Conveyor line flow-combination mechanism

A conveyor line and reset mechanism technology, applied in the field of hanging conveyor lines, can solve problems such as the inability to use hooks to carry the assembly line, and achieve the effects of simple and reliable structure, guaranteed connection reliability, and reduced component settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

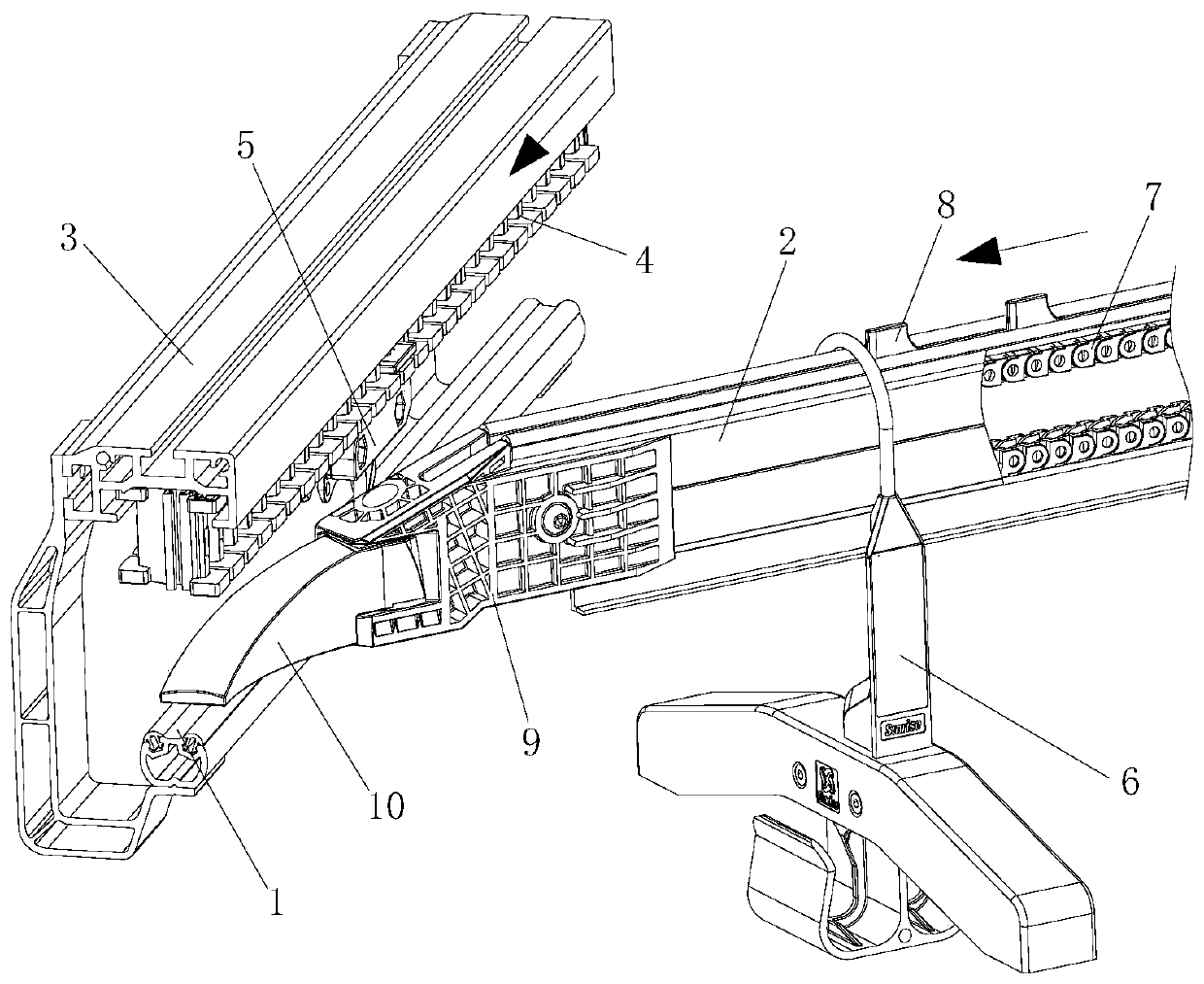

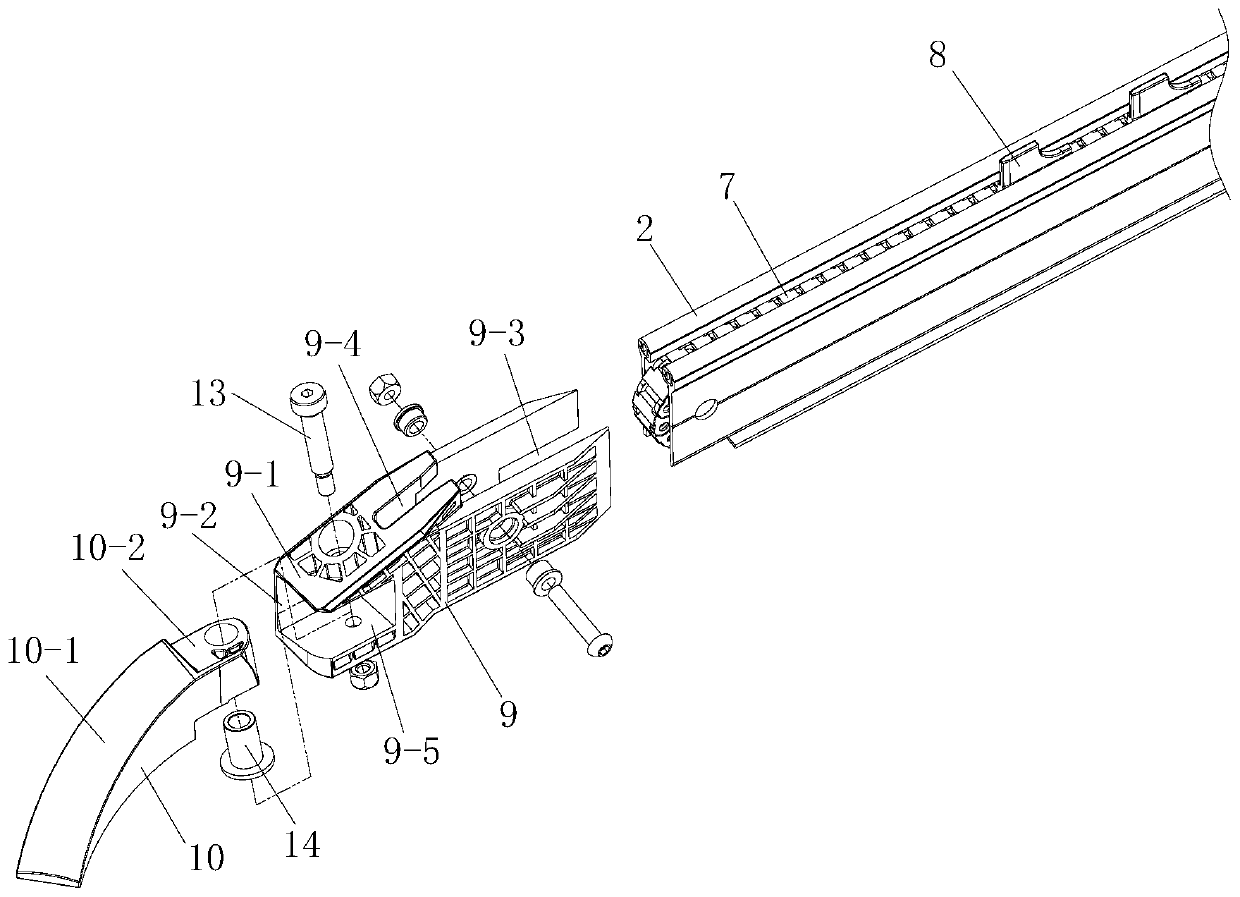

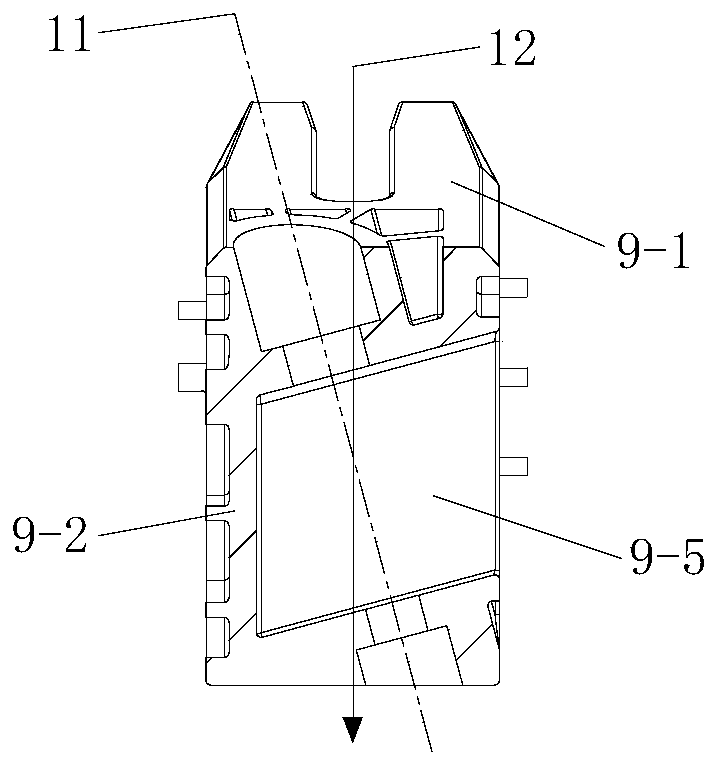

[0021] Such as Figure 1-5 As shown, the conveying line has a main rail 1 and a branch rail 2, and the branch rail 2 is arranged on one side of the main rail. A vehicle driving line is provided above the main rail 1, including a driving rail 3, a rack assembly 4 installed on the driving rail 3, and a tow hook 5 installed below the rack assembly 4. The carrier 6 can be hung on the main rail 1 and pushed forward by the tow hook 5 . There is a chain drive assembly inside the branch rail 2, the chain drive assembly includes a chain 7, the chain 7 is driven by the sprockets at both ends of the branch rail, a number of push rods 8 are installed on the chain 7, and the push rods 8 run in the middle groove of the branch rail , and expose the surface of the rail 2, so that the carrier 6 hanging on the rail 2 can be pushed forward. It is foreseeable that the branch rail 2 can also adopt the same structure as the main rail 1 .

[0022] The merging mechanism includes a fixed seat 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com