Magnetic clamping device and method for detecting and controlling an operating state of a magnetic clamping device

A technology of clamping device and electromagnetic clamp, applied in the direction of workpiece clamping device, electromagnet, manufacturing tools, etc., can solve the problems of insufficient electromagnetic coupling and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

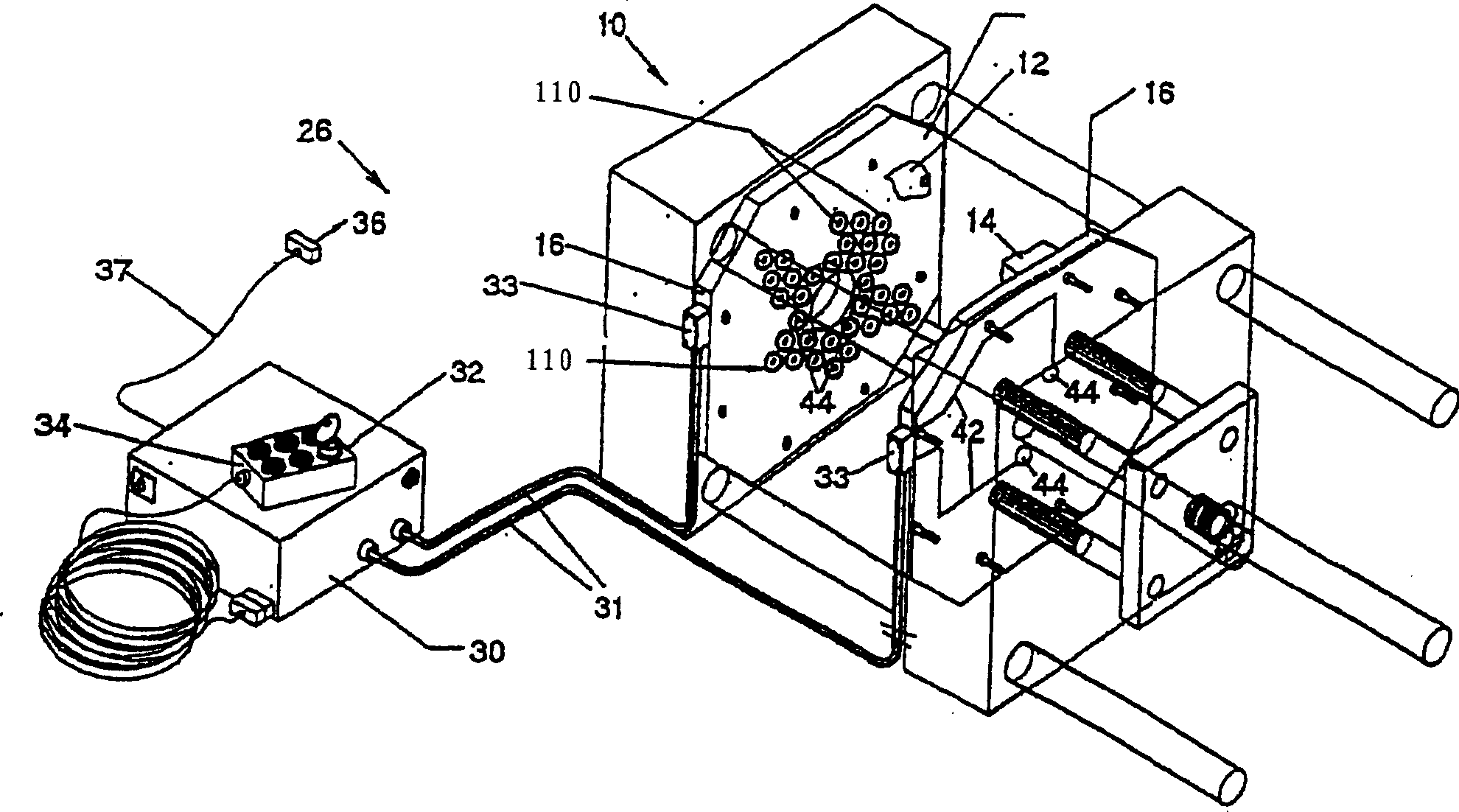

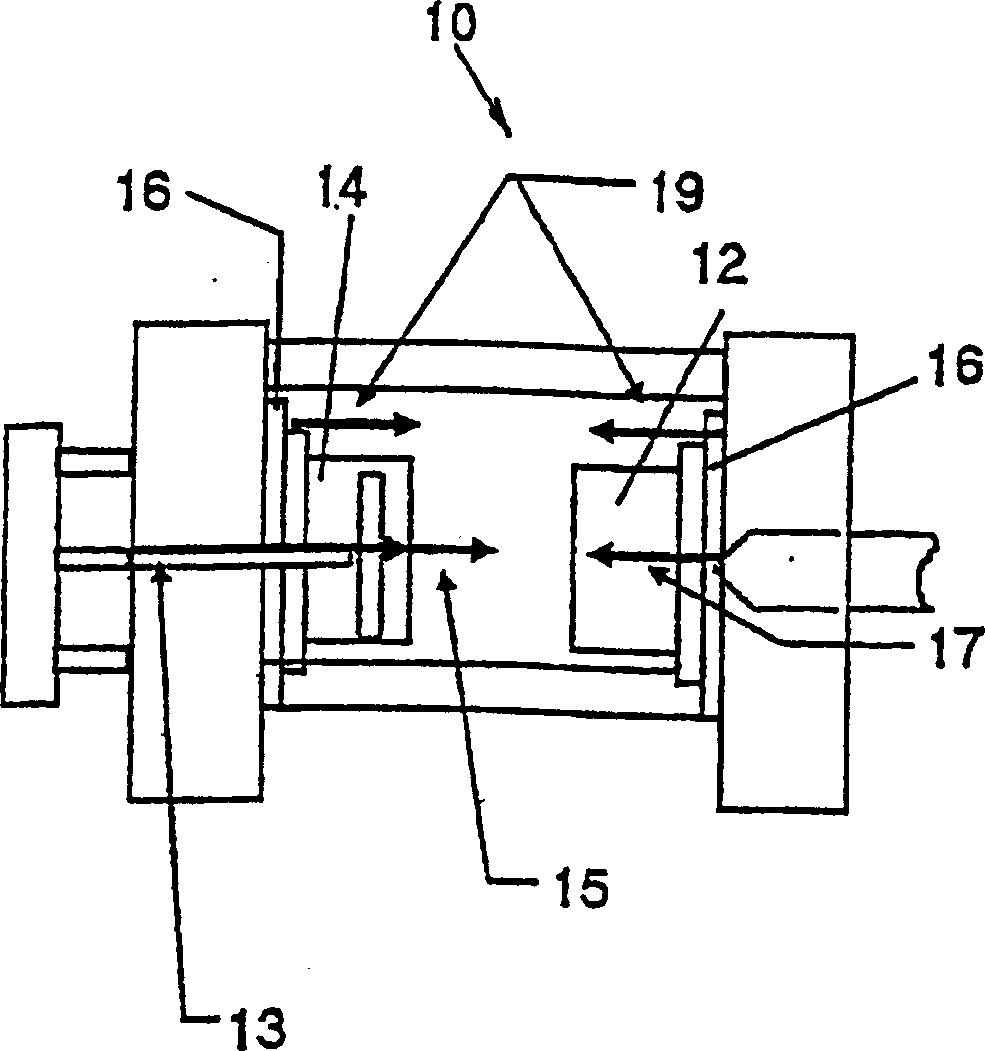

[0042] figure 2 One embodiment of an injection molding machine 10 is schematically shown having a fixed platen 12 and a movable platen 14 mounted respectively by electromagnetic clamping devices (“clamps”) 16 On the injection molding machine 10, the above-mentioned electromagnetic clamping device 16 is suitable to work as a quick mold changing device. During normal operation, there are many forces that oppose the clamping force produced by the clamp 16, namely, ejector force 13 due to incorrect machine adjustment, inertial force during mold closing stroke 15, nozzle pressure 17 and opening Mold force 19.

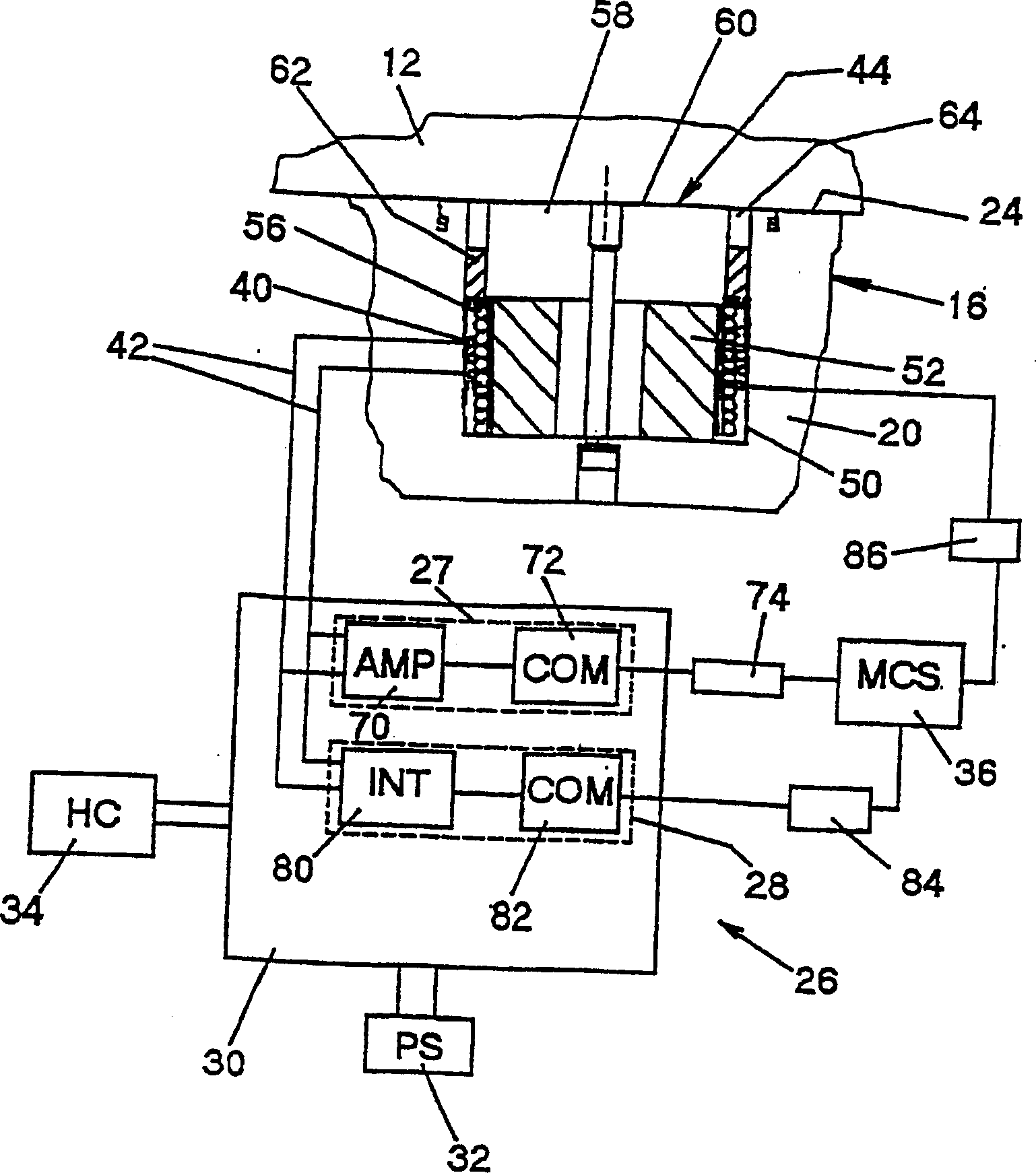

[0043] In order to counteract these effects and other operating conditions that produce interrupted electromagnetic clamping forces, an electromagnetic clamping device with a multifunctional sensing system as described below is provided at the clamping interface, that is, at the electromagnetic clamping unit 110 .

[0044] An embodiment of the electromagnetic holding unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com