Remote detection and evaluation system for tire crane

A technology of remote detection and evaluation system, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problem of long maintenance process cycle, regular inspection and missed inspection of key positions, and it is difficult for terminal users and crane manufacturers to obtain Crane operation information and other issues, to prevent the detection of invalid data pollution equipment, facilitate wiring installation and construction, and solve the effect of information islanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

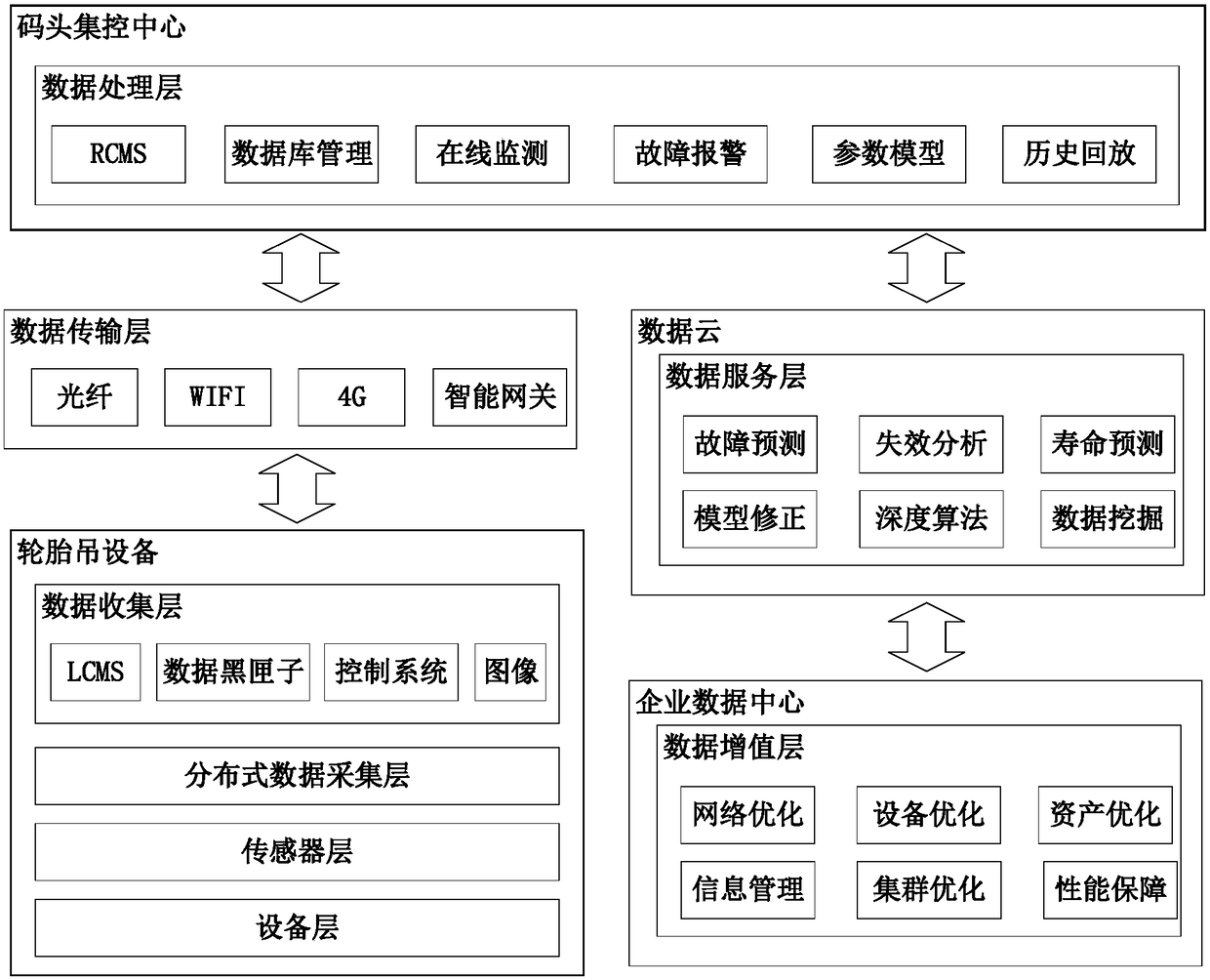

[0038] see figure 1 As shown, a tire crane remote detection and evaluation system includes tire crane equipment, data transmission layer, terminal centralized control center, data cloud, and enterprise data center.

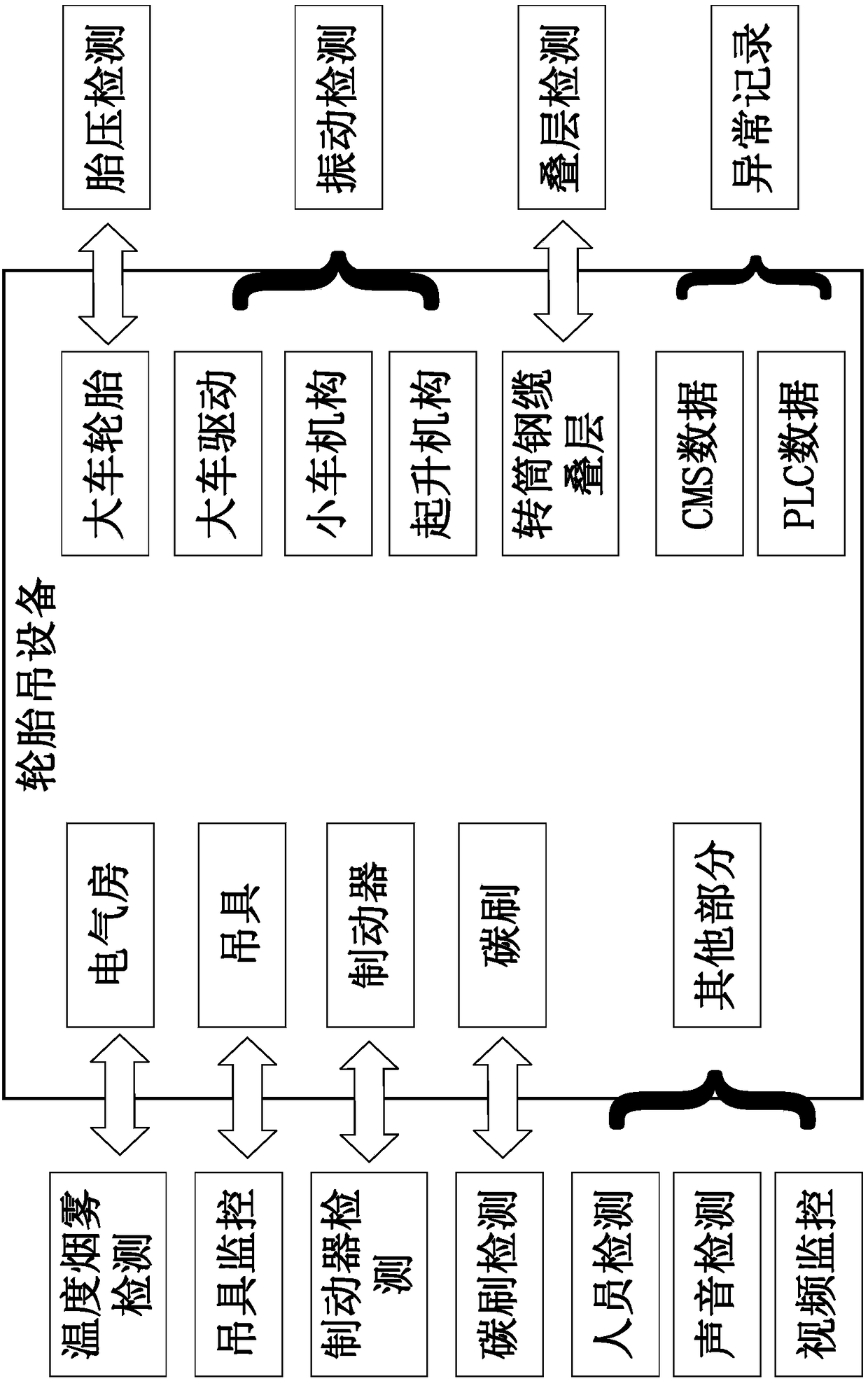

[0039] The tire crane equipment includes equipment layer, sensor layer, distributed data acquisition layer and data collection layer. The equipment layer includes various key parts of the tire crane, such as large and small trucks, lifting, electrical room, etc. The sensor layer refers to the sensors installed in various parts, including temperature, strain, acceleration, vision, laser, inclination, displacement, contact switch and other types. The distributed data acquisition layer includes three sub-acquisition modules, which are respectively installed on the electrical room of the tire crane, the trolley and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com