Shell-core nano coating PBO fiber and preparation method thereof

A nano-fiber technology, applied in fiber types, fiber treatment, textiles and papermaking, etc., can solve the problems of poor light aging performance, high-strength performance, color loss, etc., and achieve the effect of improving application performance, excellent high-strength performance, and improving application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

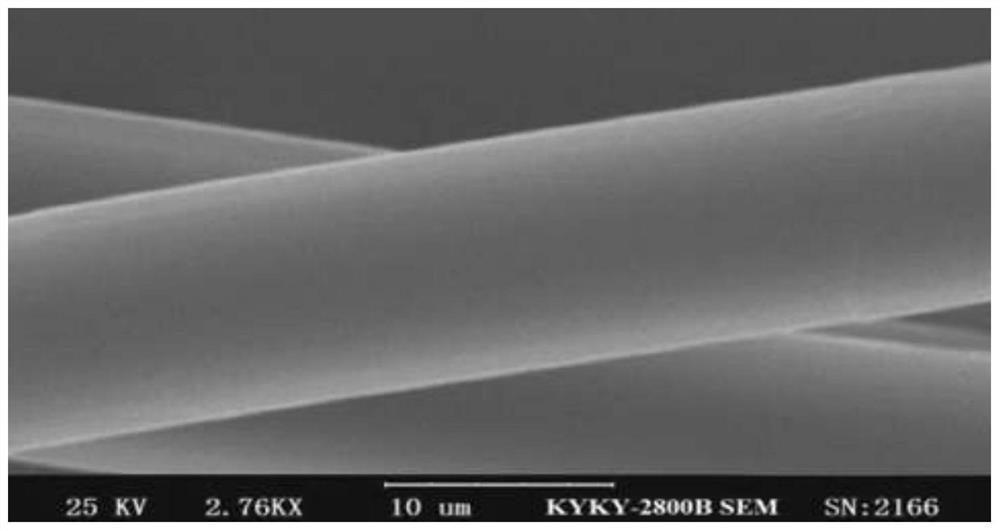

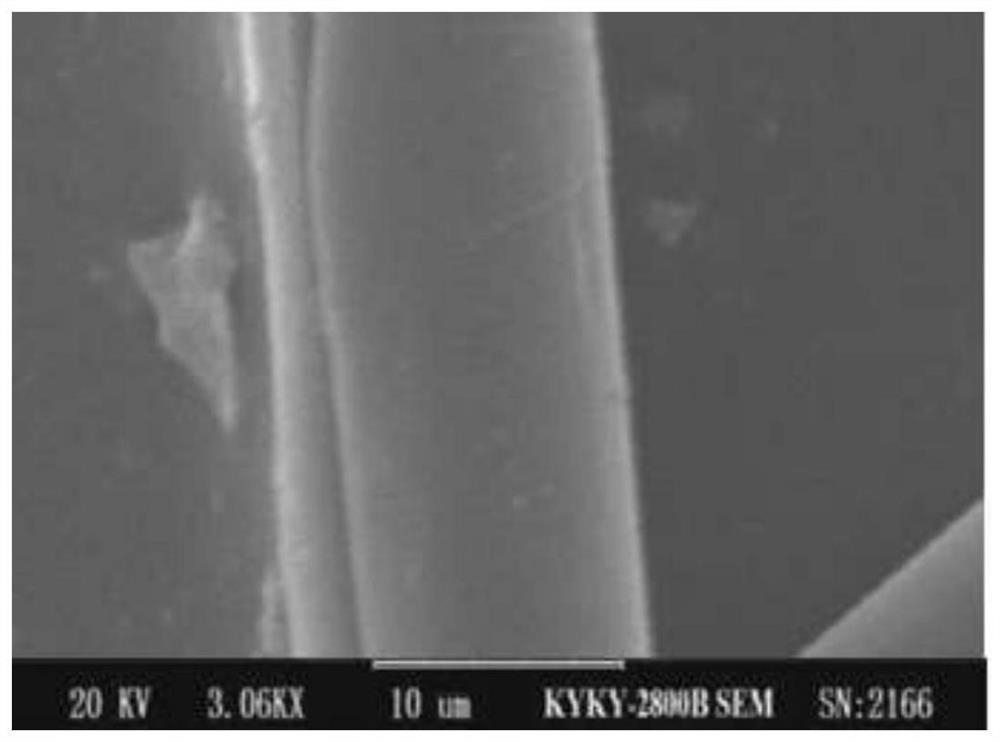

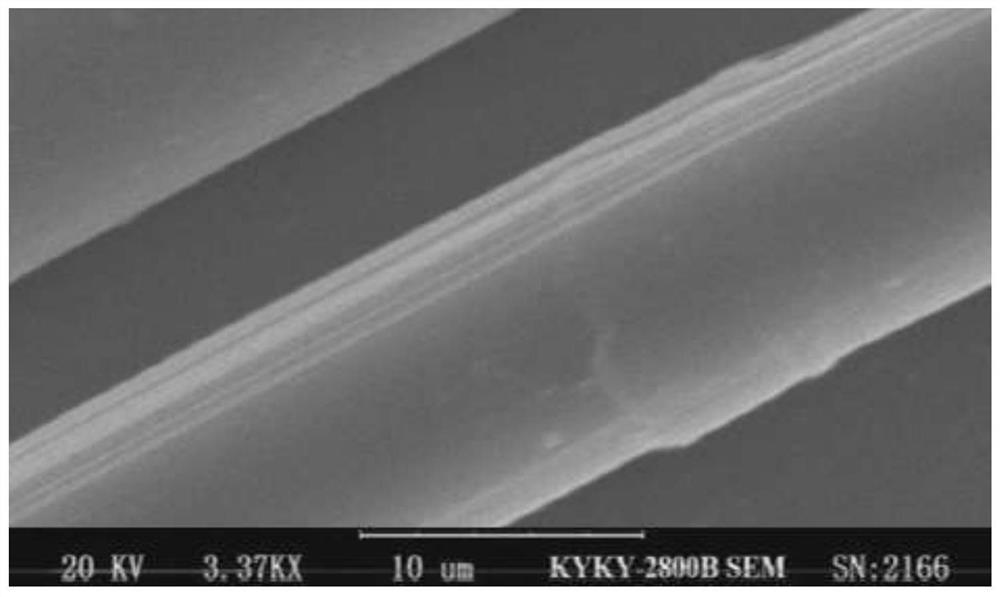

Image

Examples

Embodiment 1

[0026] A preparation method of shell-core nano-coated PBO fiber, specifically implemented according to the following steps:

[0027] Step 1, adding the nanoshell material to polyethylene acrylate and mixing to obtain a nano-coating emulsion;

[0028] In step 1, the mass ratio of nanoshell material to polyethylene acrylate, silicone polyvinyl ester emulsion, or polyacrylic acid acrylonitrile emulsion is 1:2;

[0029] In step 1, the nanoshell material is composed of nano-titanium dioxide, organic silicon, and graphene oxide, wherein the mass ratio of nano-titanium dioxide, organic silicon, and graphene oxide is 1:1:1; the particle size of nano-titanium dioxide is 30nm ;

[0030] Step 2: Add PBO fibers to the nano-coating emulsion prepared in Step 1, stir evenly, and react at a reaction temperature of 180° C. for 90 seconds to obtain the product.

Embodiment 2

[0032] A preparation method of shell-core nano-coated PBO fiber, specifically implemented according to the following steps:

[0033] In step 1, the nanoshell material is added to the silicone polyvinyl ester emulsion and mixed to obtain a nano-coating emulsion; in step 1, the nanoshell material is mixed with polyethylene acrylate, silicone polyvinyl ester emulsion, or polyacrylic acid acrylonitrile emulsion The mass ratio is 1:2 to 2:1;

[0034] In step 1, the nanoshell material is composed of nano-titanium dioxide, organic silicon, and graphene oxide, wherein the mass ratio of nano-titanium dioxide, organic silicon, and graphene oxide is 1:1:1; the particle size of nano-titanium dioxide is 50nm ;

[0035] Step 2: Add PBO fibers to the nano-coating emulsion prepared in Step 1, stir evenly, and react at a reaction temperature of 210° C. for 180 seconds to obtain the product.

Embodiment 3

[0037] A preparation method of shell-core nano-coated PBO fiber, specifically implemented according to the following steps:

[0038] In step 1, the nanoshell material is added to the polyacrylic acid acrylonitrile emulsion and mixed to obtain a nano-coating emulsion; in step 1, the quality of the nanoshell material and polyethylene acrylate, silicone polyvinyl ester emulsion, or polyacrylic acid acrylonitrile emulsion The ratio is 1:2;

[0039] In step 1, the nanoshell material is composed of nano-titanium dioxide, organic silicon, and graphene oxide, wherein the mass ratio of nano-titanium dioxide, organic silicon, and graphene oxide is 1:1:1; the particle size of nano-titanium dioxide is 40nm ;

[0040] Step 2: Add PBO fibers to the nano-coating emulsion prepared in Step 1, stir evenly, and react at a reaction temperature of 200° C. for 100 seconds to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com