Preparation method of slow-setting polycarboxylic acid water reducing agent

A technology of slow-setting polycarboxylic acid and slow-coagulation carboxylic acid, which is applied in the field of concrete water reducing agent, can solve the problems of covering up, increasing the difficulty of engineering construction, affecting the popularization and application of polycarboxylate water reducing agent, etc., and achieving good results Flow properties and retarding properties, the effect of good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

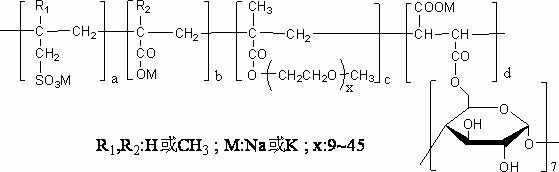

Image

Examples

Embodiment 1

[0013] Example 1: 1) Preparation of macromonomer MPEG-MAA: Add 0.4 g of hydroquinone and 110 g of MPEG into a 250 mL three-necked flask, gradually raise the temperature to 60°C under stirring, then slowly add 10.3 g of MAA and 2.2 g of concentrated sulfuric acid. After half an hour of heat preservation, the temperature was raised to 90° C., 36 g of cyclohexane was added, and the reflux was continued for 5 hours. The cyclohexane was removed by distillation and cooled to room temperature to obtain the macromonomer MPEG-MAA. 2) Preparation of macromonomer MAH–β–CD: Add 5.675 g of β–cyclodextrin, 1.5 g of MAH and 28.6 g of DMF into a round-bottomed flask, raise the temperature to 80°C with stirring, and keep the reaction for 7 hours to obtain the macromonomer Add 70 g of distilled water to the bulk MAH–β–CD solution, distill under reduced pressure, and dry it at 80°C for later use. 3) Preparation of water reducer: first add 40 grams of deionized water to a four-necked flask, and...

Embodiment 2

[0014] Example 2: 1) Preparation of macromonomer MPEG-MAA: Add 0.5 g of hydroquinone and 110 g of MPEG into a 250 mL three-necked flask, gradually raise the temperature to 60°C under stirring, then slowly add 12.8 g of MAA and 2.2 g of concentrated sulfuric acid. After half an hour of heat preservation, the temperature was raised to 95° C., 37 g of cyclohexane was added, and the reflux was continued for 5.5 hours. The cyclohexane was removed by distillation and cooled to room temperature to obtain the macromonomer MPEG-MAA. 2) Preparation of macromonomer MAH–β–CD: Add 5.675 g of β–cyclodextrin, 2.0 g of MAH and 29.6 g of DMF into a round-bottomed flask, raise the temperature to 85°C with stirring, and keep the reaction for 7.5 hours to obtain the macromonomer Add 75 g of distilled water to the bulk MAH–β–CD solution, distill under reduced pressure, and dry it at 80°C for later use. 3) Preparation of water reducer: first add 45 grams of deionized water to a four-necked flask,...

Embodiment 3

[0015] Example 3: 1) Preparation of macromonomer MPEG-MAA: Add 0.6 g of hydroquinone and 110 g of MPEG into a 250 mL three-neck flask, heat up to 60°C under stirring, then slowly add 15.3 g of MAA and 2.2 g of concentrated sulfuric acid . After half an hour of heat preservation, the temperature was raised to 100° C., 38 g of cyclohexane was added, and the reflux was continued for 6 hours. The cyclohexane was removed by distillation and cooled to room temperature to obtain the macromonomer MPEG-MAA. 2) Preparation of macromonomer MAH–β–CD: Add 5.675 g of β–cyclodextrin, 2.5 g of MAH and 30.6 g of DMF into a round bottom flask, heat up to 90°C under stirring, and keep the reaction for 8 hours to obtain macromonomer Add 80 g of distilled water to the bulk MAH–β–CD solution, distill under reduced pressure, and dry it at 80°C for later use. 3) Preparation of water reducer: first add 50 grams of deionized water to a four-neck flask, and then make a mixed monomer with 20 grams of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com