Method for quantitative measuring height of inclined flange for cylinder roller bearing ring

A cylindrical roller bearing, quantitative measurement technology, applied in the direction of mechanical bearing testing, measuring devices, mechanical measuring devices, etc., can solve the problems of easy wear of the template, affecting the rotation flexibility of the bearing, bearing life, and axial bearing capacity. To achieve the effect of avoiding the excessive difference of the rib height, enhancing the rotation flexibility and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

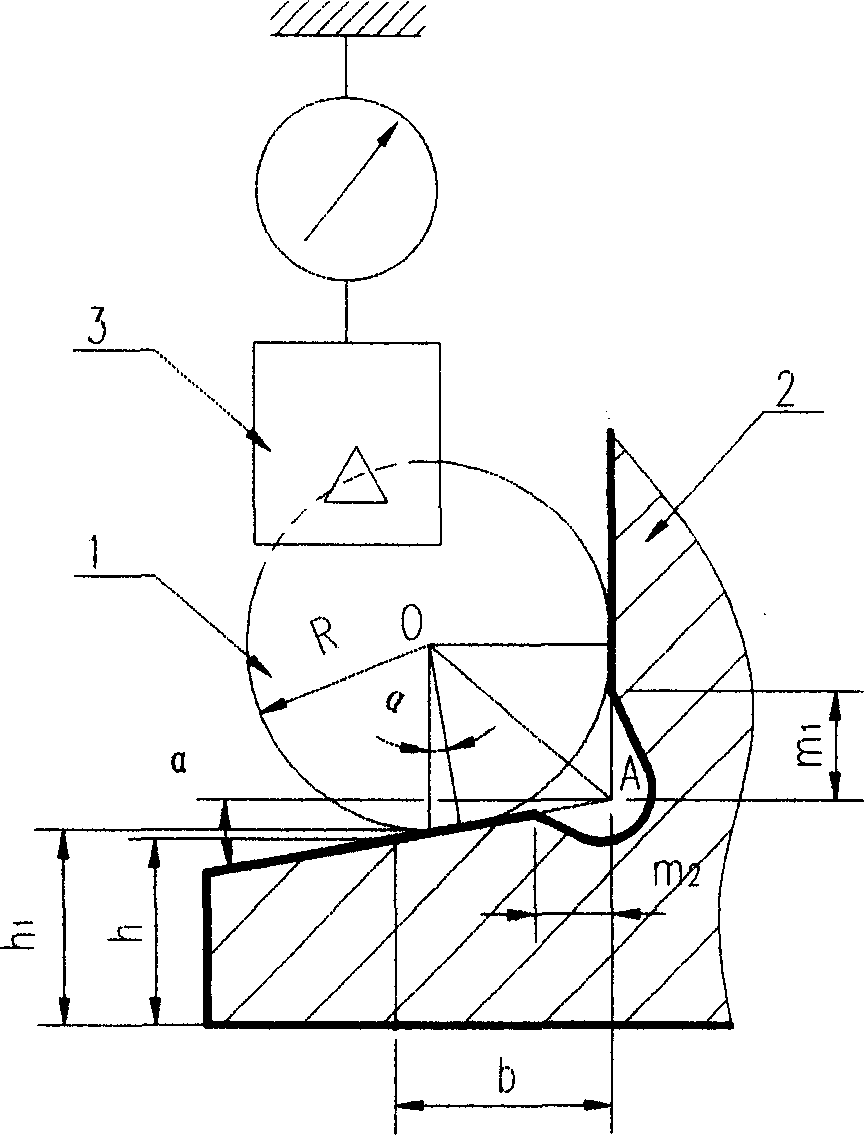

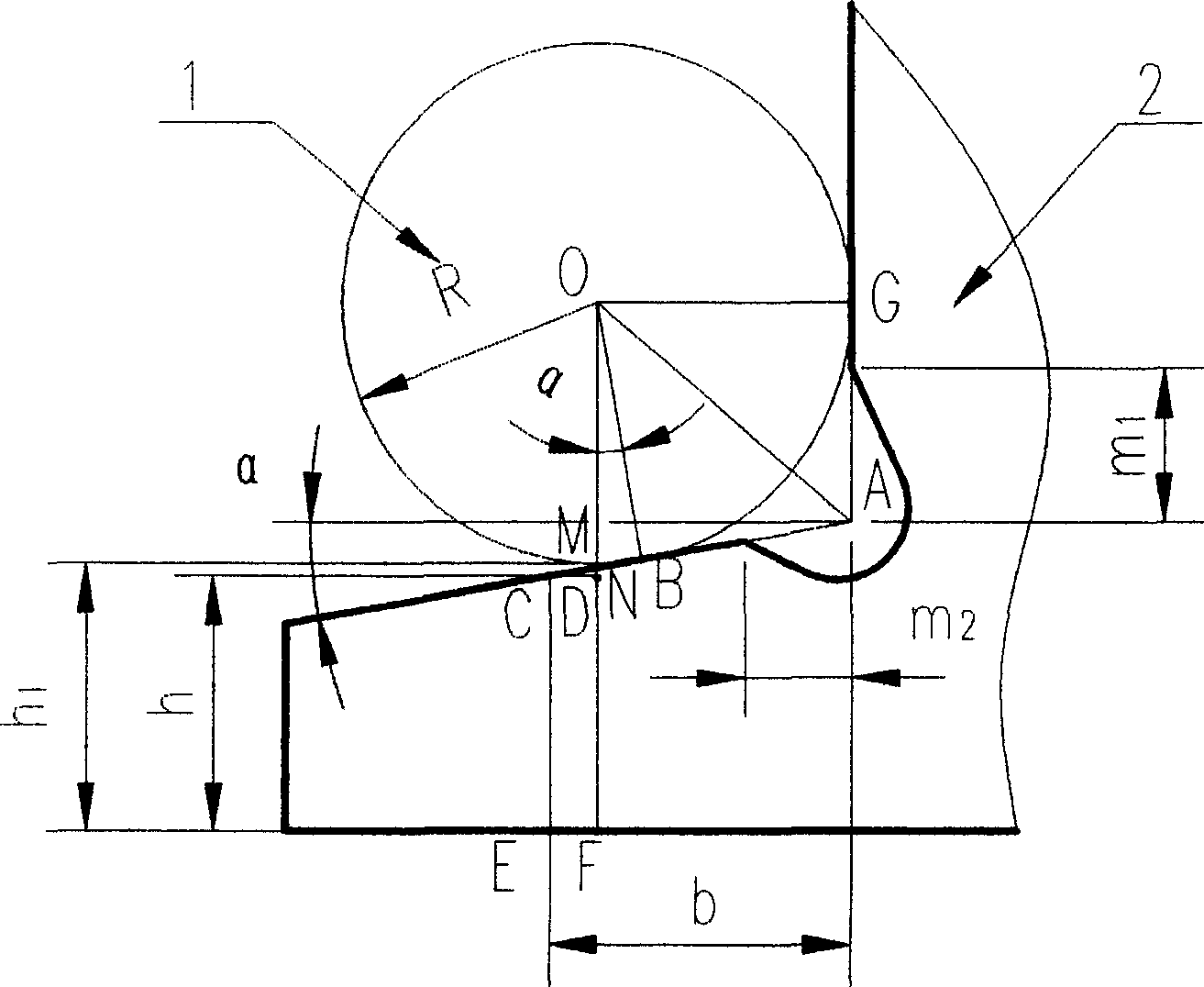

[0045] Embodiment 1: as attached figure 1 As shown, it is an inner ring of a cylindrical roller bearing, and the steps of the method for quantitatively measuring the height of the oblique rib are as follows:

[0046] (1) The size of the overtravel groove in the product picture is m1=1.5mm, m2=2.1mm, according to the formula m+δ≤R≤b (where δ is the correction value and takes 0.5mm~1.2mm) and after comparing the diameter of the standard steel ball Select the diameter of clamping ball 1 as φ7.144mm. (R=3.572mm)

[0047] (2), select the ball clamping device 3 (existing) corresponding to the clamping ball 1 for measurement.

[0048] (3), b=3.75mm, h=11.982mm, α=17' in the product picture, substitute into the deduced standard block height formula for measurement: h1=h-R+(b-R)×tgα+R / Cosα, calculate Measure the height of the inclined rib and the height of the standard block is h1=11.983mm.

[0049] (4) Use the standard block to compare and measure, and quantitatively measure the h...

Embodiment 2

[0050] Embodiment 2: refer to figure 1 , the method steps for the quantitative measurement of the height of the inclined rib are: the size of the overrun groove in the product picture is m1=1.6mm, m2=1.5mm, according to the formula

[0051] m+δ≤R≤b (where δ is the corrected value and takes 0.5mm~1.2mm) and selects the diameter of clamping ball 1 as φ5.556mm after comparing the diameter of the standard steel ball. (R=2.778mm)

[0052] (2) Select the measuring ball clamping device 3 corresponding to the clamping ball 1 .

[0053] (3), b=3.25mm, h=13.984mm, α=17' in the product picture, substitute into the deduced standard block height formula for measurement: h1=h-R+(b-R)×tgα+R / Cosα, calculate Measure the height of the inclined rib and the height of the standard block is h1=13.986mm.

[0054] (4) Use the standard block to compare and measure, and quantitatively measure the height of the oblique rib of the cylindrical roller bearing ring 2.

Embodiment 3

[0055] Embodiment 3: refer to figure 1 , the method steps of the quantitative measurement of the height of the oblique rib are as follows:

[0056] The size of the overtravel groove in the product picture is m1=2.1mm, m2=1.5mm, according to the formula

[0057] m+δ≤R≤b (where δ is the corrected value, 0.5mm~1.2mm) and compared with the diameter of the standard steel ball

[0058] Finally, select the diameter of clamping ball 1 to be φ7.144mm. (R=3.572mm)

[0059] (2) Select the measuring ball clamping device 3 corresponding to the clamping ball 1 .

[0060](3), b=4mm, h=9.983mm, α=15' in the product picture, substitute the deduced standard block height formula for measurement: h1=h-R+(b-R)×tgα+R / Cosα, calculate the measurement The height of the oblique rib height standard block is h1=9.985mm.

[0061] (4) Use the standard block to compare and measure, and quantitatively measure the height of the oblique rib of the cylindrical roller bearing ring 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com