A handling robot

A handling robot and robot technology, applied in the field of handling robots, can solve the problems of wafer breakage, wafer wear, and high friction, and achieve the effects of preventing breakage, reducing gap height, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

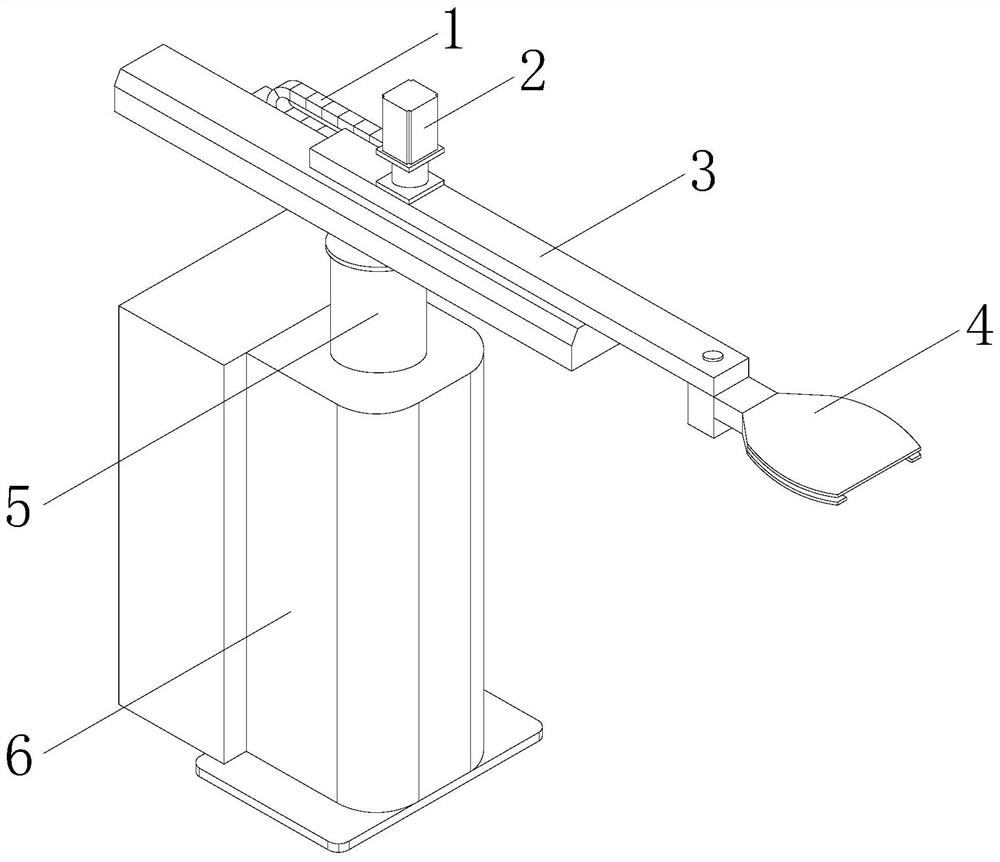

[0024] as attached figure 1 to attach Figure 6 Shown:

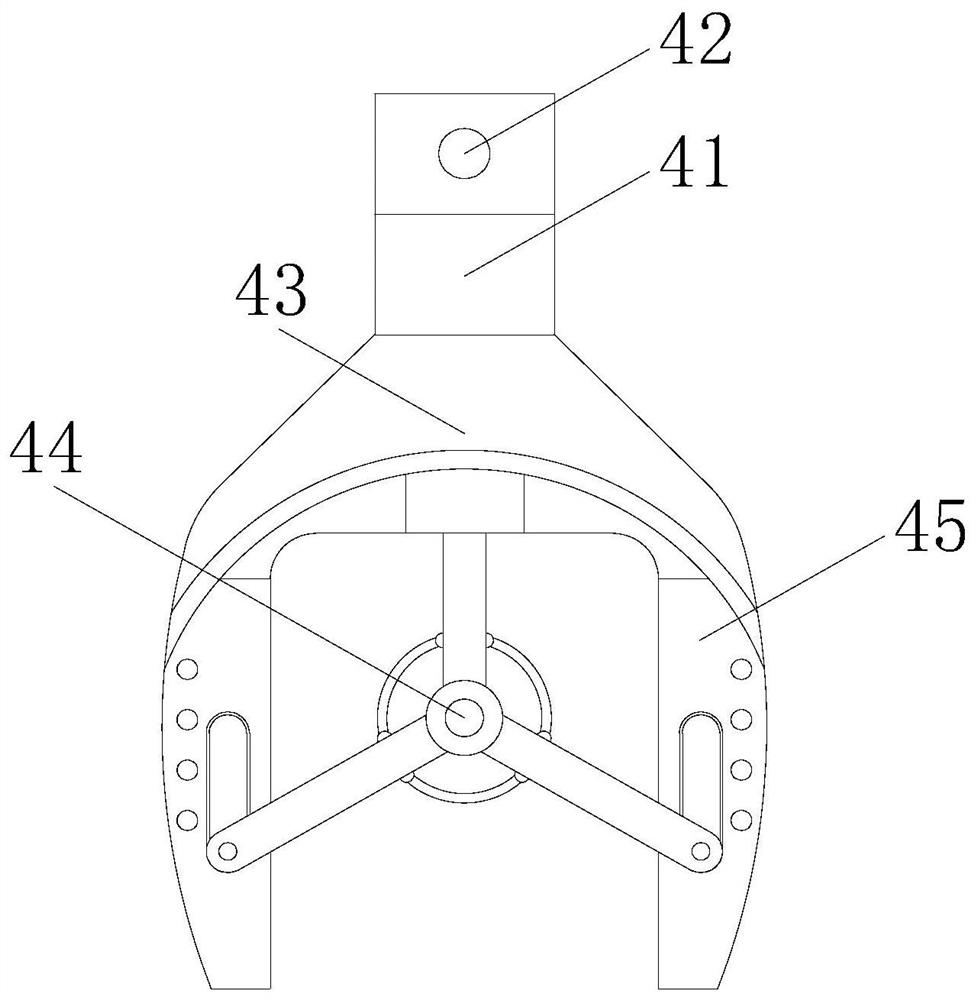

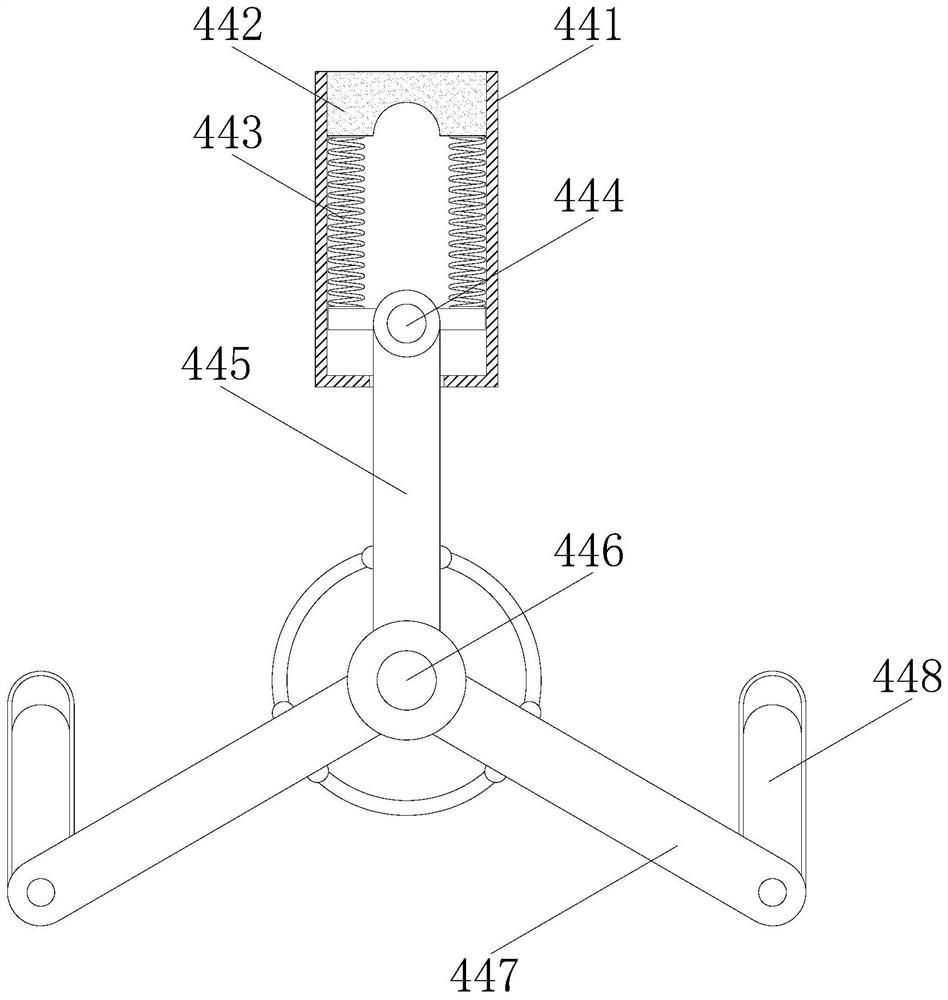

[0025] A kind of handling robot of the present invention, its structure comprises transmission belt 1, motor 2, support arm 3, clip hand 4, rotating shaft 5, robot host 6, described transmission belt 1 rotates synchronously with the output end of motor 2, and described motor 2 is installed on the top of the support arm 3, and the front end of the support arm 3 is provided with a clamping hand 4, the bottom of the support arm 3 is embedded with the top of the rotating shaft 5, and the rotating shaft 5 is installed on the top of the robot host 6, and the clamping hand 4 includes a support plate 41, a drive shaft 42, a limit interference frame 43, a supporting mechanism 44, and an outer edge interference mechanism 45. The support plate 41 is connected to the front end shaft of the support arm 3 through the drive shaft 42, and the lower end of the support plate 41 It is welded with the limit interference frame 43 and is an...

Embodiment 2

[0033] as attached Figure 7 to attach Figure 8 Shown:

[0034] Wherein, the outer edge interference mechanism 45 includes a bracket 45a, a squeeze plate 45b, a telescopic hose 45c, a transmission pipe 45d, and an air bag mechanism 45e. An extruding plate 45b is arranged inside, and the lower end of the extruding plate 45b is provided with a telescopic hose 45c, and the lower end of the extruding hose 45c communicates with the inside of the airbag mechanism 45e through a transmission pipe 45d, and the extruding plate 45b is in an arc-shaped structure , matches the diameter of the sliding shaft 48a, which is beneficial for the sliding shaft 48a to be tightly squeezed with the extrusion plate 45b in the process of sliding down. Resilience is beneficial to squeeze and shrink the telescopic hose 45c to generate a certain air pressure.

[0035] Wherein, the air bag mechanism 45e includes a fixed ring e1, an air bag membrane e2, and a conduction tube e3, the interior of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com