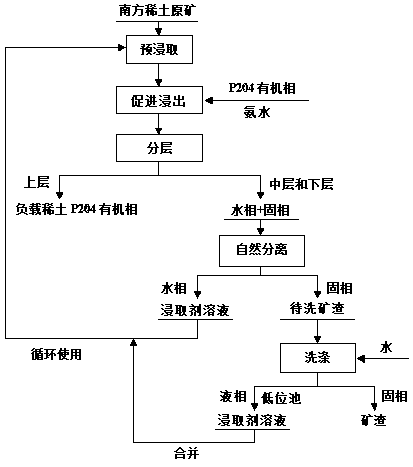

The process of extracting rare earth from southern rare earth ore by p204 extraction

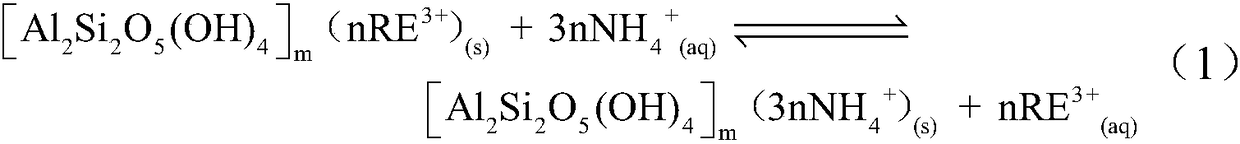

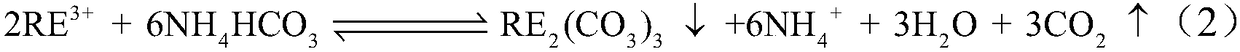

A 1.P204, extraction technology, applied in the field of jointly promoting leaching agent leaching of southern ion adsorption type rare earth raw ore, can solve the problem of large consumption of water and leaching agent ammonium sulfate, leaching agent ammonium sulfate cannot be recycled, ammonia nitrogen It can reduce the loss of rare earth, have a small impact, and have no carbon dioxide emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a reactor with a volume of 20000L, add 3000kg rare earth raw ore with a rare earth mass percentage of 0.3% based on oxides, add 12000L ammonium sulfate aqueous solution with a concentration of 1.0% and a pH value of 4, and stir and mix for 12 minutes. Then, add the kerosene solution of P204 and TBP with 540LP204 concentration of 1mol / L and TBP volume percent concentration of 15%, and stir for 12 minutes at intervals of 12 minutes. of ammonia solution. Leave to stratify for 2 hours. After the stratification is completed, the upper layer is the P204 organic phase loaded with rare earth, the middle layer is the water phase, and the lower layer is the rare earth solid phase slag. The water phase and solid phase slag are released from the lower end of the reactor, and the P204 organic phase loaded with rare earths obtained is directly used for fractional distillation, extraction and separation of rare earths. The released water phase and rare earth solid phase slag mixt...

Embodiment 2

[0026] In a reactor with a volume of 20000L, add 3000kg of rare earth raw ore with a rare earth mass percentage of 0.3% in terms of oxides, add 10000L of ammonium sulfate aqueous solution with a concentration of 0.3% and a pH value of 3, and stir and mix for 15 minutes. Then, add the kerosene solution of P204 and TBP whose concentration is 1mol / L and TBP volume percent concentration is 10% by adding 540LP204, and stir for 15 minutes every 15 minutes, and stir 6 times altogether; of ammonia solution. Leave to stratify for 2 hours. After the stratification is completed, the upper layer is the P204 organic phase loaded with rare earth, the middle layer is the water phase, and the lower layer is the rare earth solid phase slag. The water phase and solid phase slag are released from the lower end of the reactor, and the P204 organic phase loaded with rare earths obtained is directly used for fractional distillation, extraction and separation of rare earths. The released water pha...

Embodiment 3

[0028]In a reactor with a volume of 20000L, add 2500kg rare earth raw ore with a rare earth mass percentage of 0.2% based on oxides, add 12500L aqueous sodium chloride solution with a concentration of 0.5% and a pH value of 5, and stir and mix for 10 minutes. Then, add 300 LP204 concentration of 1mol / L, TBP volume percent concentration of 20% P204 and TBP kerosene solution, and stir for 10 minutes every 10 minutes, stirring 8 times in total. At the beginning of the third stirring, add 300 L of sodium hydroxide solution with a concentration of 3 mol / L. Leave to stratify for 2 hours. After the stratification is completed, the upper layer is the P204 organic phase loaded with rare earth, the middle layer is the water phase, and the lower layer is the rare earth solid phase slag. The water phase and solid phase slag are released from the lower end of the reactor, and the P204 organic phase loaded with rare earths obtained is directly used for fractional distillation, extraction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com