsApparatus for dispensing discrete articlesFood vending machinesEngineering

The invention discloses a restocking method for a food vending machine, which is used for carrying out restocking for the vending machine. The method comprises the steps of: designing a unique two-dimensional code for each food placing cavity; in each time the vending machine needs restocking, a staff reading the two-dimensional code on the food placing cavity where a meal box to be placed by using a camera in the vending machine to acquire the position information of the storage cavity; then reading the two-dimensional code of the box meals to be placed to acquire food information; the vending machine binding the food information of the meal box to be placed in the current food placing cavity, sending the information to the cloud server; and the cloud server storing the information in a database and updating original food information and inventory of the food placing cavity. According to the restocking method for the food vending machine, by means of twice code scanning of the staff,each box meal stored in the vending machine corresponds to an accurate food placing cavity position, so that it is easy for the staff to replenish, and utilization rate of the storage cabinet is improved.

Owner:ZHEJIANG UNIV OF TECH

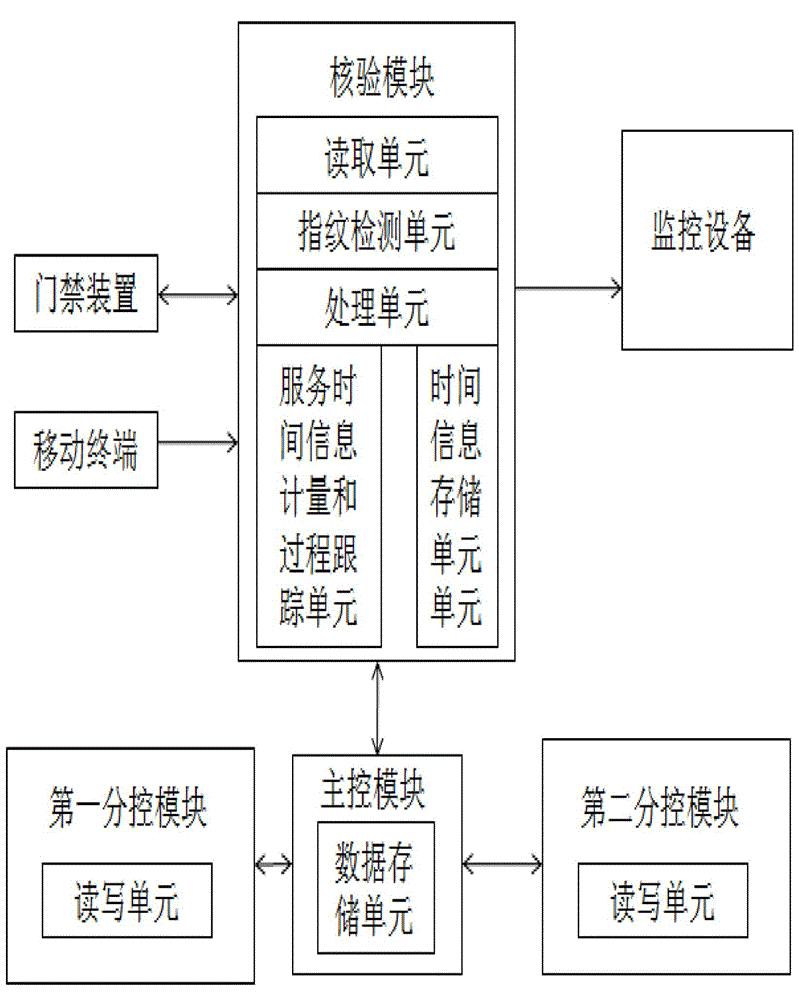

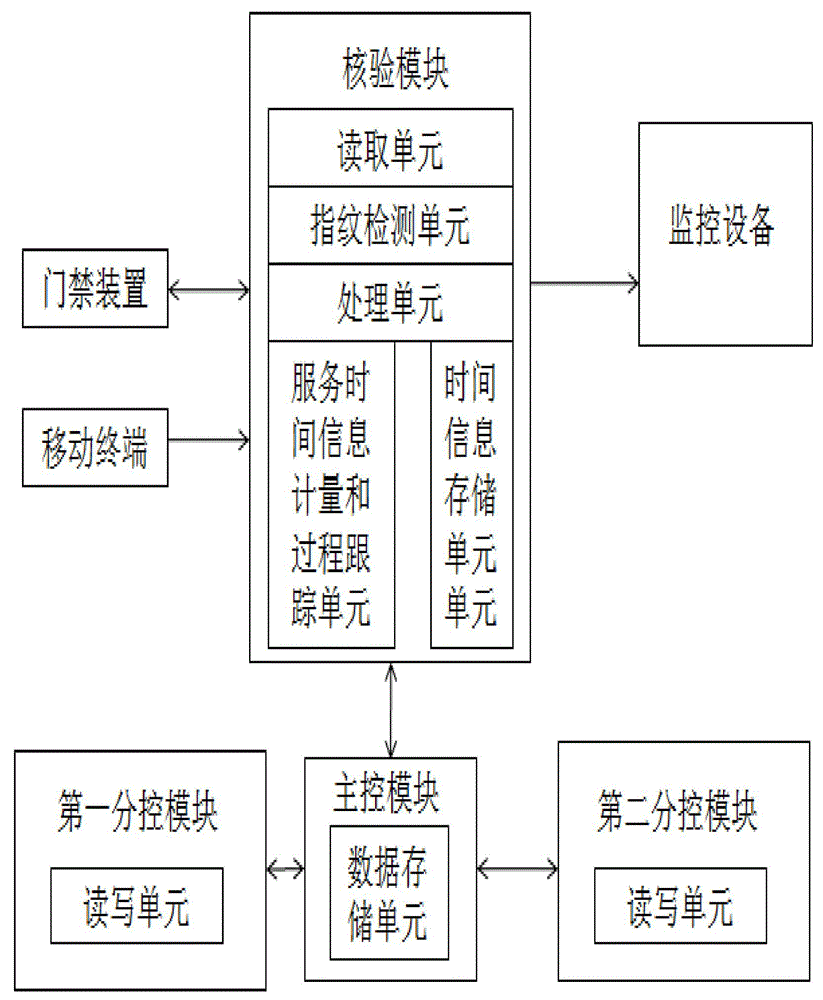

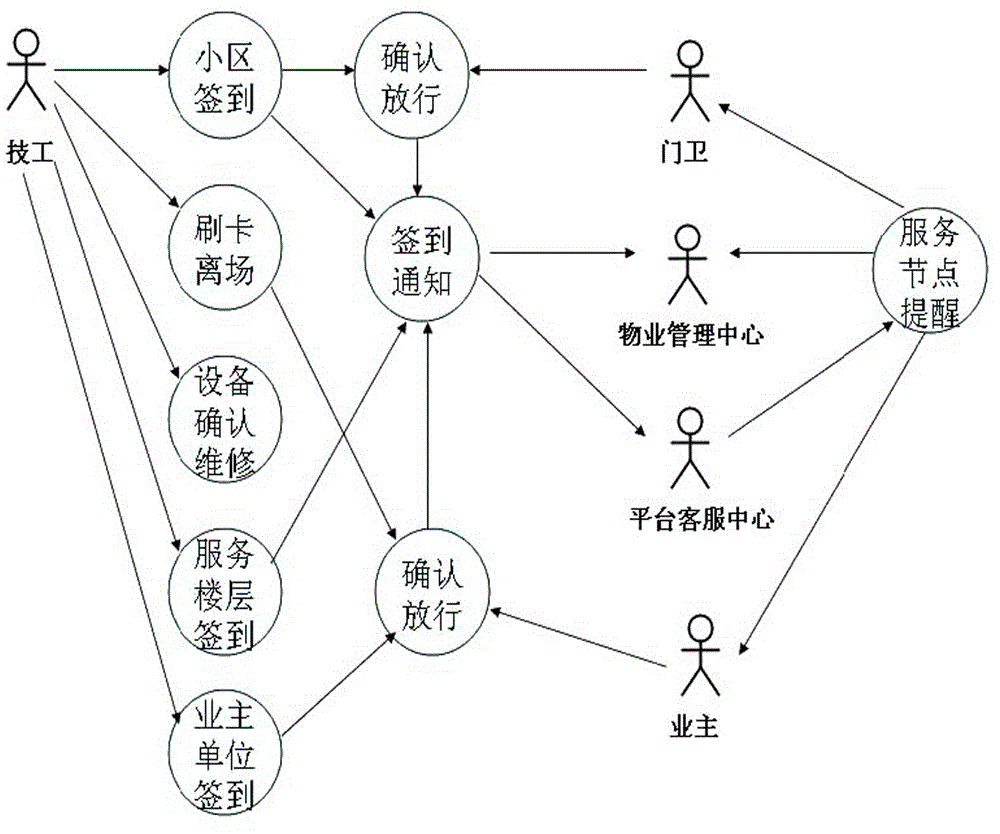

Security system for community on-site service

InactiveCN105467948AEnsure safetyAvoid safety hazardsClosed circuit television systemsResourcesService personnelData information

The invention provides a security system for community on-site service. The system comprises a server, a user client capable of communicating with the server, a mobile terminal which is carried by service personnel, and a verification device for verifying the information contained in the mobile terminal. The verification device is arranged at the entrance to a community and can communicate with the server. The server comprises a data storage module with the storage of the data information of the service personnel. The user client can read and write information in the data storage module. The verification device can compare read information and the information stored in the data storage module and returns a verification result. A user uses the user client to select the on-site service personnel, the server generates a task list and sends the task list to the mobile terminal carried by the service personnel, when the service personnel enters and leaves the community, the service personnel should be verified by the verification device at first, and thus the security of the community is ensured.

Owner:深圳市社邦创新科技有限公司

Intelligent travel assisting method and system for blind people

InactiveCN108670747ATimely, efficient and accurate travelComprehensive and effective active navigationWalking aidsInformation transmissionReal time navigation

The invention discloses an intelligent travel assisting method and system for blind people. The method comprises the steps of voice acquisition and analysis, route planning and design, real-time navigation information determination, timely navigation broadcasting and the like. The system comprises a storage module, a voice acquisition module, a voice data processing module, a positioning device module, a communication module, a route design determination algorithm module, a real-time navigation information determination module and an information transmission and broadcasting module. The methodand the system are stable and reliable, good in anti-interference performance and wide in application range, can conveniently and timely guide the blind people to travel in complex environments, havethe advantages of high system intelligence, advanced and scientific method, safe and accurate travel route and the like, greatly improve freedom of movement of the blind people, have practicability and implementability, and have higher practical value and wide application prospect.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

Intelligent navigation method and intelligent navigation system for traffic safety monitoring for the blind

InactiveCN109059920ATimely, efficient and accurate travelComprehensive and effective active navigationNavigational calculation instrumentsInformation transmissionReal time navigation

The invention discloses an intelligent navigation method and system for traffic safety monitoring for the blind. The method comprises the steps such as voice collection and analysis, route planning design, real-time navigation information determination, and timely navigation broadcast. The system comprises a storage module, a voice collection module, a voice data processing module, a positioning device module, a communication module, a route design determination algorithm module, a real-time navigation information determination module, and an information transmission broadcast module. The invention is stable and reliable, good in anti-interference performance and wide in application range, can conveniently and timely guide the blind to travel in a complex environment, and has the advantages such as high system intelligence, advanced method and safe and accurate travel route, which greatly improves freedom of movement of the blind, and the advantages of practicability and realizability,and high practical value and broad application prospects.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

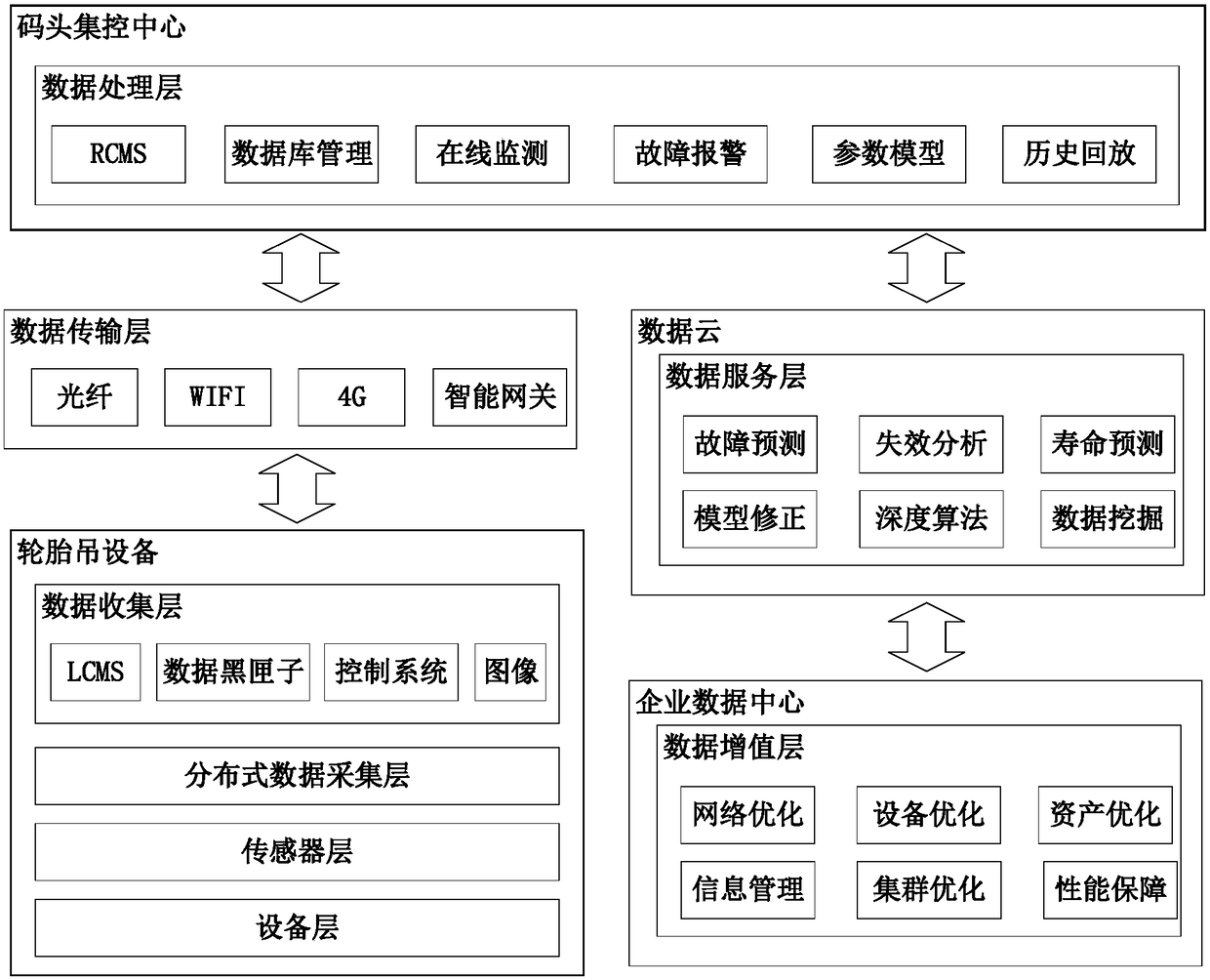

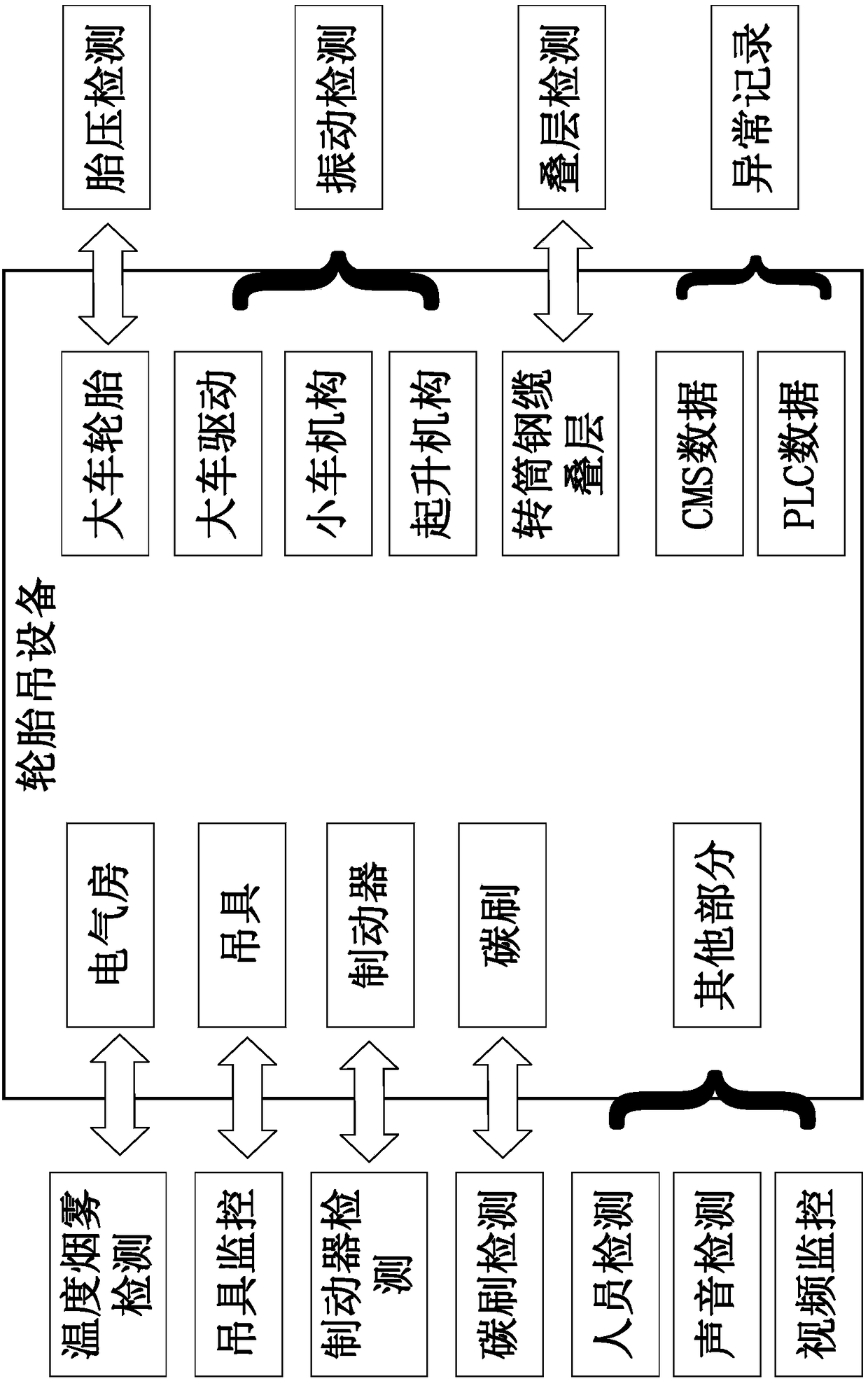

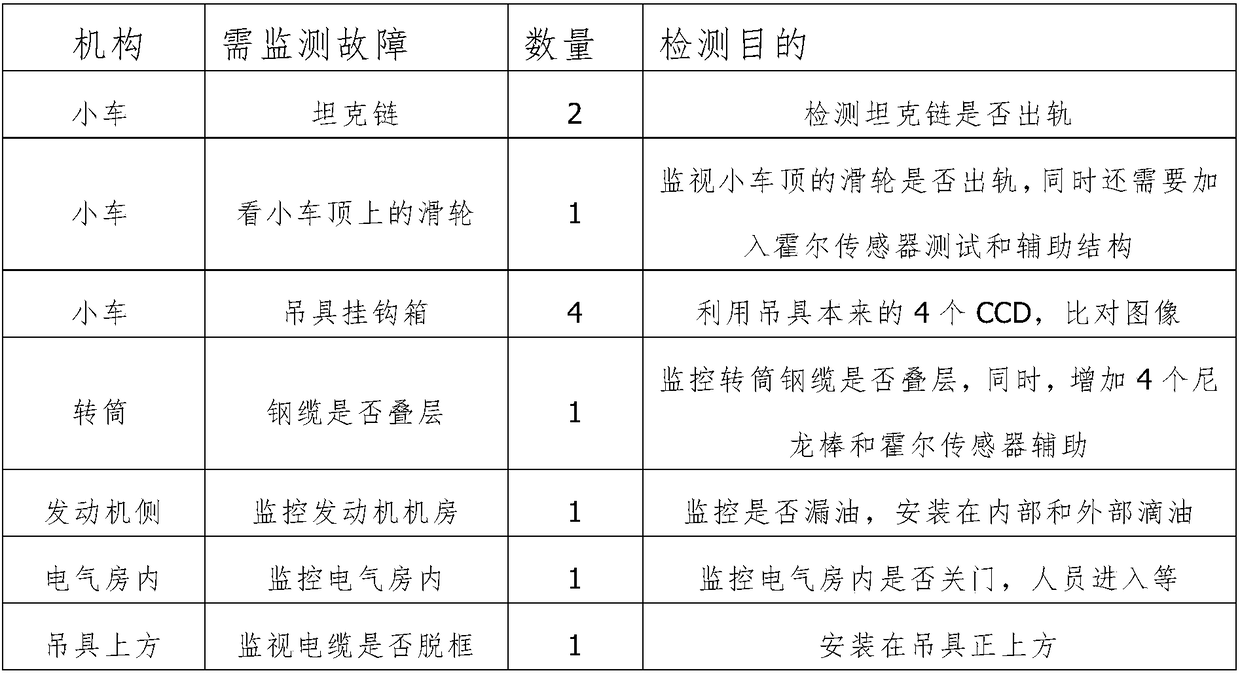

Remote detection and evaluation system for tire crane

InactiveCN108227617AConvenient itineraryAvoid wastingProgramme control in sequence/logic controllersData centerData acquisition

The invention discloses a remote detection and evaluation system for a tire crane. The system comprises an equipment layer, a sensor layer, a distributed data collection layer, a data collection layer, a data transmission layer, a data processing layer, a data service layer and a data increment layer, wherein the equipment layer, the sensor layer, the distributed data collection layer and the datacollection layer are located on tire crane equipment and complete collection work of mechanism state and safety data; the data transmission layer is located between each tire crane and a wharf centralized control center; the data processing layer is located in the wharf centralized control center and completes some local remote detection and evaluation work of a wharf; the data service layer is located on data cloud and can utilize locally deployed enterprise private cloud or public rental cloud; the data increment layer is located in a data center of an enterprise, the enterprise acquires monitoring data of the tire crane equipment for a long time, and detection and evaluation for the tire crane equipment are enhanced by the aid of enterprise resources. According to the system, the modules have independent functions, the functions are clear, and reliability of the system is enhanced and guaranteed.

Owner:SHANGHAI ZHENHUA HEAVY IND

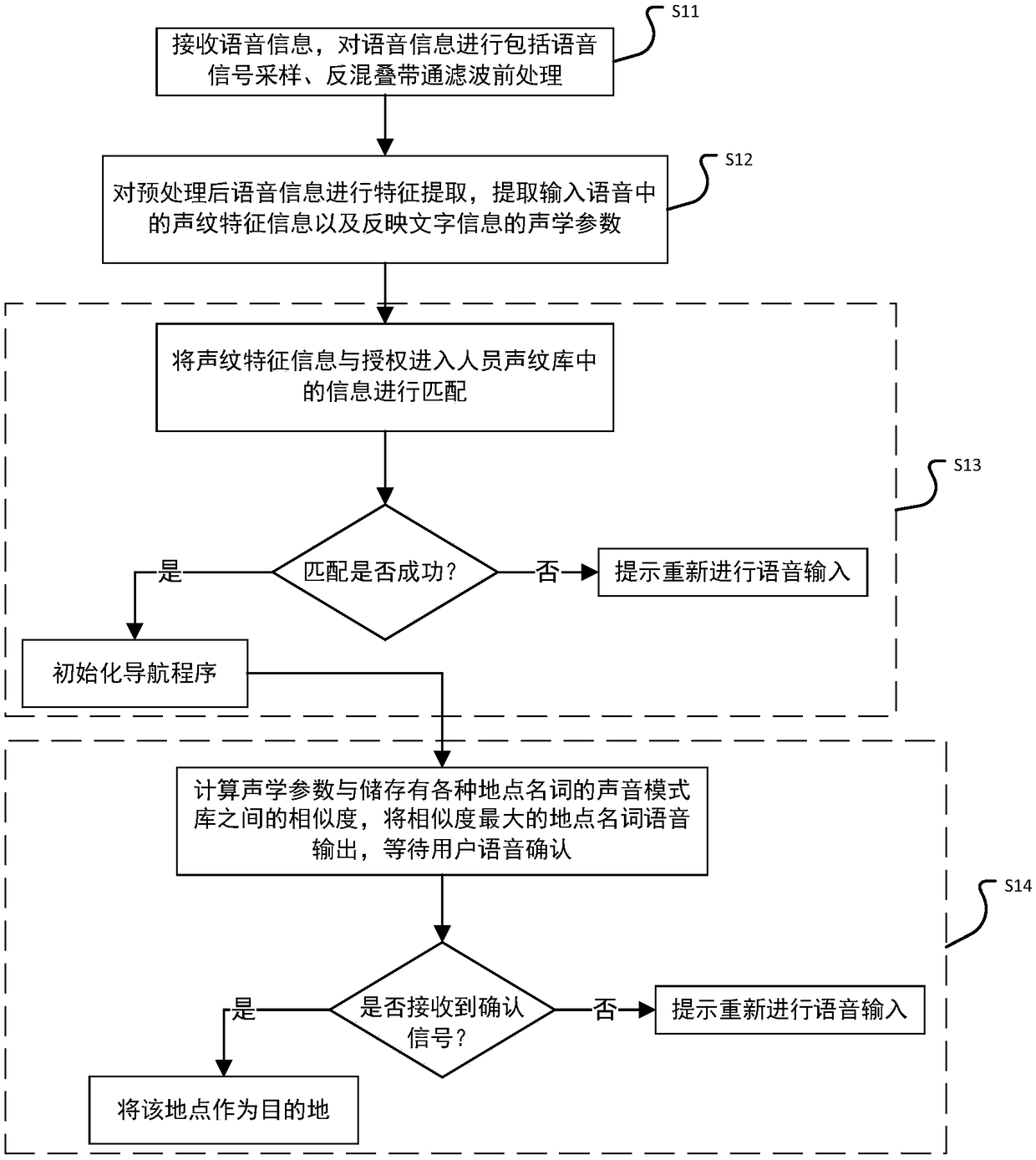

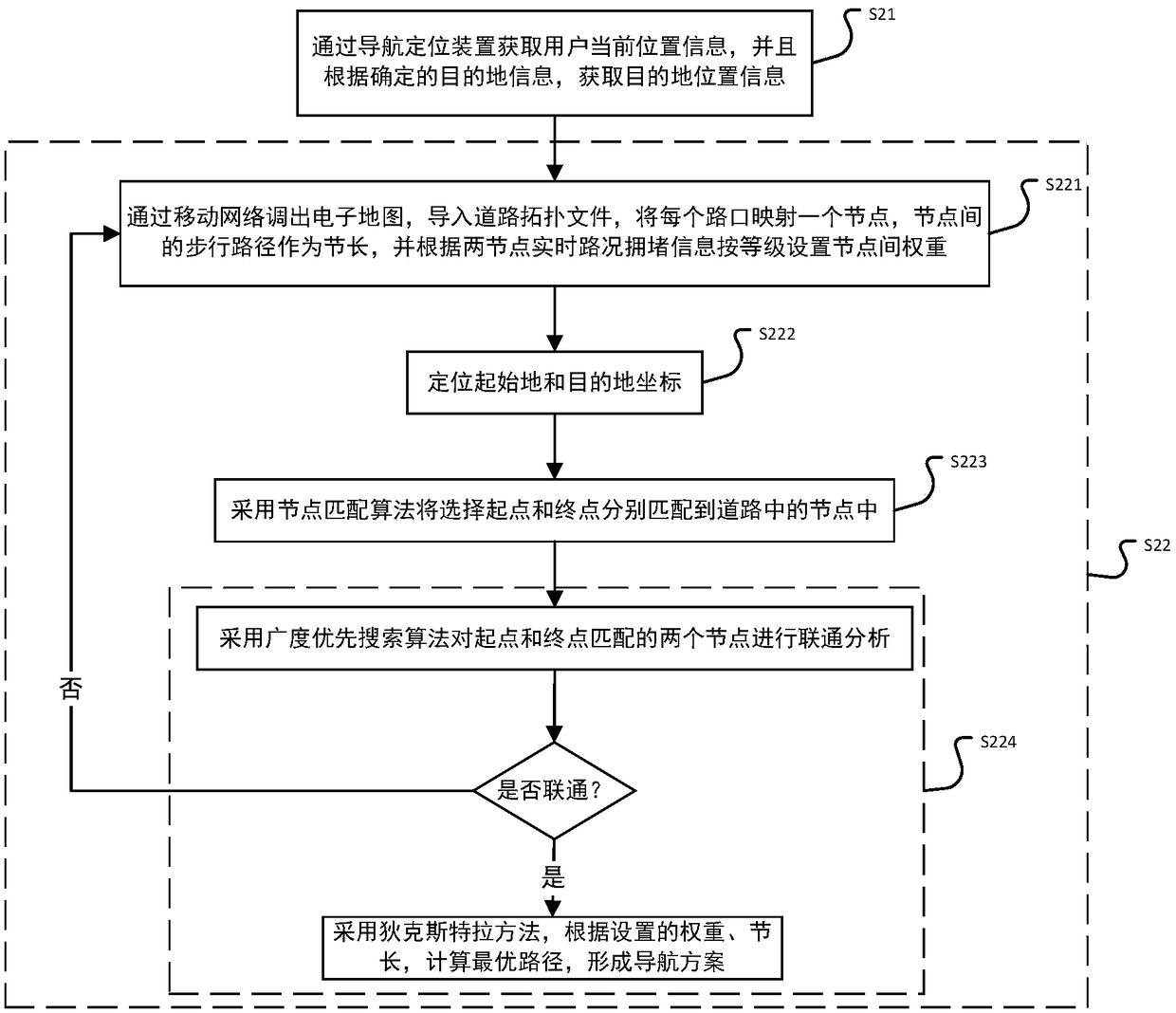

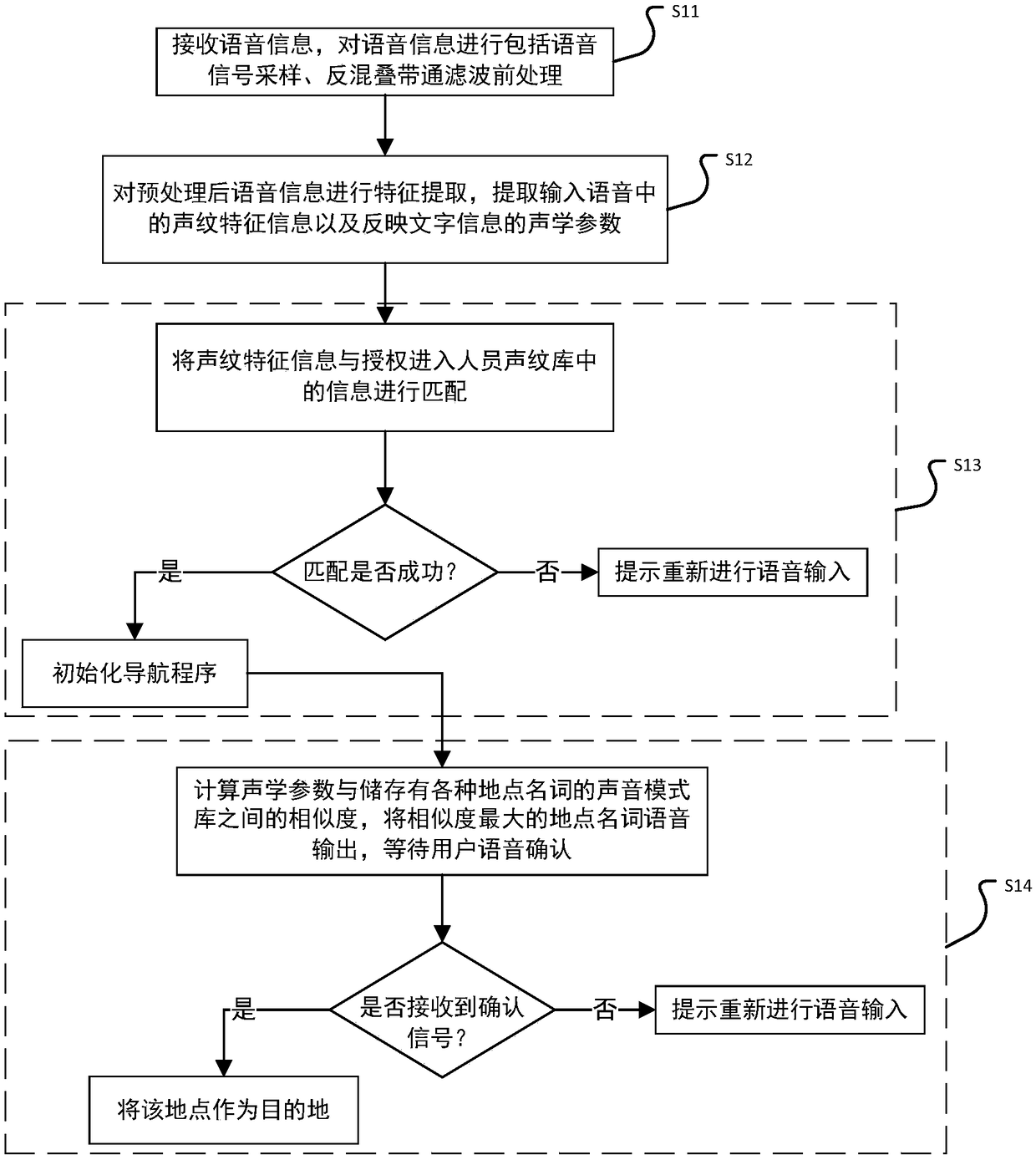

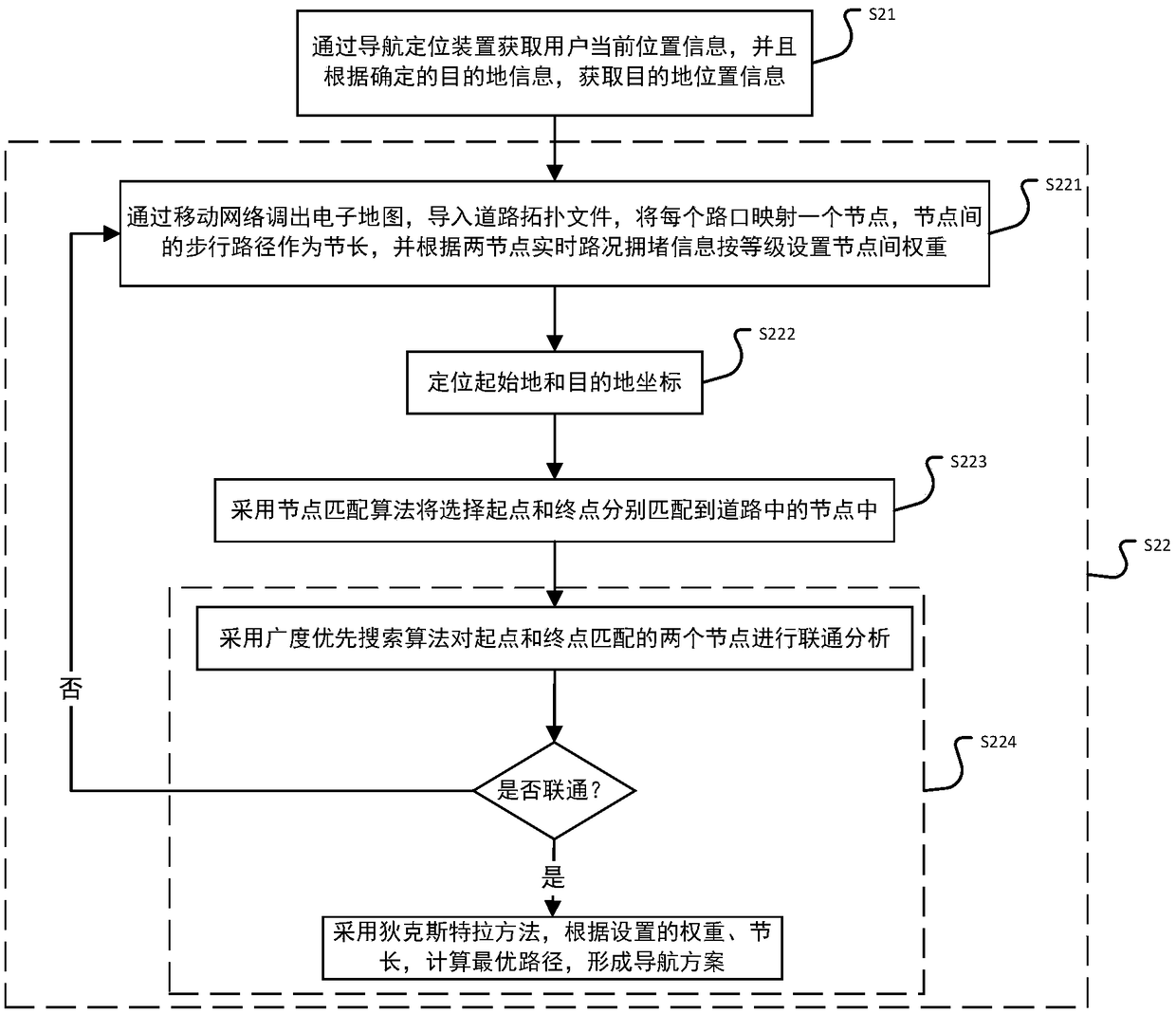

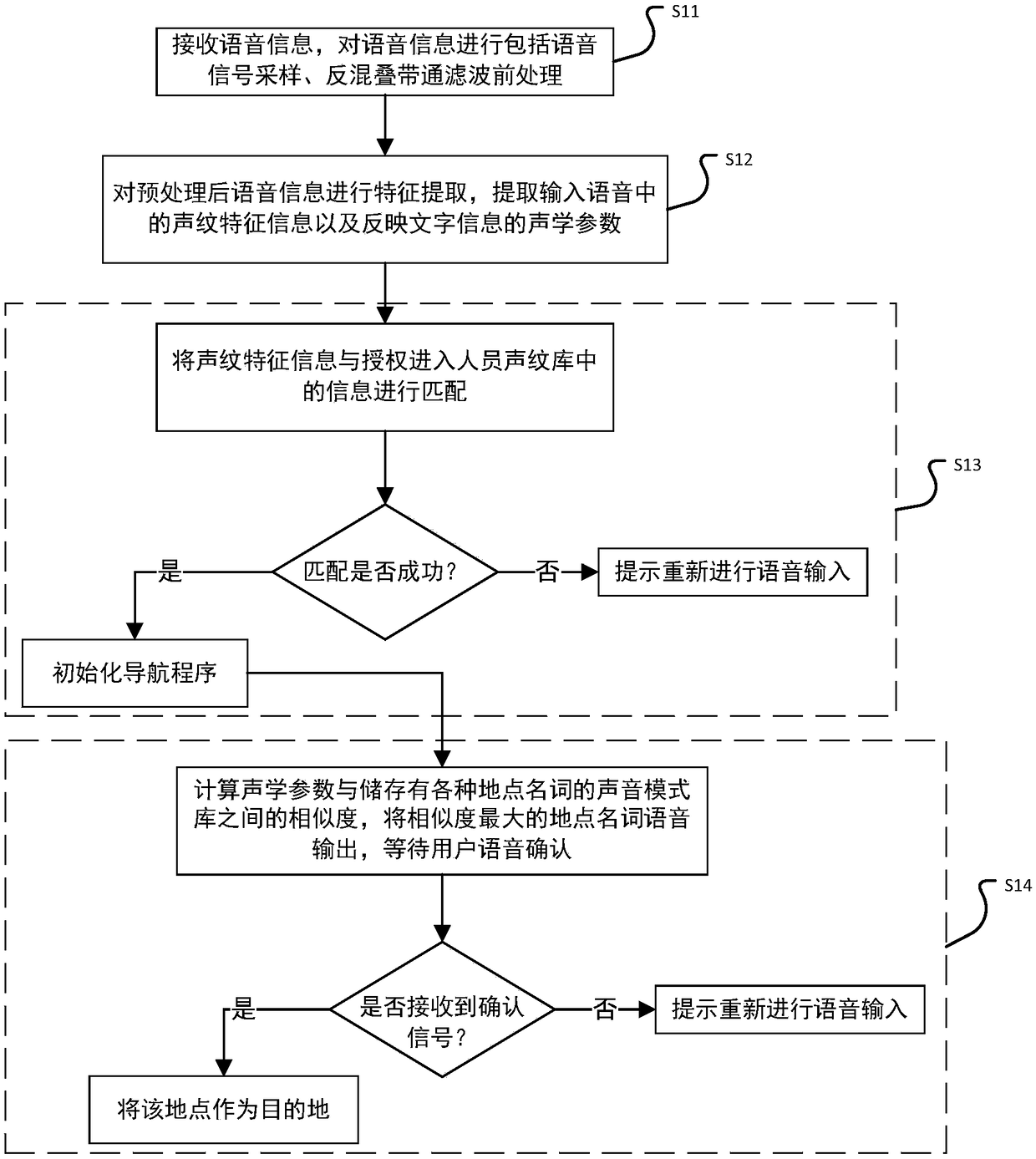

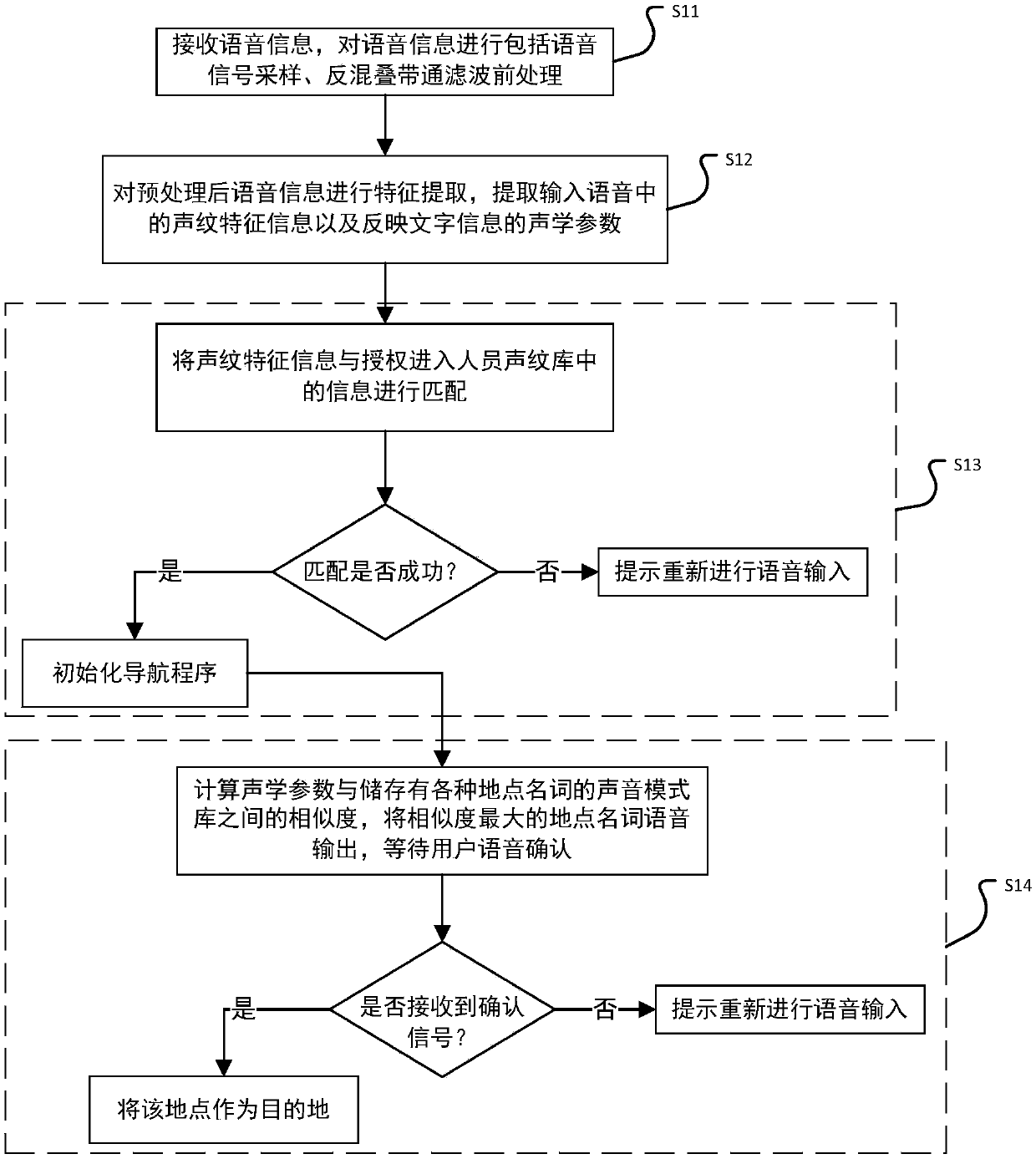

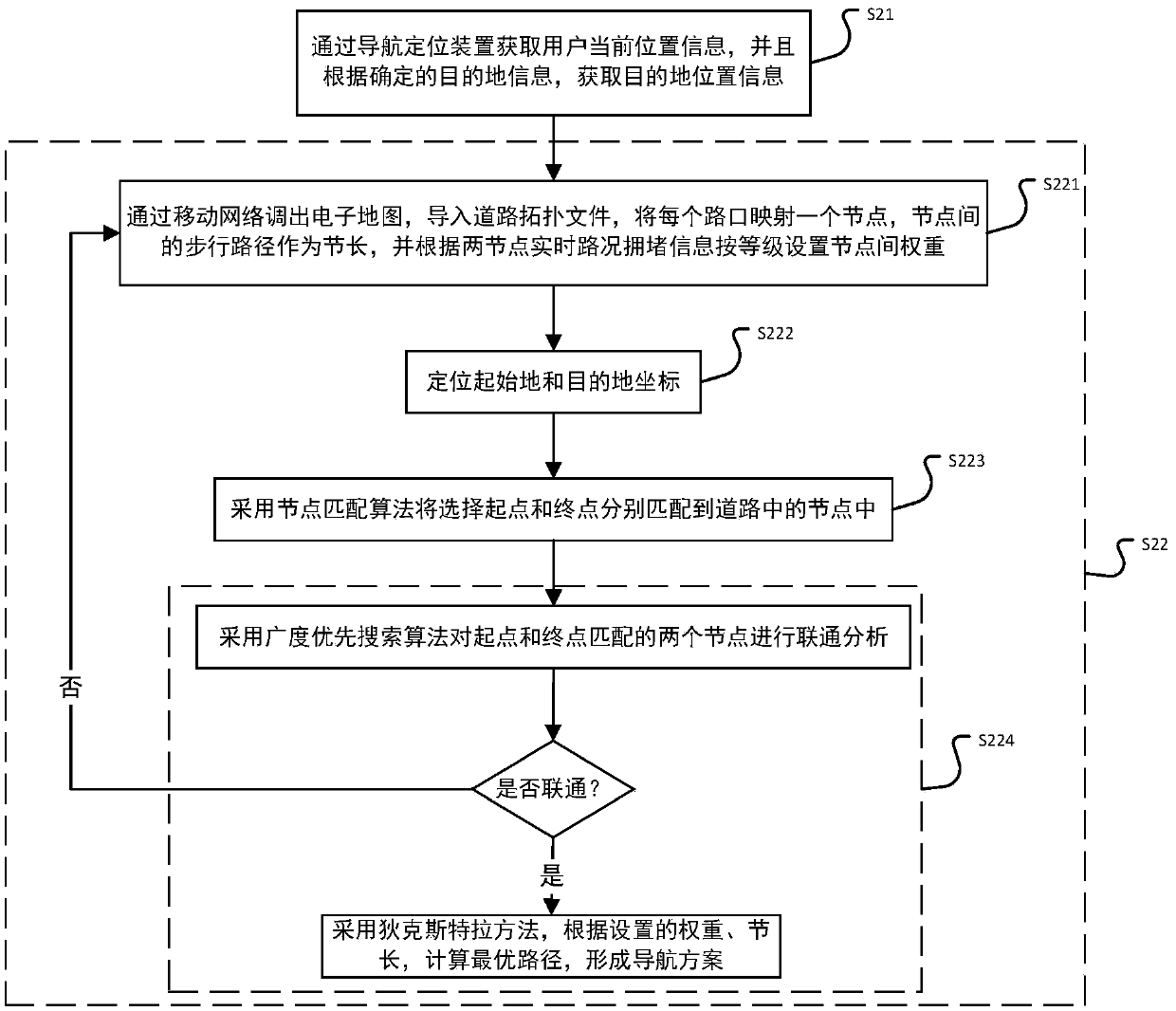

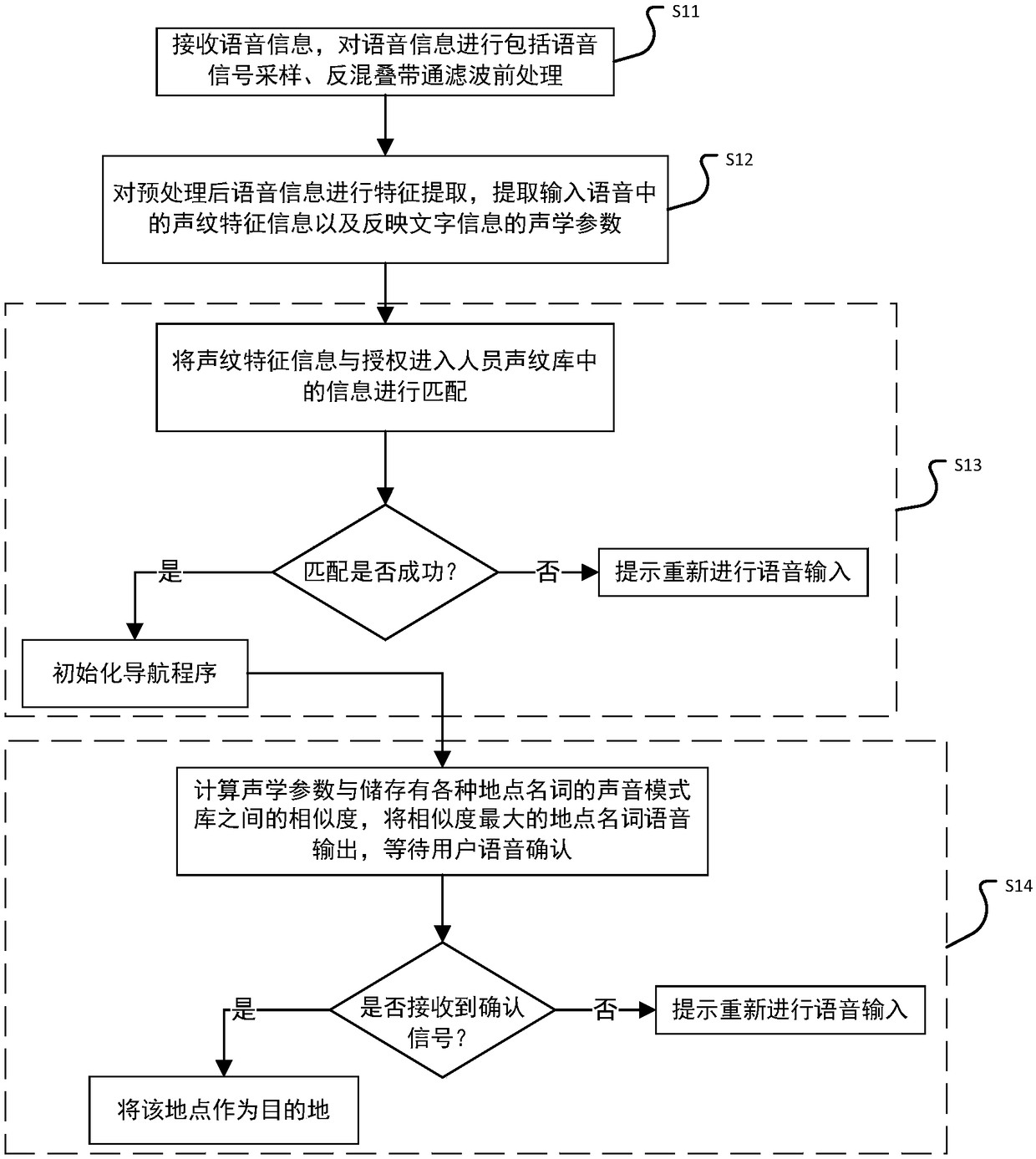

Navigation method and system based on speech recognition admission for blind person

InactiveCN108670745AComprehensive and effective active navigationTimely, efficient and accurate active navigationWalking aidsReal time navigationInformation transmission

The invention discloses a navigation method and system based on speech recognition admission for a blind person. The method comprises steps of speech acquisition and analysis, route planning and design, determination of real-time navigation information, timely navigation broadcast and other steps. The system comprises a storage module, a speech acquisition module, a speech data processing module,a positioning device module, a communication module, a route design determining algorithm module, a real-time navigation information determining module and an information transmission and broadcast module. The navigation method and system are stable, reliable, good in anti-interference performance and wide in application range, can guide the blind person to walk in a complicated environment conveniently and timely and have the advantages that the system is high in intelligent degree, the method is advanced and scientific, a route is safe and accurate and the like, practicability, realizabilityand higher practical value and broad application prospect are achieved, and action freedom of the blind person is improved greatly.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

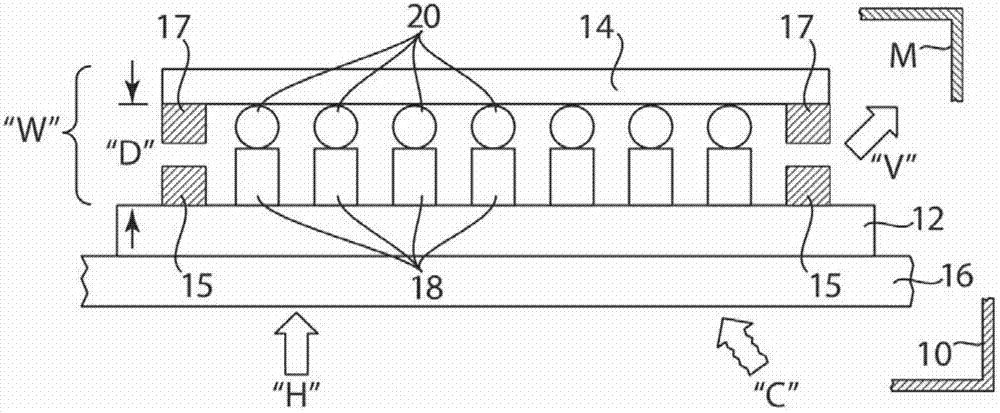

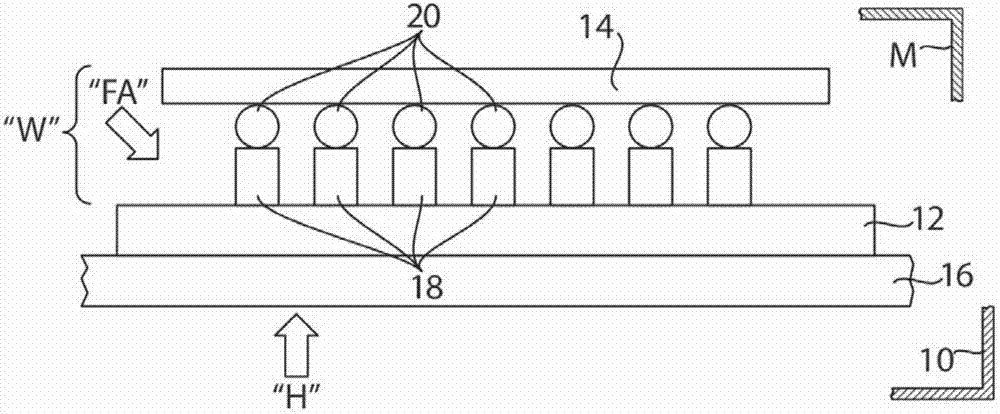

Serial thermal linear processor arrangement

ActiveCN103681363AEasy to removeEven and controllable heatingSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

A linear, serial chip / substrate assembly processing machine for stepwise advancing a pre-assembled chip / die substrate on a support plate through a series of sealable chambers having displacable bottom processing portions. The process begins at a loading station and ends up at an unloading station after various melting and vacuuming of chip / substrate components supported on a device tray through those various chambers to the final joining thereof.

Owner:PSK INC +1

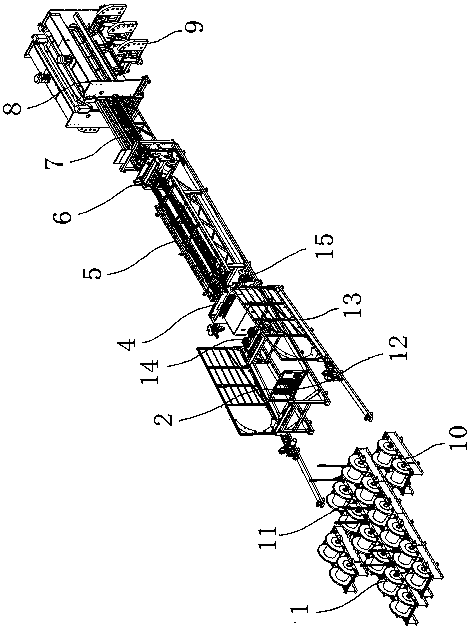

Composite heat-preservation system steel bar truss welding forming production line and truss production method

ActiveCN109014961AReduce wearPrecise positioningOther manufacturing equipments/toolsProduction lineEngineering

The invention belongs to the technical field of wire mesh machining device, and discloses a composite heat-preservation system steel bar truss welding forming production line and a truss production method. The composite heat-preservation system steel bar truss welding forming production line is mainly technically characterized in that a straightening mechanism, a welding mechanism, a net pull mechanism, a net cutting mechanism, a net piece sending mechanism, a bending mechanism and a discharging mechanism are included; the welding mechanism comprises one or more pairs of horizontal wire positioning mechanisms, each horizontal wire positioning mechanism comprises a fixing base and a fixing bracket, a spring steel sheet is arranged on the upper portion of each fixing bracket, a fixed ruler head is arranged at the front end of each spring steel sheet, a transverse wire penetrating hole is formed in each fixed ruler head, a wire outlet is formed in the front end of each wire penetrating hole, and a magnetic block is arranged at the rear end of each wire penetrating hole; and the bending mechanism comprises an upper bending cutter and a lower bending cutter corresponding to the upper bending cutter, a wire-jacking clamping groove with the section being semicircular is formed in the upper portion of the lower bending cutter, and a net piece conveying rack is located between the upperbending cutter and the lower bending cutter. When a net piece is pulled forwards, a transverse bar is pulled out from the wire outlet, the net piece is uplifted, abrasion of a lower electrode is avoided, the bent net piece is hooked by a discharging hook, and discharging is facilitated.

Owner:河北骄阳焊工有限公司

Method and system for optimizing guide blind monitoring by real-time obstacle avoidance in actual traffic environment

InactiveCN108836770APersistent lockContinuous identificationWalking aidsAlarmsBroadcastingRoute planning

The invention discloses a method and a system for optimizing guide blind monitoring by real-time obstacle avoidance in actual traffic environment. The method comprises the following steps of an audioacquisition and analysis, route planning and design, real-time navigation information determination, timely navigation broadcasting and the like. The system comprises a storage module, an audio acquisition module, an audio data processing module, a positioning device module, a communication module, a route design determining algorithm module, a real-time navigation information determination moduleand an information transmission broadcasting module. The method and the system are stable and reliable, good in anti-interference performance and wide in application range, can guide a blind person to travel in a complicated environment conveniently and timely, and has the advantages that the system is high in intelligence degree, the method is advanced and scientific, a travelling route is safeand accurate and the like; the action freedom of the blind person is greatly improved; the method and the system have practicability and realizability and have high practical value and wide application prospect.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

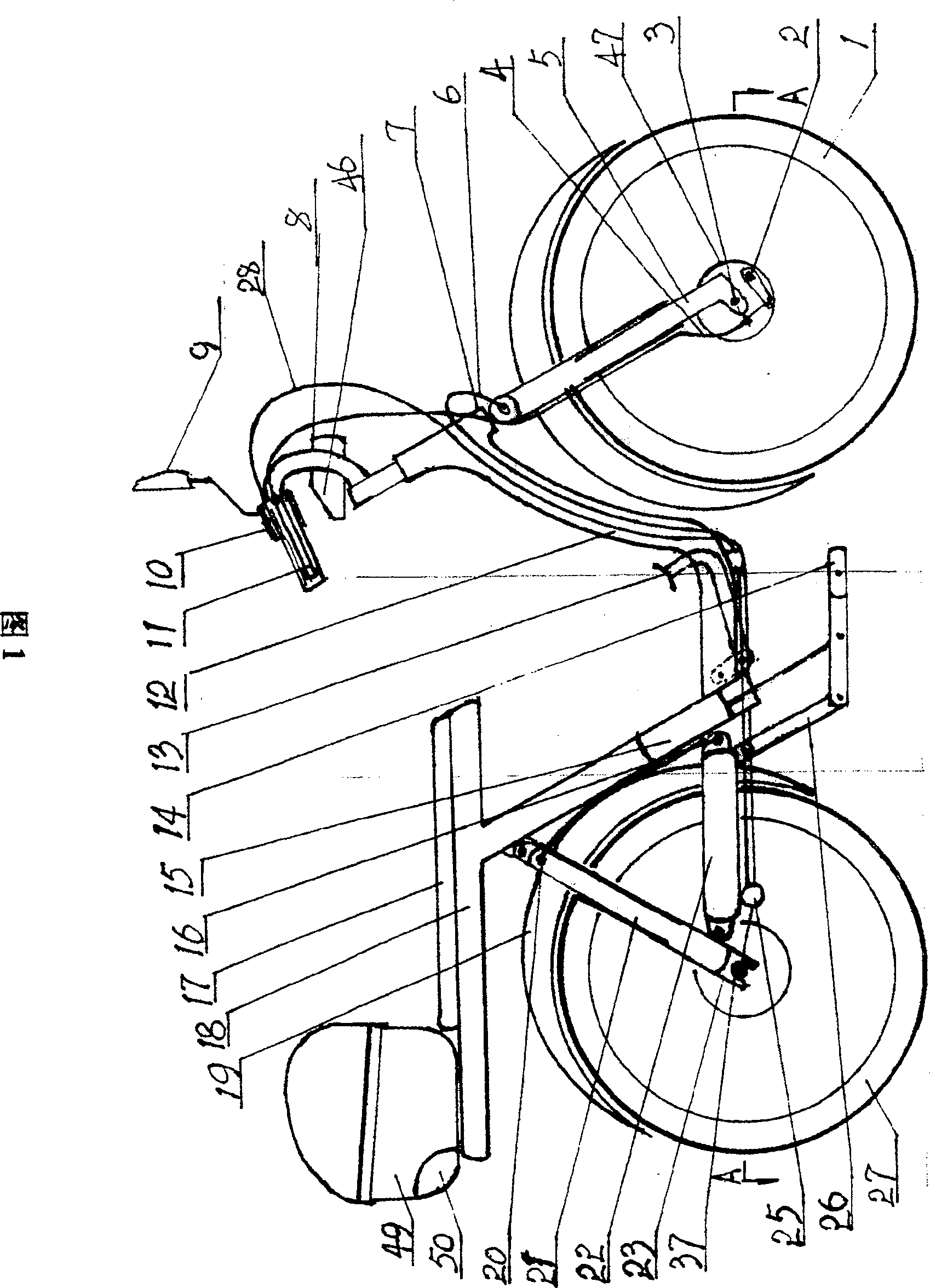

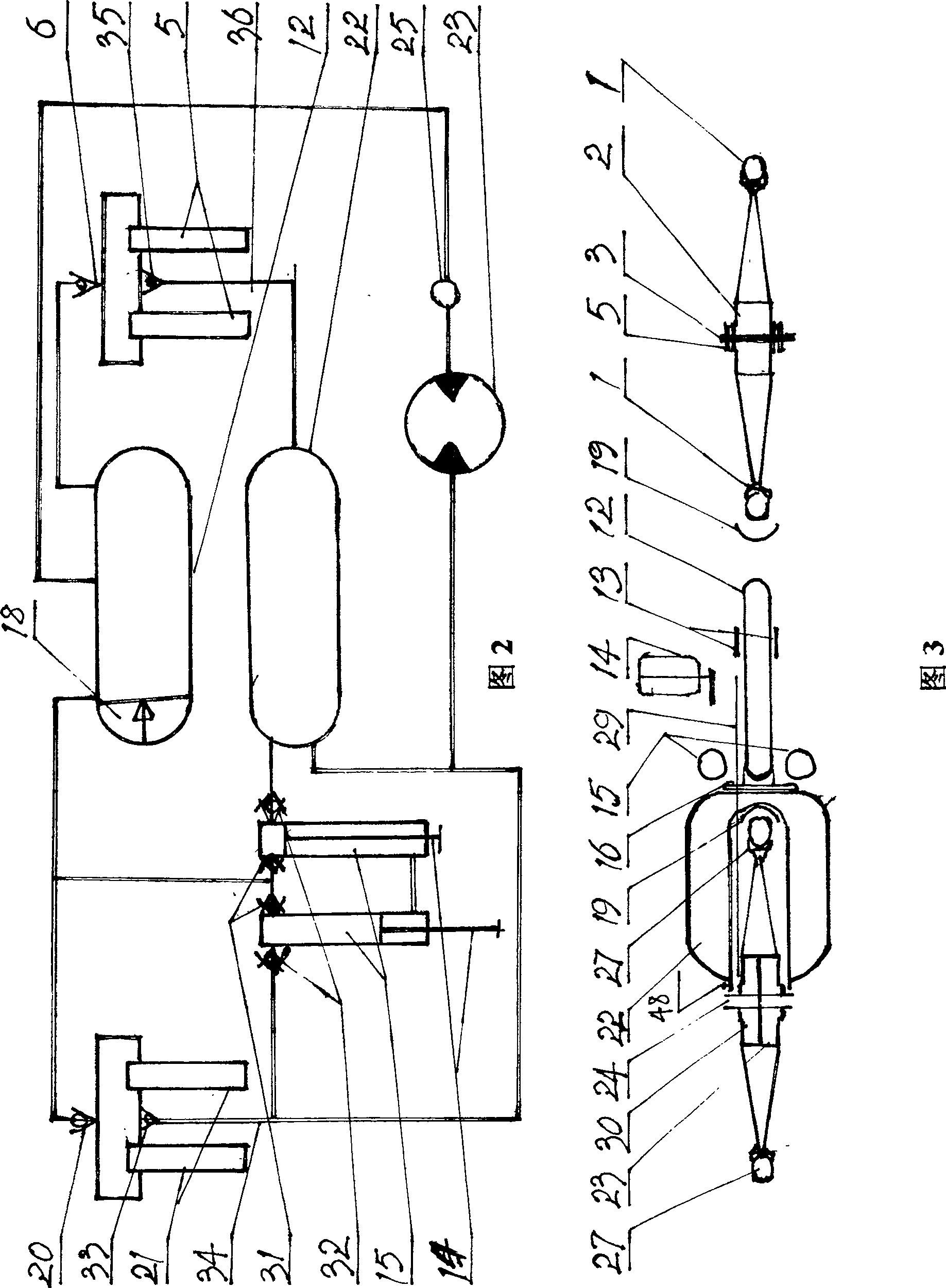

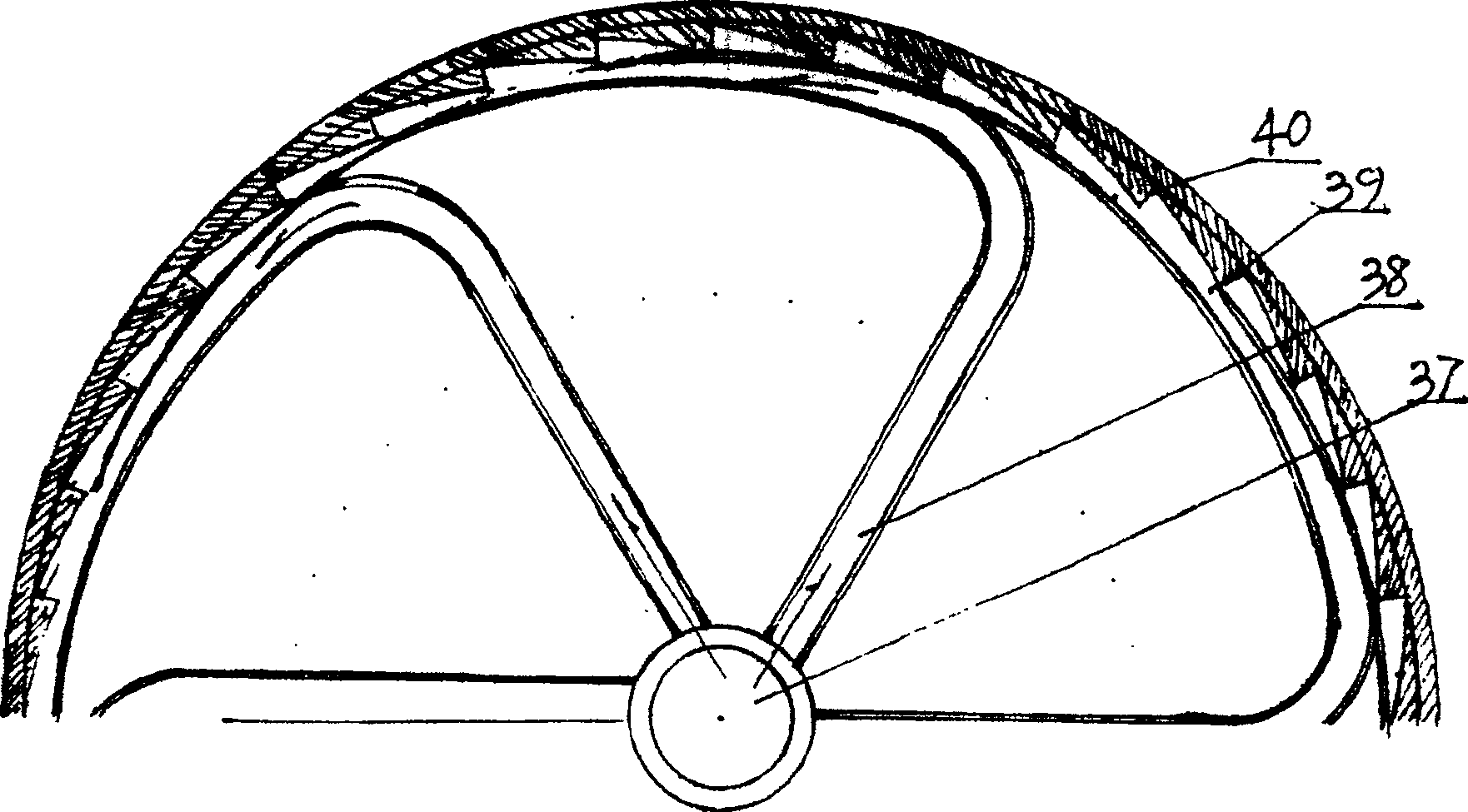

Hydraulic body-building bicycle

InactiveCN100484821CImprove the effective working positionConvenient angleNon-mechanical gearing transmissionBicyclesAgricultural engineering

Owner:余美平

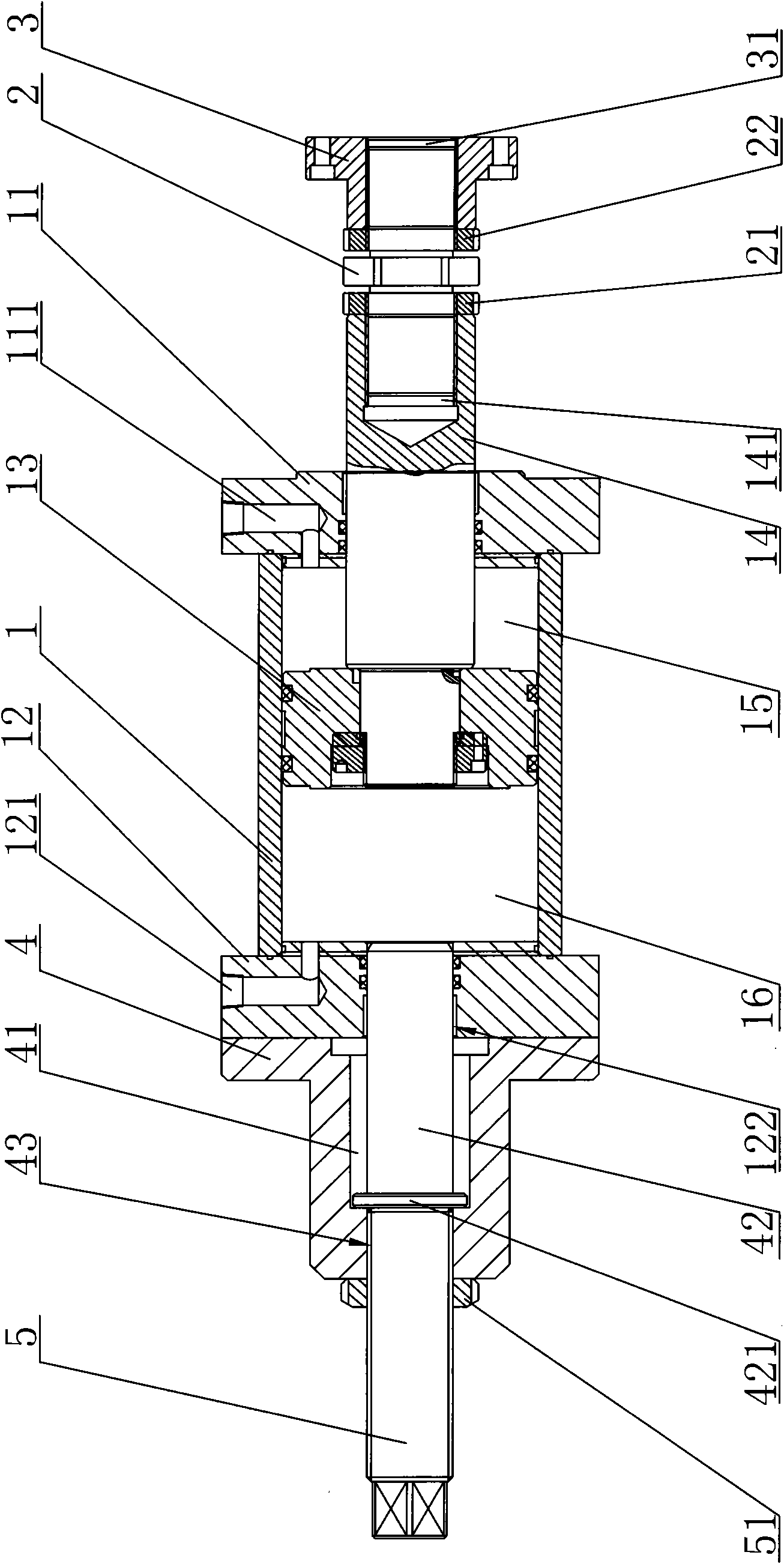

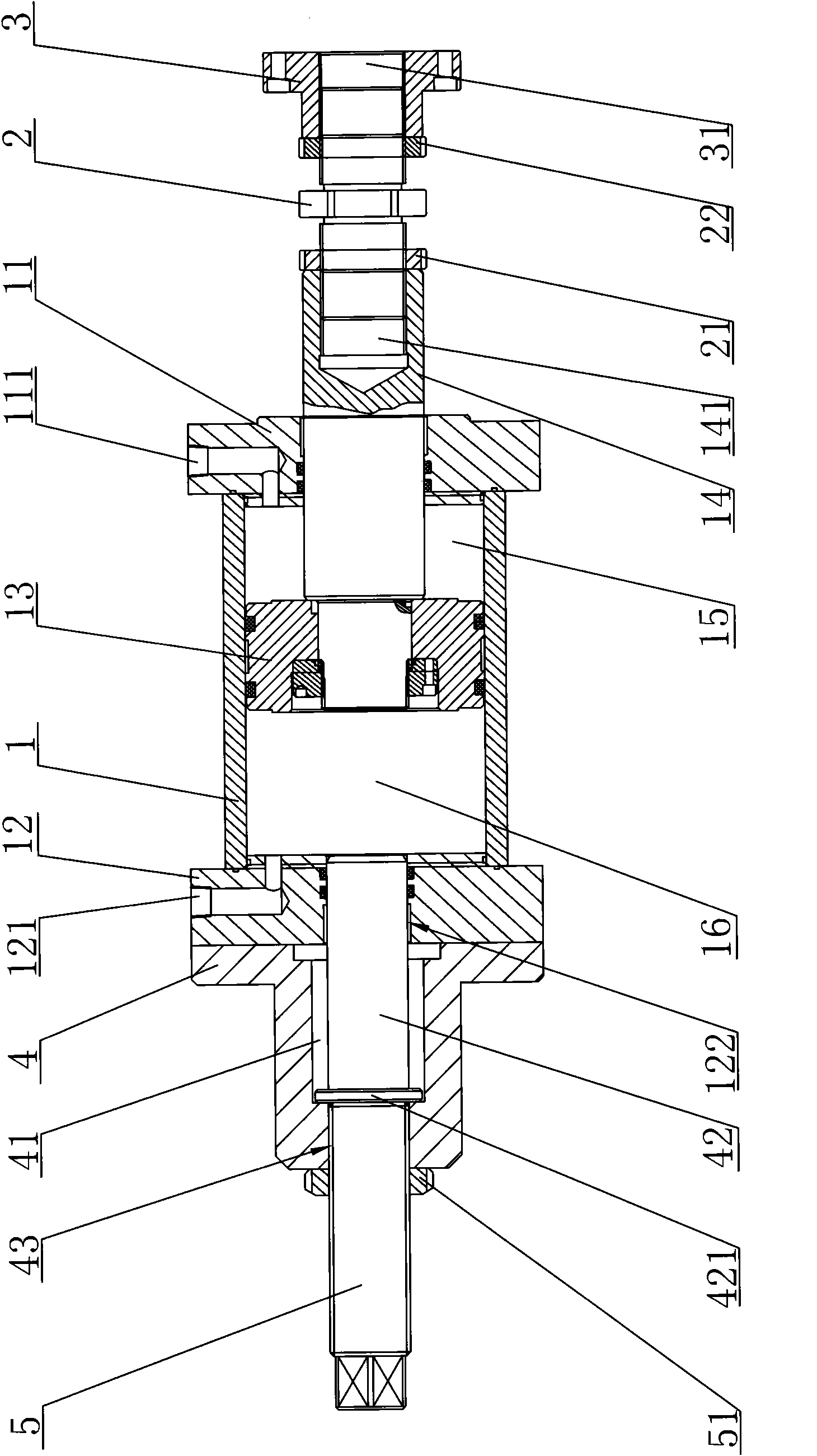

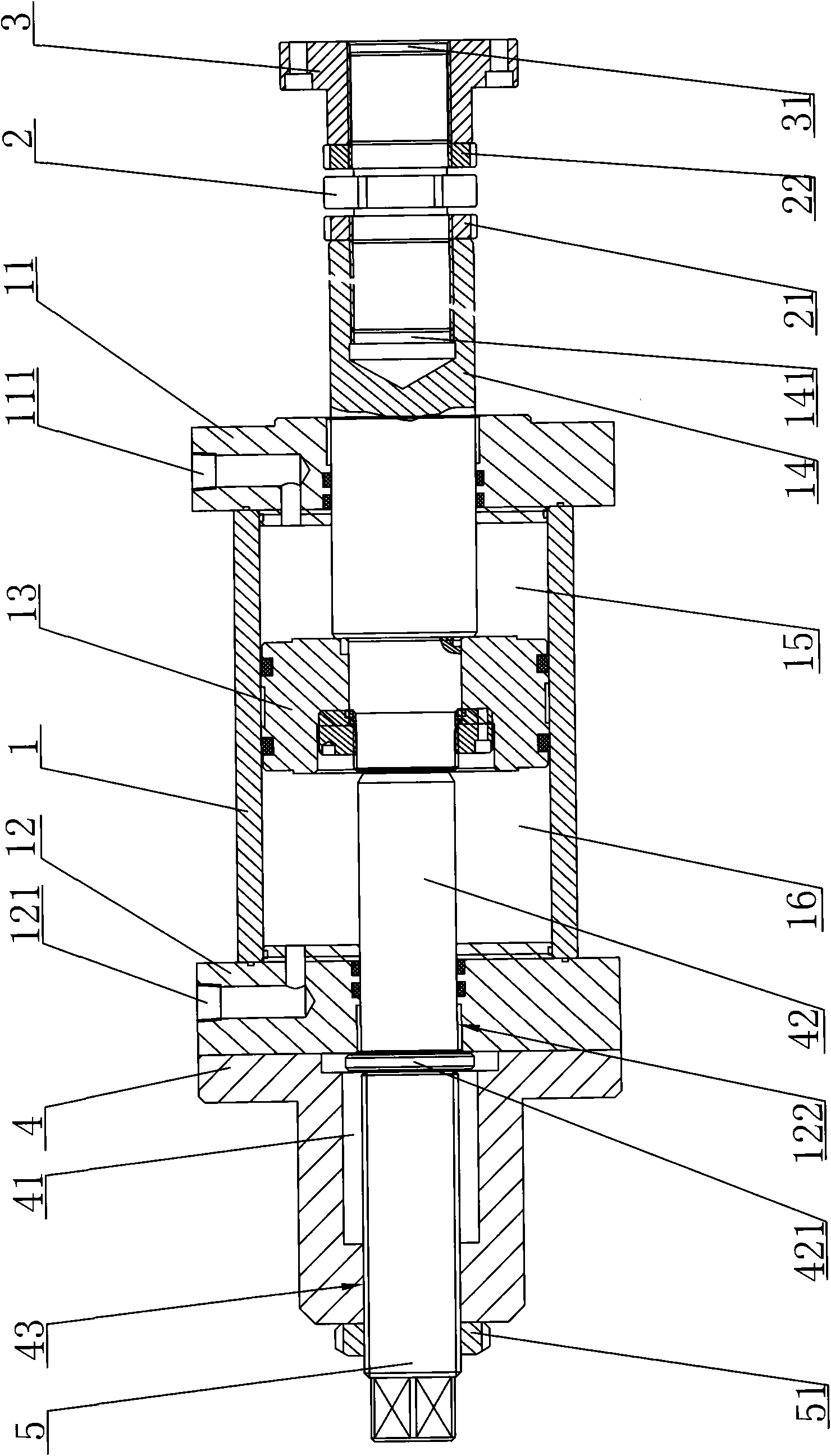

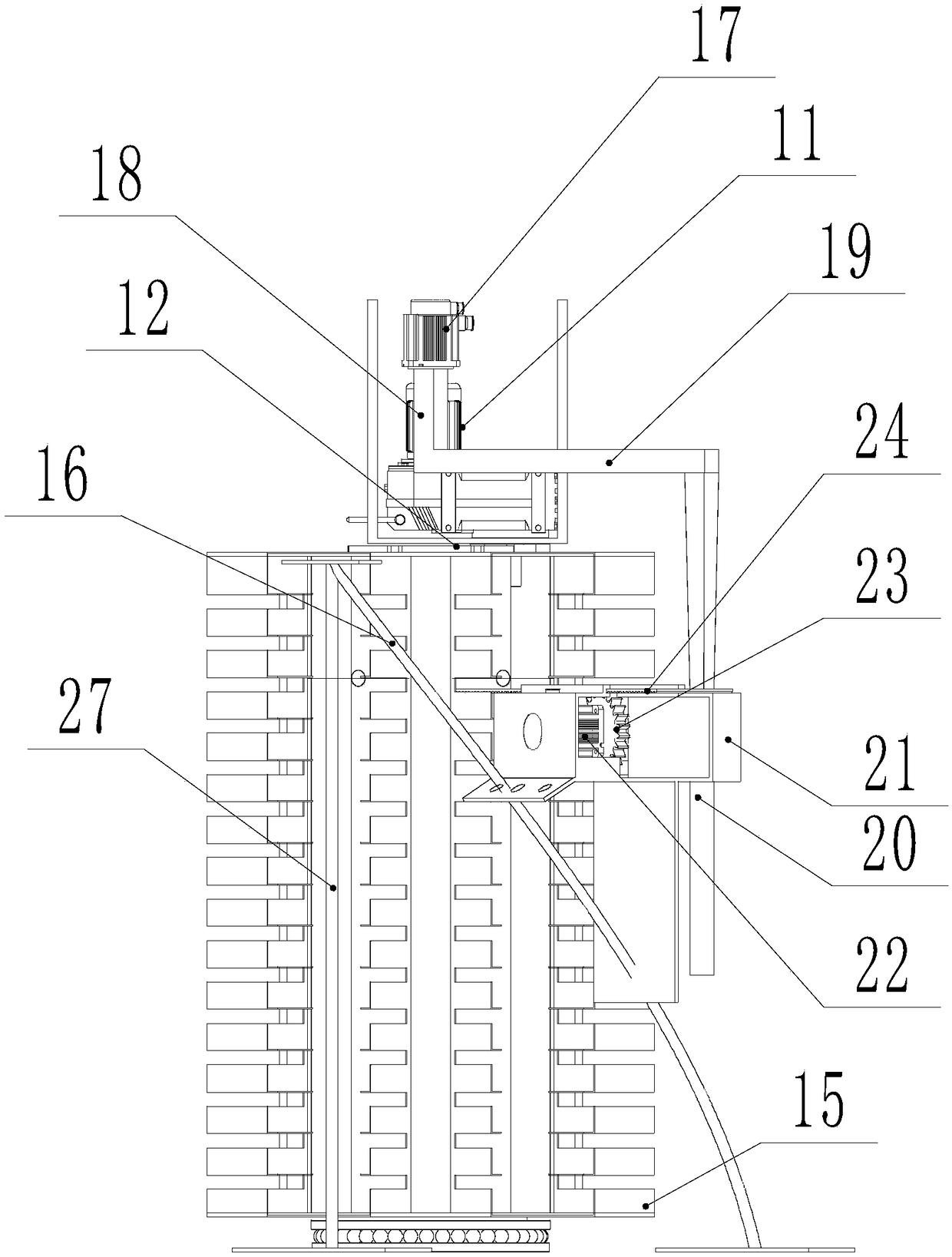

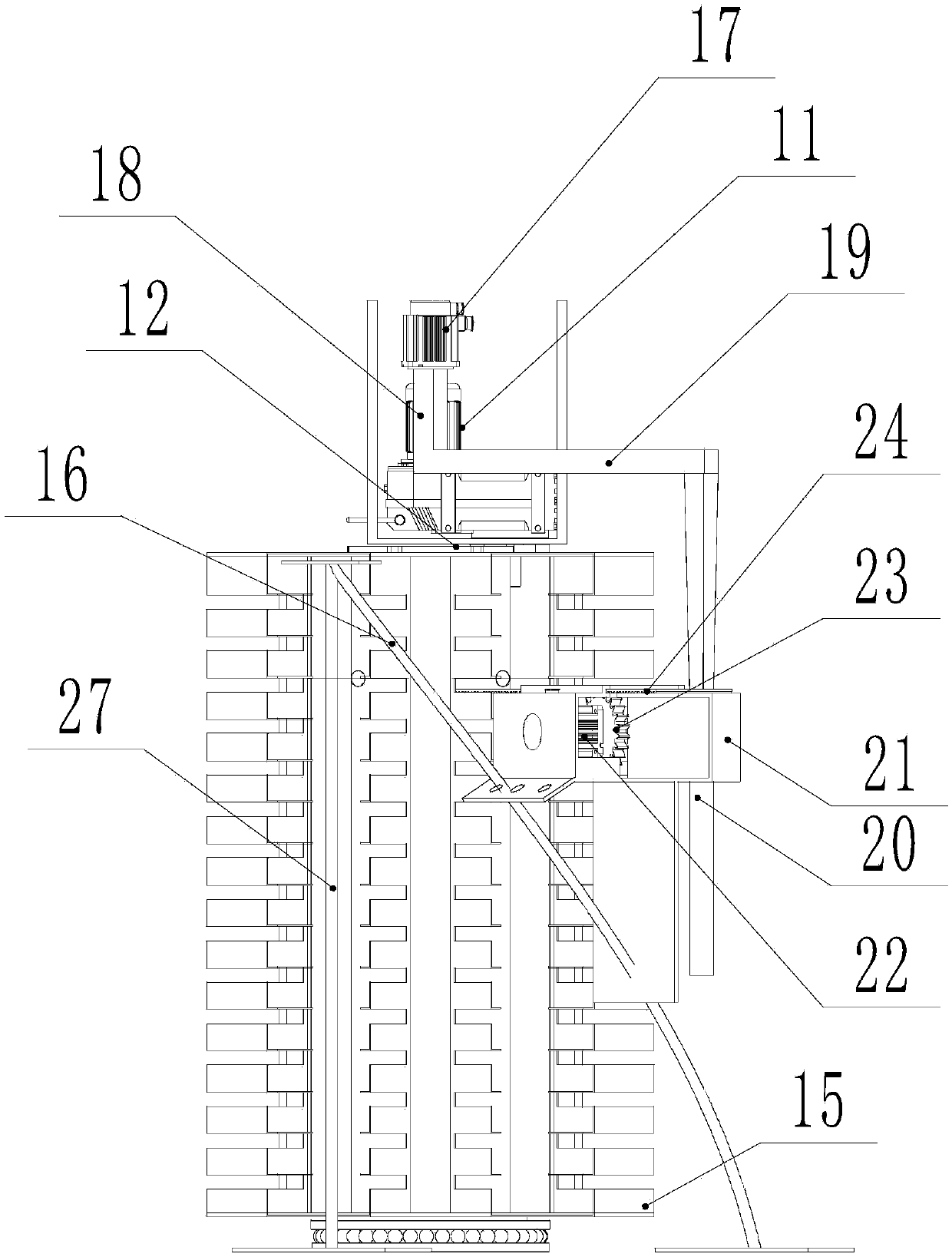

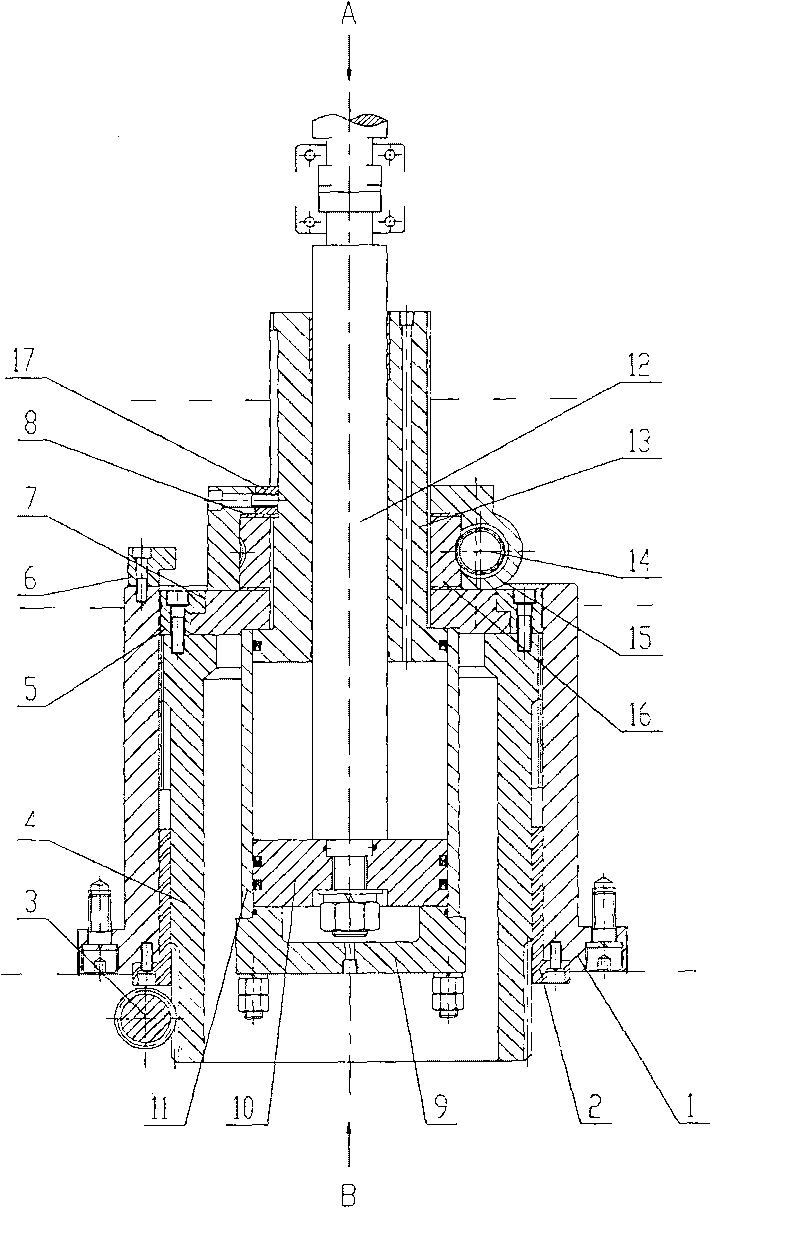

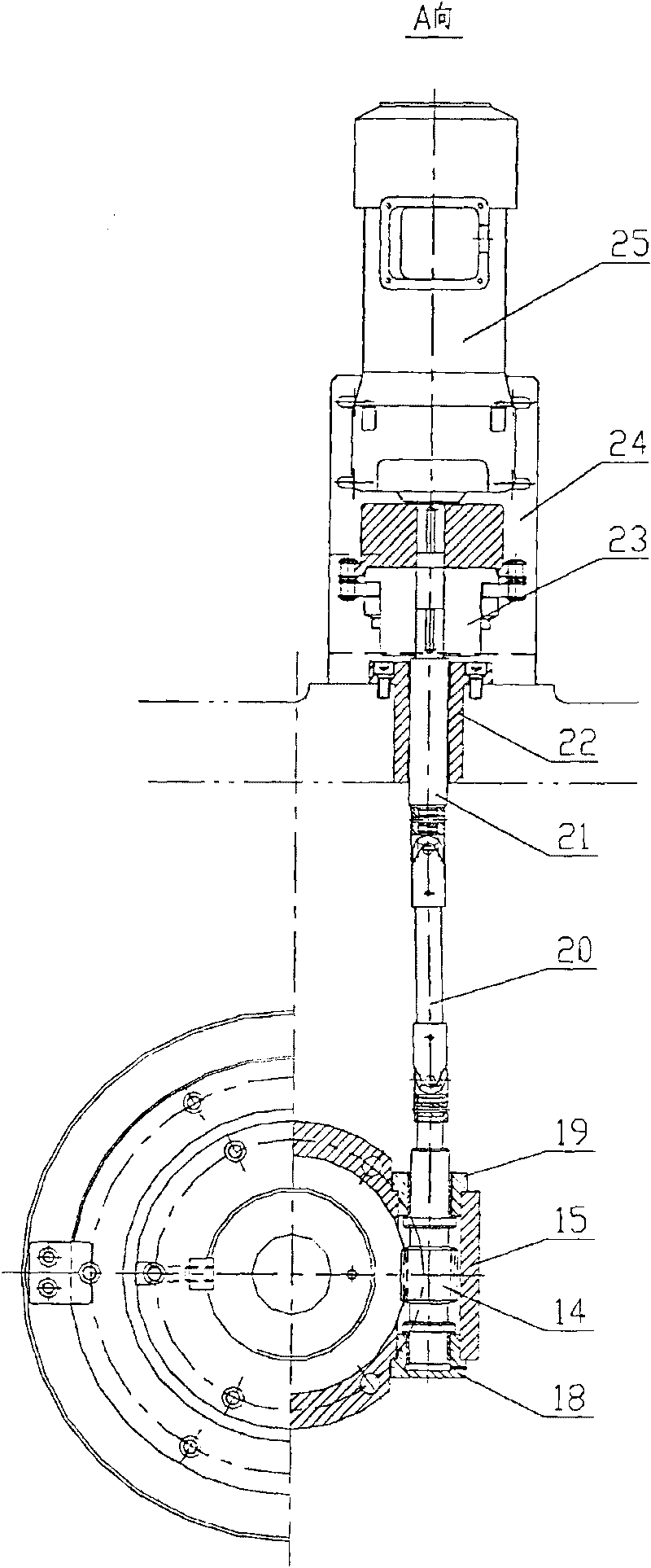

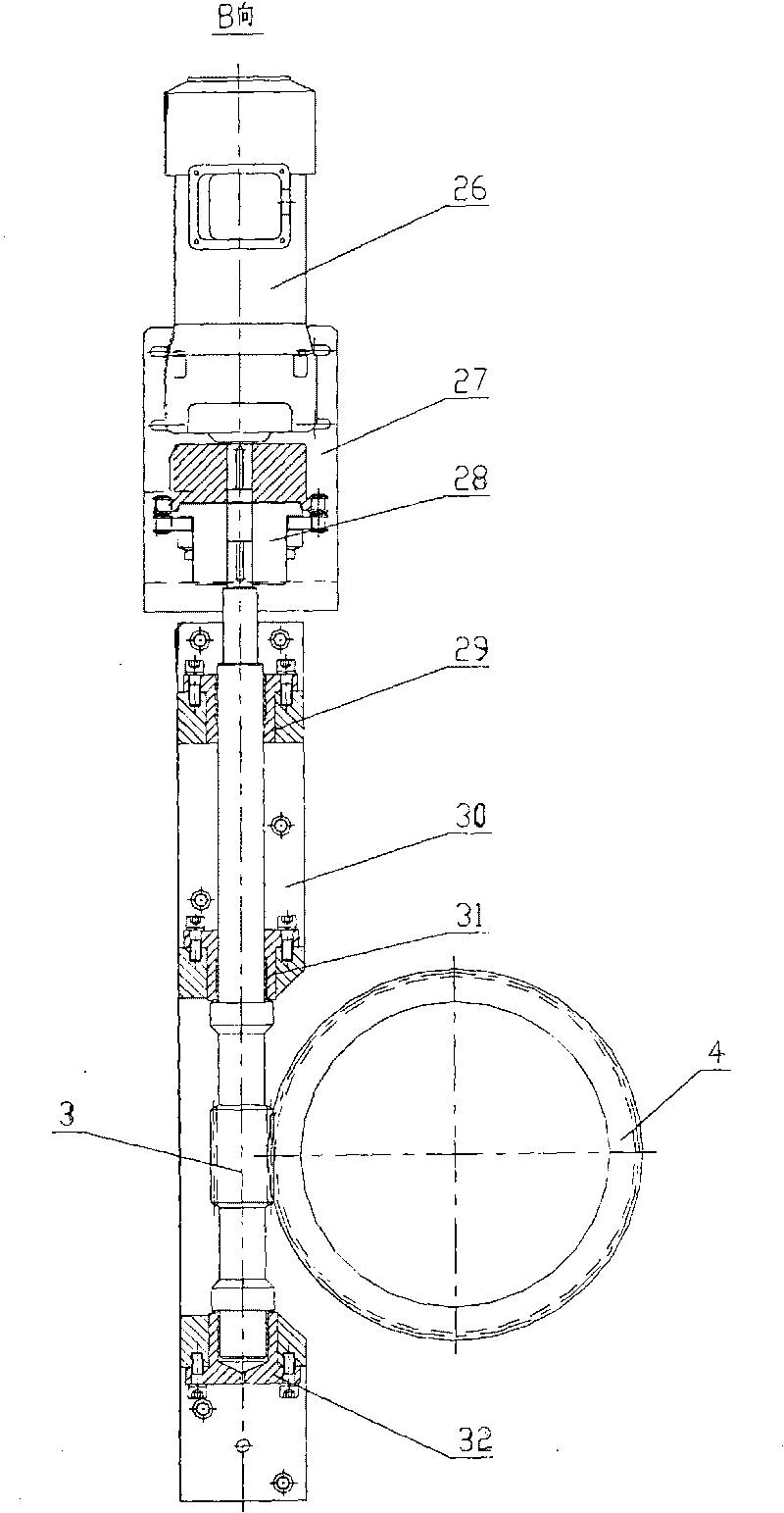

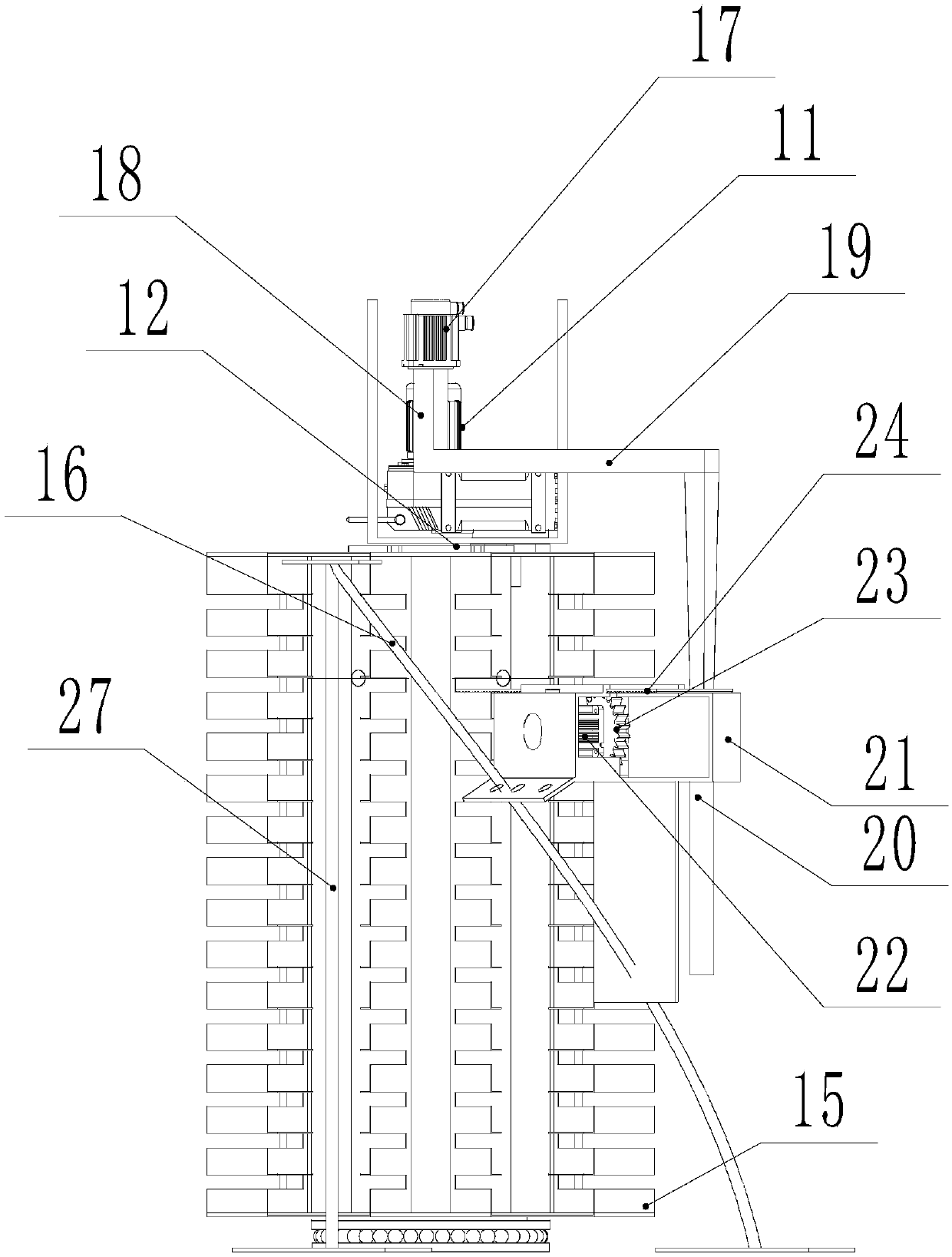

Full-automatic dry powder press floating-type core rod cylinder device

The invention relates to a full-automatic dry powder press floating-type core rod cylinder device applicable to a full-automatic dry powder press and suitable for forming multi-step and multi-layer complex abnormal-shaped parts. The full-automatic dry powder press floating-type core rod cylinder device comprises a worm-gear case base plate, a piston, a core rod, a cylinder body, a cylinder cover, a core rod stroke adjustment mechanism and a core rod cylinder height adjustment mechanism, wherein the core rod stroke adjustment mechanism comprises a worm-gear case, a worm gear, a worm, an adjusting shim, a standstill locking key, a worm-gear case blind-hole flange, a worm-gear case through-hole flange, an adjusting threaded sleeve, a first belt brake speed-reducing motor, a first coupling, a first motor mounting bracket, a long flange sleeve, a connecting shaft and a telescopic universal coupling; and the core rod cylinder height adjustment mechanism comprises a cylinder body jacket, a sliding bearing, a worm shaft, a worm gear sleeve, a press cover, a stop block, a second belt brake speed-reducing motor, a second motor mounting bracket, a second coupling, a mounting bracket, a first mounting bracket through-hole flange, a second mounting bracket through-hole flange and a mounting bracket blind-hole flange.

Owner:南京东部精密机械有限公司

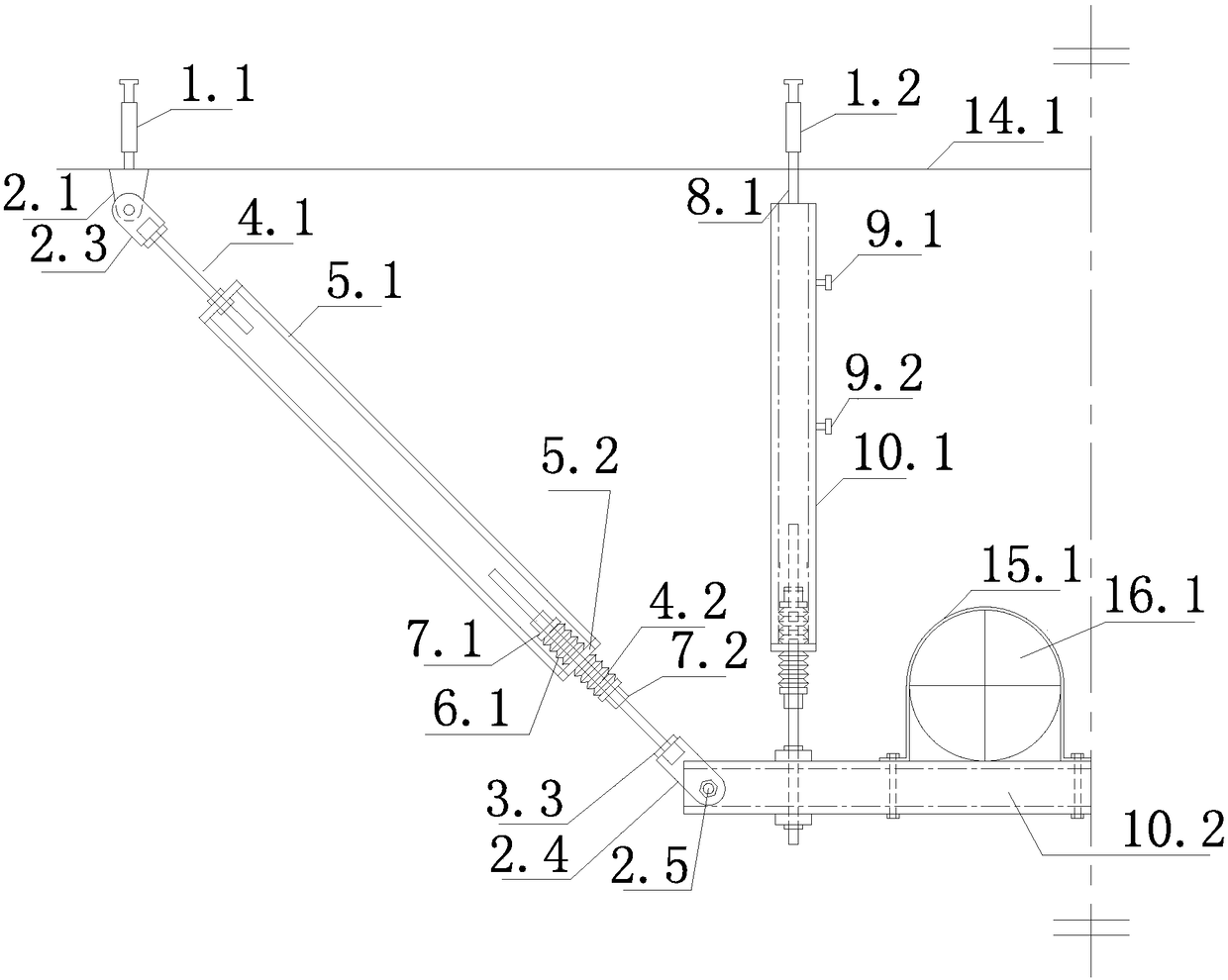

Anti-seismic supporting hanger based on belleville spring vibration reduction

PendingCN108506584AQuick and easy stiffness adjustmentPracticalPipe supportsEngineeringSeismic resistance

The invention discloses an anti-seismic supporting hanger based on belleville spring vibration reduction. The anti-seismic supporting hanger comprises a horizontal rod, a vertical rod and an anti-seismic diagonal rod. The diagonal support rod is hinged to the left end of the horizontal support rod, and the vertical support rod is connected to the left end of the horizontal support rod through a bolt; the upper ends of the anti-seismic diagonal rod and the vertical rod are connected with a structural layer; a belleville spring vibration reduction assembly is mounted at the lower end of the anti-seismic diagonal rod and comprises a half-thread positioning rod and a belleville spring; and a smooth section is arranged in the middle of the half-thread positioning rod, and thread sections are arranged at the two ends of the half-thread positioning rod. According to the anti-seismic supporting hanger, the belleville spring vibration reduction assemblies are mounted at the lower ends of the anti-seismic diagonal rod and the vertical rod, and thus the capabilities of seismic resistance, vibration reduction and reinforcing of the supporting hanger are achieved; the anti-seismic supporting hanger is simple in structure, easy to produce, flexible in demounting and mounting, convenient to maintain, capable of reducing the cost greatly and good in durability, and can be applied to the severeservice environment; and the travel is short, the load is large, the mounting space can be saved, and the efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH +1

Blind man guide method and blind man guide system based on real-time road condition information optimization

InactiveCN108871340APersistent lockContinuous identificationInstruments for road network navigationNavigational calculation instrumentsReal time navigationBroadcasting

The invention discloses a blind man guide method and a blind man guide system based on real-time road condition information optimization. The method comprises the steps of voice collection and analysis, route planning and design, real-time navigation information determination, timely navigation and broadcasting, and the like. The system comprises a storage module, a voice collection module, a voice data processing module, a positioning device module, a communication module, a route design determination algorithm module, a real-time navigation information determination module and an informationtransmitting and broadcasting module. The method and the system are stable and reliable, good in anti-interference performance and wide in application range, are capable of conveniently and timely guiding a blind man to travel in a complex environment, and have the advantages of being high in system intelligence, advanced and scientific in method, safe and accurate in travel route, and the like,thus greatly improving the freedom of movement of the blind man; the method and the system are practical and achievable, and have a higher practical value and a broad application prospect.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

Blind guiding method and system with functions of high-recognition route optimization and intelligent monitoring

InactiveCN108670746APersistent lockAccurate identificationWalking aidsReal time navigationInformation transmission

The invention discloses a blind guiding method and system with functions of high-recognition route optimization and intelligent monitoring. The method comprises steps of voice acquisition and analysis, route planning and design, determination of real-time navigation information, timely navigation broadcast and other steps. The system comprises a storage module, a voice acquisition module, a voicedata processing module, a positioning device module, a communication module, a route design determining algorithm module, a real-time navigation information determining module and an information transmission and broadcast module. The blind guiding method and system are stable, reliable, good in anti-interference performance and wide in application range, can guide a blind person to walk in a complicated environment conveniently and timely, have the advantages that the system is high in intelligent degree, the method is advanced and scientific, a route is safe and accurate and the like, have practicability, realizability and higher practical value and broad application prospect, and action freedom of the blind person is improved greatly.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

Blind guiding method and system for public transport roads

InactiveCN108743265APersistent lockContinuous identificationWalking aidsForecastingReal time navigationComputer module

The invention discloses a blind guiding method and system for public transport roads. The method includes: performing voice collecting and analysis, planning and designing routes, determining real-time navigation information, timely performing navigation broadcasting and the like. The system comprises a storage module, a voice collecting module, a voice data processing module, a positioning devicemodule, a communication module, a route designing and determining algorithm module, a real-time navigation information determining module and an information transmitting and broadcasting module. Theblind guiding method and system has the advantages that the method and system is stable and reliable, good in anti-interfere performance, wide in application range and capable of conveniently and timely guiding blind people to advance in complex environments, the system is high in intelligent level, the method is advanced and scientific, advancing routes are safe and accurate, the moving freedom of the blind people is increased greatly, practicality and implementability are achieved, and a high practical value and promising application prospect are achieved.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

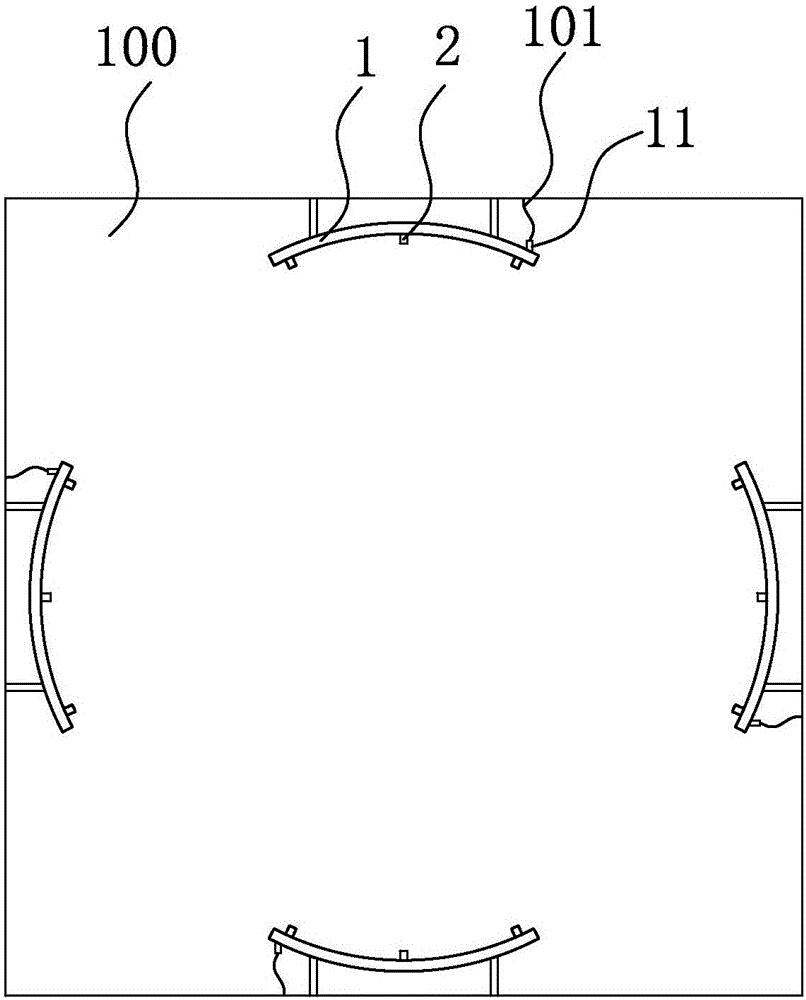

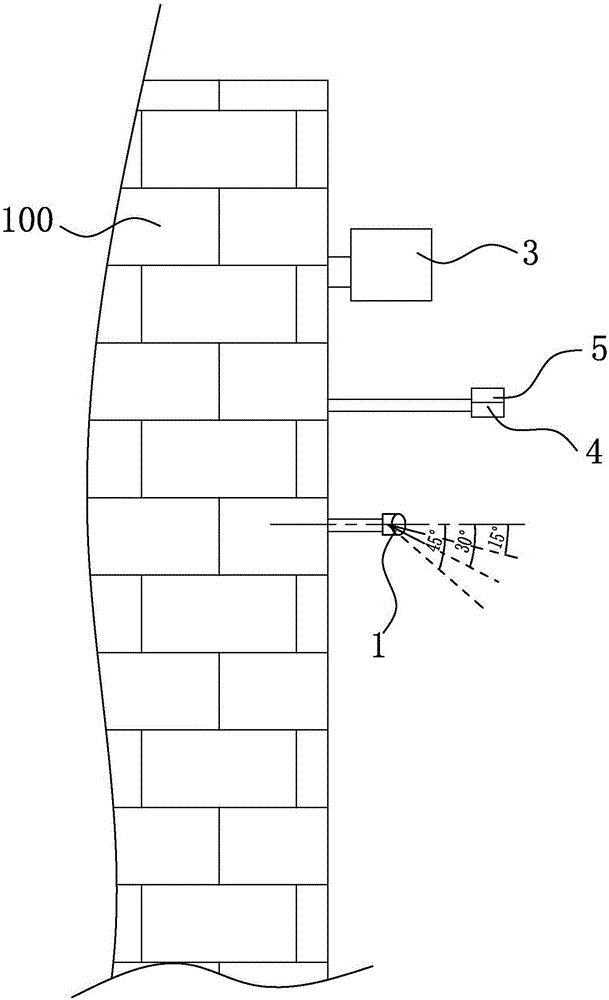

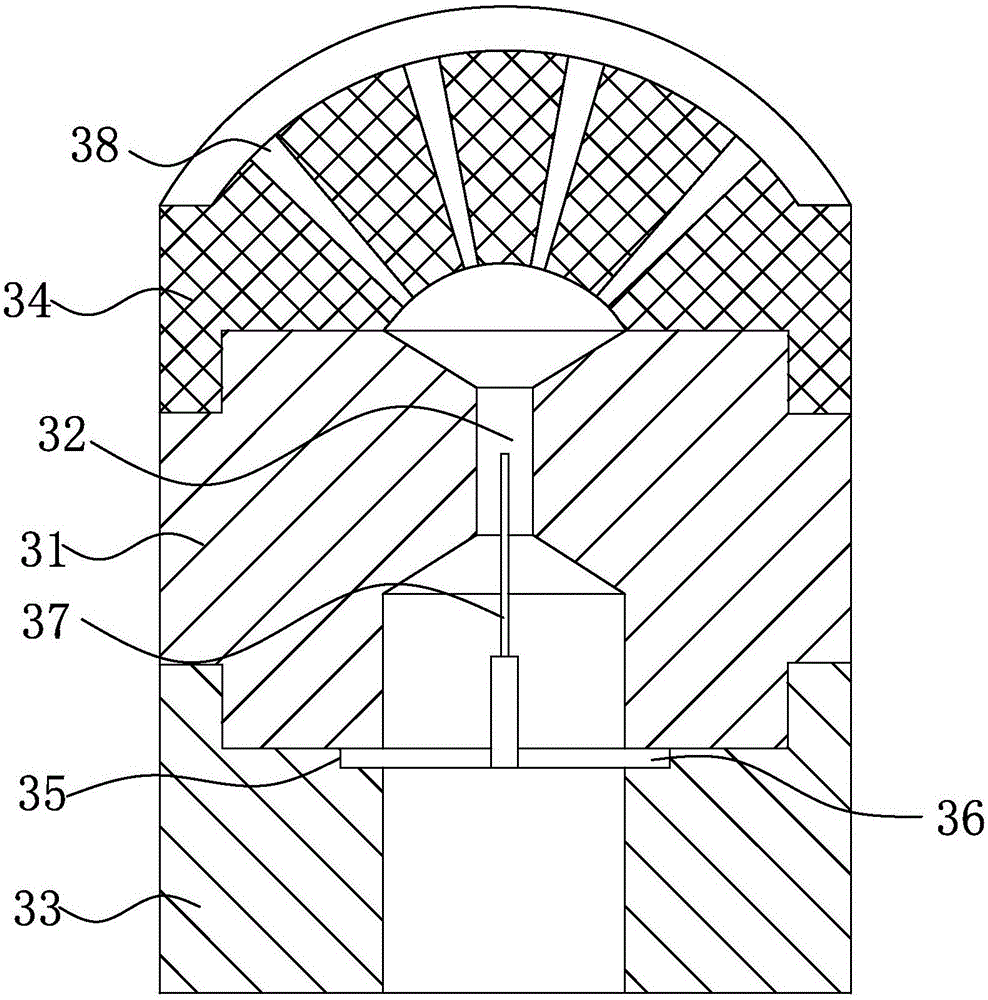

Atomization dust removal device for refuse treatment station

ActiveCN106823623AGuaranteed water mist concentrationWill not touch each otherUsing liquid separation agentDirt cleaningSlant angleSpray nozzle

The invention relates to the environmental purification field and particularly relates to an atomization dust removal device for a refuse treatment station. The atomization dust removal device comprises a water pump, atomization equipment and four atomizing nozzle mechanisms, wherein the four atomizing nozzle mechanisms are connected to the atomization equipment and the water pump through pipelines and are respectively mounted on four walls in a discharging room. The atomization dust removal device is characterized in that each atomizing nozzle mechanism comprises a spray pipe and a plurality of nozzles arranged on the radial direction of the spray pipe, wherein a water inlet connected with the atomization equipment or the water pump is formed in one end of the spray pipe, horizontal downward slant angles formed by the output directions of the spray nozzles and the horizontal direction are 15-45 degrees, and the slant angles formed by the output directions of the spray nozzles and the horizontal direction are different and uniformly increase from the water inlet to the other end of the spray pipe; and each atomizing nozzle mechanism comprises a parallel nozzle, and the parallel nozzle is arranged above the spray pipe and is connected with the atomization equipment.

Owner:福建鑫骉科技有限公司

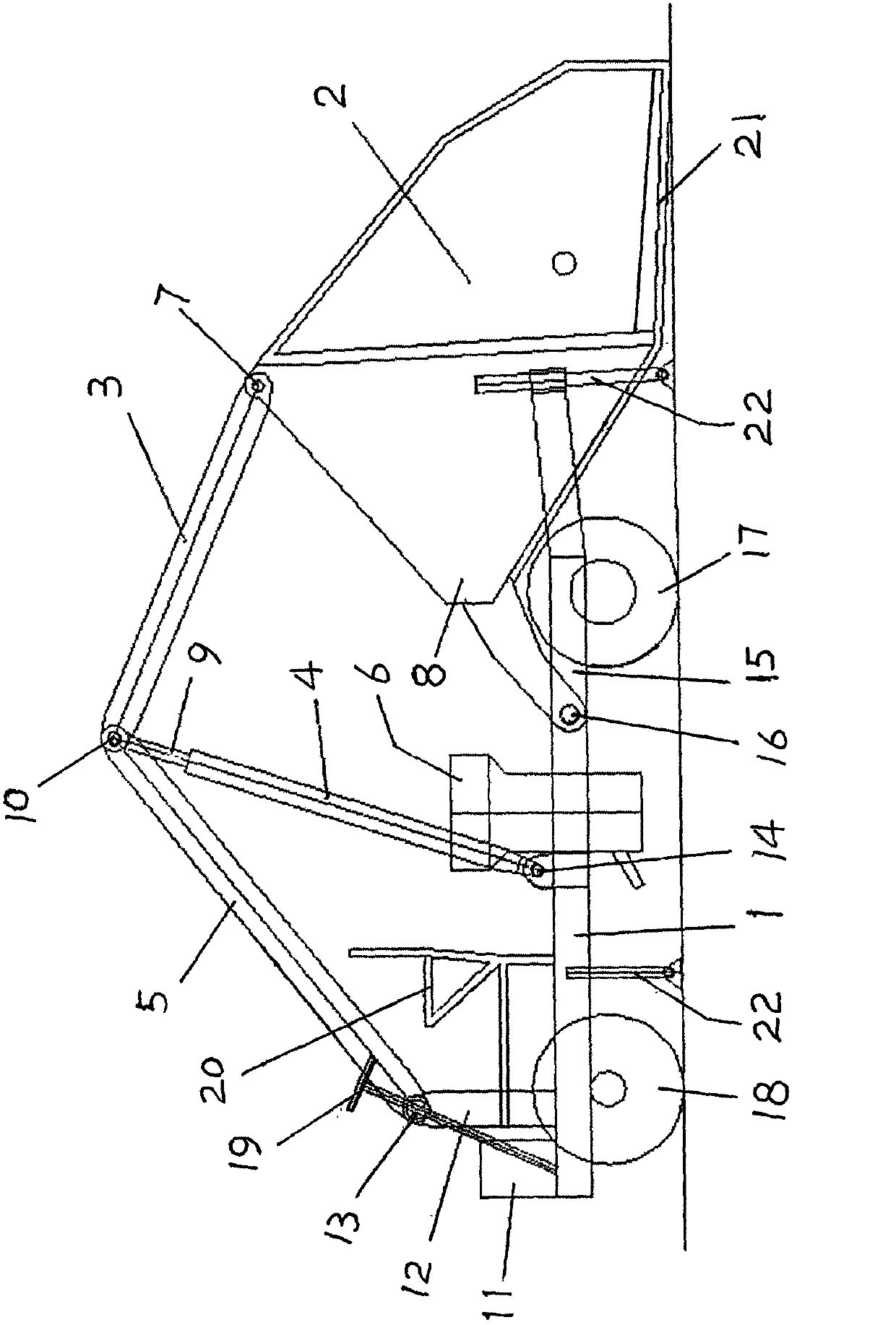

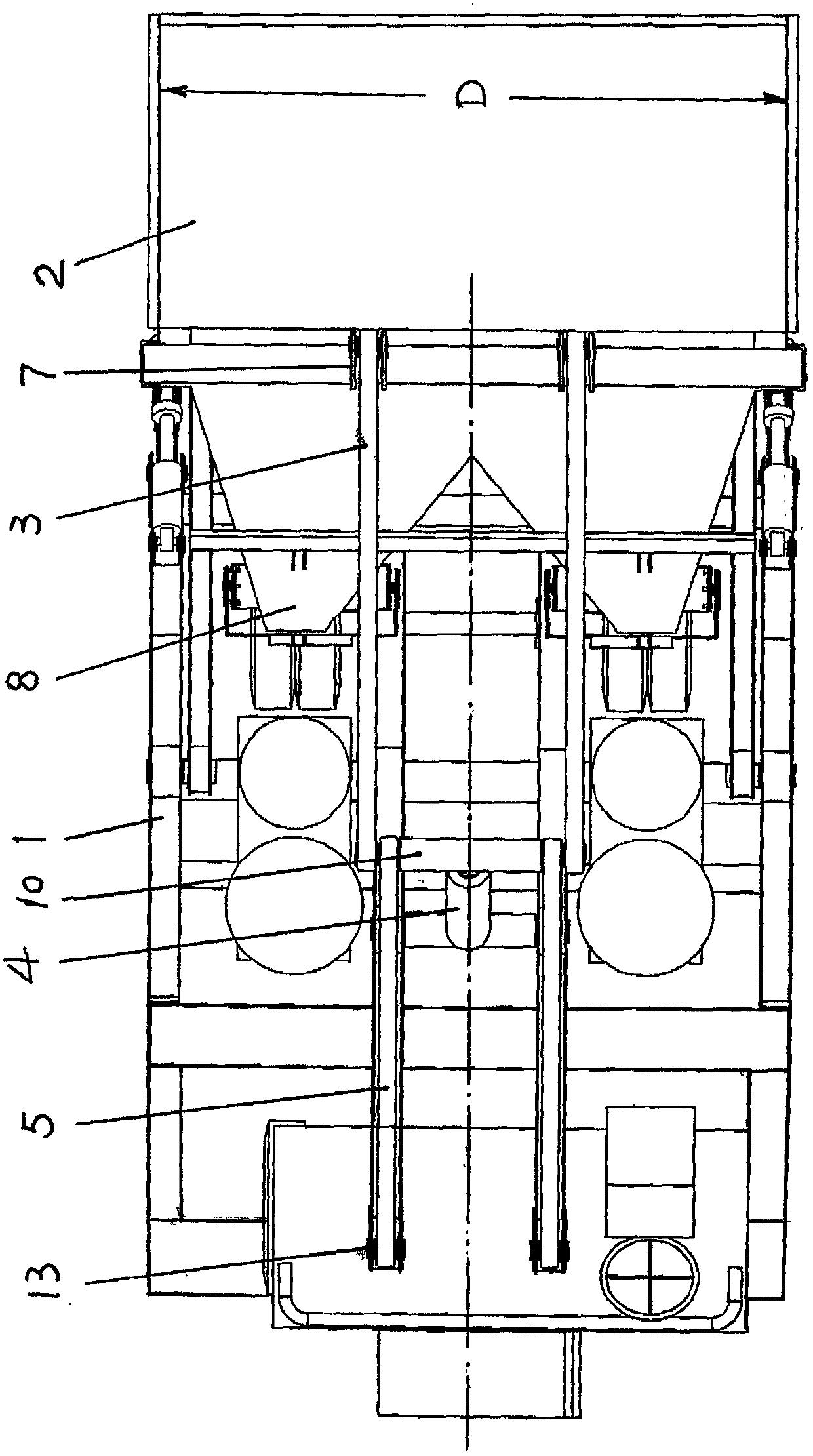

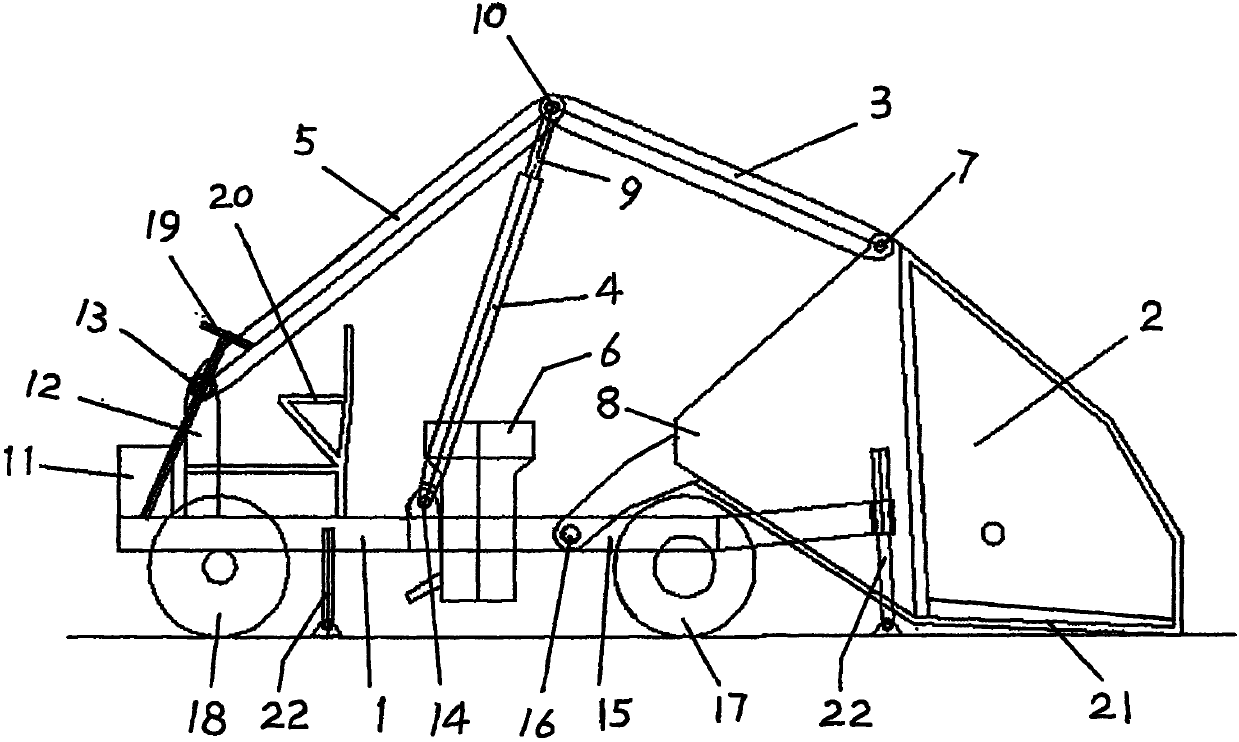

Traveling type automatic material loading patching machine device

InactiveCN102677904AShort tripSolve the contradiction between thrust and strokeBuilding material handlingHinge jointHydraulic pressure

The invention relates to a traveling type automatic material loading patching machine device. The device comprises a device body rack, a charging hopper, a patching machine and a hydraulic pressure oil cylinder used for loading material. The device is characterized in that the charging hopper is in a hinged connection with a hinged joint point which is close to device body rear portion, the upper portion of the charging hopper is in a hinged connection with a hinged joint point which is close to the head portion of the device body sequentially through a pair of pull rods and a pair of connecting rods which are in the hinged connection, the hydraulic pressure oil cylinder is installed at the front of the charging hopper, a cylinder body of the hydraulic pressure oil cylinder is in a hinged connection with a hinged joint point which is close to the middle of the device body, a push rod of the hydraulic pressure oil cylinder is in a hinged connection with a hinged joint point of the pull rods and the connecting rods, and therefore a five-connecting rod charging mechanism composed of the device body rack, connecting rods, the hydraulic pressure oil cylinder, the push rod and the charging hopper is formed to load materials. According to the traveling type automatic material loading patching machine device, the complete device is beneficial to widening the charging hopper and substantially increasing the hopper capacity, and the hopper capacity can be increased by about 100%, lifting and turning performances are stable, the charging operation is convenient, the structure is simple, the device is energy-saving and environment-friendly, and the cost is low.

Owner:FUJIAN FANGZHENG MACHINERY CO LTD

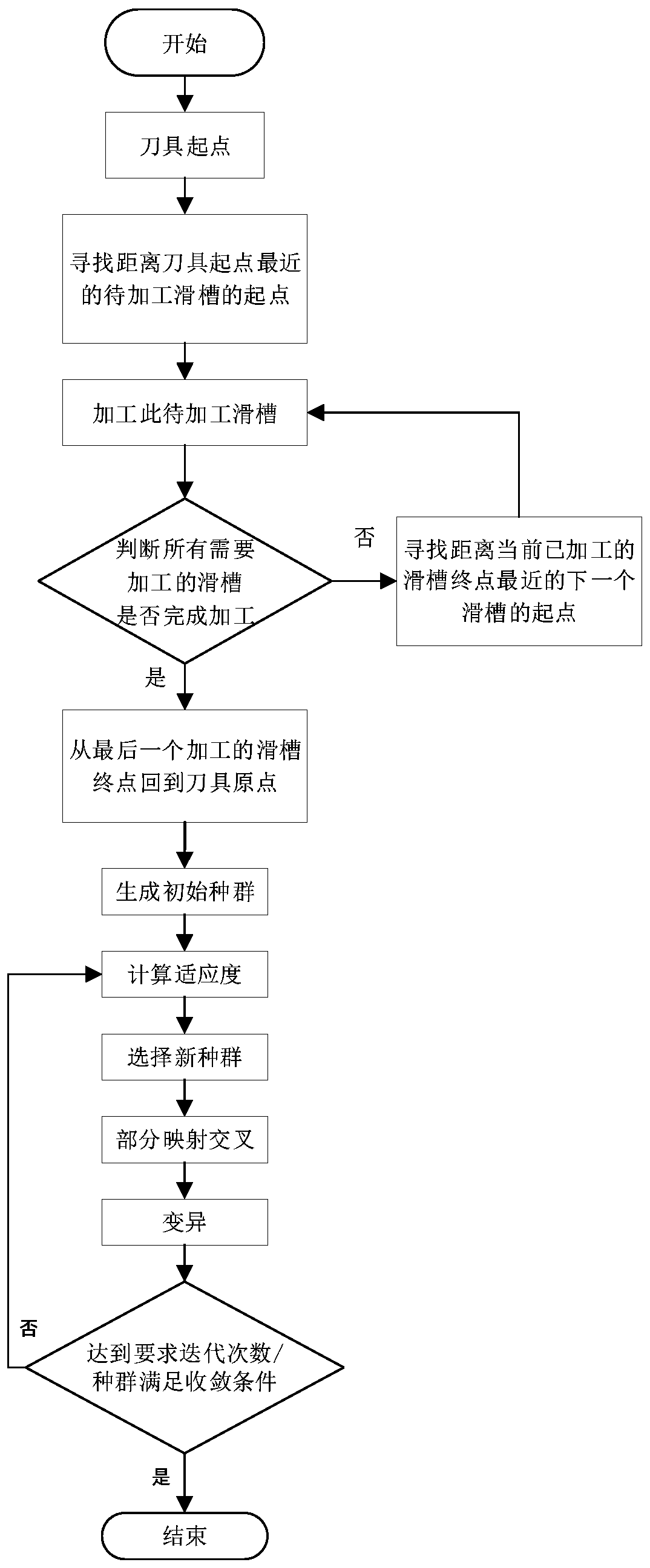

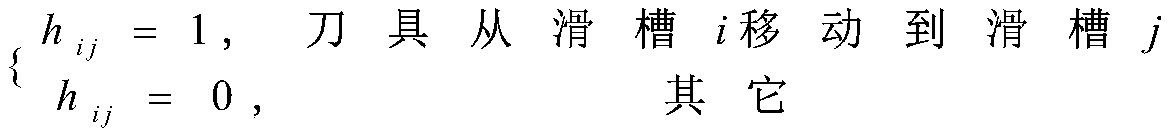

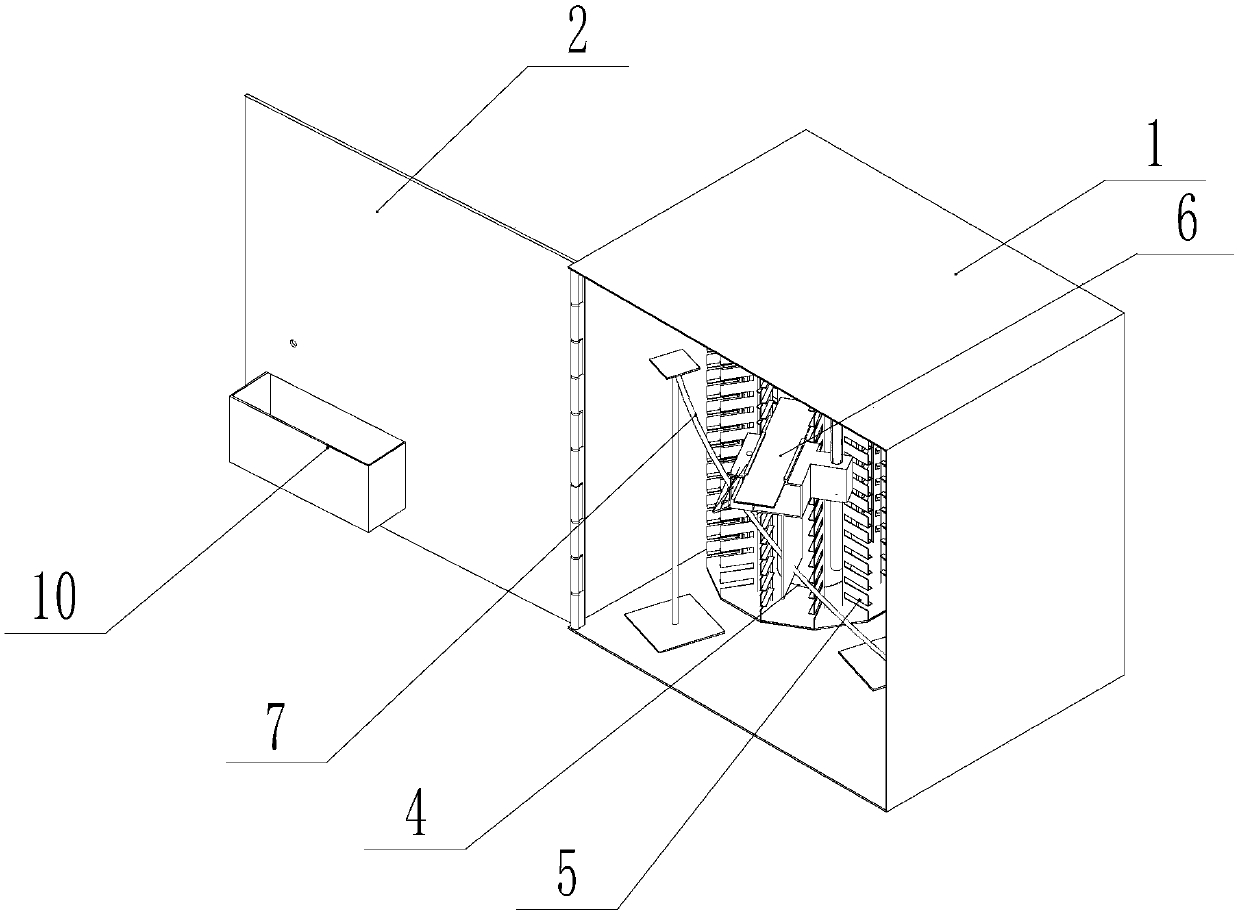

Urban rail underframe sliding groove cutter idle feeding machining path planning method

ActiveCN110298102AImprove processing efficiencyConvenient itineraryAutomatic control devicesForecastingManufacturing technologyMathematical model

The invention relates to the technical field of urban rail train manufacturing. The invention particularly discloses an urban rail underframe sliding groove cutter idle feeding machining path planningmethod. The method comprises the following steps: establishing a mathematical model of a cutter idle feed moving path; finding a starting point of the to-be-processed chute closest to the original point of the cutter; the cutter moving to the starting point of the nearest to-be-machined sliding groove from the cutter original point idle feed; the cutter moving from the starting point of the current to-be-processed chute to the end point of the current to-be-processed chute; completing machining of sliding groove, if the to-be-machined chute is not completely machined, machining the to-be-machined chute; finding a starting point of a to-be-machined chute closest to the end point of the current machined chute of the cutter; and the cutter moving to the starting point of the nearest to-be-machined sliding groove from the current machined sliding groove end point idle feed, conducting machining operation, and if all the to-be-machined sliding grooves are machined, the cutter moving to thecutter original point from the current machined sliding groove end point idle feed, and obtaining the numerical value of the cutter idle feed moving distance. According to the method, the cutter idlefeeding path is shortened, and the machining efficiency is improved.

Owner:DALIAN JIAOTONG UNIVERSITY

A method for adjusting and optimizing goods between vending machine stations

ActiveCN109685239AReduce scrap rateLow costCoin-freed apparatus detailsForecastingOptimal decisionRejection rate

The invention discloses a method for adjusting and optimizing goods between vending machine stations, which comprises vending machines arranged at the vending stations, and comprises the following specific steps of: 1, setting parameters; 2, assuming an access sequence number; Step 3, determining an objective function; 4, determining constraint conditions of the objective function; 5, solving theobjective function; 6, obtaining an optimal decision variable according to an algorithm solving result in the step 5; According to the method, a replenisher can adjust the goods between the selling stations in the replenishment process according to the optimal path obtained by the optimization algorithm, and the optimization algorithm enables the replenisher to complete replenishment and goods adjustment along the shortest path; The goods adjustment scheme can reduce the food rejection rate and reduce the cost.

Owner:ZHEJIANG UNIV OF TECH

Intelligent blind people navigation method and system

InactiveCN109044754ATimely, efficient and accurate travelSafe independent travelWalking aidsVoice dataData processing

The invention discloses an intelligent blind people navigation method and system. The method comprises the steps of voice collecting analysis, route planting designing, real-time navigation information determination, timely navigation broadcasting and the like; the system comprises a cache module, a voice collecting module, a voice data processing module, a positioning device module, a communication module, a route designing determining algorithm module, a real-time navigation information determining module and an information transmitting broadcasting module. The method and the device are stable, reliable, good in anti-interference performance and wide in application range, blind people can be conveniently and timely guided to proceed in a complicated environment, the system is high in intelligence degree, the method is scientific and advanced, the proceeding route is safe and accurate, the moving freedom of blind people is greatly improved, and the method and the system have practicability, implementability and higher practical value and extensive application prospects.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com