Method for improving the gas separation performance of supported MOF membrane by utilizing polymer coating

A polymer coating and gas separation technology, applied in the field of membrane separation, can solve the problems of poor repeatability, selectivity decline, and poor stability of MOF membranes, and achieve the effects of protecting brittleness, high separation performance, and improving hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

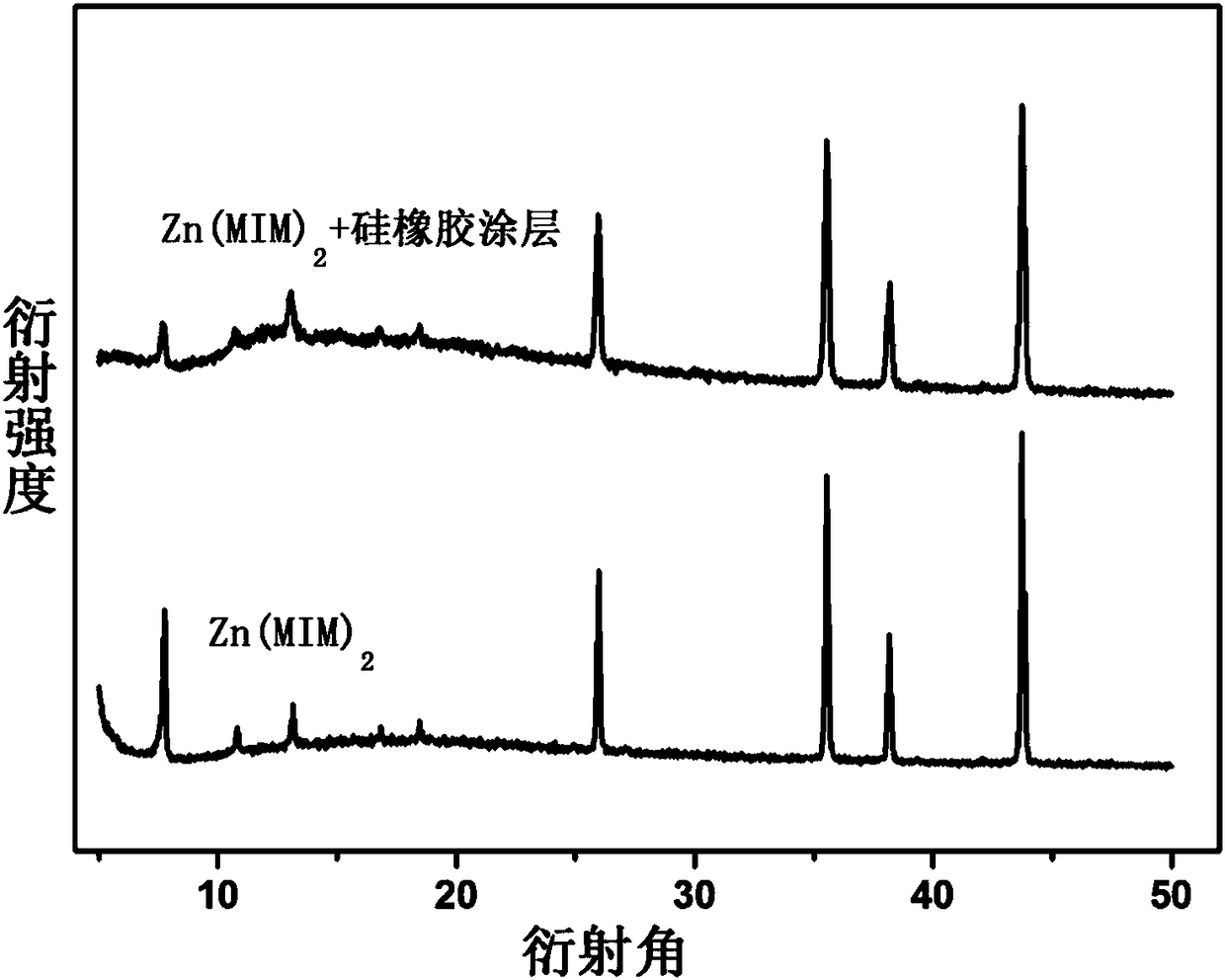

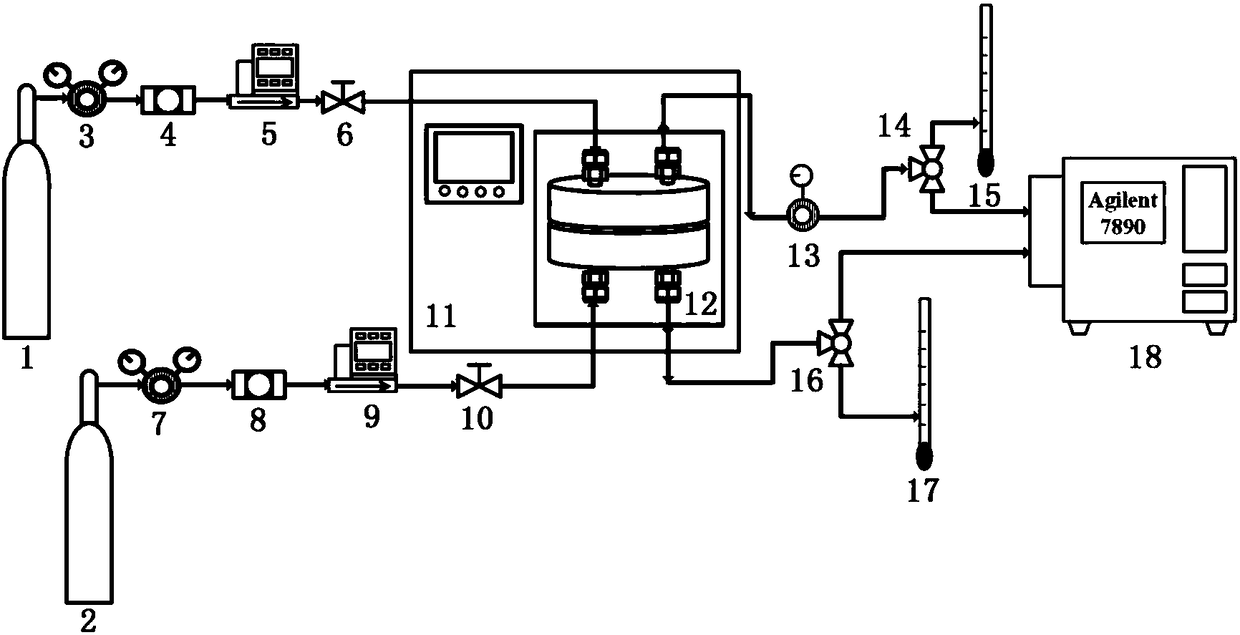

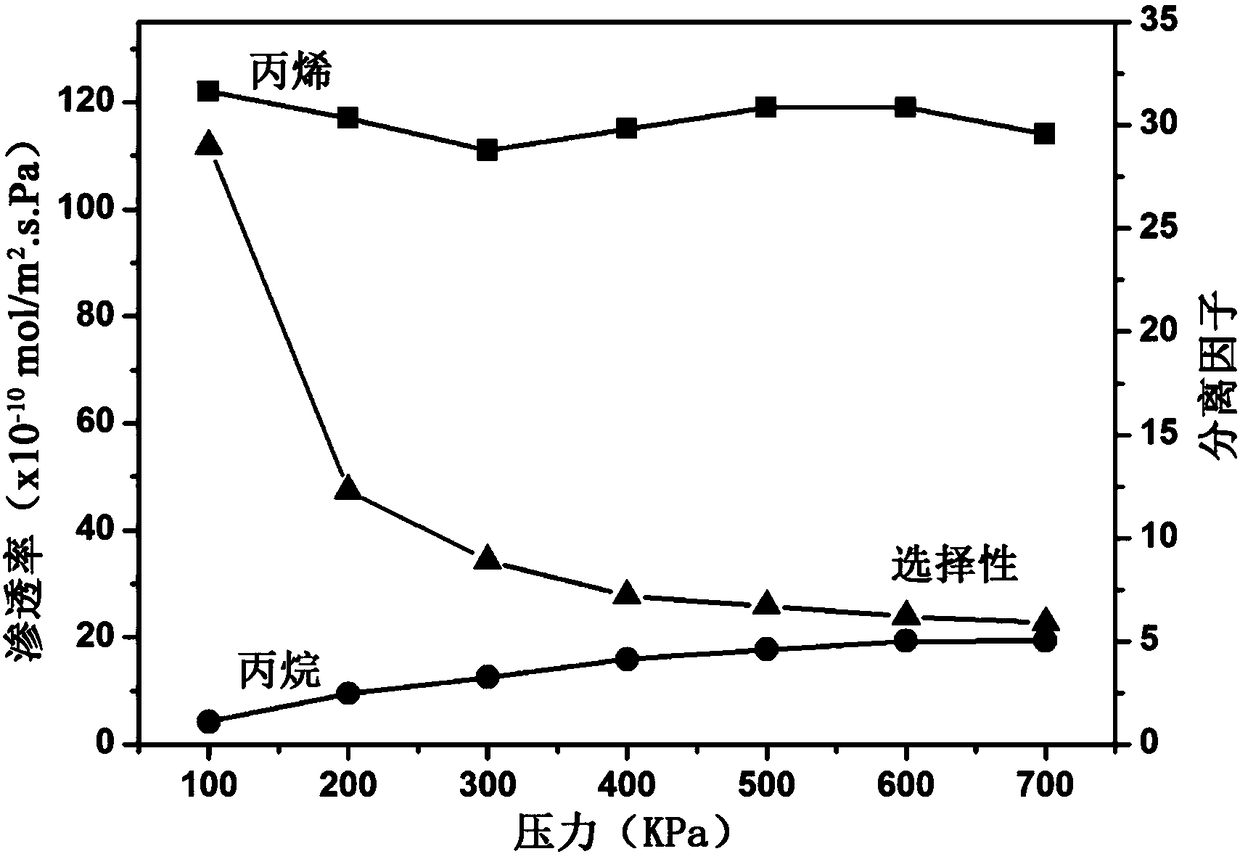

[0034] Embodiment 1 surface is coated with the Zn (MIM) of silicone rubber coating 2 The preparation of the film, the preparation steps are as follows:

[0035] Step 1: Zn(MIM) 2 Membrane preparation, using secondary growth method for Zn(MIM) 2 film preparation,

[0036] Zn(MIM) according to the method reported by Pan et al. 2 The membrane is synthesized,

[0037] (1) Carry out pretreatment to porous alumina carrier, adopt 600 # 、1000 # Polish the porous alumina carrier with sandpaper until the surface is smooth, then put the carrier in clean water and ultrasonically clean it for 10 minutes, the ultrasonic frequency is 120KHz, after drying, put it into a muffle furnace at 300°C for calcination for 5 hours, take it out for use,

[0038] (2) Preparation of seed liquid, 1.17g zinc nitrate hexahydrate and 22.7g 2-methylimidazole were dissolved in 88ml deionized water, stirred at room temperature for 5h, centrifuged and washed, then evenly dispersed in methanol solution to ma...

Embodiment 2

[0047] The Co(MIM) that embodiment 2 surface is coated with silicone rubber coating 2 Membrane preparation, prepared as follows,

[0048] Carry out the Co(MIM) that surface is coated with silicone rubber coating according to the preparation method of embodiment 1 2 membrane. Co(MIM) 2 The raw materials for membrane preparation are cobalt nitrate hexahydrate and 2-methylimidazole, and the molar ratio is 1:80. The resulting Co(MIM) 2 The membrane thickness is 2 μm with pore sizes ranging from 0.2 nm to 0.5 nm. Prepare a 40wt.% silicone rubber solution according to the method in Example 1, and the solution is evenly drip-coated on the Co(MIM) 2 The surface of the membrane was dried at 80°C for 3 days to remove the solvent, and the Co(MIM) coated with a silicone rubber coating was obtained. 2 Membrane, in which the thickness of the silicone rubber coating is 40 μm. It has been determined that at 35°C and 0.1MPa, pure Co(MIM) 2 The permeation fluxes of propylene and propane...

Embodiment 3

[0049] Embodiment 3 surface is coated with the Zn (BIM) of silicone rubber coating 2 Membrane preparation, prepared as follows,

[0050] Carry out the Zn(BIM) that the surface is coated with silicone rubber coating according to the preparation method of embodiment 1 2 membrane. Among them, Zn(BIM) 2 The raw materials of the membrane are zinc nitrate hexahydrate and benzimidazole, the molar ratio of which is 1:2, and the resulting Zn(BIM) 2 The thickness of the membrane is 1 μm and the pore size ranges from 0.2 nm to 0.5 nm. Prepare a 10wt.% silicone rubber solution according to the method in Example 1, and apply the solution evenly on the Zn(BIM) by spin coating 2 On the surface of the film, the rotation speed of the spin coater is 1500 rpm, the spin time is 10s, and the Zn(BIM) coated with silicone rubber coating is obtained after drying at 60°C for 1 day. 2 Membranes, in which the thickness of the silicone rubber coating is 0.5 μm. It has been determined that at 35°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com