Double-liner concurrent vacuum plastic uptake molding machine

A plastic forming machine, forming machine technology, applied in metal processing, etc., can solve the problems of large space occupation and high equipment cost, and achieve the effect of reducing space, saving space and cost, and shortening the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] It should be understood that the transmission mechanisms described below are common transmission mechanisms in the field, such as lead screws and gears, unless otherwise specified.

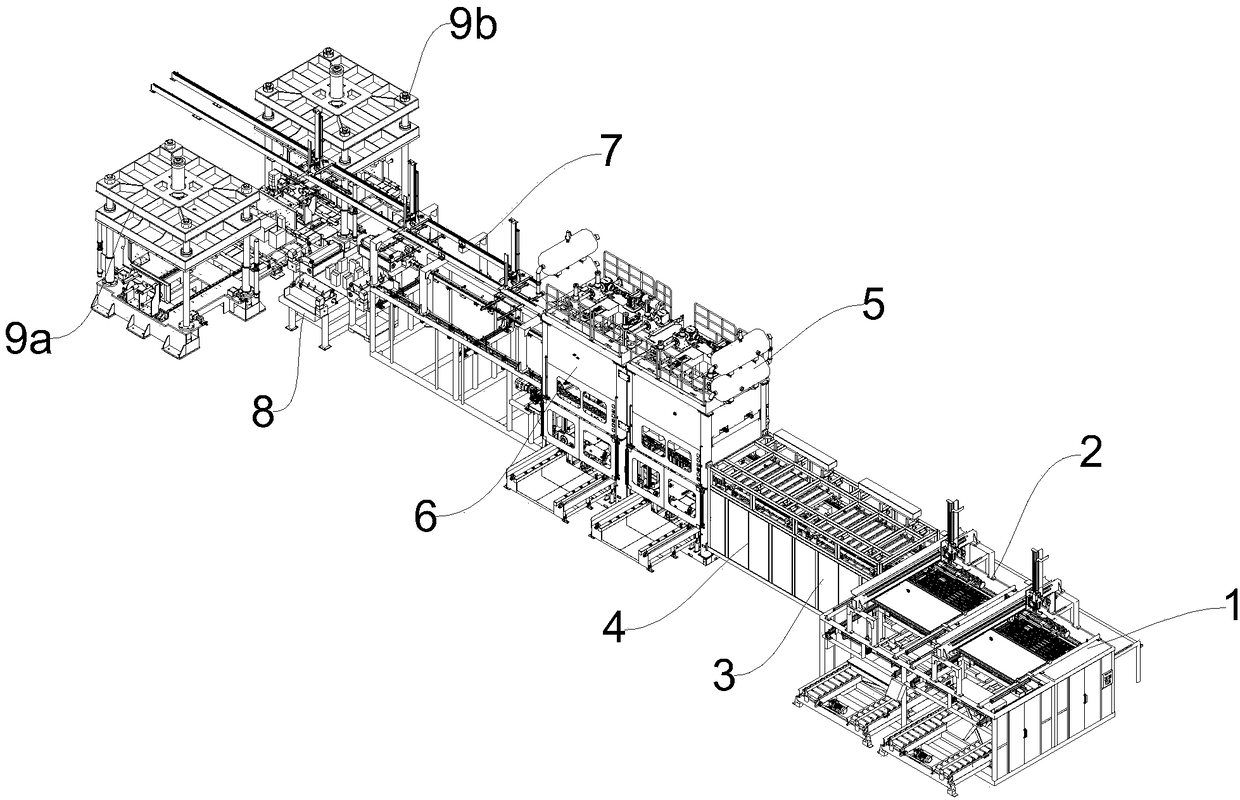

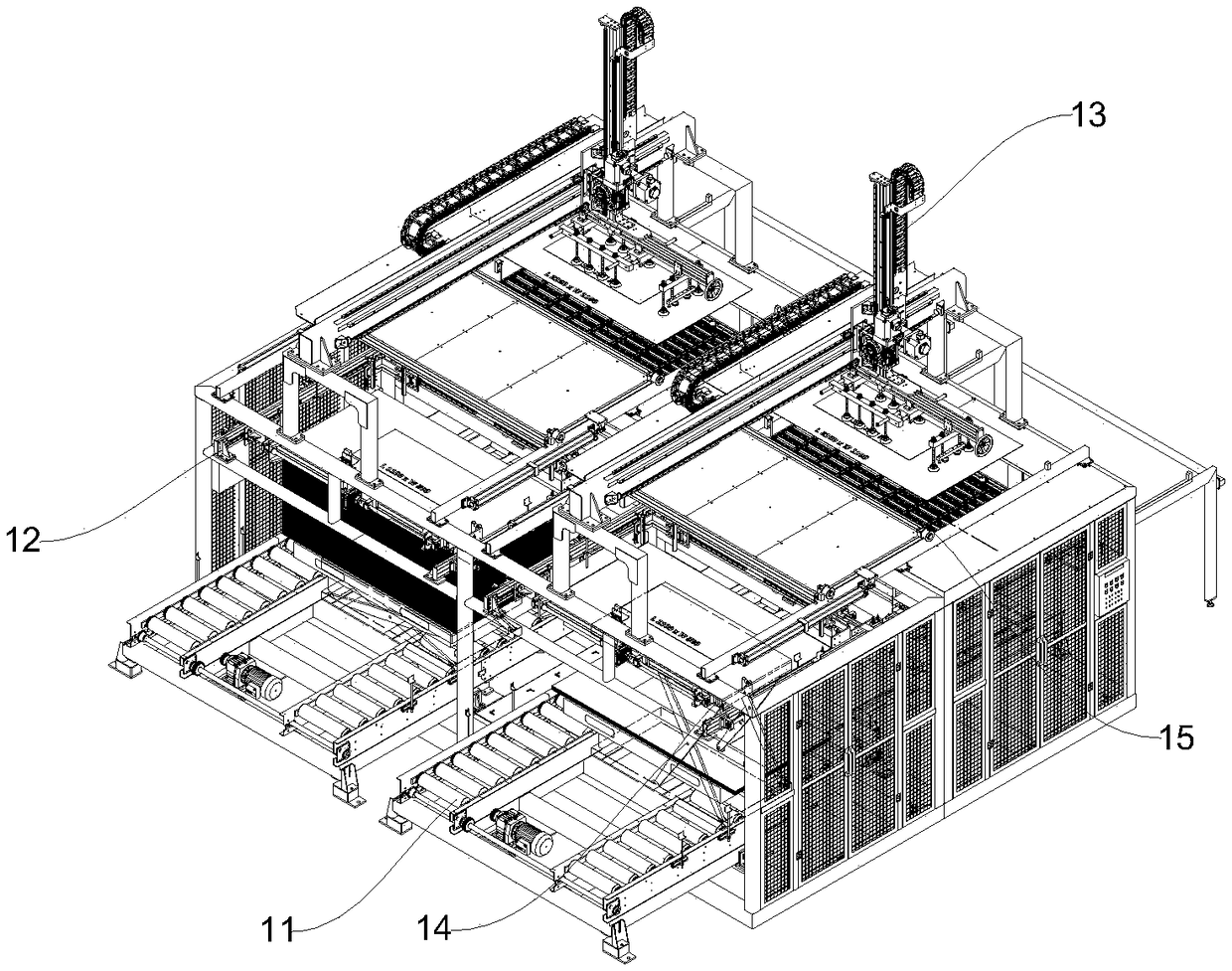

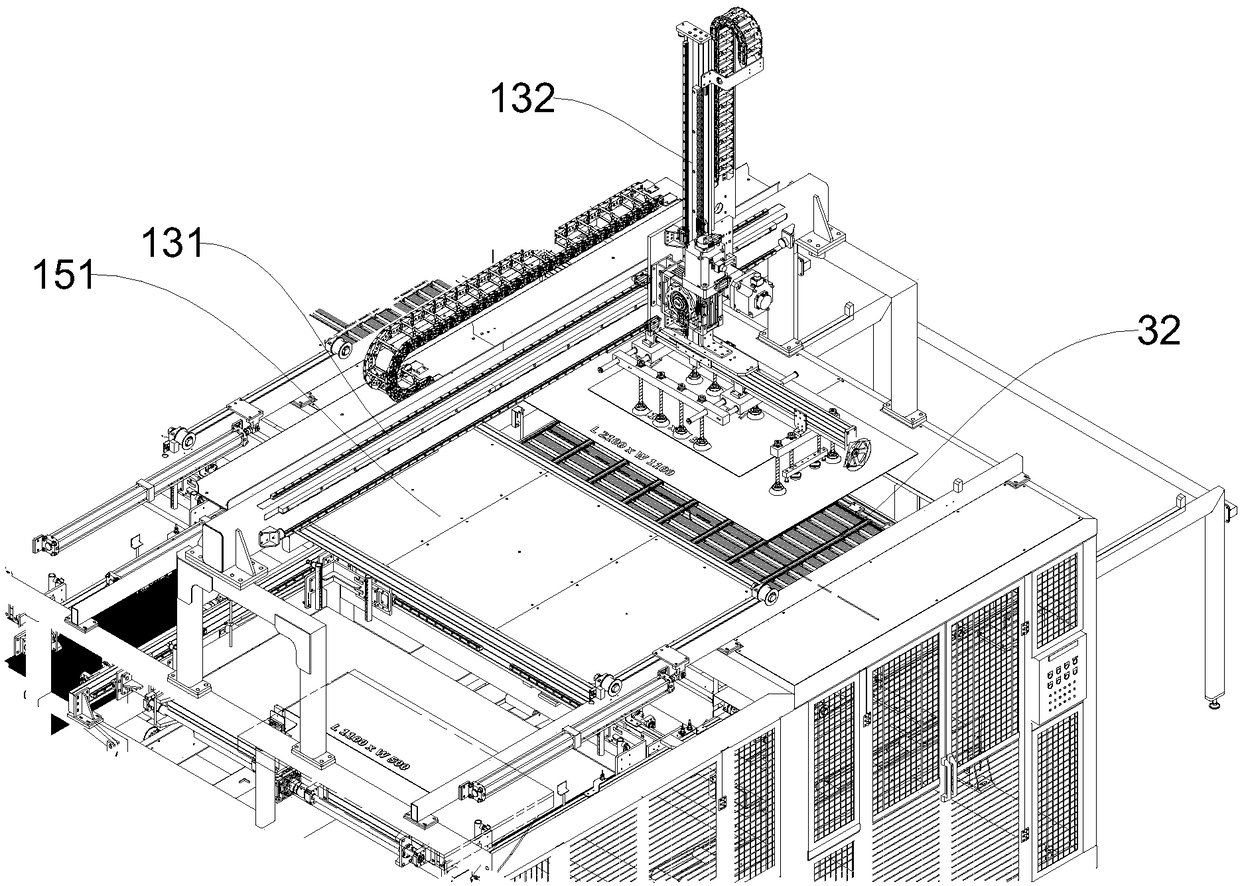

[0031] Such as figure 1 As shown, the double-bladder parallel air-absorbing molding machine includes the first integrated device for feeding, centering and preheating 1, the second integrated device for feeding, centering and preheating 2, the first main heating device 3, and the second The main heating device 4, the first molding machine 5, the second molding machine 6, the blanking device 7, the trimming machine 8 and the first punch press 9a and the second punch press 9b side by side also include a conveying device, and the conveying device includes a conveyor chain, the conveying chain is sequentially set in the first integrated device for feeding and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com