Compressive yield strength test method for material

A technology of compressive yield strength and test method, applied in the field of material compressive yield strength test, can solve the problem of inability to obtain accurate room temperature compressive yield strength and material high temperature stress-strain curve, affecting the accuracy of test data, stability and neutrality. and other problems to achieve the effect of improving the validity of test data, saving test time, and optimizing neutrality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

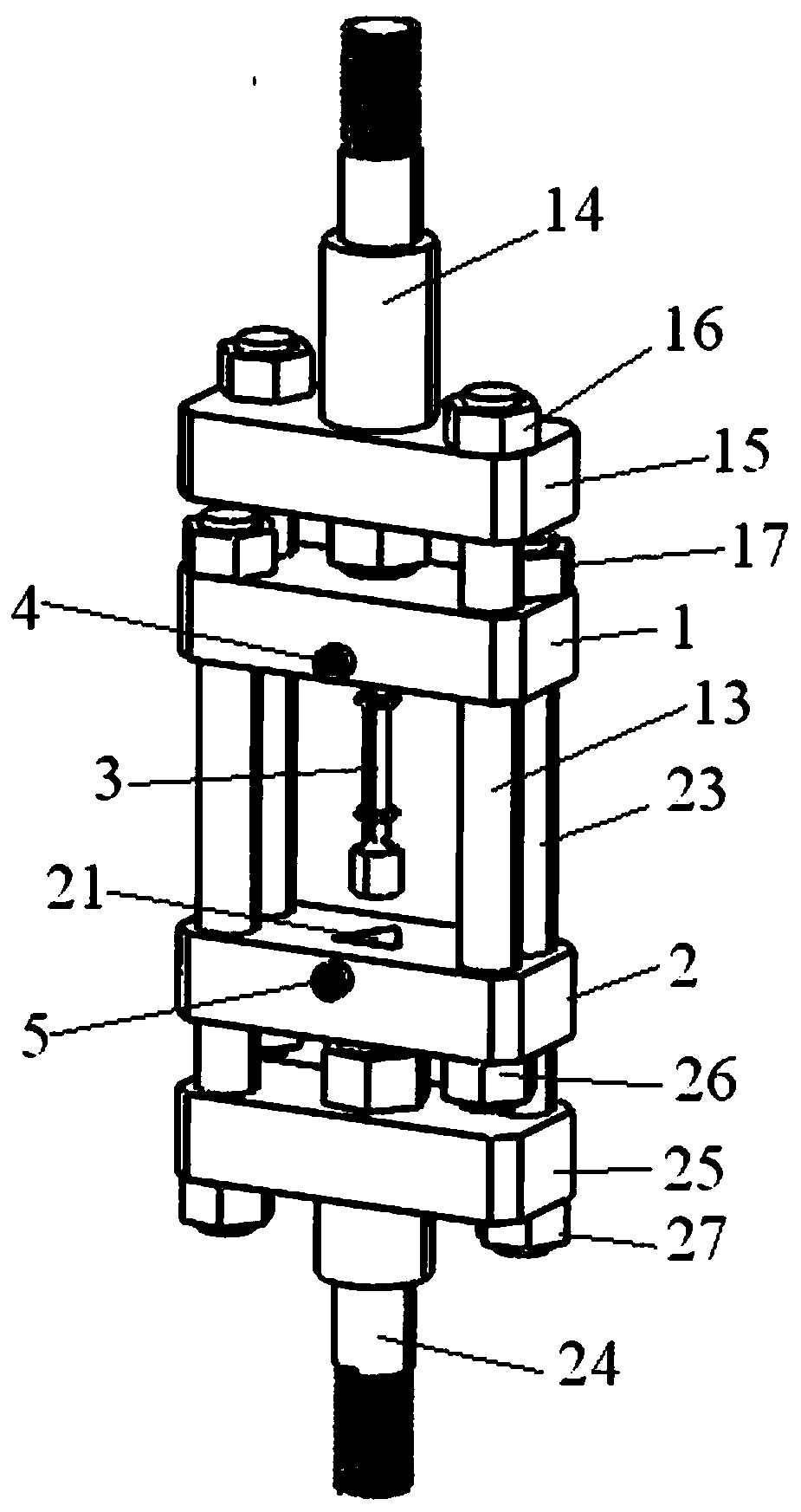

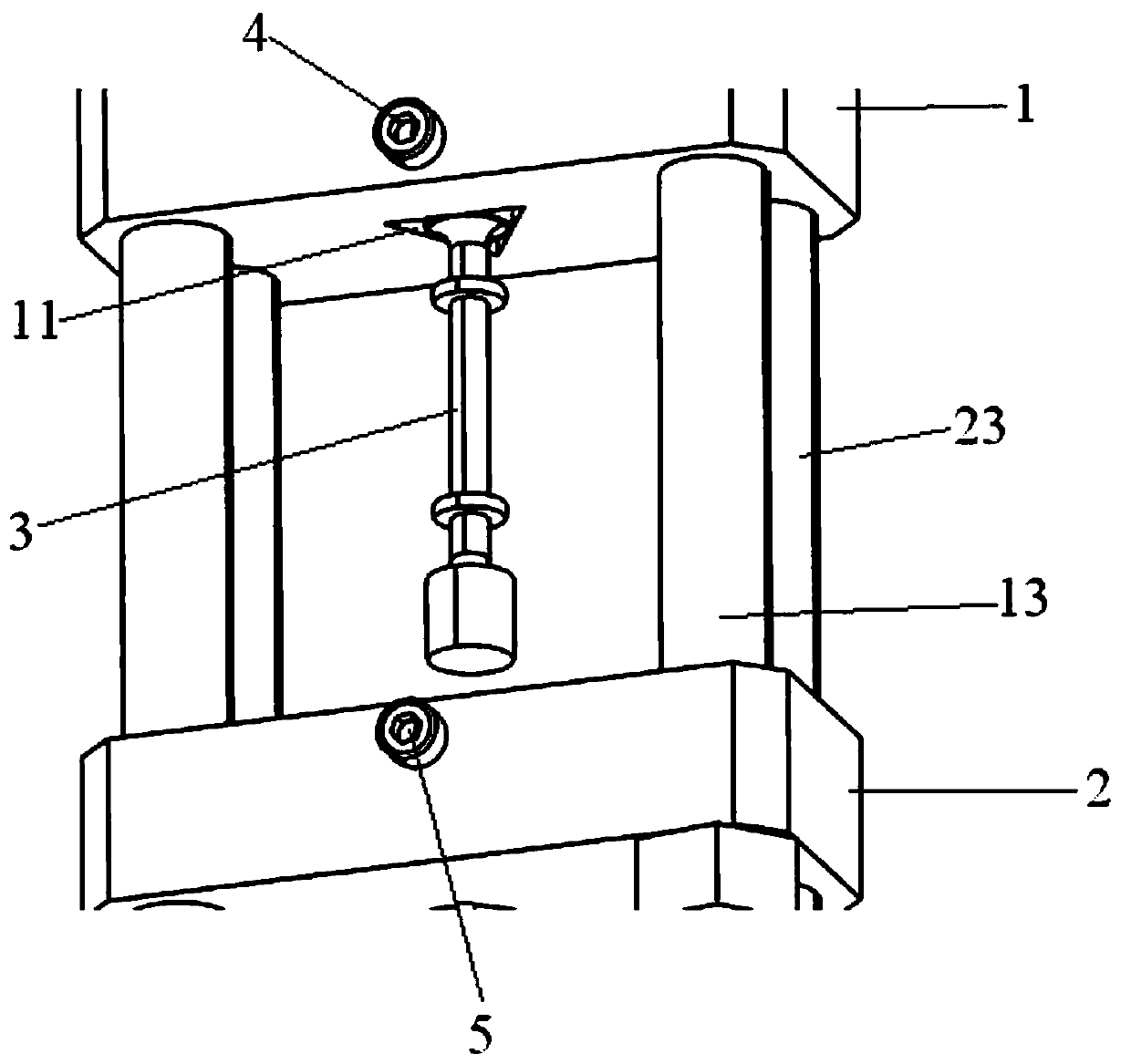

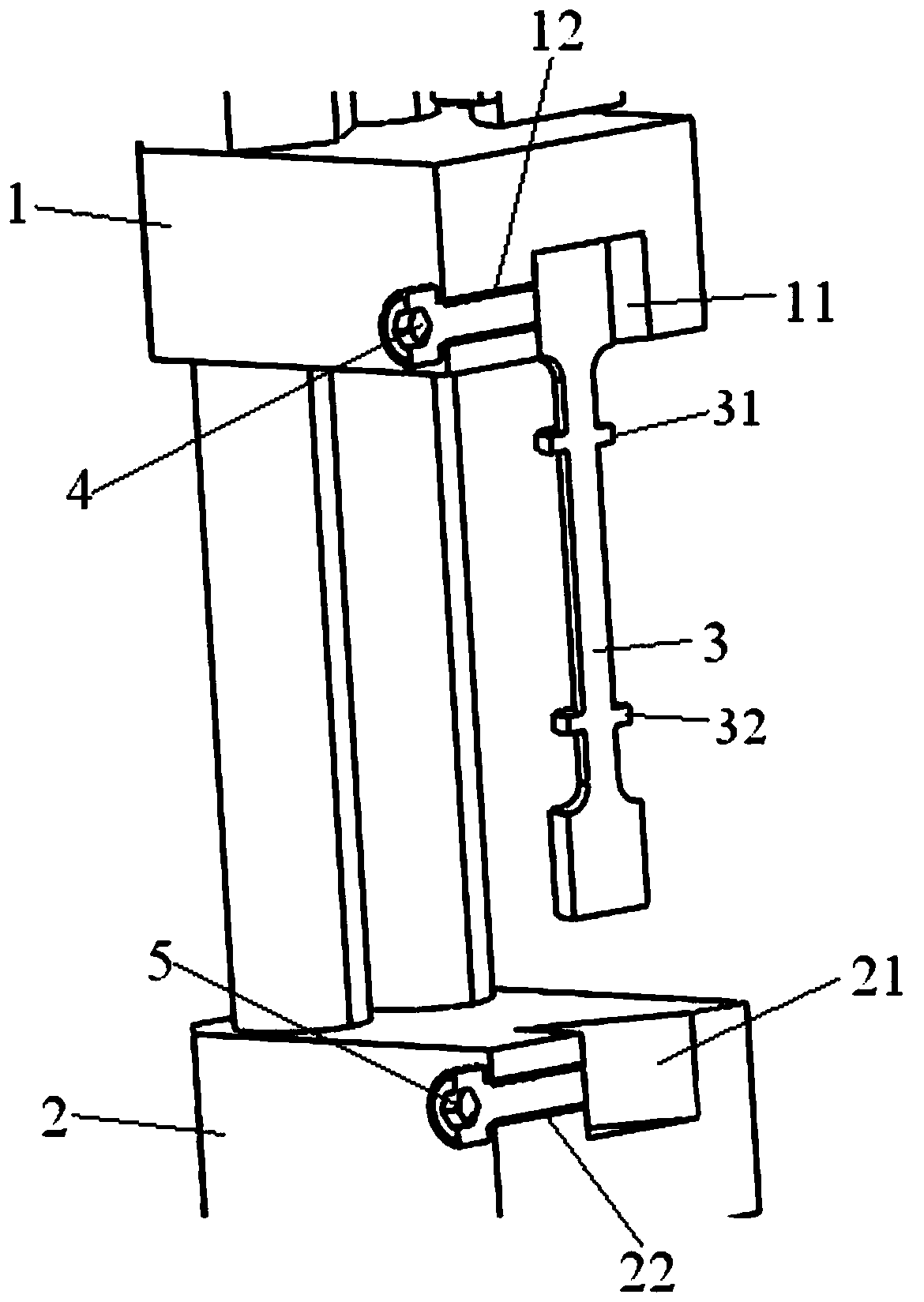

[0040] see Figure 1 ~ Figure 3 A method for testing material compressive yield strength, including using a universal testing machine and a compression fixture to carry out a normal temperature compressive loading test on the material;

[0041] The compression fixture includes a tightening part 1, a tightening part 2 5 and a commutator for connecting between the upper and lower connectors of the universal testing machine (that is, the upper connector and the lower connector, not shown in the figure). The device includes an upper briquetting block 1 and a lower briquetting block 2, and there is a distance between the upper briquetting block and the lower briquetting block along the tensile direction of the universal testing machine for installing the sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com