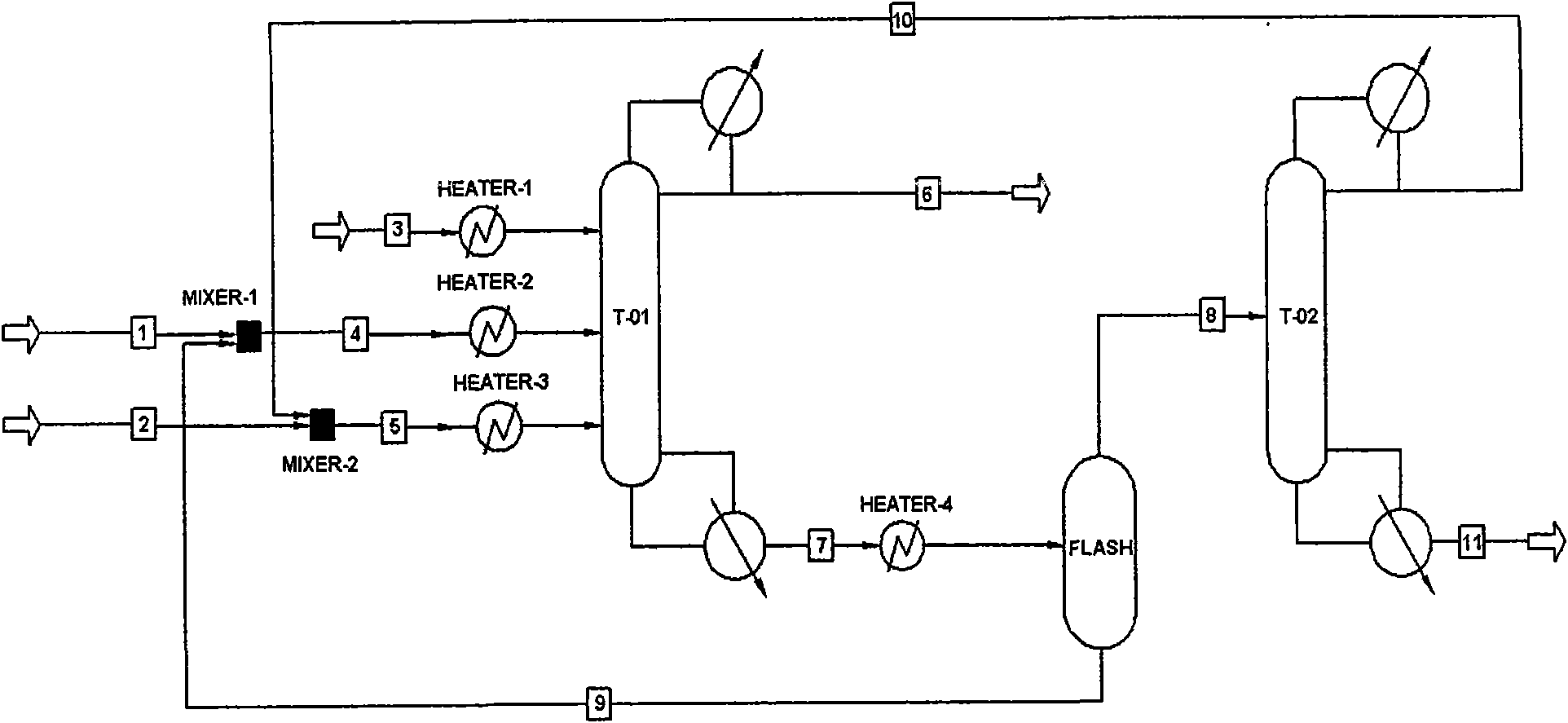

Process for continuously generating methyl acetate by reactive distillation taking ionic liquid as catalyst

A technology of ionic liquid and methyl acetate, which is applied in the fields of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, chemical industry, etc., can solve the trouble of catalyst recovery and recycling, and the complexity of ionic liquid synthesis method , Difficulty in large-scale production and other issues, to achieve the effect of improving raw material utilization, reducing heat energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

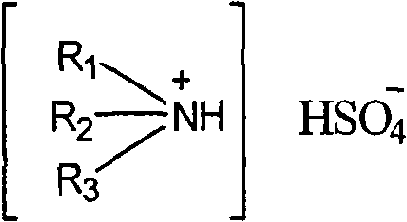

[0031] Embodiment 1: the synthesis of triethyl tertiary amine bisulfate ionic liquid

[0032] Make 98g (1mol) of concentrated sulfuric acid into an aqueous solution with a mass fraction of 40% to 50%, then put 101g (1mol) of triethylamine into a 1L reaction kettle, and slowly add dilute sulfuric acid solution dropwise under the condition of stirring. Reflux for 12 hours. After the reaction was completed, the water was removed by vacuum drying to obtain triethyl tertiary amine bisulfate ionic liquid with a yield of 99%.

Embodiment 2

[0033] Embodiment 2: the synthesis of N-methylimidazolium bisulfate

[0034]Put 82g (1mol) of N-methylimidazole into a 1L reaction kettle, add 100ml of acetonitrile, add 98g (1mol) of concentrated sulfuric acid while stirring, and reflux at room temperature for 10 hours. After the reaction was completed, the solvent was evaporated, and N-methylimidazolium bisulfate ionic liquid was obtained after vacuum drying, with a yield of about 98.5%.

Embodiment 3

[0035] Embodiment 3: the synthesis of pyridine bisulfate

[0036] Put 79g (1mol) of pyridine into a 1L reactor, add 100ml of acetonitrile, add 98g (1mol) of concentrated sulfuric acid while stirring, and reflux at room temperature for 8 hours. After the reaction was completed, the solvent was evaporated, and after vacuum drying, the pyridine bisulfate ionic liquid was obtained, and the yield was about 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com