Method and device for synthesizing and refining optical fiber grade germanium tetrachloride

A technology of germanium tetrachloride and optical fiber, which is applied in the field of synthesis and refining of optical fiber-grade germanium tetrachloride and devices, can solve the problems of increased production cost, high energy consumption of the process, and a large amount of waste acid, so as to save energy consumption and improve The degree of greening and the effect of reducing waste acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

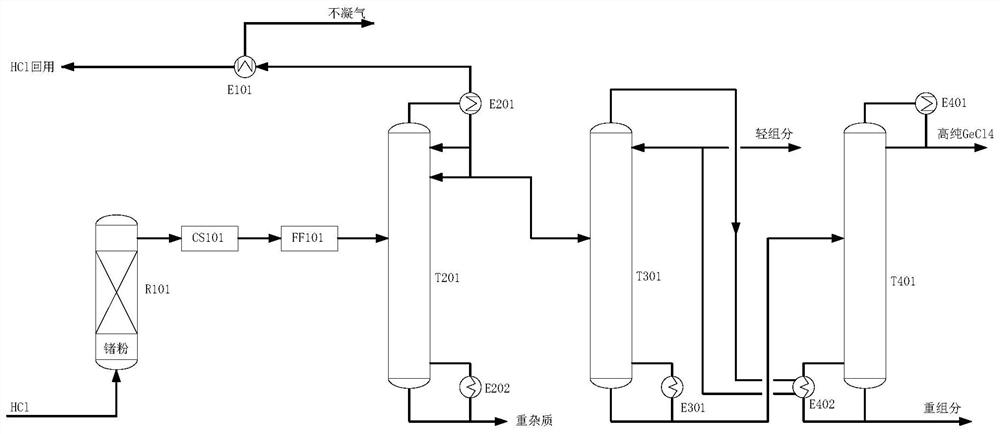

[0059] Attached below figure 1 The present invention will be further described with reference to specific embodiments.

[0060] Add 1000g of germanium powder into the reactor R101, and gradually introduce 2011g of high-purity hydrogen chloride, control the pressure of the reactor to 0.2MPa, the temperature of 200°C, and the reaction time of 8h, the reaction produces 1773g of germanium tetrachloride. The crude germanium tetrachloride (germanium tetrachloride, hydrogen germanium trichloride, hydrogen, hydrogen chloride) obtained through the reaction is collected and dedusted by the cyclone separator CS101 and the bag filter FF101, and then enters the spray tower T201 to remove heavy impurities. The operating pressure of the spray tower T201 is 0.3MPa, and the operating temperature is 123°C. Part of the material at the top of the spray tower T201 is condensed and cooled by the spray tower condenser E201, and part of it returns to the spray tower T201 as spray liquid, and part of...

Embodiment 2

[0063]Add 1000g of germanium powder to the reactor R101, and gradually introduce 4022g of high-purity hydrogen chloride, control the pressure of the reactor to 0.6MPa, the temperature to 300°C, and the reaction time to 4h, the reaction produces 2215.9g of germanium tetrachloride. The crude germanium tetrachloride (germanium tetrachloride, hydrogen germanium trichloride, hydrogen, hydrogen chloride) obtained through the reaction is collected and dedusted by the cyclone separator CS101 and the bag filter FF101, and then enters the spray tower T201 to remove heavy impurities. The operating pressure of the spray tower T201 is 0.1MPa, and the operating temperature is 82°C. Part of the material at the top of the spray tower T201 is condensed and cooled by the spray tower condenser E201, and part of it returns to the spray tower T201 as spray liquid, and part of it enters the light removal tower T301; the uncondensed gas phase is extracted and enters the depth of the dephlegmator E101...

Embodiment 3

[0066] Add 1000g of germanium powder into the reactor R101, and gradually introduce 6033.1g of high-purity hydrogen chloride, control the pressure of the reactor at 1MPa, the temperature of 400°C, and the reaction time of 2h, the reaction produces 2659.1g of germanium tetrachloride. The crude germanium tetrachloride (germanium tetrachloride, hydrogen germanium trichloride, hydrogen, hydrogen chloride) obtained through the reaction is collected and dedusted by the cyclone separator CS101 and the bag filter FF101, and then enters the spray tower T201 to remove heavy impurities. The operating pressure of the spray tower T201 is 0.2MPa, and the operating temperature is 106°C. Part of the material at the top of the spray tower T201 is condensed and cooled by the spray tower condenser E201, and part of it returns to the spray tower T201 as spray liquid, and part of it enters the light removal tower T301; the uncondensed gas phase is extracted and enters the depth of the dephlegmator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com