Sorting machine discharge port for preventing material residues and dust from accumulating

A technology of discharge port and sorting machine, which is applied in sorting, dust removal, chemical instruments and methods, etc., can solve problems such as inability to suction, increase of sorting machines, and blockage of suction holes, so as to save materials , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

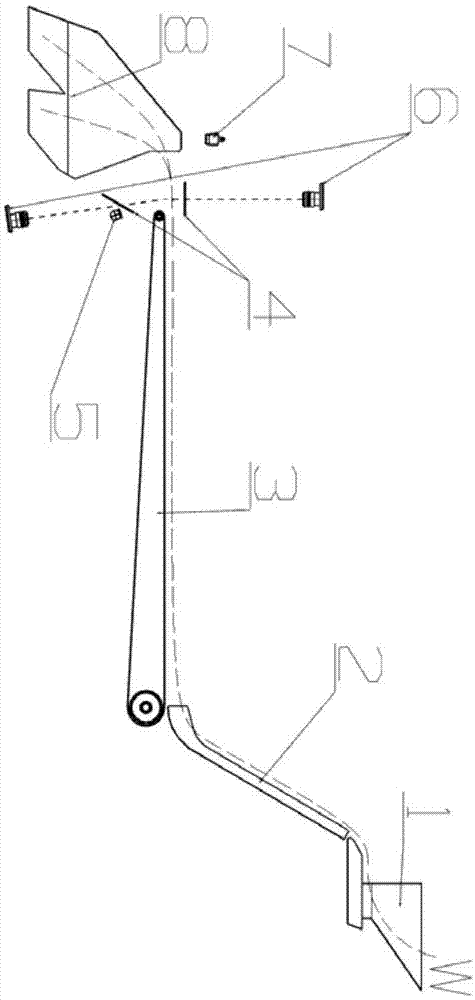

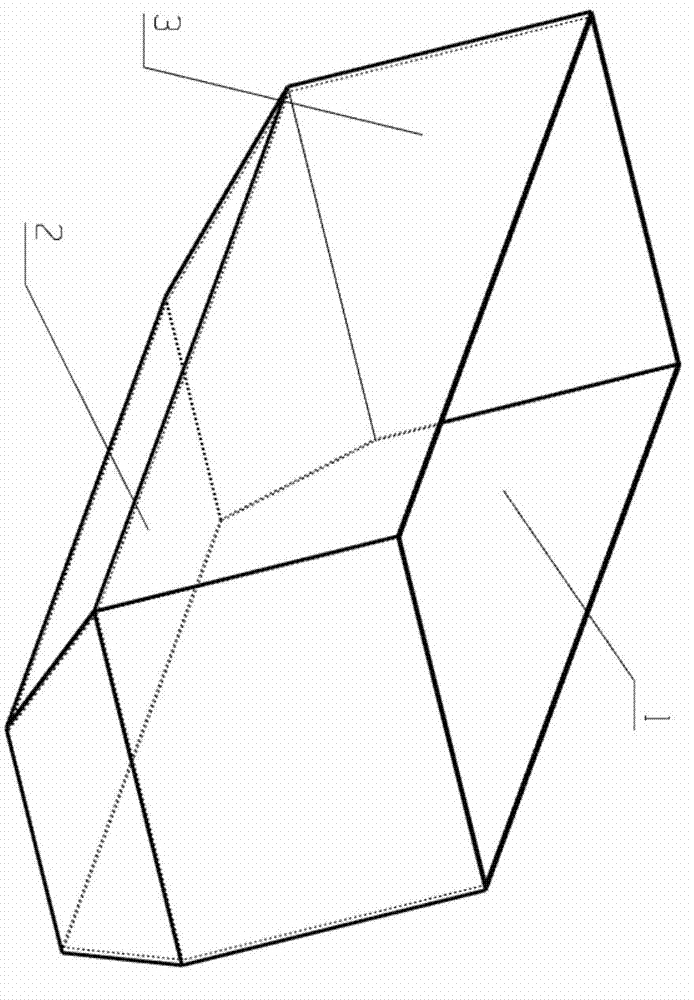

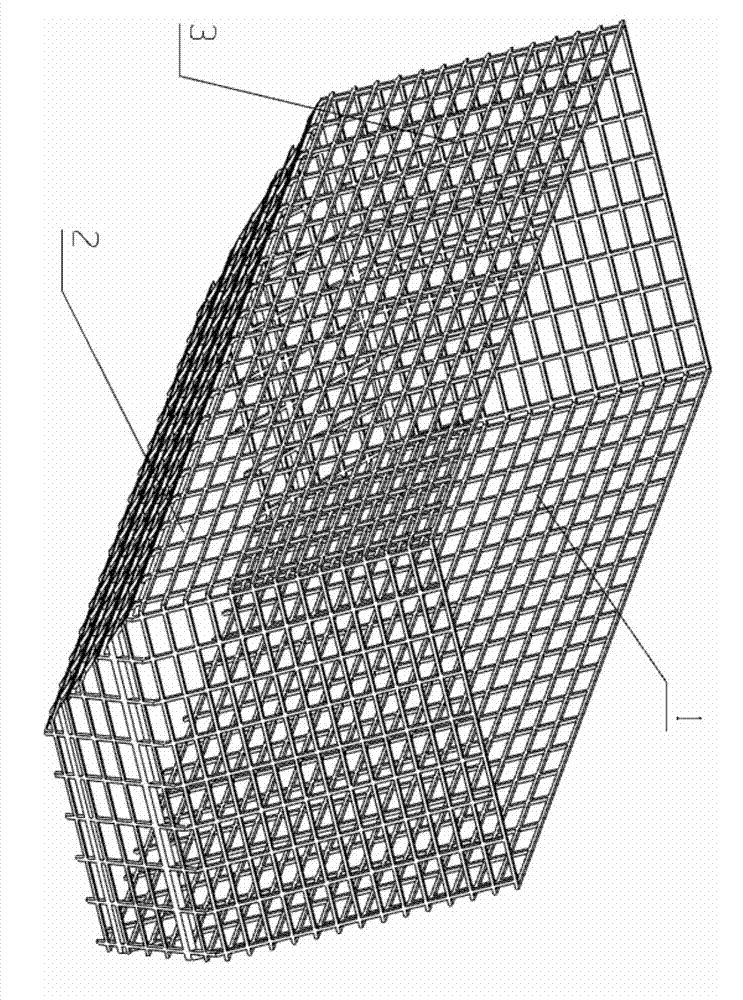

[0022] Combine below image 3 An embodiment of the outlet of the sorter according to the present invention will be introduced.

[0023] image 3 is a schematic diagram briefly showing the outlet of the classifier of this embodiment.

[0024] The discharge port of the sorter in this embodiment is used to pick up specific materials, which contain more residue and dust.

[0025] like image 3 As shown, the wall surface of the discharge port of the separator is designed as a grid wall surface 3 . In this embodiment, the discharge port is applied to the garlic sorting machine, and the size of the garlic cloves is about 2 (cm) x 1.5 (cm), so the grid is designed as a rectangle of 1.5 (cm) x 1 (cm), which Smaller in size than most garlic cloves, but allows the passage of most peeled garlic skins (matter residue) and dust. The material residue enters the outlet channel from the material inlet 1 along with the material, and is discharged from the material outlet 2.

[0026] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com