Spherical metal shell assembling method and detection tool special for implementing same

A technology for detecting tooling and spherical shells, applied in metal processing equipment, auxiliary devices, measuring devices, etc., can solve the problems of high cost and inability to guarantee the roundness of spheres, and achieve easy operation, ensure assembly accuracy and quality, and ensure roundness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

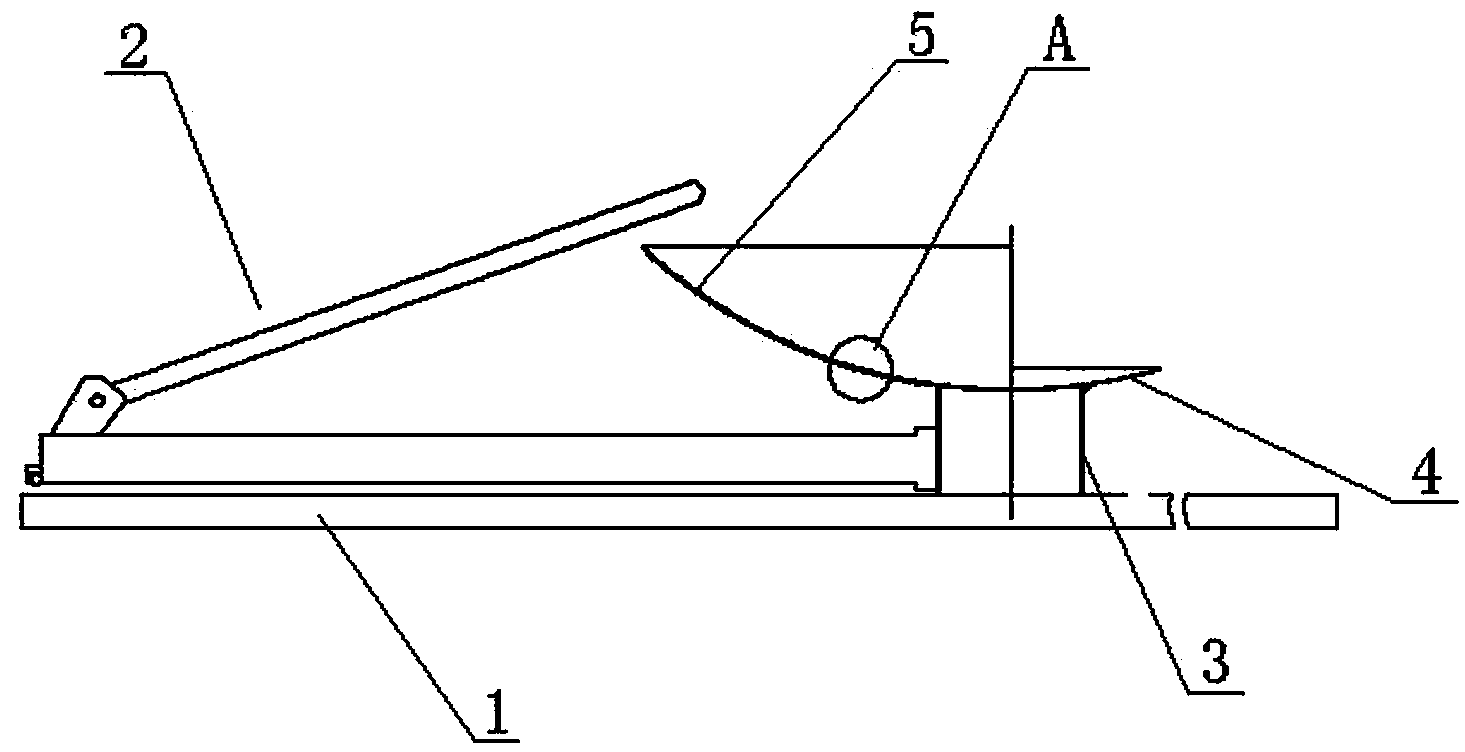

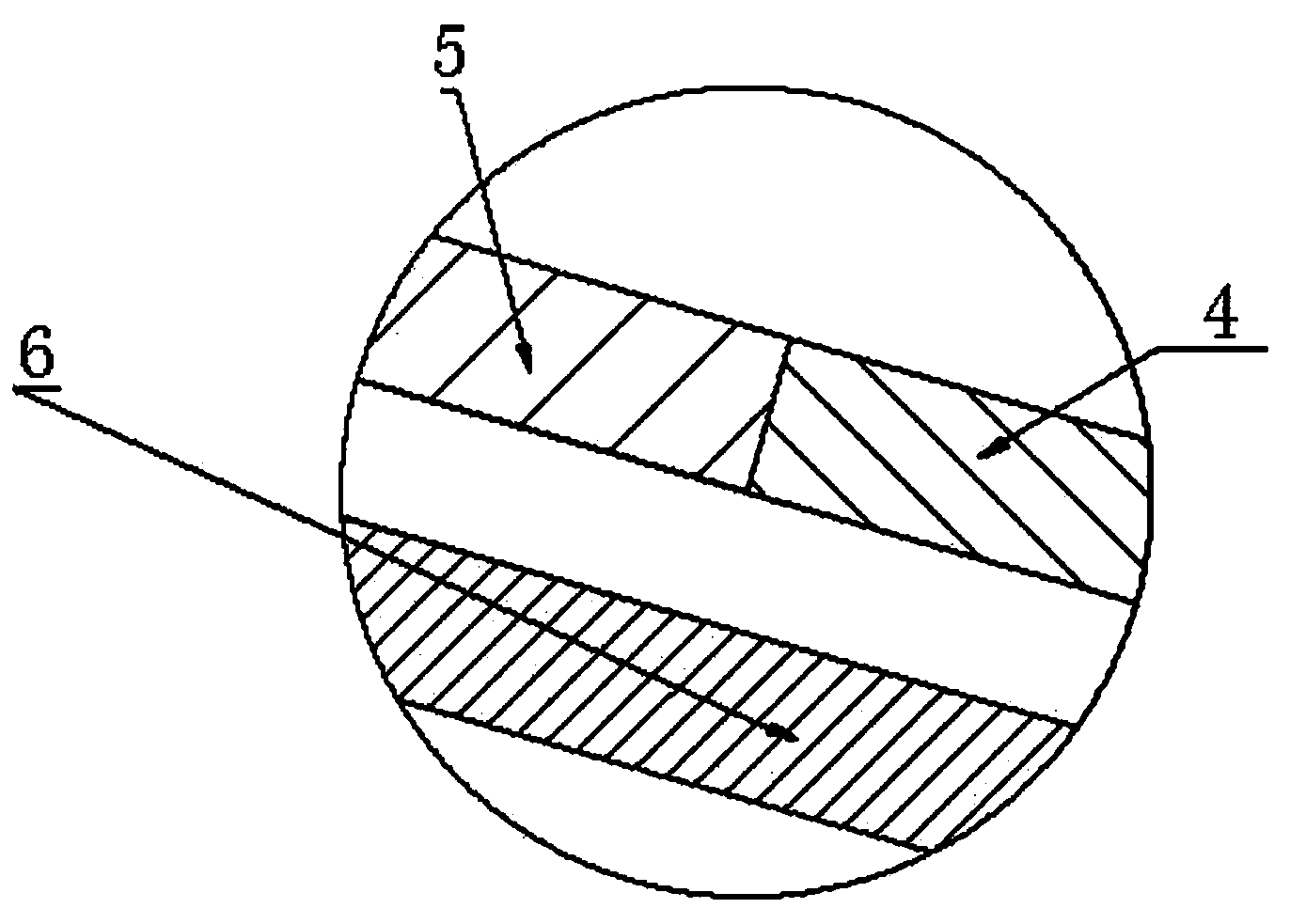

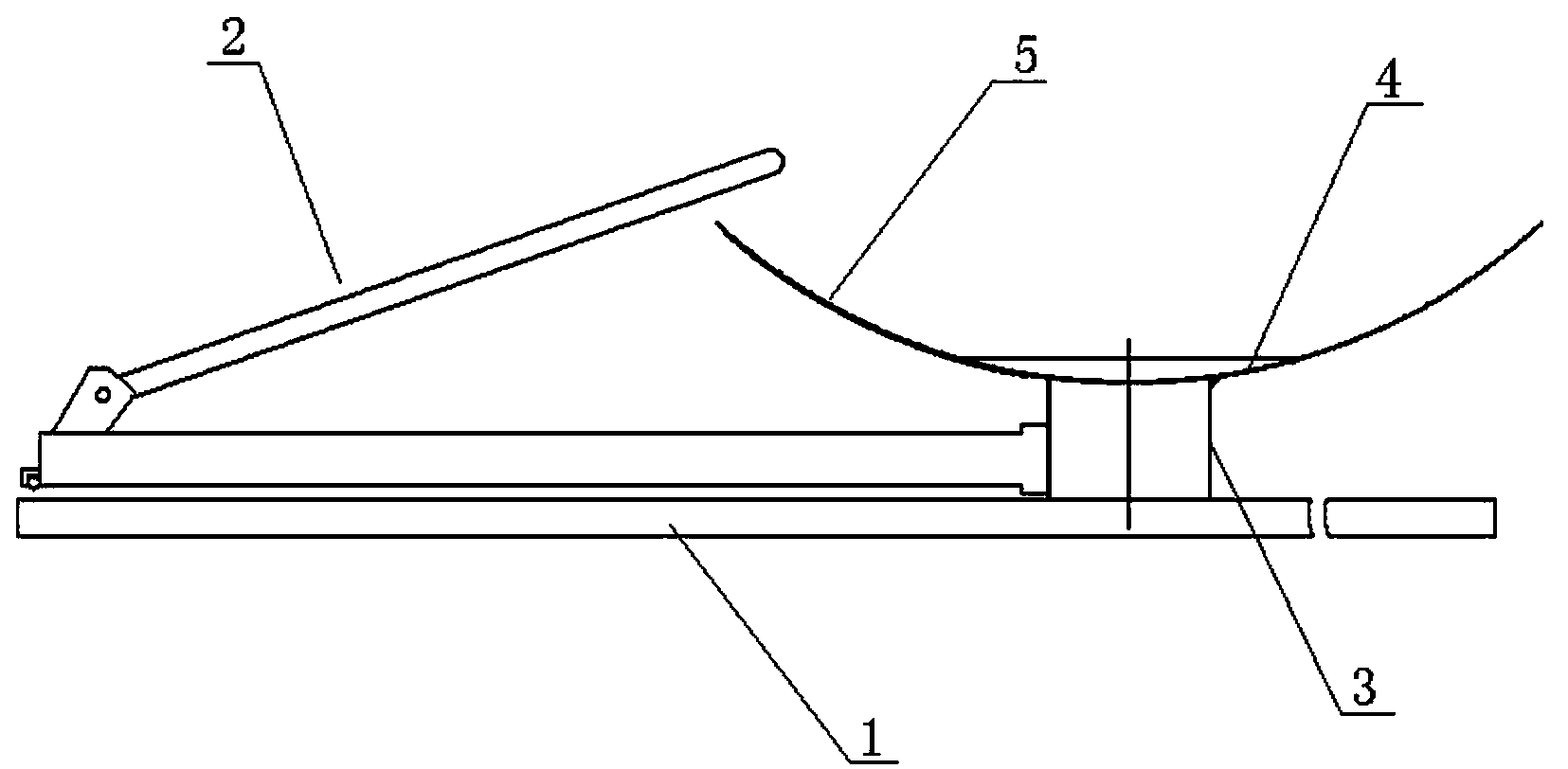

[0046] The embodiment of metal spherical shell assembling method of the present invention: as Figure 1 to Figure 25 As shown, the assembling method of the metal spherical shell includes the following steps: (1) according to the theoretical calculation, use the corresponding mold on the press to press out the spherical crown shell 4 with the same radius as the spherical shell to be assembled, and the spherical crown shell 4 Three sets of spherical curved plates for assembling the hemisphere are cut out respectively, the three sets of spherical curved plates are the first group of spherical curved plates 5, the second group of spherical curved plates 7 and the third group of spherical curved plates 8. The arc-shaped plate used for blanking is pressed on the mold so that it reaches the same spherical cap as the required metal ball, so that the radius of each spherical curved plate obtained by blanking is guaranteed, and there is no need for pressure processing one by one, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com