A kind of extraction and separation method of co-producing 4n holmium and 5n ytterbium

A separation method and extraction technology are applied in the field of extraction and separation of co-production of 4N holmium and 5N ytterbium, and can solve the problems of poor process stability of 4N-grade holmium chloride, large acid-base consumption, and low qualification rate of 4N-grade holmium chloride products. , to achieve the effect of improving stability, reducing acid-base consumption and improving qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

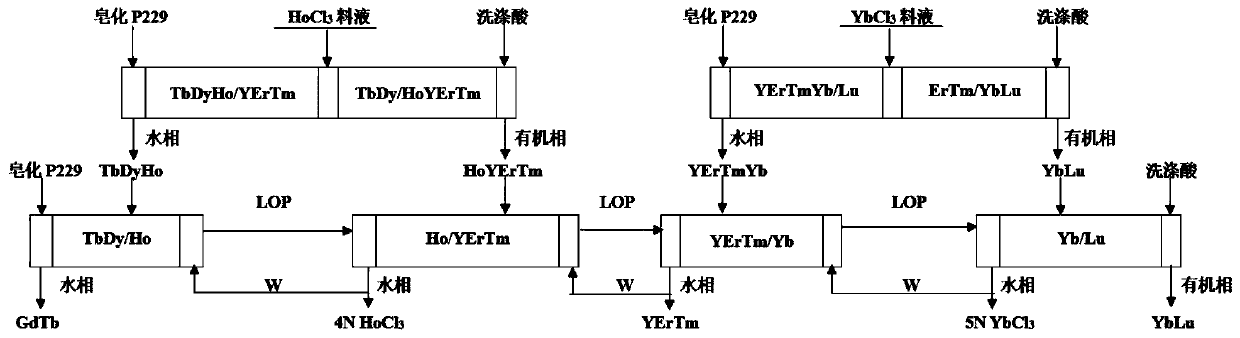

Image

Examples

Embodiment 1

[0029] The organic phase of saponified P229 is 30% by volume of P229 in the kerosene solution of extractant P229, and the saponification rate is 36%.

[0030] The pH of the 2N grade holmium chloride solution is 3, and the concentrations of rare earth elements are: Tb 0.050g / L, Dy 0.10g / L, Ho155.0g / L, Y 0.30g / L, Er 0.10g / L, Tm 0.030g / L.

[0031] The pH of 2N-grade ytterbium chloride is 3, and the concentrations of rare earth elements are: Y 0.020g / L, Er 0.050g / L, Tm 0.10g / L, Yb 160.0g / L, Lu 0.30g / L.

[0032] Step 1: Fractional distillation and extraction to separate TbDyHo / HoYErTm

[0033] The saponified P229 organic phase is used as the extracted organic phase, the 2N grade holmium chloride solution is used as the first feed solution, and 3.0mol / L HCl is used as the washing acid. The saponified P229 organic phase enters the TbDyHo / HoYErTm fractional extraction system from the first stage, the first feed liquid enters the TbDyHo / HoYErTm fractional extraction system from the ...

Embodiment 2

[0048] The organic phase of saponified P229 is 30% by volume of P229 in the kerosene solution of extractant P229, and the saponification rate is 36%.

[0049] The pH of the 2N-grade holmium chloride solution is 2, and the concentrations of rare earth elements are Tb0.10g / L, Dy 0.30g / L, Ho160.0g / L, Y 0.50g / L, Er 0.20g / L, Tm 0.050g / L L.

[0050] The pH of 2N-grade ytterbium chloride is 4, and the concentrations of rare earth elements are: Y 0.050g / L, Er 0.10g / L, Tm 0.30g / L, Yb 155.0g / L, Lu 0.70g / L.

[0051] Step 1: Fractional distillation and extraction to separate TbDyHo / HoYErTm

[0052]The saponified P229 organic phase is used as the extracted organic phase, the 2N grade holmium chloride solution is used as the first feed solution, and 3.0mol / L HCl is used as the washing acid. The saponified P229 organic phase enters the TbDyHo / HoYErTm fractionation extraction system from the first stage, the first feed liquid enters the TbDyHo / HoYErTm fractionation extraction system from th...

Embodiment 3

[0067] The organic phase of saponified P229 is 30% by volume of P229 in the kerosene solution of extractant P229, and the saponification rate is 36%.

[0068] The pH of the 2N-grade holmium chloride solution is 4, and the concentrations of rare earth elements are: Tb 0.010g / L, Dy 0.050g / L, Ho150.0g / L, Y 0.10g / L, Er 0.050g / L, Tm 0.010g / L.

[0069] The pH of 2N-grade ytterbium chloride is 2, and the concentrations of rare earth elements are: Y 0.010g / L, Er 0.020g / L, Tm 0.050g / L, Yb 165.0g / L, Lu 0.10g / L.

[0070] Step 1: Fractional distillation and extraction to separate TbDyHo / HoYErTm

[0071] The saponified P229 organic phase is used as the extracted organic phase, the 2N grade holmium chloride solution is used as the first feed solution, and 3.0mol / L HCl is used as the washing acid. The saponified P229 organic phase enters the TbDyHo / HoYErTm fractionation extraction system from the first stage, the first feed liquid enters the TbDyHo / HoYErTm fractionation extraction system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com