Heat-resistant composite light stabilizer for plastics and preparation method thereof

A technology of hindered amine light stabilizer and composite light, applied in the field of plastic additives, can solve the problems of lack of oxidation resistance, reduced service life, easy to be oxidized and decomposed, etc., achieve good industrialization prospects, improve heat resistance, compatibility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

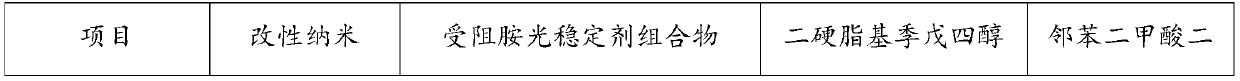

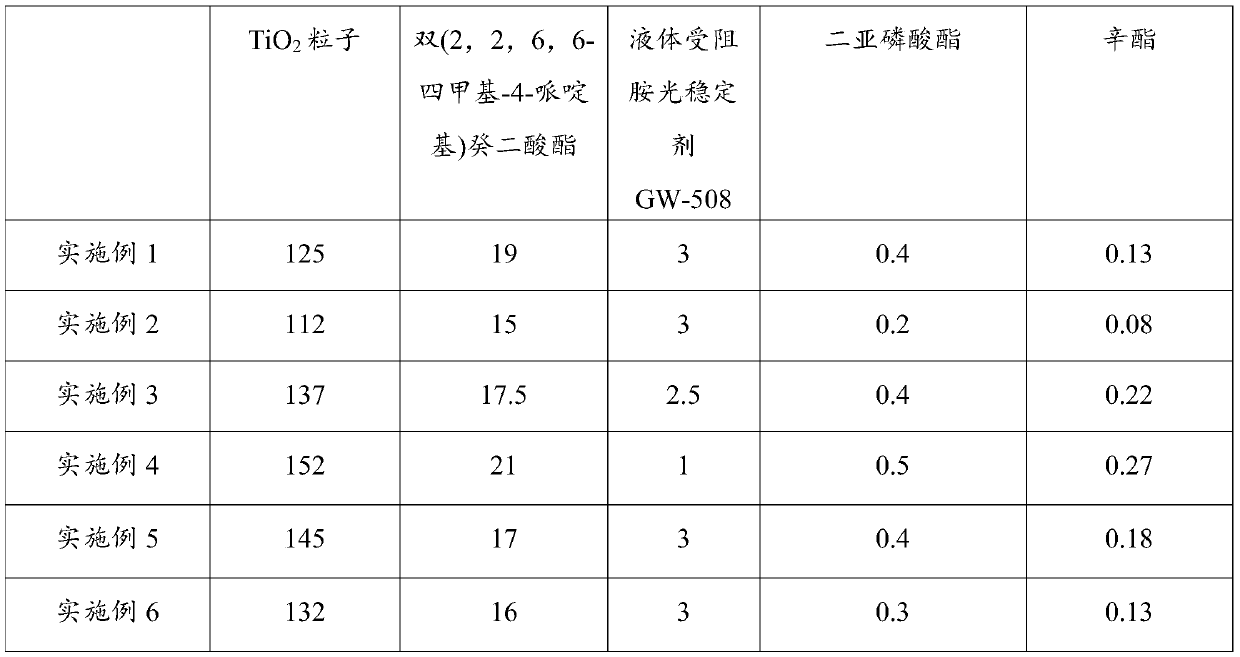

[0036] The preparation method of the heat-resistant composite light stabilizer for plastics of above-mentioned embodiment 1-6, comprises the following steps:

[0037] (1) Modified nano-TiO 2Particle preparation: Add the organic solvent into the reaction kettle, add butyl hydroxyanisole and auxiliary antioxidant, and stir evenly at room temperature to obtain an antioxidant solution; add nano-titanium dioxide preheated to 80-100°C into the antioxidant solution, Then add calcium stearate, stir at 800-1000r / min at a high speed for 40-60min to obtain a modified mixture, filter, dry, and ultrafinely pulverize to obtain modified nano-TiO with a particle size range of 10-15μm 2 particle. Among them, the superfine pulverization uses a fluidized bed airflow pulverizer, and its air consumption is 6m 3 / min, the working pressure is 0.7-0.9MPa.

[0038] (2) Mixing: ultrasonically disperse the hindered amine light stabilizer composition for 6 minutes and add it into the reaction kettle. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com