Slag conveying device of biomass gas furnace

A biomass gas and conveying device technology, which is applied in the treatment of combustion products, combustion methods, and removal of solid residues, etc., can solve the problems of affecting the scraping efficiency, increasing the gap, and easily tilting the scraper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

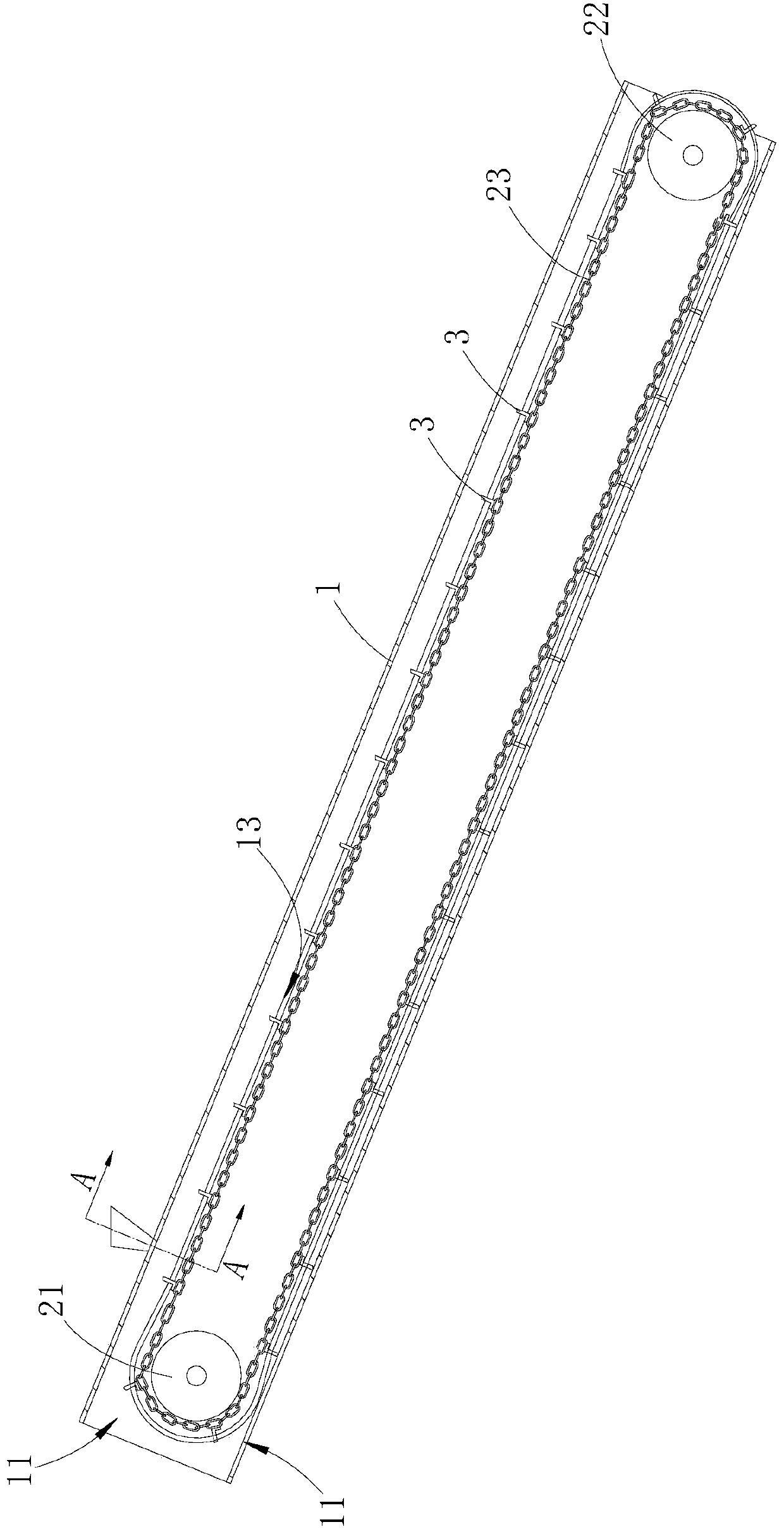

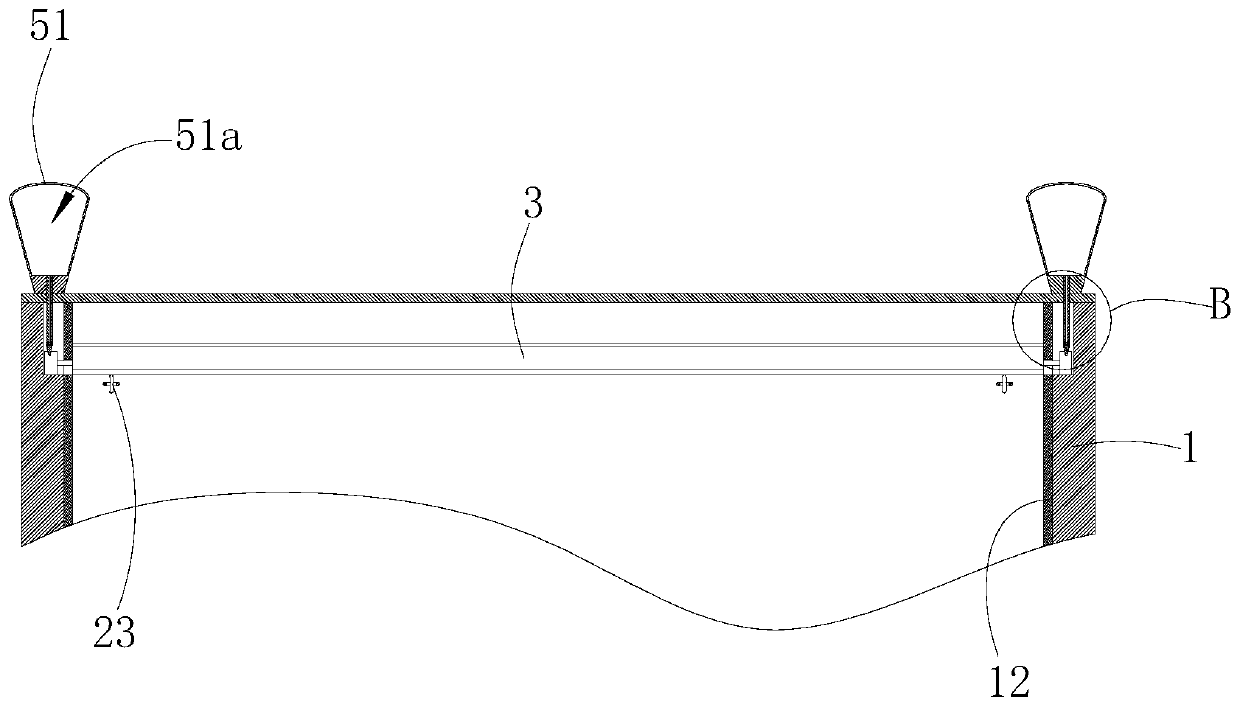

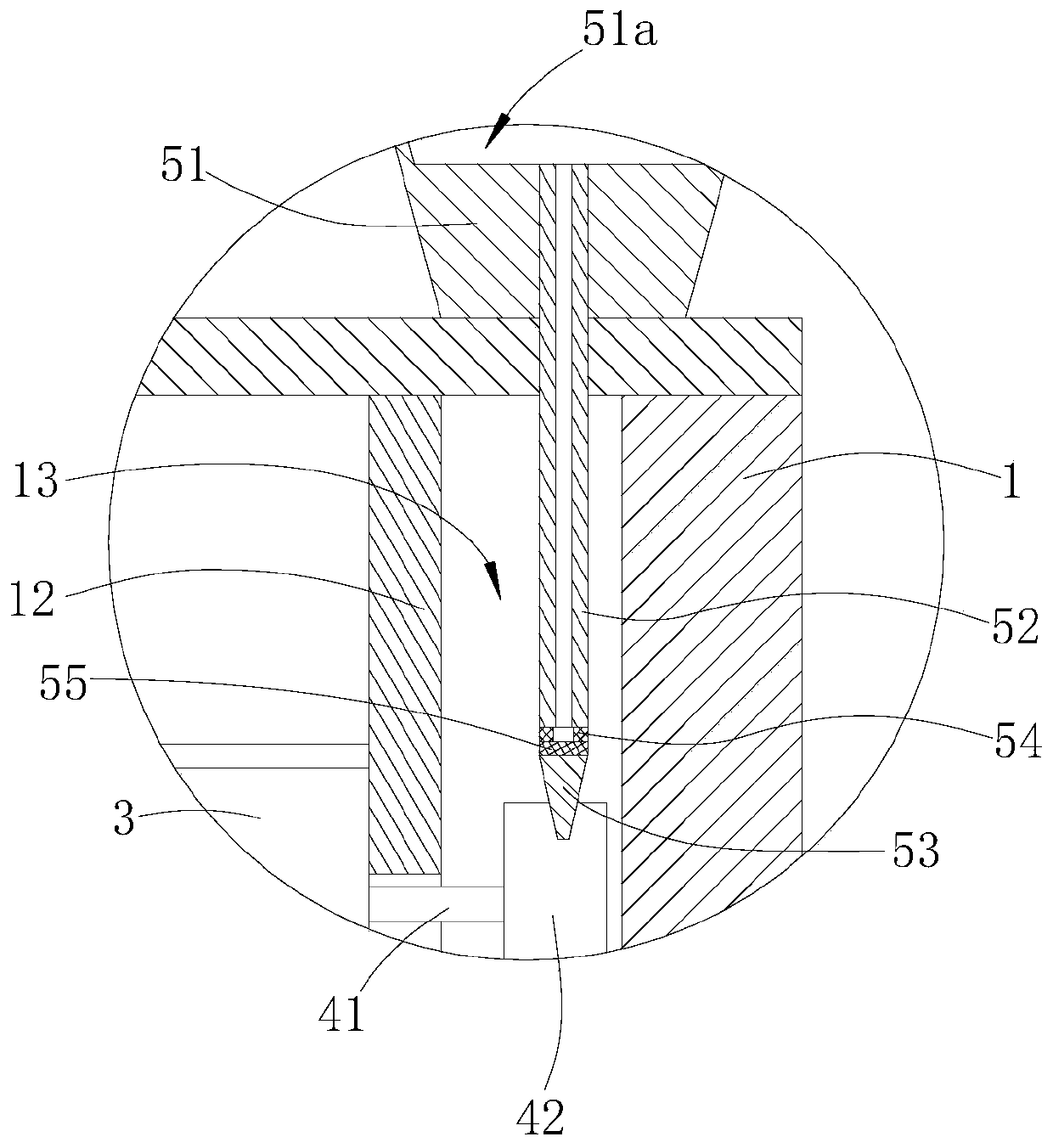

[0015] Such as Figures 1 to 3 shown

[0016] The slag conveying device includes a conveying pipeline 1 , a chain transmission mechanism, two sets of lubricating components and a plurality of scrapers 3 .

[0017] The conveying pipe 1 is a square pipe, the lower end of the conveying pipe 1 extends into the bottom of the biomass gas furnace, the upper end of the conveying pipe 1 protrudes outside the biomass gas furnace, and the bottom wall and the upper end of the upper end of the conveying pipe 1 are provided with a slag outlet 11 for discharging slag .

[0018] The chain transmission mechanism includes a driving roller 21, a driven roller 22 and two chains 23. The two chains 23 are tensioned outside the driving roller 21 and the driven roller 22. The driving roller 21 is driven by an external motor, and multiple scrapers 3 are sequentially Welded on the two chains 23 at intervals, the movement track of the end of the scraper 3 is in contact with the lower inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com