Sealed steel wire rope drive system

A transmission system and wire rope technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of radioactive harmful gas leakage, operator injury, poor sealing, etc. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

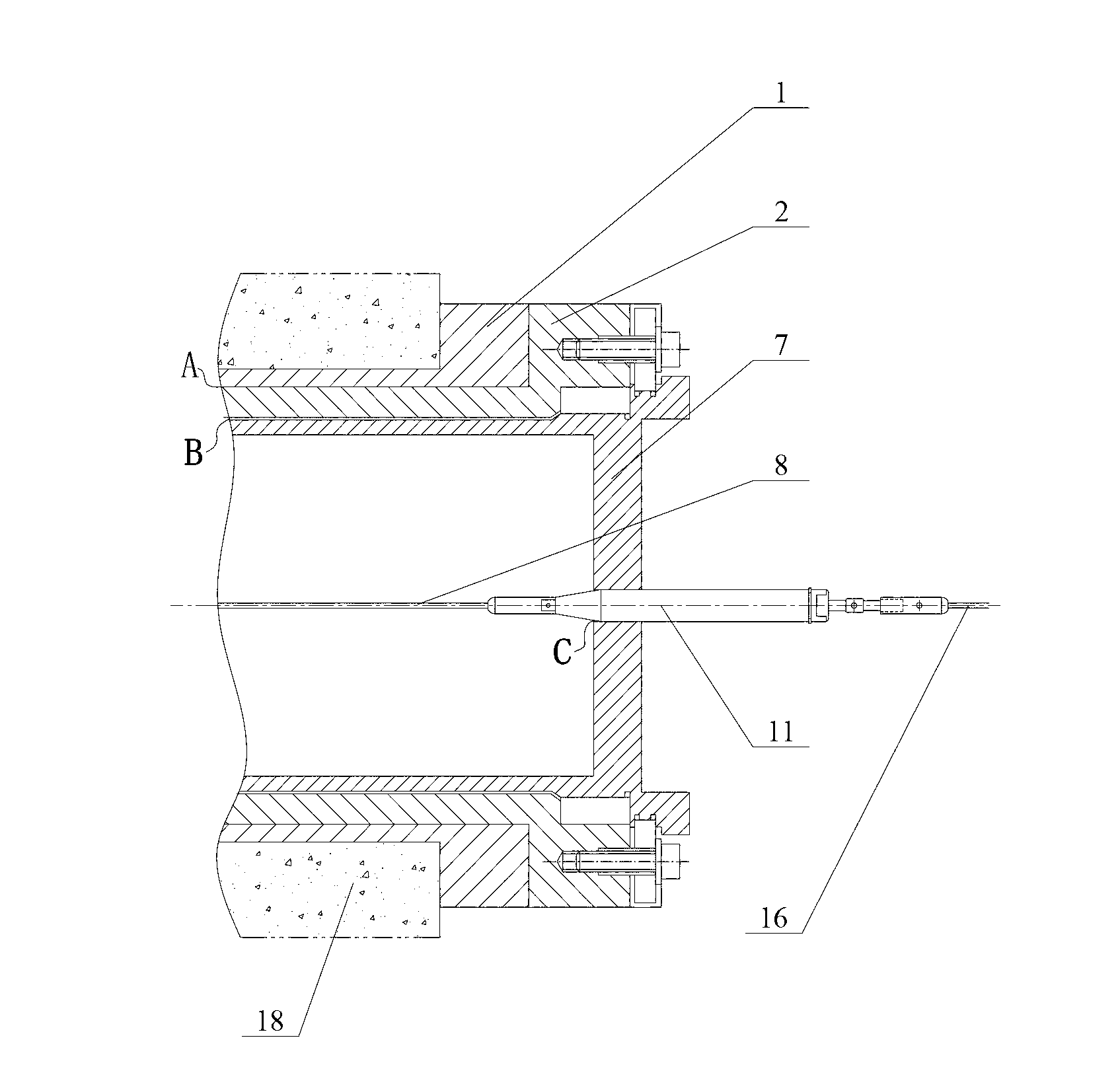

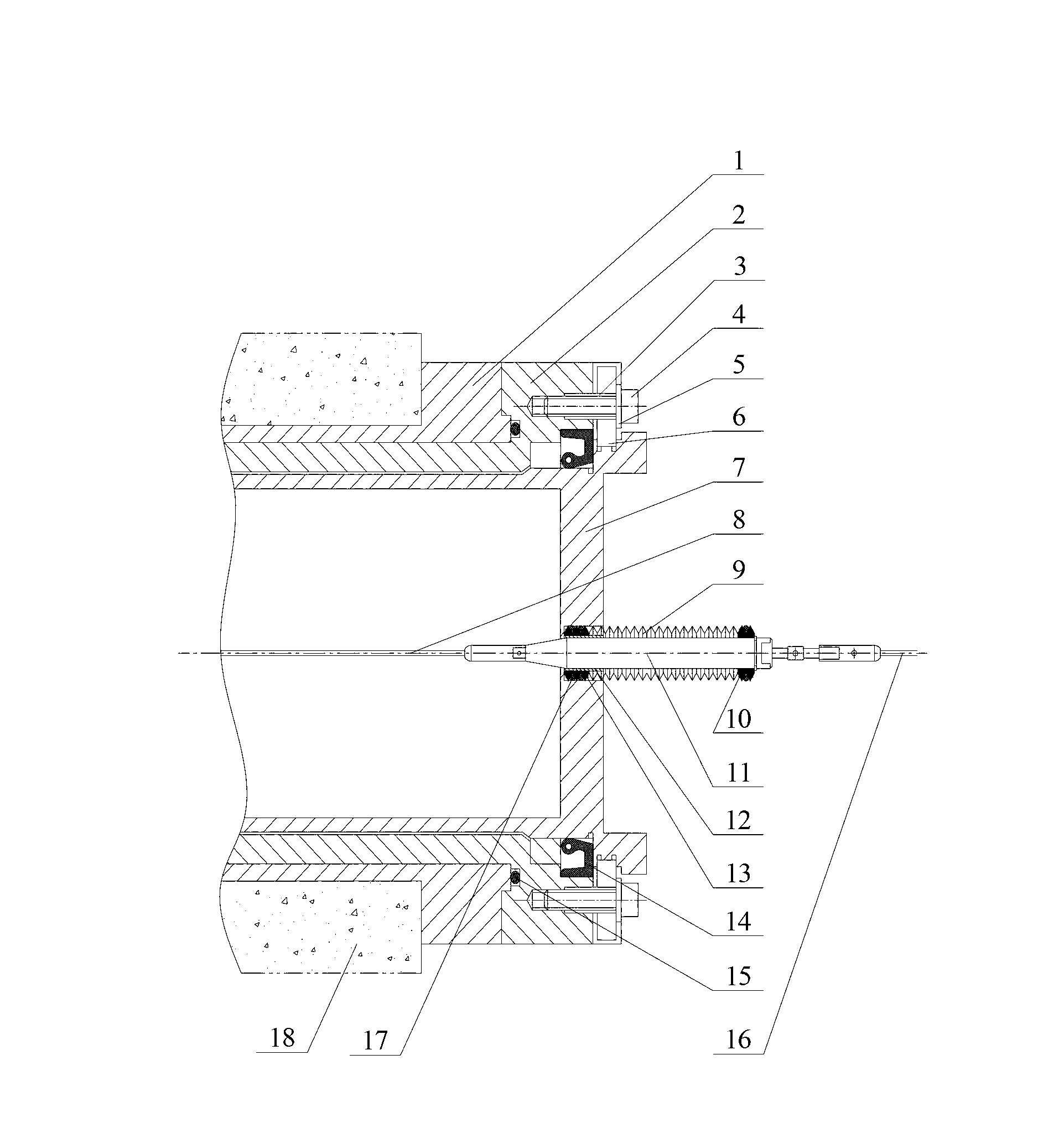

[0022] The steel wire rope sealed transmission system of the present invention is mainly used for transmission connection between the active mechanical arm outside the hot room and the driven mechanical arm inside the hot room. The indoor steel wire rope and the outdoor steel wire rope in the steel wire rope sealed transmission system are connected by a connecting shaft, The suit has a bellows, one end of the bellows is sealed and fixed with the wall pipe assembly, and the other end of the bellows is sealed and fixed with the end of the connecting shaft (the end connected with the outdoor wire rope). During the axial movement of the connecting shaft, the bellows It expands and contracts with the movement of the connecting shaft, so no matter whether the connecting shaft is in motion or at rest, there is always no leakage of radioactive gases such as α aerosol, thus ensuring the safety of operators. The present invention will be further described in detail below in conjunction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com