Printer roller

A technology for printing machines and adjusting rollers, applied in printing machines, printing, rotary printing machines, etc., can solve problems such as insufficient help, and achieve the effect of eliminating gear loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

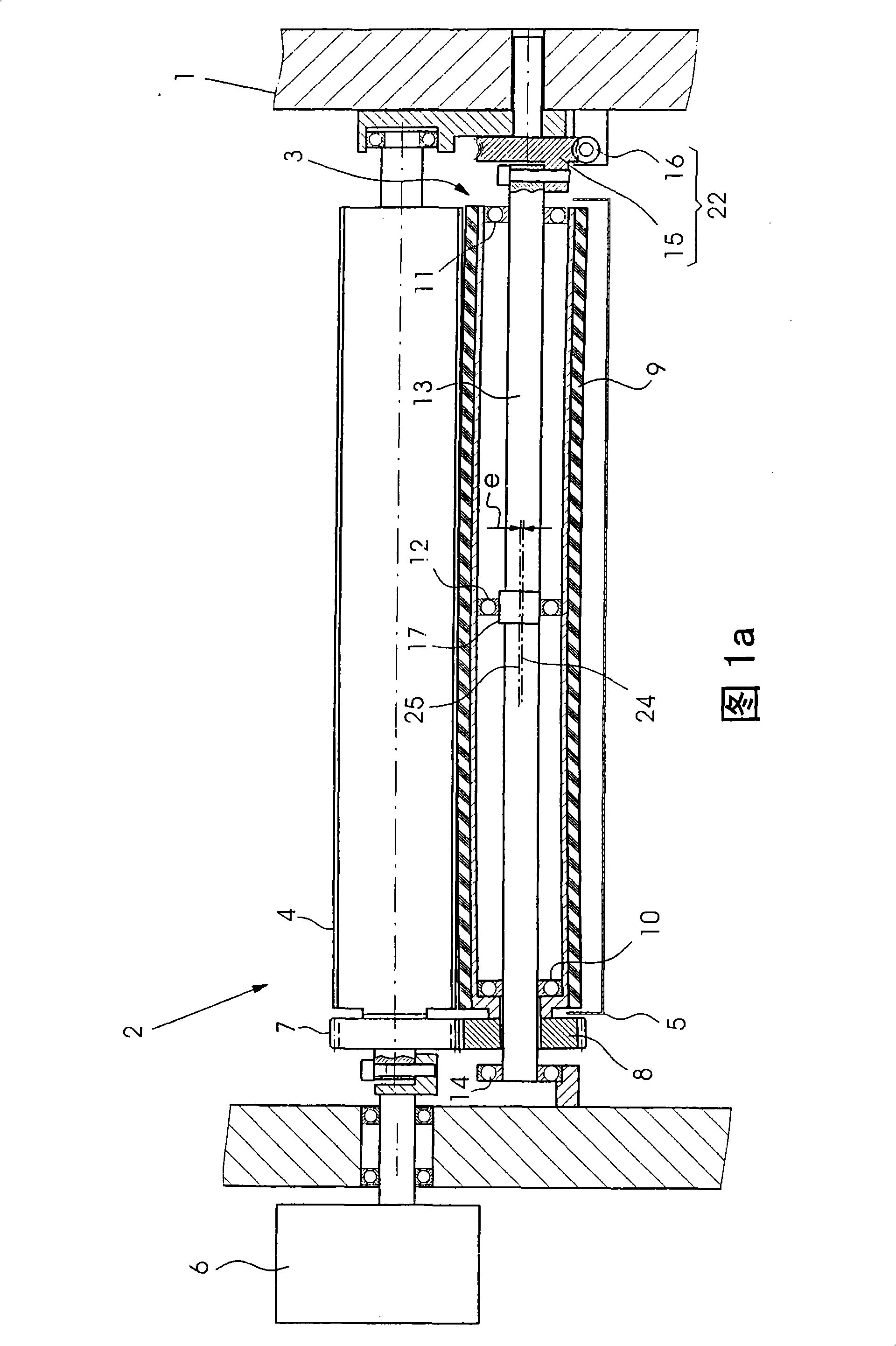

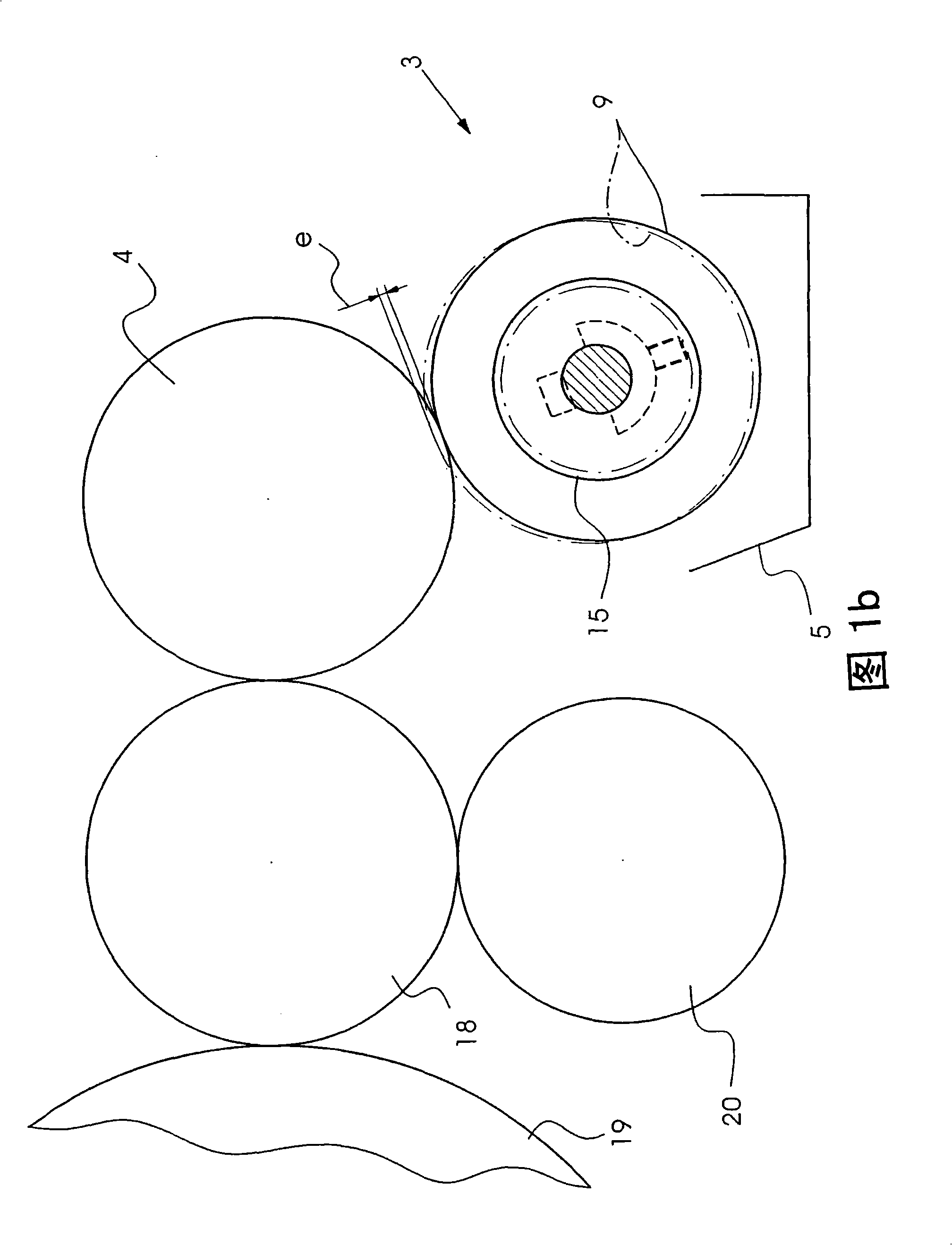

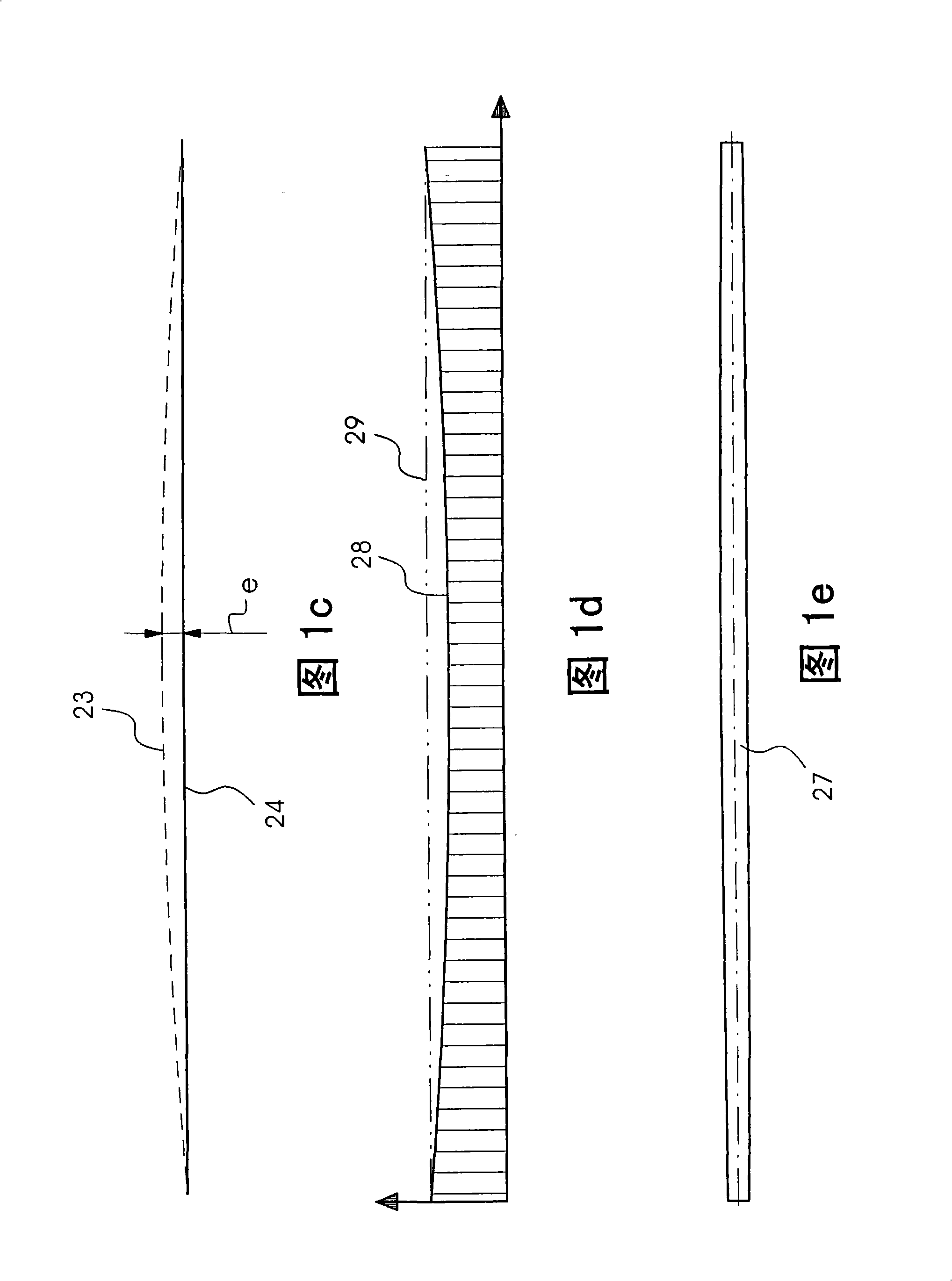

[0039] FIGS. 1 a , 2 a and 3 a show a printing press 1 for offset lithography comprising a dampening unit 2 with a roller 3 and a further roller 4 . The roll 3 is a flooded roll and is arranged in a dampening tank 5 for drawing dampening agent from the dampening tank. The roller 3 rests against the further roller 4 in order to transfer the picked up dampening agent to the further roller. An electric motor 6 drives the other roller 4 in rotation. A first gear 7 , which is rotationally fixed to the further roller 4 , meshes with a second gear 8 . The second gear wheel 8 is non-rotatably connected to the tubular or hollow-cylindrical roller jacket 9 of the roller 3 . The roll jacket 9 is rotatably supported on a fixed shaft 13 via roll-end-side or axially outer pivot bearings 10 , 11 and a pivot bearing 12 situated between or in between the aforementioned pivot bearings. The outer diameter of these pivot bearings 10, 11, 12 is substantially equal to the inner diameter of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com