A kind of organic coated nano-titanium dioxide grafted SBS modified asphalt and preparation method thereof

A technology of nano-titanium dioxide and modified asphalt, applied in building components, building insulation materials, buildings, etc., can solve the problems of reduced high and low temperature performance of modified asphalt, easy to cause diseases on the road surface, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

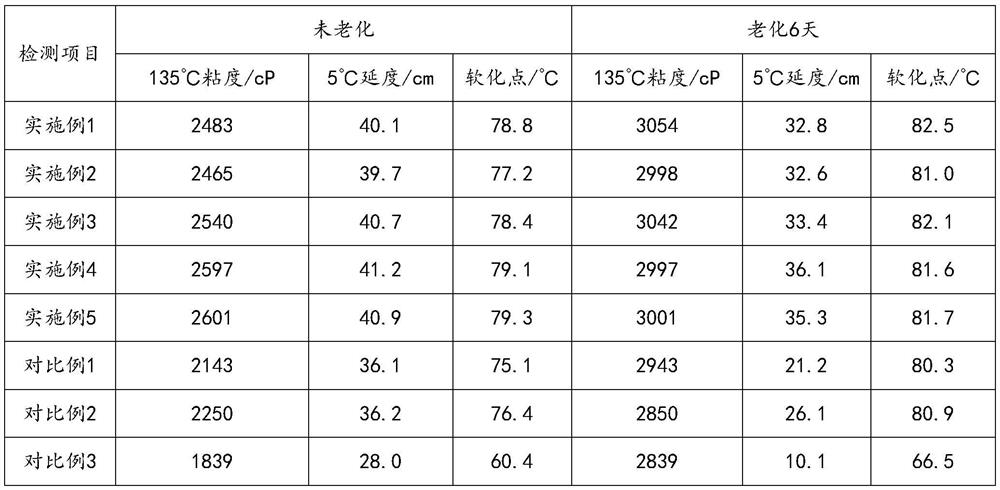

Examples

Embodiment 1

[0029] Heat 90 parts of base asphalt to 165°C, add 3 parts of grafted SBS modifier, 1.2 parts of 4-aminobenzothiophene, 0.8 parts of diaminobenzamide, and 1 part of flavonol to the base asphalt, keeping The reaction temperature is 170°C, stirred for 0.5h to mix the raw materials evenly, and ground for 0.5h in the colloid mill. After the colloid mill is stopped, keep the reaction temperature and continue to stir for 2h to obtain the organic-coated nano-titanium dioxide grafted SBS modified asphalt .

Embodiment 2

[0031] Heat 100 parts of base asphalt to 175°C, add 5 parts of grafted SBS modifier, 1.7 parts of 4-aminobenzothiophene, 1.3 parts of diaminobenzamide, and 3 parts of soybean isoflavones to the base asphalt, Keep the reaction temperature at 190°C and stir for 0.5h to mix the raw materials evenly. Grind in the colloid mill for 1h. After stopping the colloid mill, keep the reaction temperature and continue stirring for 3h to obtain organic-coated nano-titanium dioxide grafted SBS modified asphalt. .

Embodiment 3

[0033] Heat 95 parts of base asphalt to 170°C, add 4 parts of grafted SBS modifier, 1.5 parts of 4-aminobenzothiophene, 1.5 parts of diaminobenzamide, 2 parts of 7-methoxy Base flavanol, keep the reaction temperature at 180°C, stir for 0.5h, mix the raw materials evenly, grind in the colloid mill for 0.7h, stop the colloid mill, keep the reaction temperature, continue stirring for 2.5h, and the organic coated nano Titanium dioxide grafted SBS modified asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com