Urban rail underframe sliding groove cutter idle feeding machining path planning method

A technology of machining paths and idle cutting tools, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of long tool idle cutting tool paths, low processing efficiency of urban rail chassis chute, etc. Machining efficiency and the effect of shortening the idle travel of the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

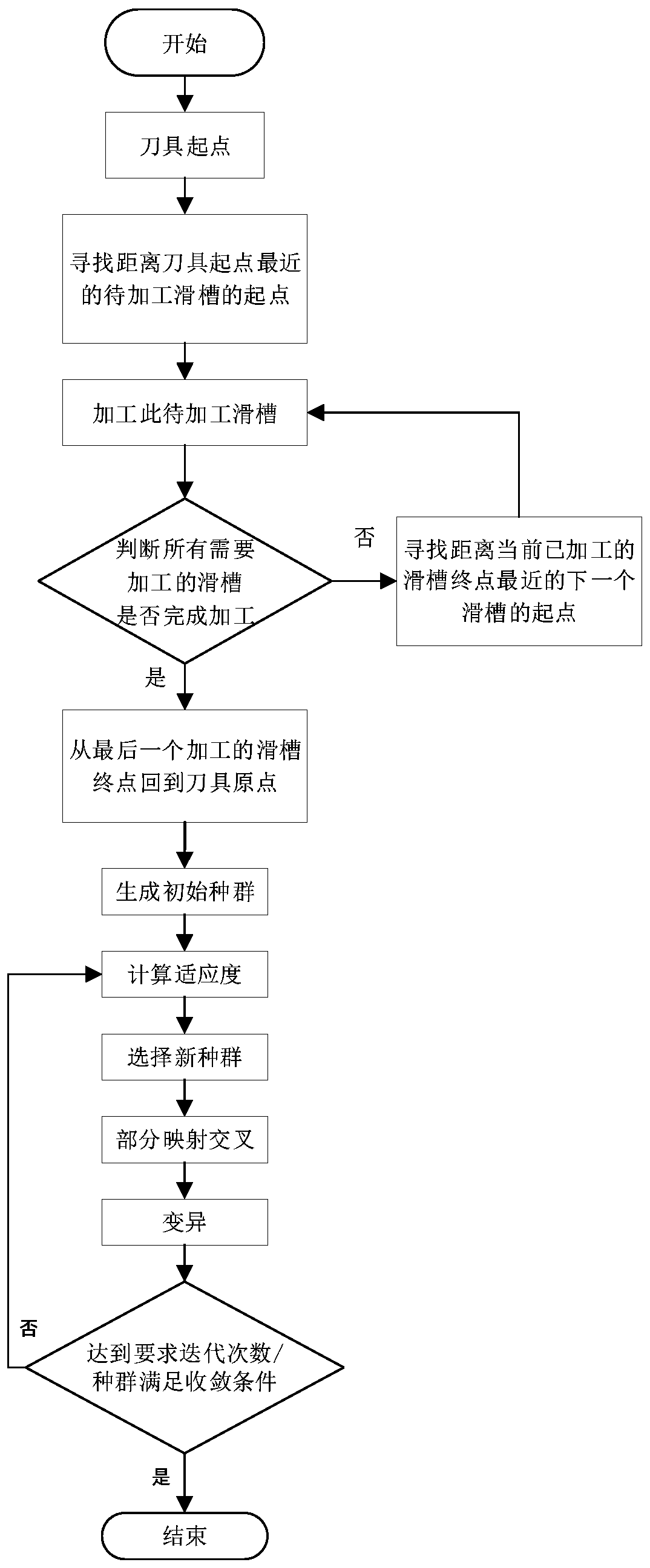

[0027] In this embodiment, the hybrid algorithm combining the dynamic programming method and the genetic algorithm is used to optimize the planning of the empty tool path of the urban rail chassis chute tool.

[0028] The working principle of the dynamic programming method: the basic idea of the dynamic programming method is to first find the starting point of the first chute to be processed that is closest to the origin of the tool. When the current chute is processed, the tool needs to move from the end point of the processed chute. Continue processing to the starting point of the chute to be processed. The selection principle of the starting point of the chute to be processed is to find the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com