Wind power self-cleaning device for insulator

An insulator and wind power technology is applied in the field of automatic cleaning devices for contamination on the outer surface of power insulators, which can solve the problems of poor cleaning effect and unreasonable structure of the cleaning device, achieve automatic cleaning, avoid pollution flashover accidents, and improve operation safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

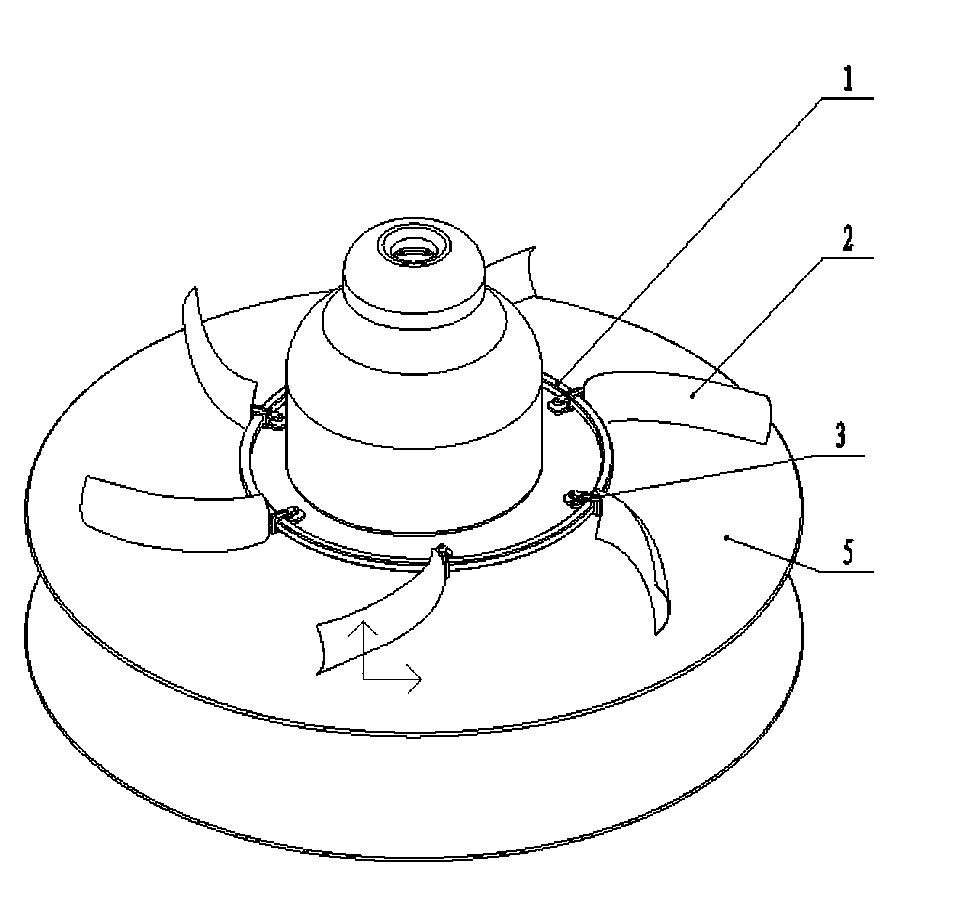

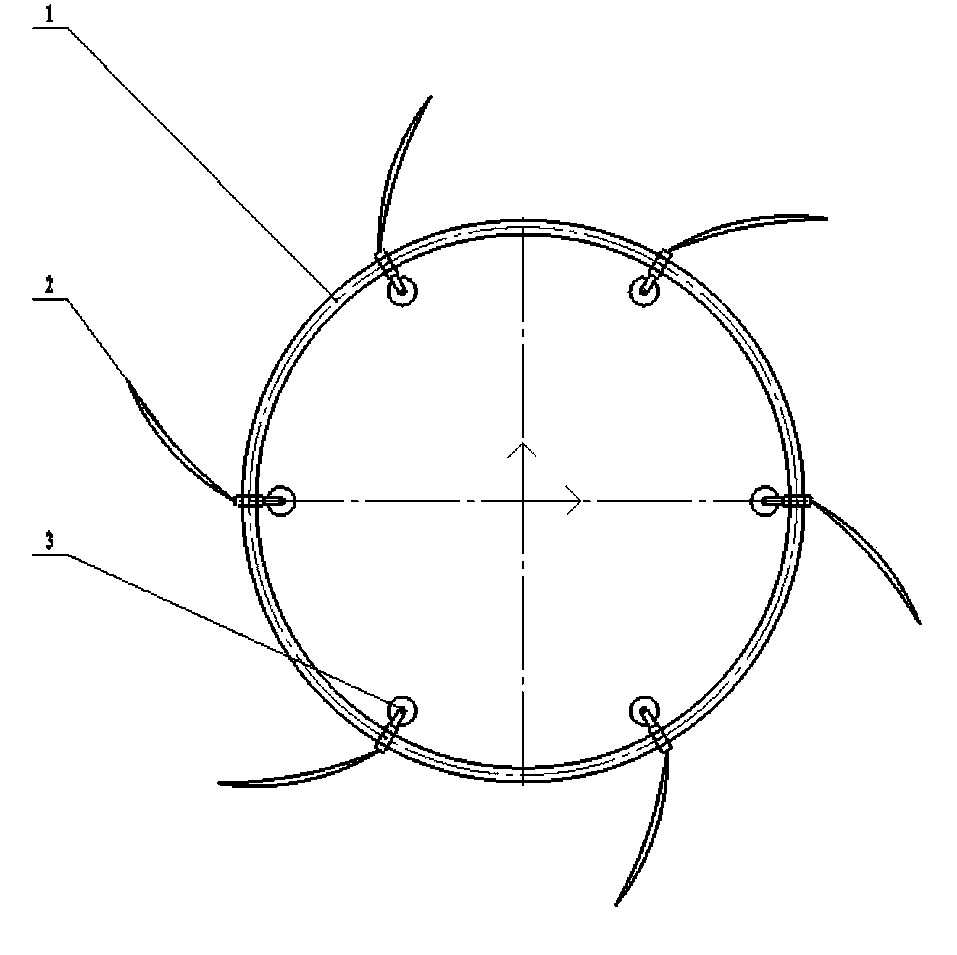

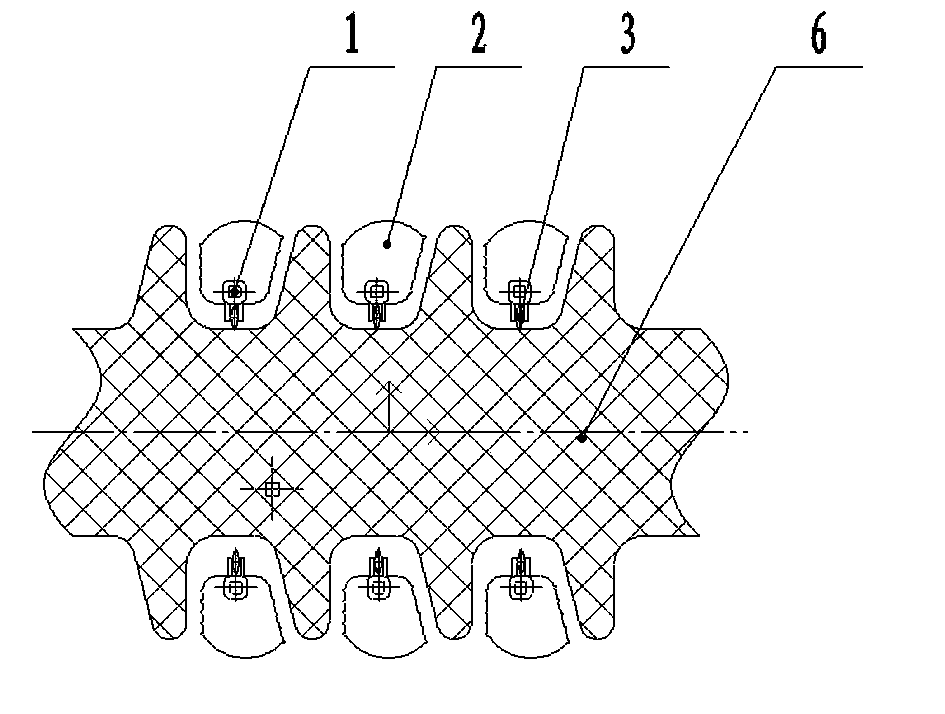

[0020] Such as figure 2 As shown, the circular ring 1 is a rigid ring made of insulating material. On the outer edge of the circular ring 1, there are six (the number can be increased or decreased) fixedly connected to the outer edge of the circular ring 1 along the circumference. The wind guide blade 2 is provided with a number of roller frames on the inner edge of the circular ring 1, and a horizontal roller 3 is installed on each roller frame. The wheel edge of the roller 3 protrudes from the roller frame to contact the insulator form rolling friction.

[0021] Depend on figure 1 It can be seen that the centrifugal wind guide vane 2 made of insulating material is a long sheet-shaped body with a concave arc surface, its shape is arc-shaped, and its cross-section is arc-shaped. Figure 4 Among them, the connecting end on the left side of the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com