Seal head structure part welding dislocation control tool and assembling method

A technology for structural parts and tooling, which is applied in the field of welding and manufacturing of ultra-high-strength steel pressure-bearing structural parts, can solve the problems of dislocation and deformation of circumferential seam welding on the end face of the front head, achieve satisfactory weld quality, reduce welding dislocation deformation, and improve The effect of clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

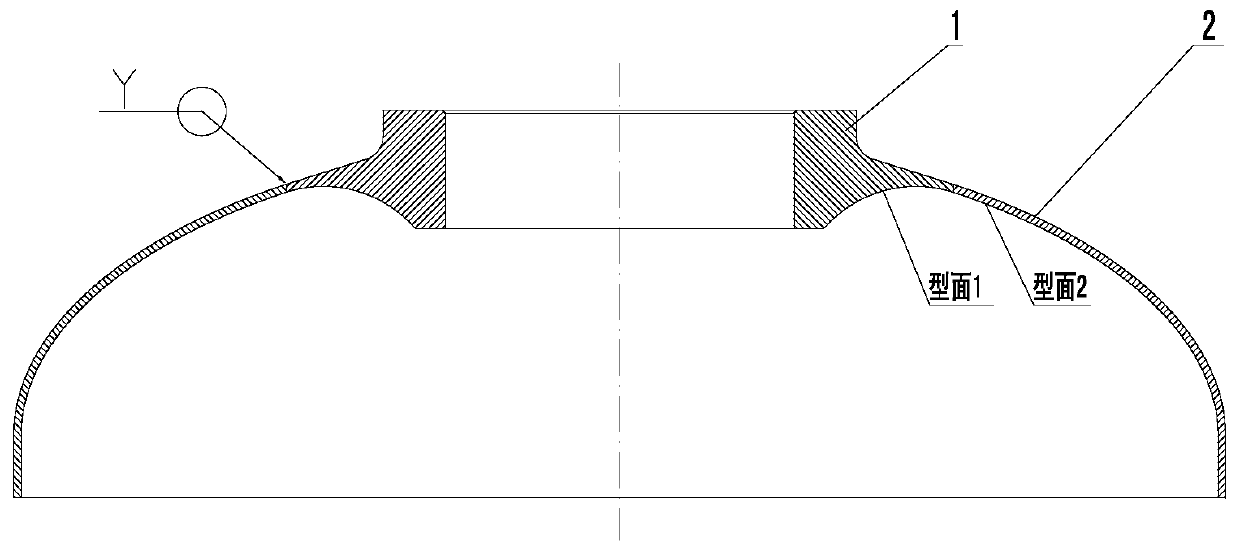

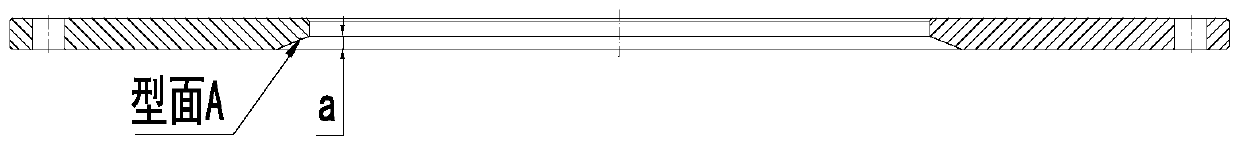

[0022] In order to achieve the purpose of controlling and solving the welding dislocation and deformation of the front head structure of the engine, the present invention designs a tooling fixture. According to the dislocation deformation rule of the front head after welding, when assembling the front joint and the hemisphere, the structure of the tooling itself is used to adjust the butt joint dislocation. Reserve a certain amount of misalignment before, increase the positioning solder joints, and increase the degree of restraint. The assembly positioning method reduces the misalignment deformation after welding.

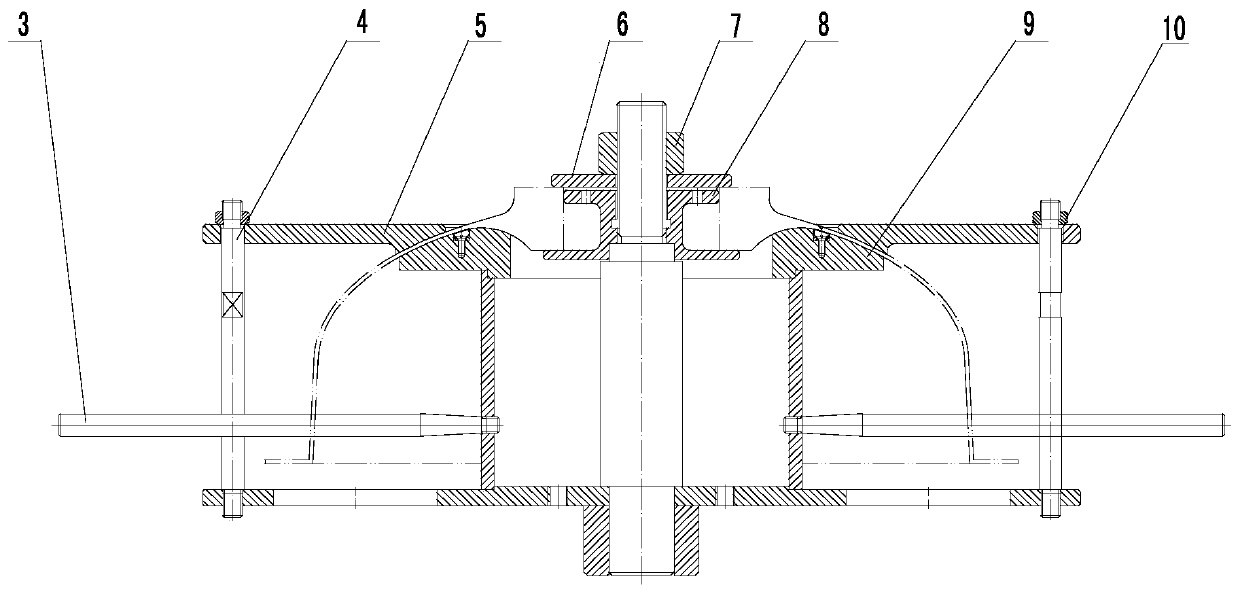

[0023] figure 2 It is a schematic diagram of the fixture structure, which is mainly composed of a handle (detachable without affecting welding), compression nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com