Multi-point equal clamping device

A clamping device and equal technology, applied in the field of clamping devices, can solve the problems of unfavorable objects, stable clamping and movement, increase of defective rate of thin-walled products, unfavorable product quality maintenance, etc., to ensure clamping contact area and eliminate clamping The weakening of the force and the effect of reducing the damage rate of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

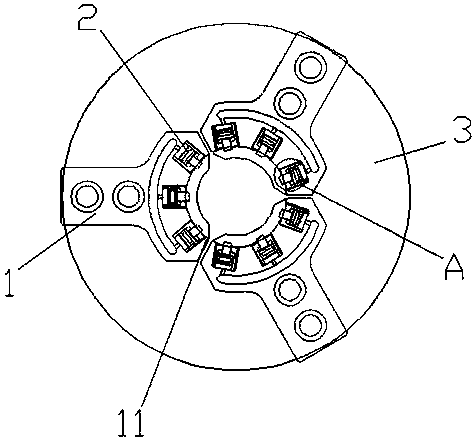

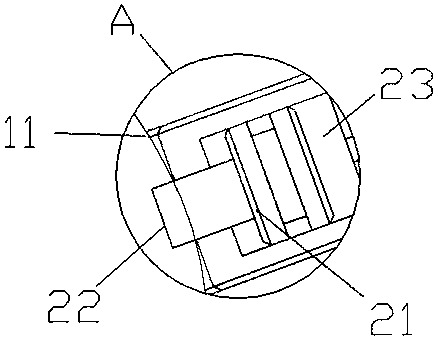

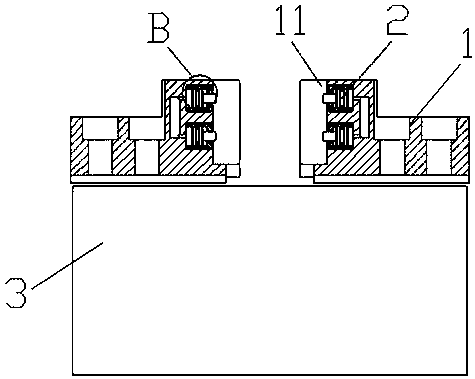

[0024] Such as figure 1 As shown, the clamping device is a three-jaw chuck. The three-jaw chuck utilizes a finger driving mechanism to radially move three movable fingers 1 evenly distributed on the chuck body 3, and then performs clamping and picking operations on the clamped object. The clamping portions 11 of the three claws 1 are arranged in an arc-shaped structure, and it can be known from the working principle of the clamping jaws that the three claws 1 have a fixed clamping center. When the three claw fingers 1 cooperate to carry out the clamping operation, the three arc-shaped clamping parts 1 form a circular accommodation area, and then the picking operation of the circular workpiece can be realized. At the same time, the arc-shaped structure can increase the contact area with the object, ensuring the clamping effect of irregular wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com