Serial thermal linear processor arrangement

A thermal processor and processor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult cleaning and high cost of processing equipment, achieve uniform and controllable heating, improve system requirements, and transmit Simple and controllable effect of mechanical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

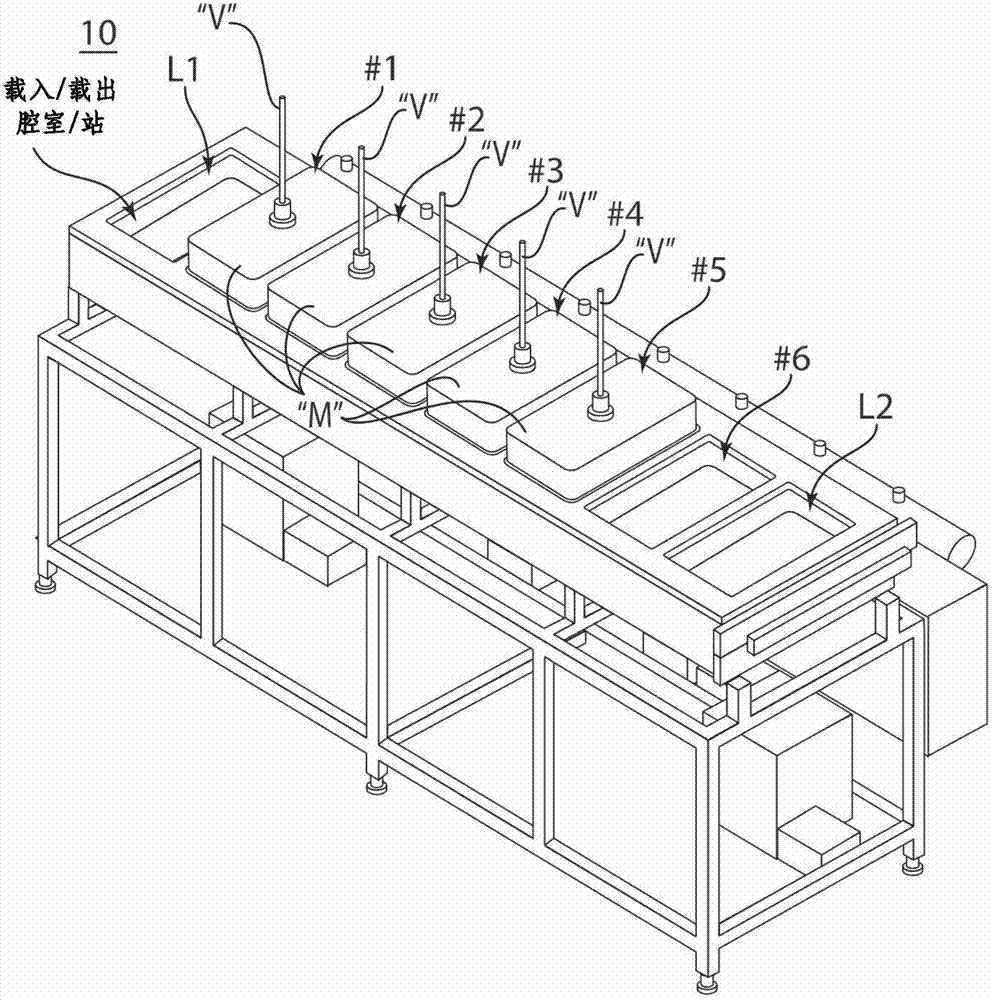

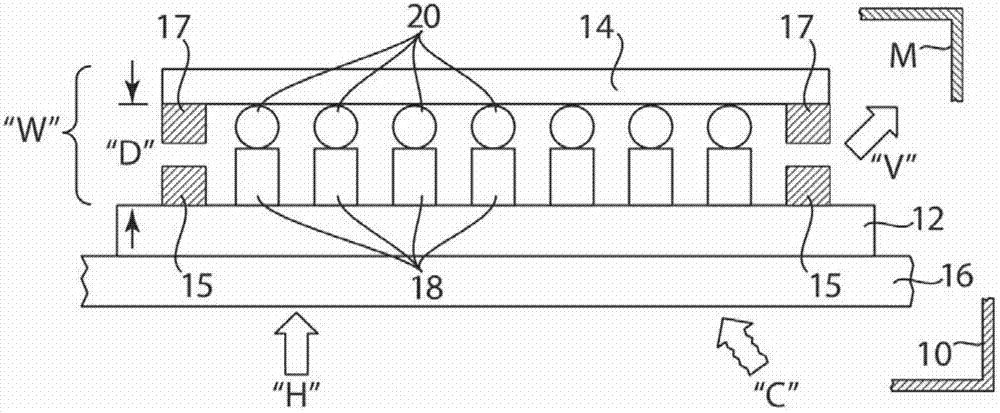

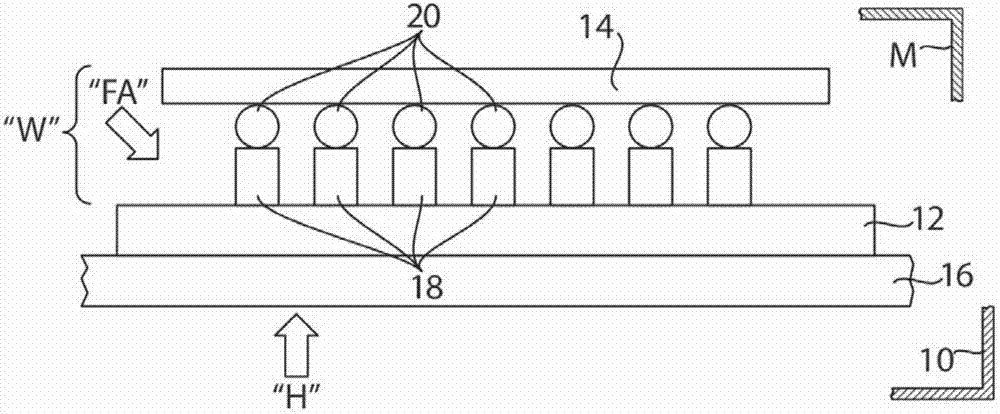

[0046] The present invention encompasses electronic chips fabricated by a stepwise and linear series of thermal processor arrays 10, wherein the fabrication method is a series of thermal processor arrays 10 sequentially passing through a series of at least six separate and enclosed chambers / station, the initial loading / unloading chamber / station and the final loading / unloading chamber / station processing the chip / substrate assembly W prior to processing, as above figure 1 shown.

[0047] Such as figure 1 The serial linear thermal processor array 10 shown is arranged to progressively process material, for example, a semiconductor substrate assembly, in a series of linearly arranged and spatially separated locations, starting with an initial load / unload chamber / station to each numbered processing chamber / station, for example: the first, second, third, fourth, fifth and sixth chamber / station, wherein the temperature, pressure and presence of each chamber / station The gases can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com