A kind of construction method of wet laying waterproof and thermal insulation integrated board

A construction method and integrated panel technology, applied to roofing tools, roofs using flat/curved panels, roofing, etc., can solve problems such as low construction efficiency and unsuitable integrated panel laying, and achieve high work efficiency. Improve the applicability and flexibility of use, and enhance the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

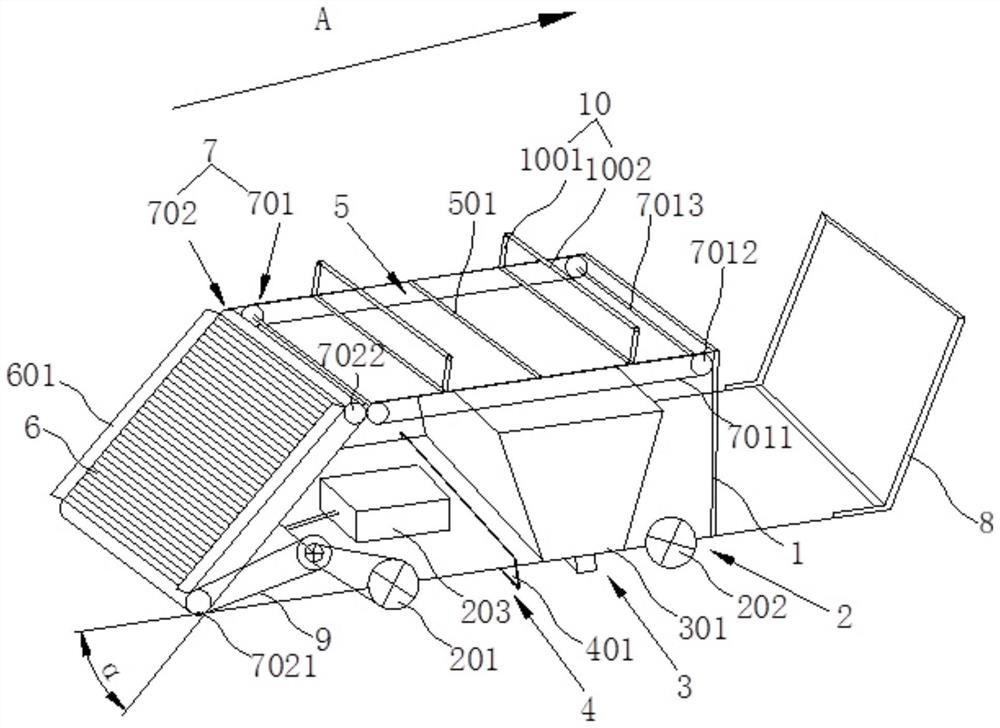

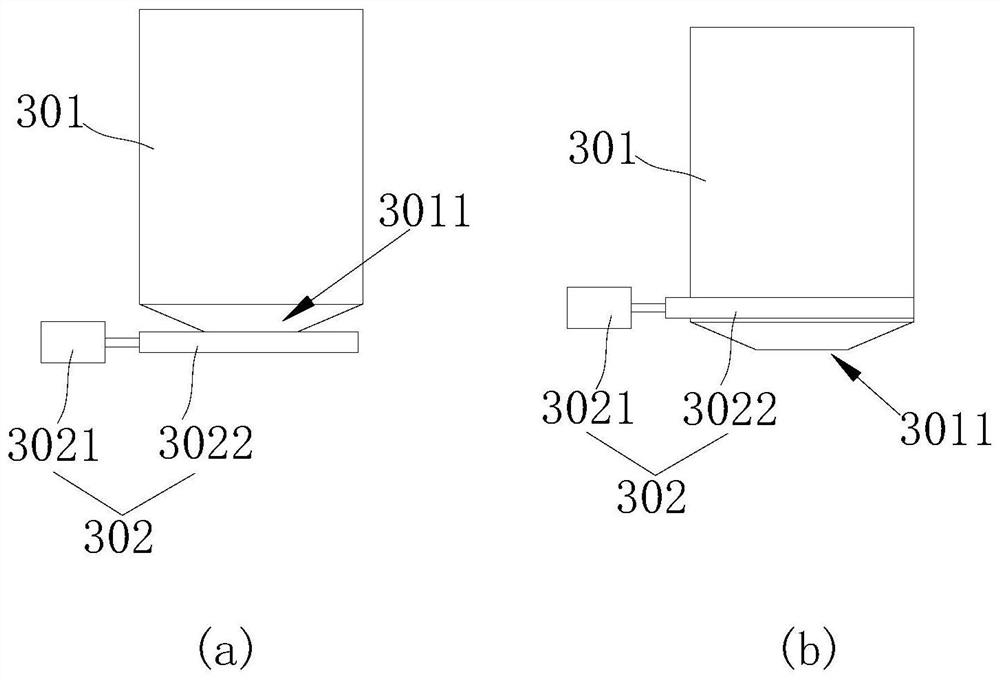

[0100] refer to figure 1 , this embodiment discloses a laying equipment for a waterproof and heat-insulating integrated board, including a vehicle frame 1 and a running device 2 arranged on the vehicle frame 1. In the figure, the arrow A indicates the forward direction of the vehicle frame 1, and the direction of the arrow A is One end is the front end of the vehicle frame 1, and the other end is the rear end of the vehicle frame 1. The vehicle frame 1 is sequentially provided with an adhesive material thickness control mechanism 4 and an adhesive material coating mechanism 3 along its advancing direction. The mechanism 3 coats the bonding material toward the ground, and the bonding material thickness control mechanism 4 maintains a distance from the ground for controlling the thickness of the bonding material;

[0101] The frame 1 is provided with a plate storage platform 5, a laying inclined plate 6, and a plate conveying assembly 7. The thermal insulation integrated plate i...

Embodiment 2

[0136] This embodiment discloses another type of laying equipment for waterproof and thermal insulation integrated boards, which is based on Embodiment 1 and differs from Embodiment 1 in that:

[0137] In this implementation, the vertical bar 1001 is fixed to the vehicle frame 1 , and the connecting rod 1002 is detachably connected to the vertical bar 1001 .

[0138] Further, as a preferred embodiment, the vertical bar 1001 is provided with a socket, and the two ends of the connecting rod 1002 are respectively provided with a plug-in end that matches with the socket.

[0139] As an alternative embodiment, two ends of the connecting rod 1002 are provided with a blind insertion hole, and the vertical rod 1001 is matched with the blind insertion hole.

Embodiment 3

[0141] This embodiment discloses a construction method for wet-laying waterproof and thermal insulation integrated board, which includes the following steps:

[0142] S1: The base layer to be constructed is cleaned up;

[0143] S2: Node strengthening processing;

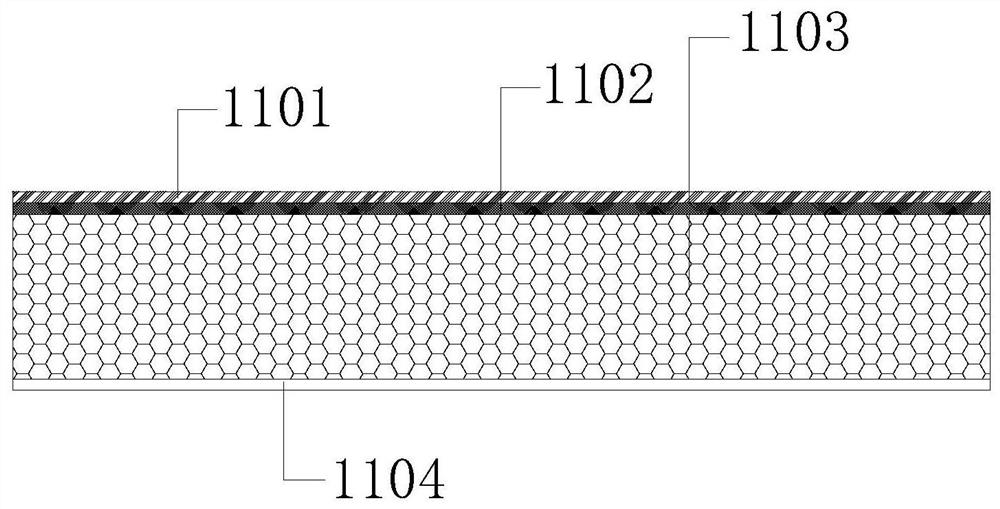

[0144] S3: constructing waterproof paint to form a waterproof paint base 1106;

[0145] S4: deployment of bonding materials;

[0146] S5: Coating the adhesive material and laying the board;

[0147] S6: plate welding;

[0148] S7: weld inspection;

[0149] Step S5 is carried out through the laying equipment of the waterproof and thermal insulation integrated board in embodiment 1 or implementation 2, and step S5 includes:

[0150] S5.1: Place the prepared bonding material in the bonding material coating mechanism;

[0151] S5.2: The vehicle frame is driven forward by the traveling device, and the bonding material coating mechanism applies the bonding material to the waterproof coating base layer 1106;

[0152] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com