A liquid rocket engine pump screw wheel set bearing cooling structure

A liquid rocket and cooling structure technology, which is applied to rocket engine devices, bearing cooling, machines/engines, etc., can solve the problems of loss of high-pressure medium energy, increase of engine weight, and difficulty in product processing, so as to reduce fluid energy loss and reduce weight , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

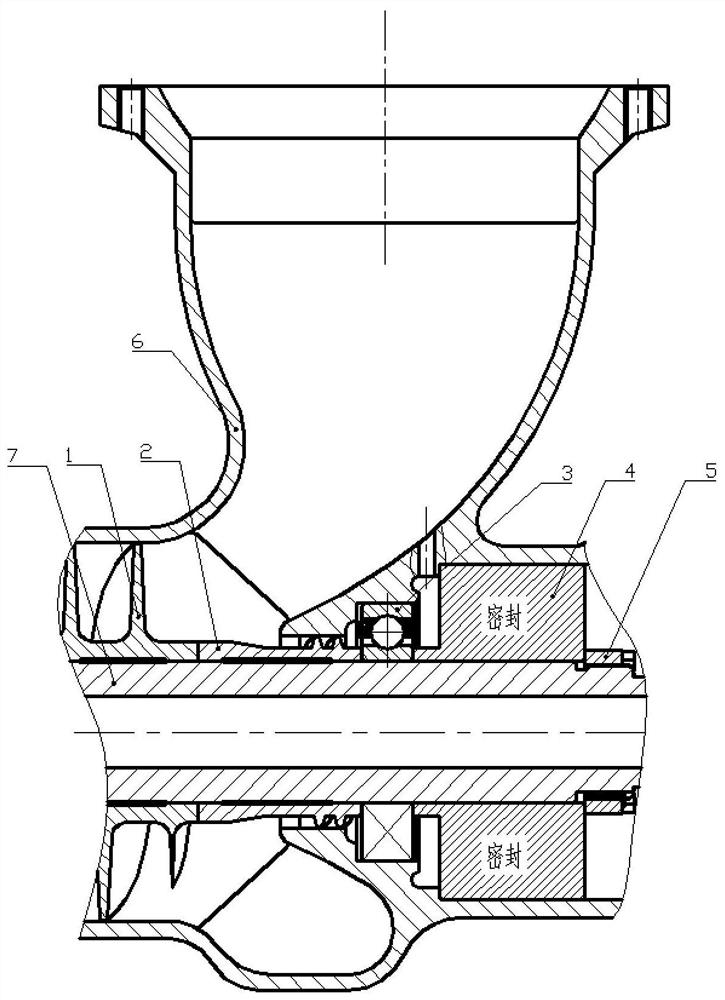

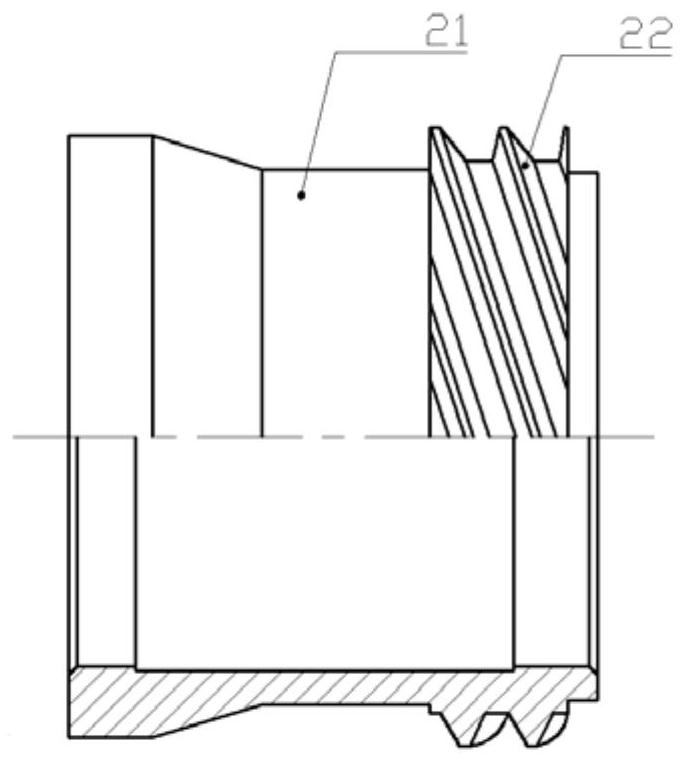

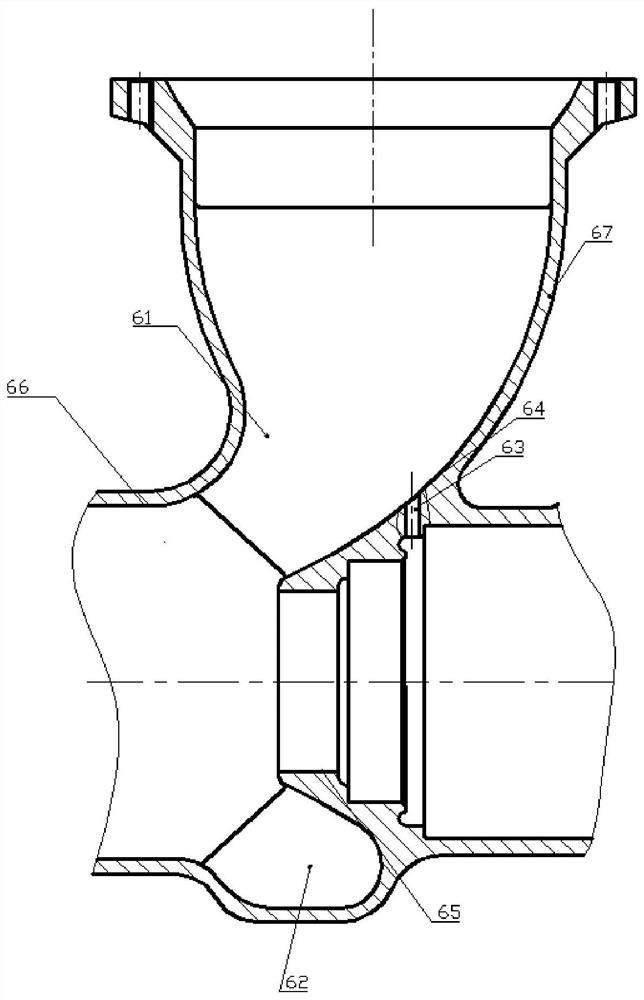

[0042] The invention relates to a liquid rocket engine pump spiral wheel pair bearing cooling structure, comprising: an induction wheel (1), a spiral wheel (2), a bearing (3), a seal (4), a shaft end compression nut (5), an inlet Housing (6) and shaft (7); inlet housing (6), including: inlet section (67) and ring section (68); ring section (68), including: outlet section, transition section and bearing cooling section; The inner cavity of the transition section of the annular section (68) is provided with a through hole (63) on the side close to the cooling section of the bearing; the liquid medium enters the inlet housing (6) from the inlet section (67) and flows out from the outlet section. , the shaft (7) drives the helical wheel (2) to rotate, generating a suction force, pumping part of the liquid medium passing through the transit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com