Bus spacer device not easy to slip and capable of being accurately adjusted

A spacer device, an uneasy technology, applied in the field of electric power, can solve problems such as the inability to achieve the spacer effect, the inability to realize multiple installations, and the inability to adjust the length, etc., and achieve the effects of quick and convenient adjustment, improved spacer efficiency, and reduced number of units used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

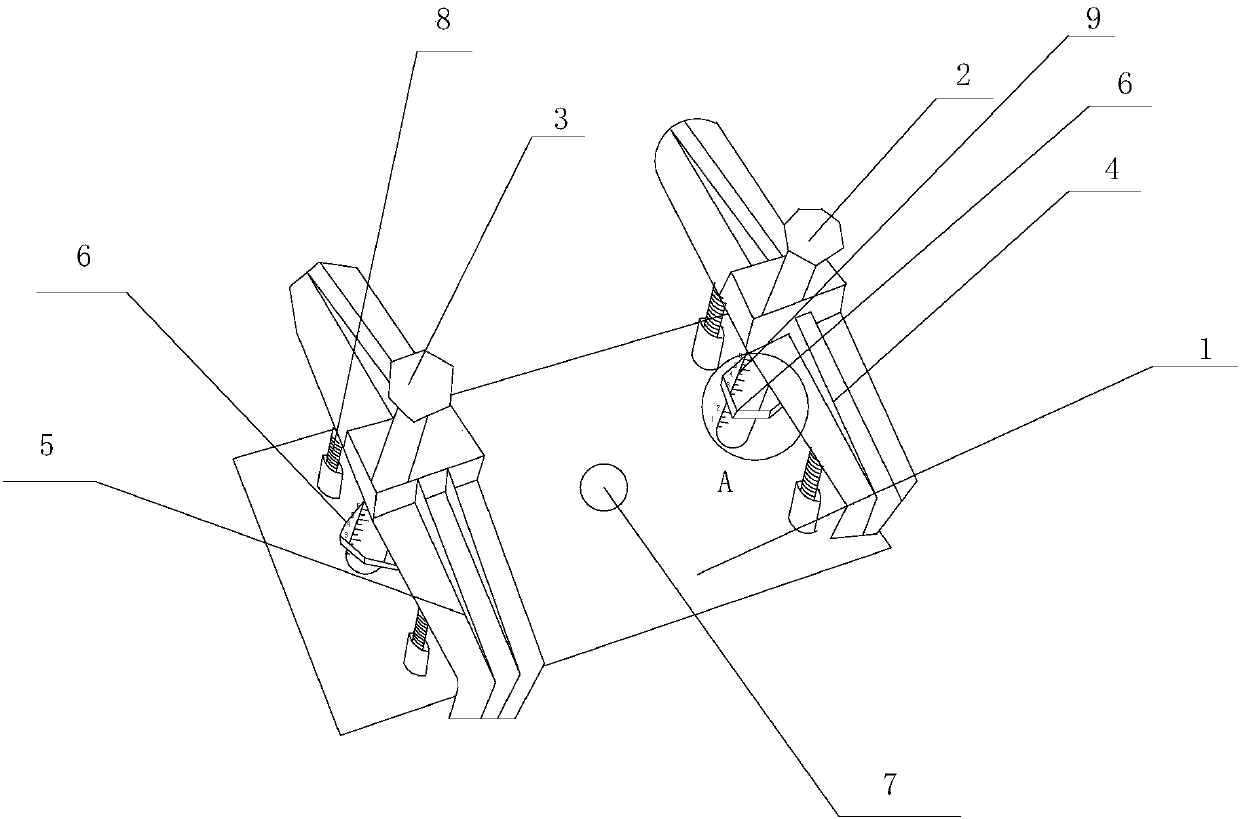

[0021] Such as Figure 1-2 As shown, this includes a busbar spacing device that is not easy to slip and can be accurately adjusted, including a base plate 1, a first installation column 2, a second installation column 3, a telescopic rod 8 and a scale line 9, the first installation column 2 and the second installation column The second mounting column 3 is vertically installed on the base plate 1, the first clamping plate 4 is set on the first mounting column 2, the first clamping plate 4 can move up and down on the first mounting column 2, and the second mounting column 3 is covered with The second clamping plate 5, the second clamping plate 5 can move up and down on the second mounting column 3, and both the first mounting column 2 and the second mounting column 3 are covered with limit nuts 6, and the limiting nuts 6 are located on the first clamping plate. The bottom of plate 4 and second clamping plate 5 is also provided with ventilation hole 7 on base plate 1; Also verti...

Embodiment 2

[0024] This embodiment is preferably as follows on the basis of the above embodiments: two telescopic rods 8 are provided at the bottoms of the first clamping plate 4 and the second clamping plate 5 . The two telescopic rods are fully able to support the first clamping board and the second clamping board well, so that the positions of the first clamping board and the second clamping board will not change.

[0025] The two telescopic rods 8 at the bottom of the first clamping plate 4 are symmetrical with respect to the first mounting column 2 . The stability of the first pallet and the second pallet is further improved.

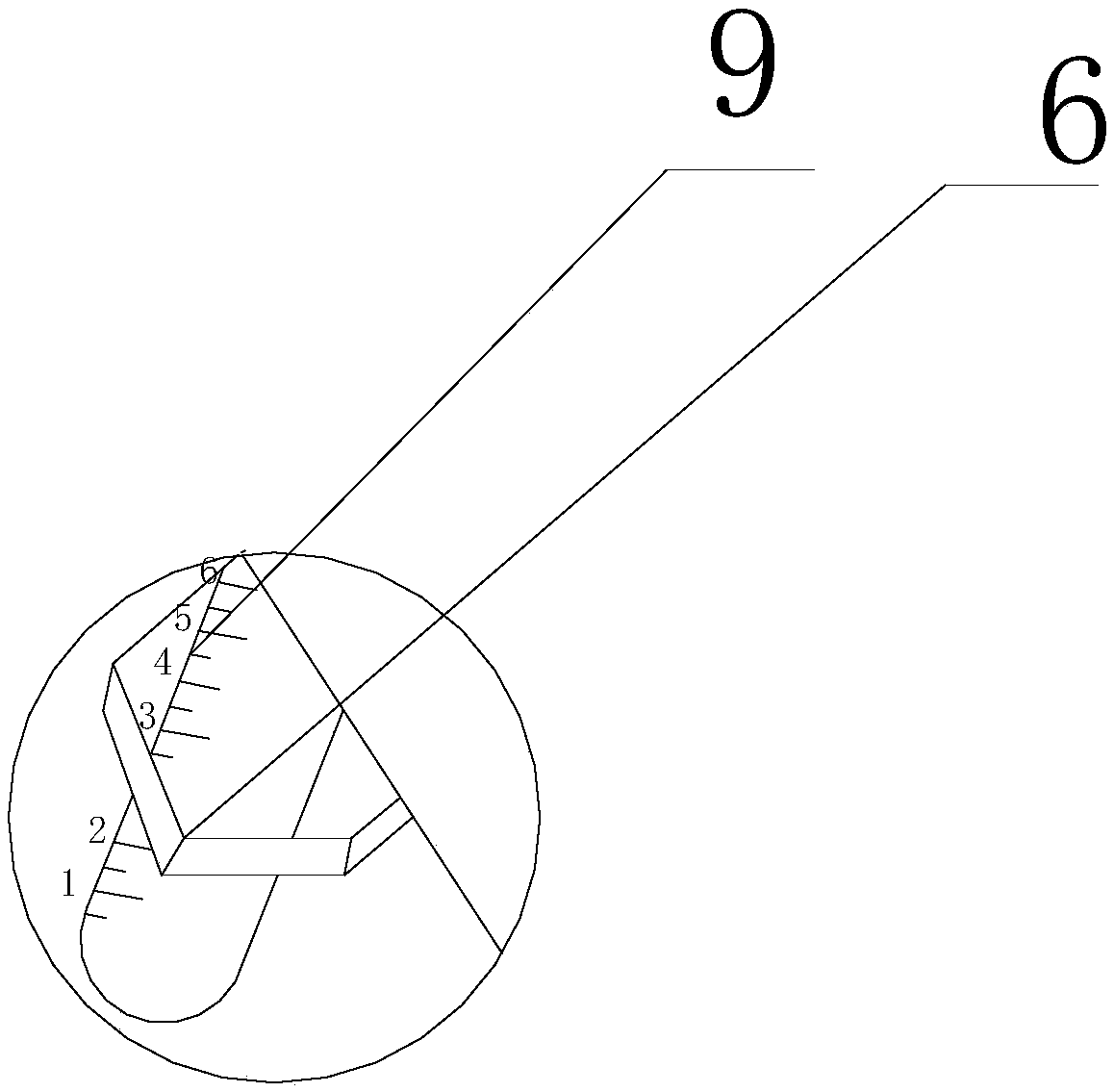

[0026] The scale lines 9 form depressed horizontal stripes on the surfaces of the first mounting post 2 and the second mounting post 3 . The depressed horizontal stripes are used as scale lines, and are not easy to fall off during the long-term friction process between the first clamp and the second clamp.

[0027] A waterproof and scratch-resistant layer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com