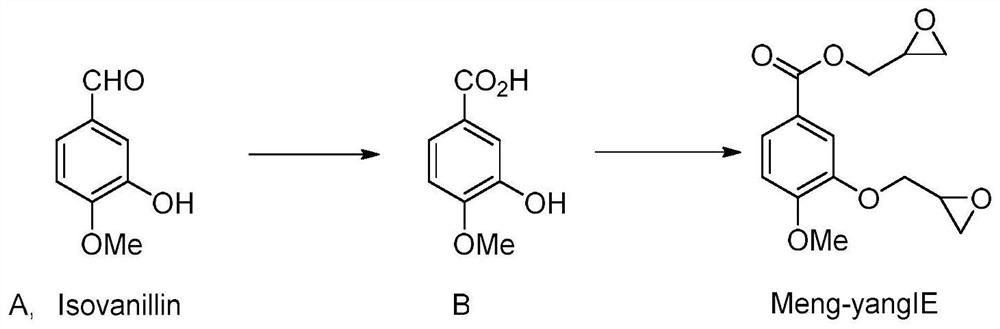

Application of novel isovanillin epoxy resin monomer in preparation of silicon-containing polymer

A silicon polymer, isovanillin technology, applied in organic chemistry and other directions, can solve the problem of unreported monomer structure research, and achieve the effects of low curing processing temperature, wide source and good biological safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation of embodiment 1 intermediate B

[0051] Add sodium hydroxide (32.17g) and potassium hydroxide (48.25g) and 16mL of deionized water to a 500mL single-necked bottle in sequence, heat to 160°C within 10min, then add isovanillin (96.5g, 0.635 mol). After reacting the obtained reaction system at 160°C for 4 hours, slowly add water, dissolve it in a beaker, and then lower it to room temperature, then acidify it with phosphoric acid to adjust the pH=2, filter and wash the obtained precipitate, and finally dry the obtained solid. 92 g of product intermediate B was obtained with a yield of 86.2%.

[0052] 1 H NMR(400MHz,DMSO)δ12.50(s,1H),9.39(s,1H),7.41(dd,J=8.4,2.0Hz,1H),7.35(d,J=2.0Hz,1H),6.99 (d,J=8.5Hz,1H),3.82(s,3H).

Embodiment 2

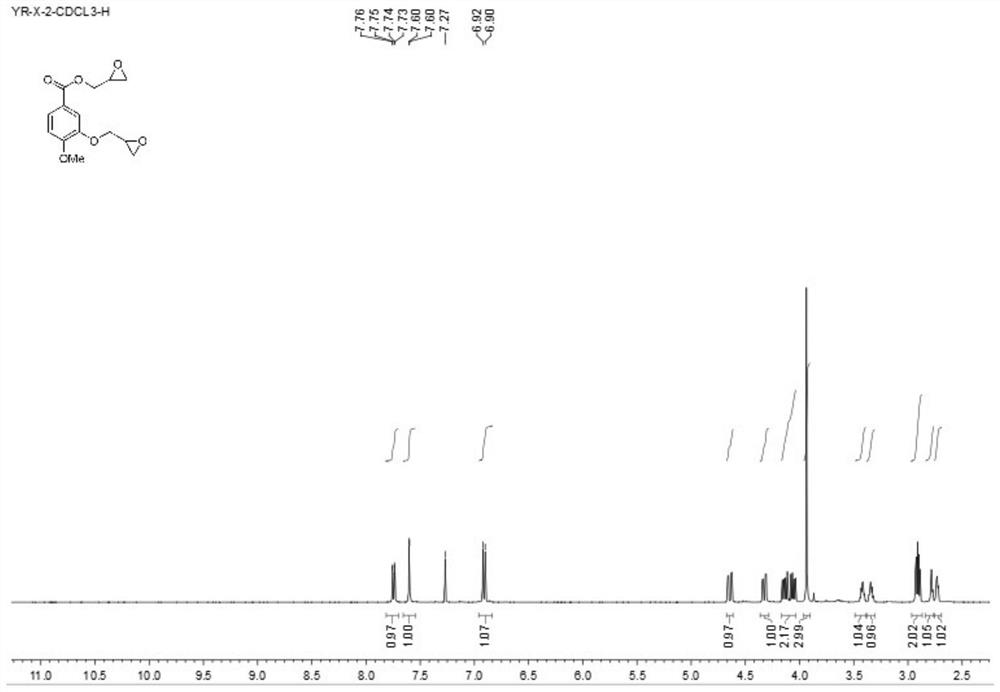

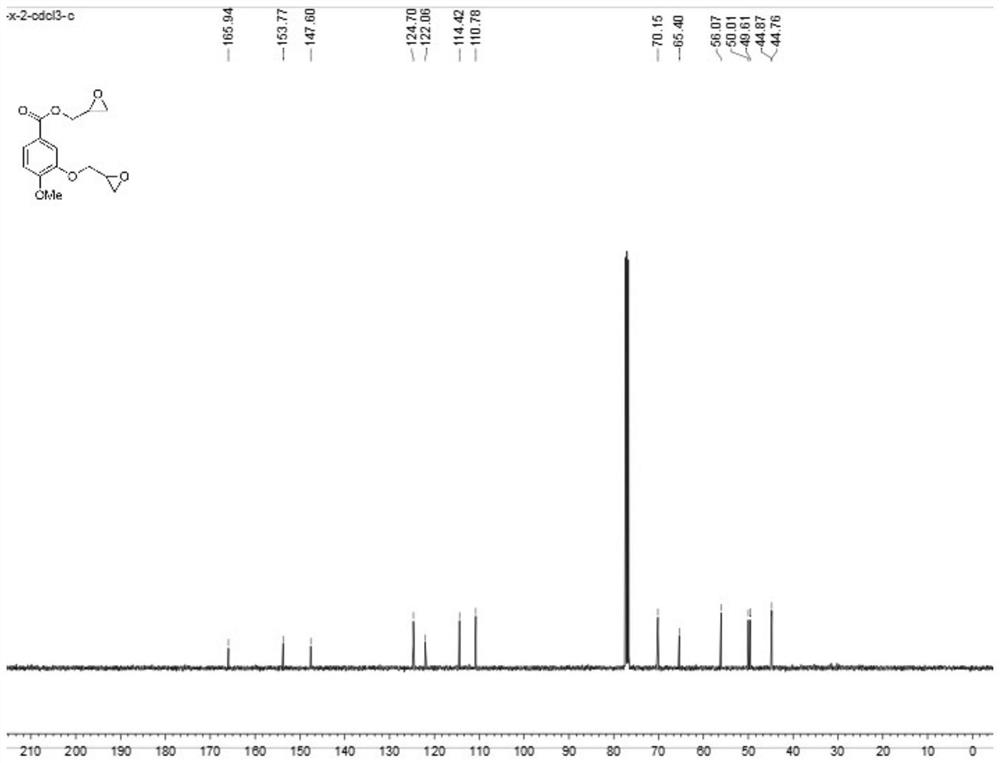

[0053] The preparation of embodiment 2 isovanillin bio-based epoxy resin monomer

[0054] Add intermediate B (2.52g), benzyltriethylammonium chloride (TEBAC, 0.34g) and epichlorohydrin (13.8g) to a 250mL single-mouth round bottom bottle, and react at 80°C for 4.5h under magnetic stirring. Then add another part of TEBAC (0.34g) and an aqueous solution of sodium hydroxide (2.4g, the concentration is 5.0mol / L). After the addition, stir and react at room temperature for 1.5h. After the reaction is complete, add ethyl acetate to extract the organic phase. Ethyl acetate was extracted three times, and then the organic phase was combined, and the obtained organic phase was washed three times with water, then dried over anhydrous sodium sulfate, and then concentrated to obtain a mixed product containing isovanillin bio-based epoxy resin monomer. After filtering off the desiccant, the condensate was obtained by rotary evaporation. The above mixture was separated on a silica gel column,...

Embodiment 3

[0060] Weigh the isovanillin bio-based epoxy resin monomer (0.109g) represented by the formula Meng-yangIE in the reaction bottle, add curing agent D (0.097g) at 25°C, heat up to about 75°C, and the sample is in a molten state , Stir quickly to keep the material fully melted and mixed evenly. Then gradually raise the temperature to 100°C to start curing, and then maintain at this temperature for 2 hours to obtain a transparent colorless polymer material. By judging its infrared data, such as Figure 5 As shown, the infrared peaks of ethylene oxide in the original epoxy substrate (860 and 910cm -1 Equal intensity stretching vibration) disappears, indicating that the epoxy group and amine group of the epoxy resin have been completely polymerized, and at the same time due to the ring-opening process of the epoxy, the 3426cm -1 Relative to the raw material epoxy monomer, there is a large absorption, which is inferred to be caused by a large number of hydroxyl groups formed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com