Patents

Literature

49results about How to "Improves photoaging performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing supercritical hydrotalcite grafted with flame retardant

ActiveCN103387757AGood dispersionImprove mechanical propertiesBulk chemical productionPigment treatment with organosilicon compoundsFiberPolyester

The invention belongs to the field of organic functional molecule modified hydrotalcite and particularly relates to hydrotalcite of which the surface is grafted with an organophosphorus heterocyclic compound, and a preparation method of hydrotalcite. According to the method disclosed by the invention, a silane coupling agent serves as a bridging linker in supercritical carbon dioxide, and the organophosphorus heterocyclic compound is chemically grafted to the surface of hydrotalcite, wherein the silane coupling agent accounts for 0.1-50 wt% of the total weight of hydrotalcite of which the surface is grafted with organic functional molecules, the organophosphorus heterocyclic compound accounts for 0.1-50 wt%, and the balance is hydrotalcite. The hydrotalcite of which the surface is grafted with the organic functional molecules, disclosed by the invention, can serve as a functional assistant, is added into macromolecular materials, such as polyolefins, polyesters, epoxy resin, binders, coating materials, rubber or fibers, and is used for improving the thermal ageing resistance, photo-aging resistance, heat resistance, transparency, flame retardance and the like of the prepared materials.

Owner:BEIJING ACAD OF BUILDING ENG

Epoxy polyurethane anticorrosive coating capable of resisting light aging and preparation method

InactiveCN101597455AImproves photoaging performanceEffectively adjust viscosityAnti-corrosive paintsEpoxy resin coatingsEpoxyPhosphate

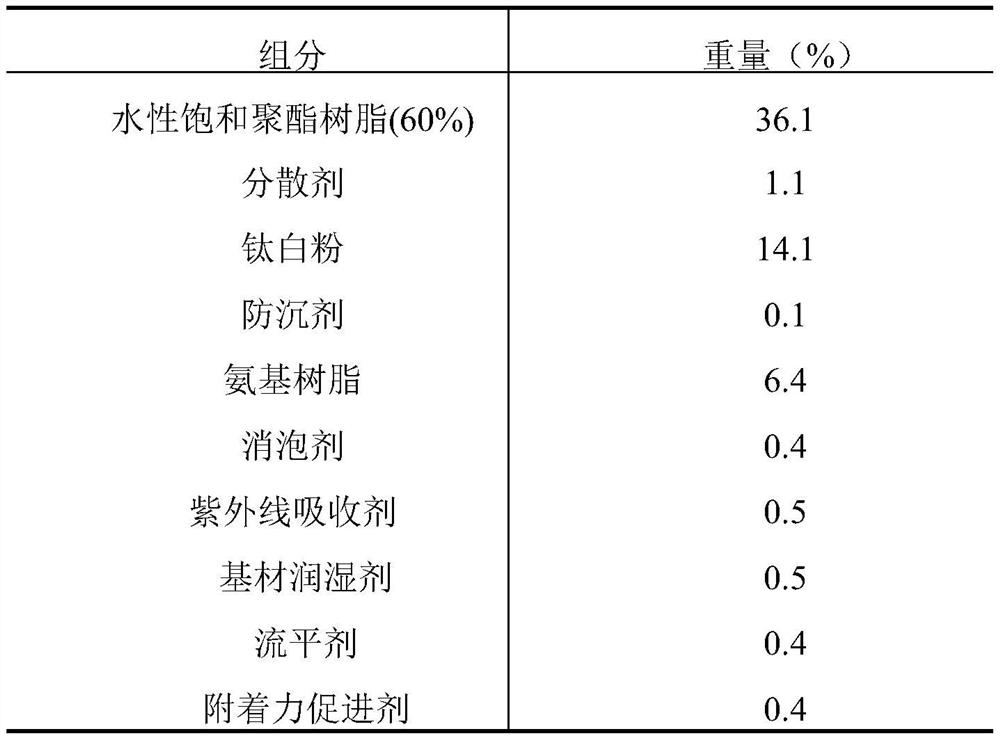

The invention discloses an epoxy polyurethane anticorrosive coating capable of resisting light aging and a preparation method; A component is prepared by mixing, stirring and grinding epoxy resin with medium molecular weight, hydroxyl-containing polyester resin, dimethylbenzene, butyl acetate, titanium pigment, ultraviolet absorber, talcum powder, mica powder, organosiloxane, isopropyl tri (dioctylpyrophosphato) titanate, poly-organic phosphate and the like; B component is prepared by mixing and stirring diphenylmethane diisocyanate and biuret. A component and B component are uniformly mixed according to weight ratio of 4:1 to be used. The epoxy polyurethane anticorrosive coating is capable of resisting light aging and has excellent corrosion resistance against acid, alkali and salt and salt fog resistance. The invention is external anticorrosive preferential coating for steel structures under severe environment such as chemical factories, refineries and the like.

Owner:CNPC RES INST OF ENG TECH

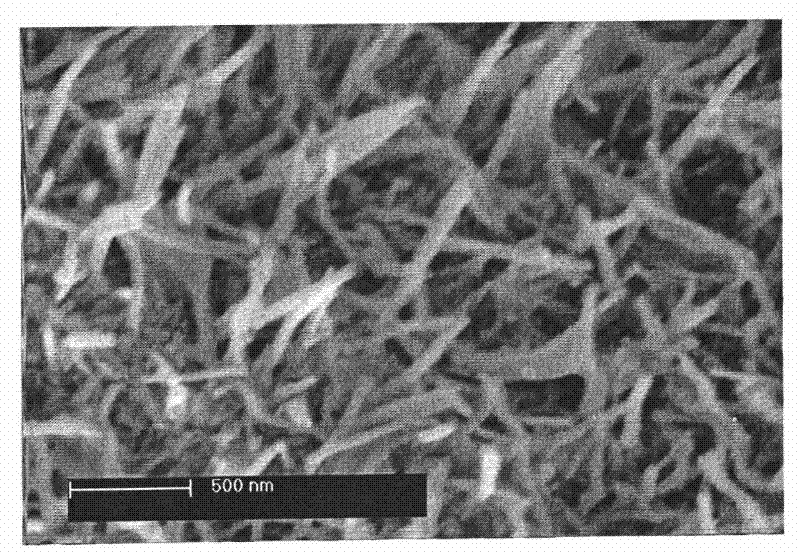

Natural lignocellulose material with modified zinc oxide and preparation method thereof

The invention relates to a natural lignocellulose material with modified nano zinc oxide and a preparation method thereof. The method prepares the natural lignocellulose material with modified nano zinc oxide by impregnating natural lignocellulose material with zinc salt solution by means of constant pressure, vacuum or vacuum pressure, and then conducting heat treatment on the material obtained through impregnation at the temperature of 70-120 DEG C for 1-6h. Being simple and effective, the preparation method not only maintains the color, texture and structure of natural lignocellulose material totally, but also improves the resistance to photochromism by 10-20 times and improves mildewproof performance by 25-30 times and changes unavailable antibacterial performance to over 99 percent sterilization rate of colibacillus, candida albicans and other strains. The natural lignocellulose material with modified nano zinc oxide can be widely applied outdoors, and in indoor basements, hospitals and other places that have high requirement on the anti-aging, mildewproof and antibacterial performances of the material.

Owner:国际竹藤网络中心

Water-based epoxy paint and preparation method thereof

InactiveCN104910759AIncrease crosslink densityImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

The invention provides a water-based epoxy paint and a preparation method thereof. The paint comprises an amino resin, a leveling agent, distilled water, a water-based epoxy acrylic resin, a dispersing agent, a defoaming agent, iron oxide black, superfine talcum powder, precipitated baryte, zinc phosphate, a rust inhibitor and the like; and a nano MoS2 anti-wear agent and a nano CaCO3 ultraviolet absorbent are further added to enhance the properties. By reasonably designing the component types and contents, the thickness of the paint film can reach 100 mu m above, the water resistance is greater than 240 hours, the transmittivity for ultraviolet light with the wavelength of 290-400nm is less than 0.4, the wear-resistant revolution number is up to 1000-1400, the mass loss of the paint film is less than 0.07 g / 100r, and the salt spray resistance is greater than 200 hours. The paint can be brushed on the internal and external walls of an iron building, has excellent protective effect, and is especially suitable for protecting iron building cultural relics.

Owner:JIANGSU UNIV OF TECH

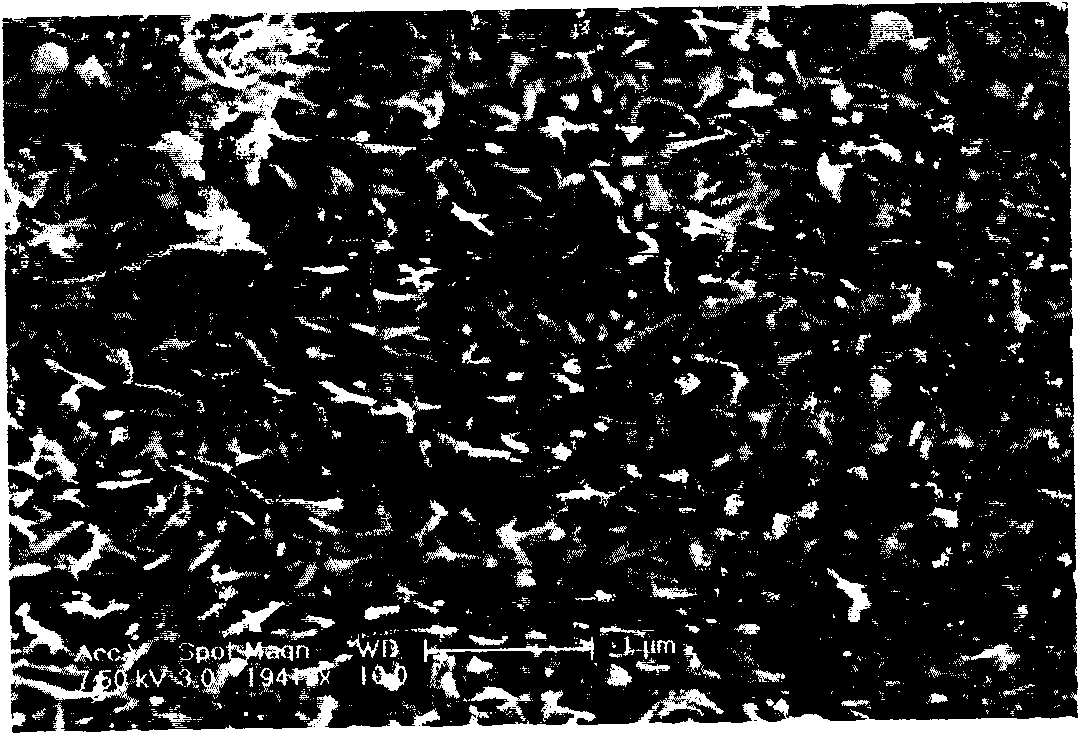

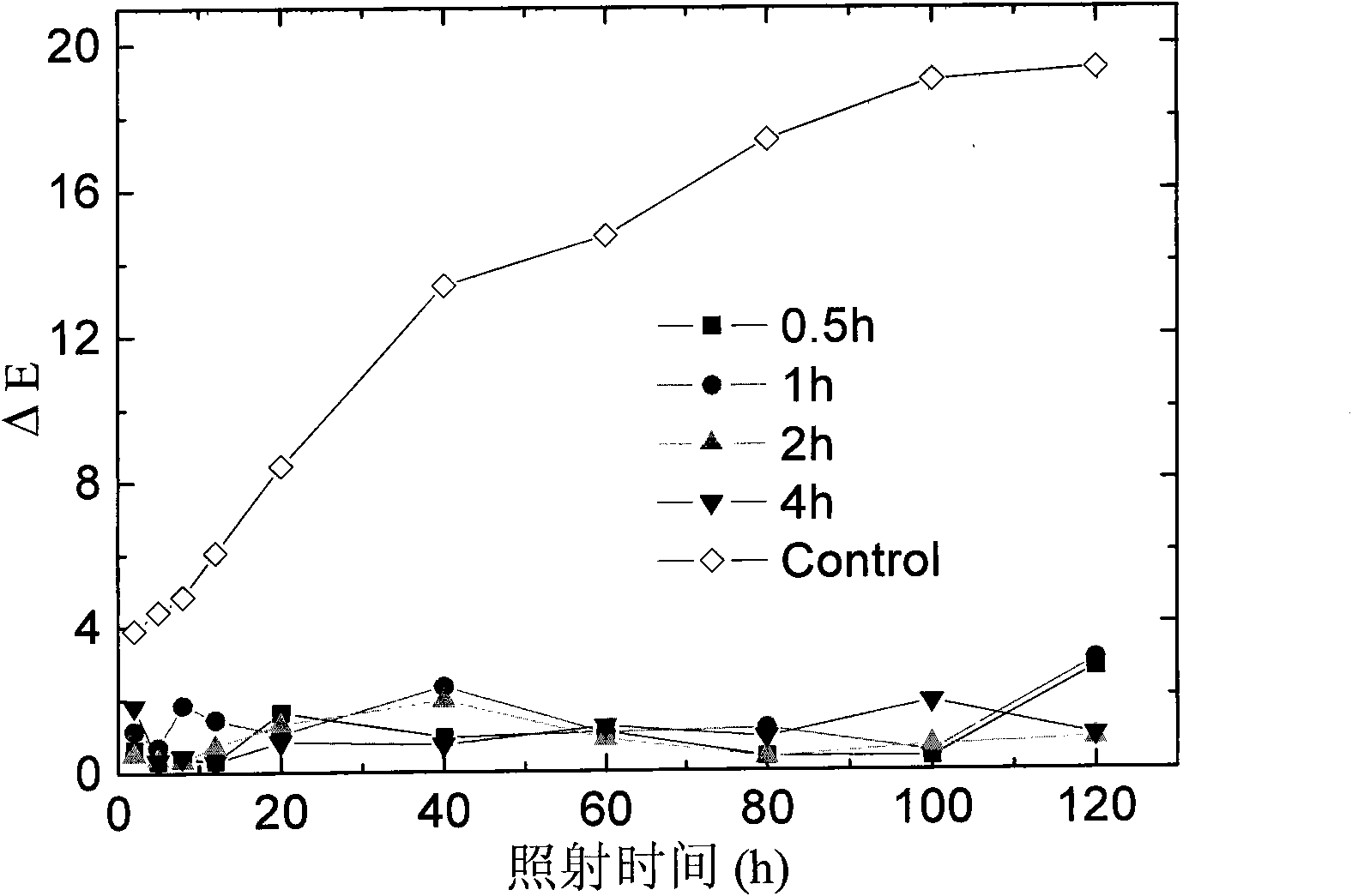

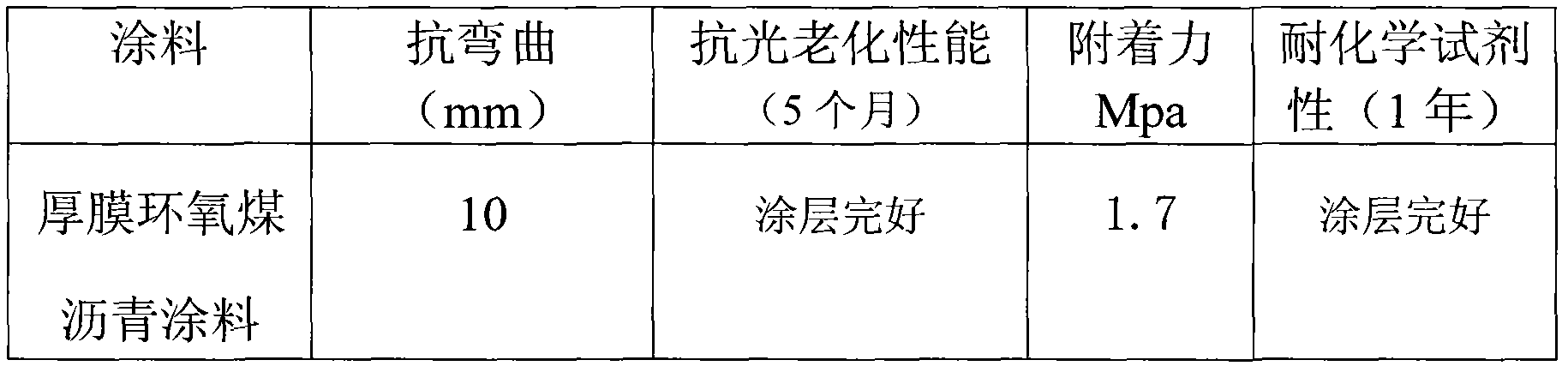

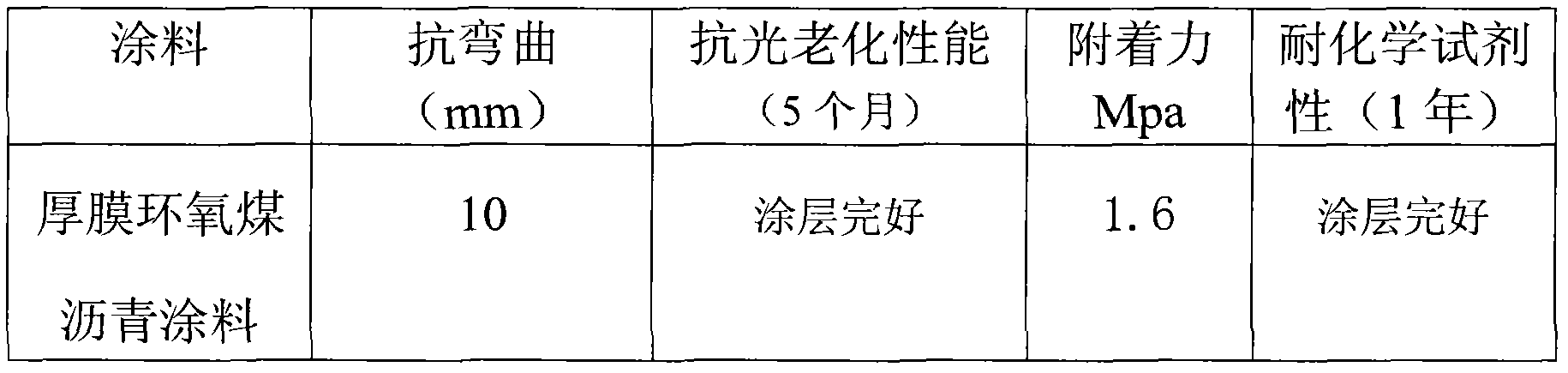

High-build epoxy coal tar pitch anticorrosive coating and preparation method thereof

InactiveCN102040902AGood resistance to microbial damageModerate softening pointCorrosion preventionAnti-corrosive paintsN-Butyl AlcoholTalc

The invention relates to a high-build epoxy coal tar pitch anticorrosive coating and a preparation method thereof. The preparation method comprises the following steps of: adding dimethylbenzene, n-butyl alcohol, butanone, coal tar pitch resin liquid, toughened resin, precipitated barium sulfate, silk mica powder, talc powder, a hoof-joint type rheological control aid, a coupling agent 01, a CibaEFKA3650 aid, an organic defoaming agent and poly organic carboxylate into bisphenol A type epoxy resin with medium molecular weight, stirring, dispersing at a high speed, and grinding into a component A; stirring phenolic ammonia, an accelerator, ethanol and a CibaTINUVIN 460 light stabilizer to form a component B; and uniformly mixing the component A and the component B in a ratio of 10:1. The high-build epoxy coal tar pitch anticorrosive coating has certain toughness, and has excellent adhesion, high microbial corrosion resistance, long construction operating period and certain light ageing resistance when applied to prestressed concrete cylinder pipe (PCCP) exterior walls.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC

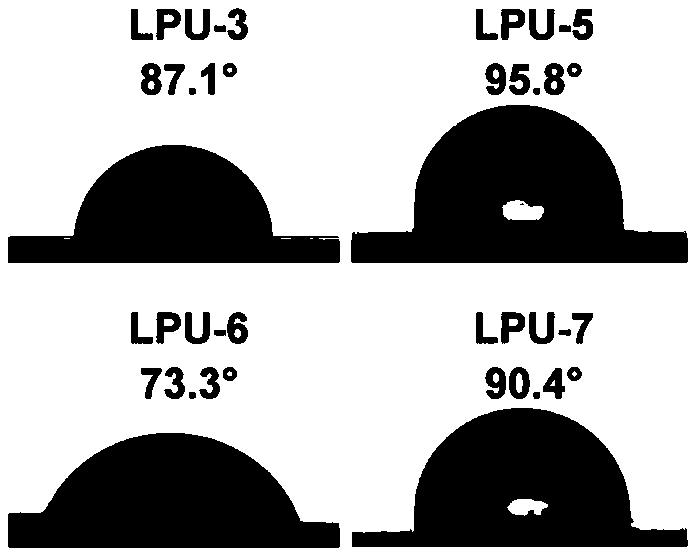

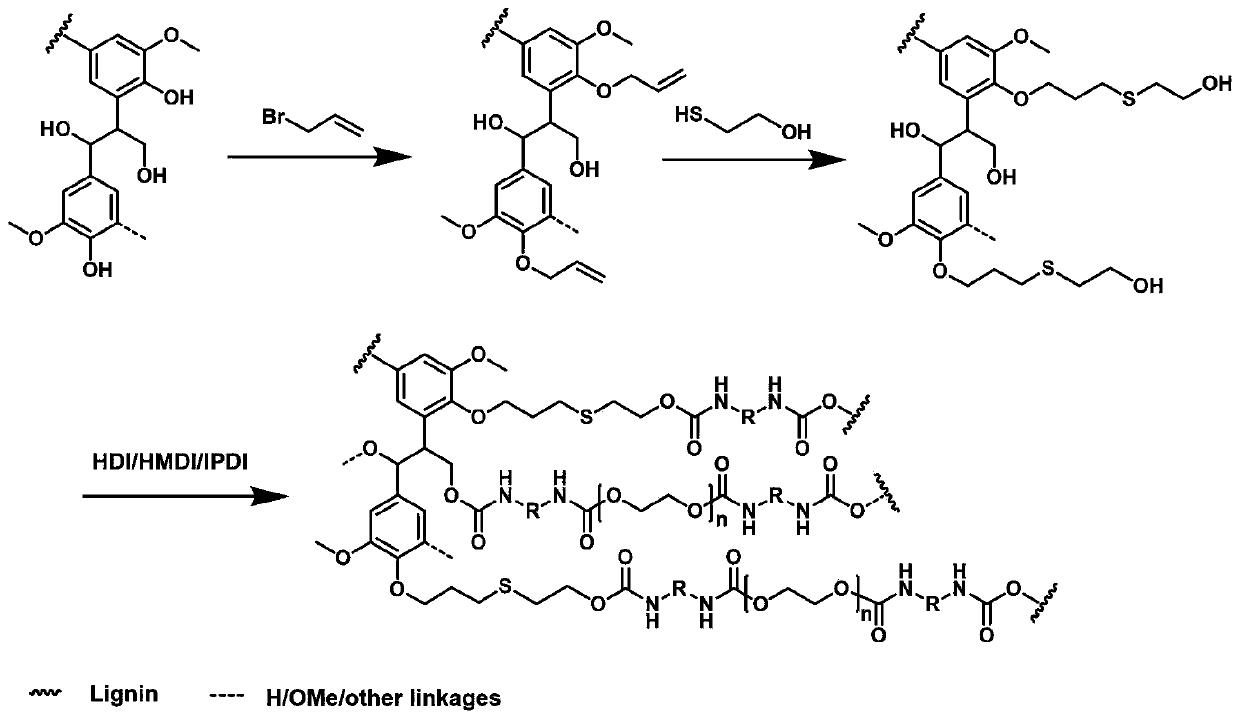

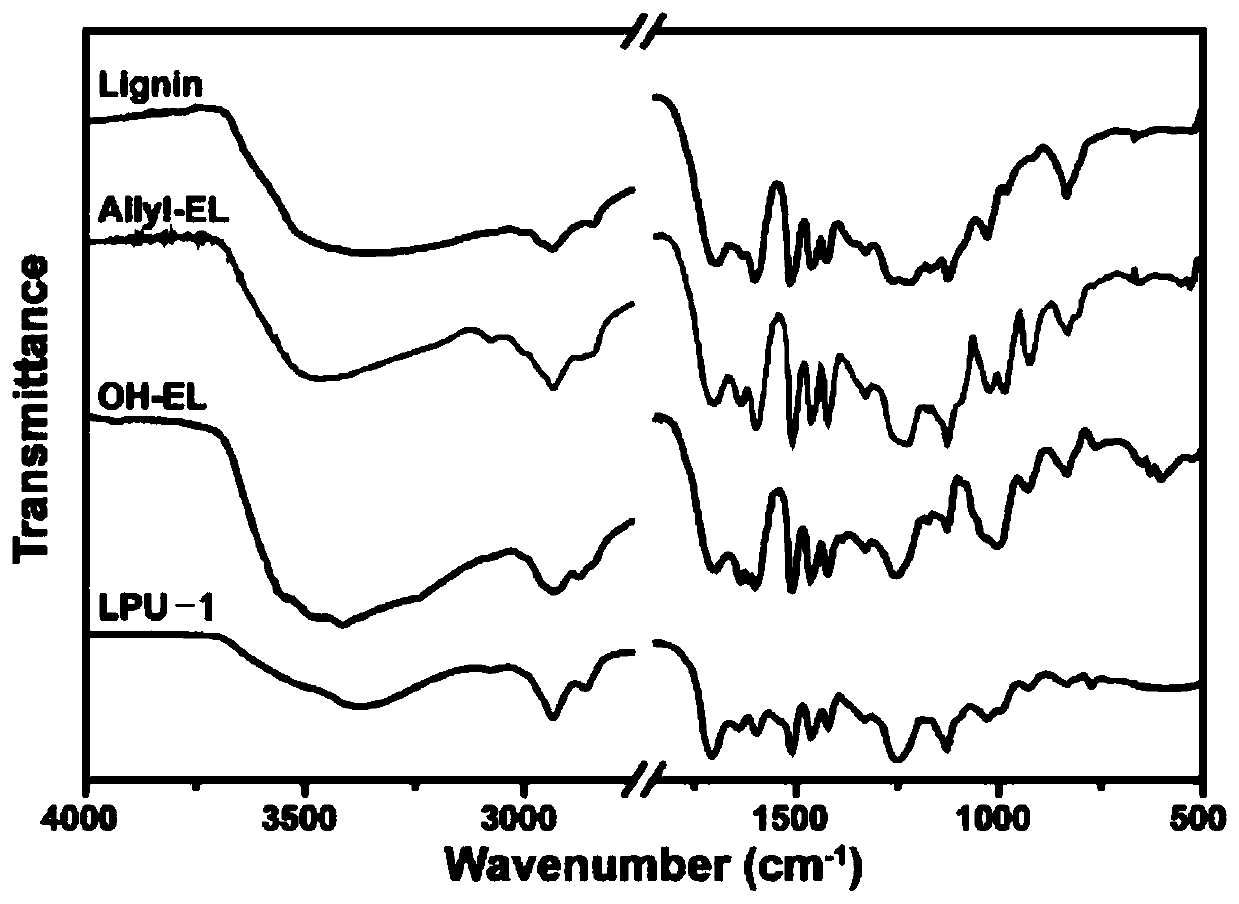

Lignin-based polyol, modified lignin-based polyurethane material, modified lignin-based polyurethane film, preparation method and application

ActiveCN111187428AImprove solubilityIncrease the degree of cross-linkingPolyureas/polyurethane adhesivesAnti-corrosive paintsPolymer sciencePolyol

The invention provides lignin-based polyol, a modified lignin-based polyurethane material, a modified lignin-based polyurethane film, a preparation method and application, and belongs to the technicalfield of polyurethane industry. The preparation method provided by the invention comprises the following steps: mixing lignin, a sodium hydroxide solution, ethanol and an allyl compound, and carryingout an allylation reaction to obtain allylation modified lignin; and mixing the allylation modified lignin, an organic solvent and a sulfhydryl compound, and carrying out a sulfhydryl-alkene click reaction to obtain the lignin-based polyol. The lignin-based polyol prepared by the invention is used for preparing the modified lignin-based polyurethane material, and the prepared modified lignin-based polyurethane material has good mechanical properties, heat resistance and light aging resistance.

Owner:SOUTH CHINA AGRI UNIV

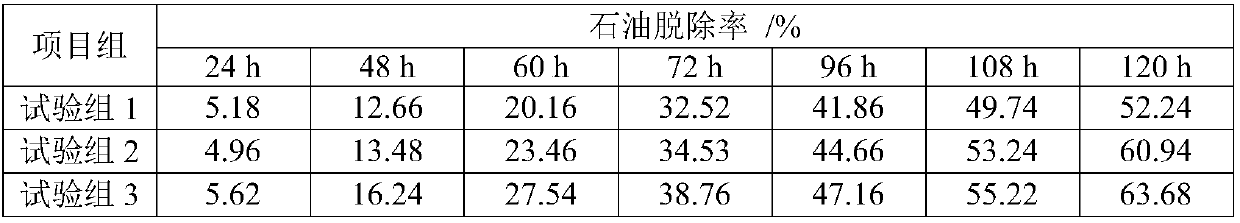

Microorganism loading type resin adsorbent capable of degrading greasy dirt and preparation method of resin adsorbent

The invention relates to the technical field of remediation of oil-overflowing water bodies and particularly relates to a microorganism loading type resin adsorbent capable of degrading greasy dirt and a preparation method of the resin adsorbent. The resin adsorbent is prepared by the steps of dipping a microorganism loading body into an acrylate copolymer emulsion, and drying, wherein the microorganism loading body is prepared by loading a multi-channel carrier particle with petroleum hydrocarbon degrading bacteria, and the carrier particle is a konjac glucomannan aerogel particle. The resinadsorbent is capable of degrading adsorbed petroleum and continuously treating petroleum in water; konjac glucomannan aerogel is loaded with petroleum hydrocarbon degrading bacteria and is embedded into acrylate resin, so that the curing stability of a strain is high; and konjac glucomannan aerogel and acrylate resin are internally provided with rich micro-fine channels, so that the resin adsorbent has huge oil absorption capacity and is high in adsorption velocity.

Owner:ZHEJIANG OCEAN UNIV

Bidirectional easy-to-tear PE film and preparation method thereof

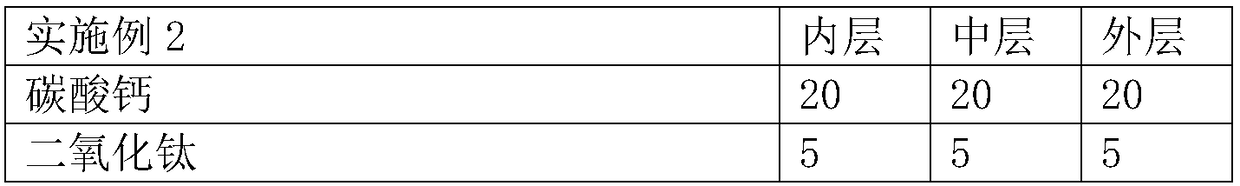

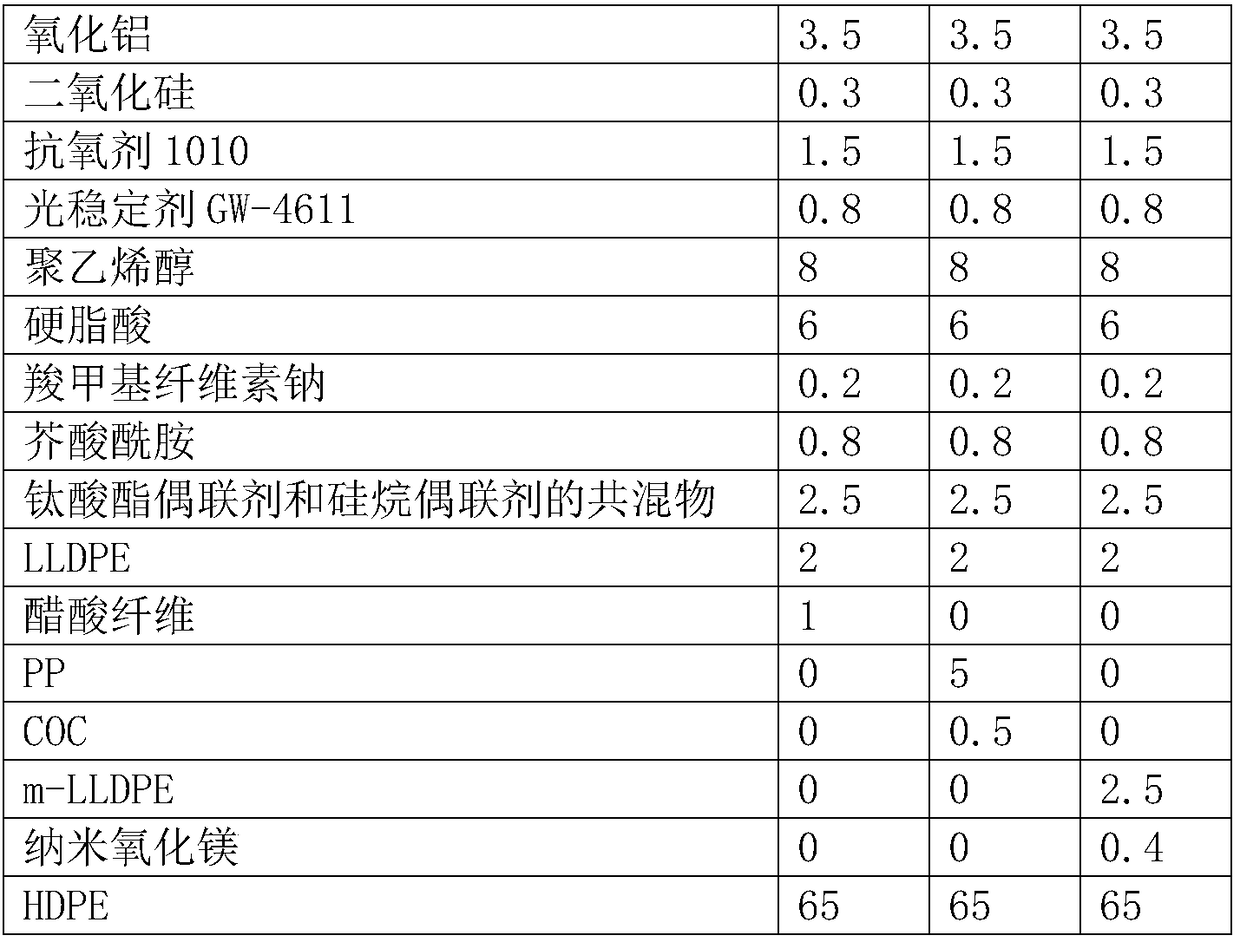

ActiveCN108276640AImprove uniformityGood flexibilitySynthetic resin layered productsFiberAntioxidant

The invention discloses a bidirectional easy-to-tear PE film and a preparation method thereof. The bidirectional easy-to-tear PE film is of a three-layer structure, namely an inner layer, a middle layer and an outer layer; the PE film comprises the following preparation raw materials: calcium carbonate, titanium dioxide, aluminum oxide, silicon dioxide, an antioxidant, a light stabilizer, a dispersing agent, a lubricating agent, a tackifier, a smoothing agent, a coupling agent, acetate fibers, PP, COC, m-LLDPE, nanometer magnesium oxide and HDPE. The PE film is prepared by preparing an inner layer film forming material, a middle layer film forming material and an outer layer film forming material by selecting the different raw materials and then adding the film forming materials in a three-layer co-extrusion casting stretcher. The casting PE film prepared by the preparation method disclosed by the invention has good tensile strength, impact strength and light aging resistance while having bidirectional easy-to-tear performance.

Owner:四川厚诚新材料有限公司

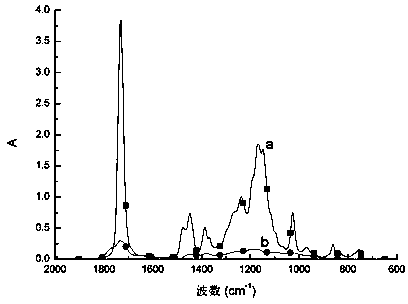

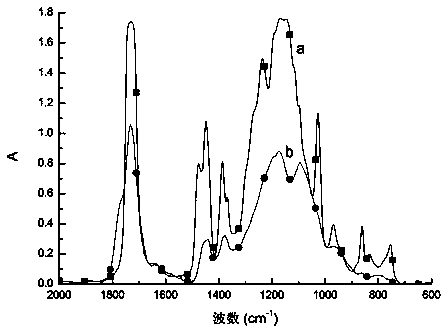

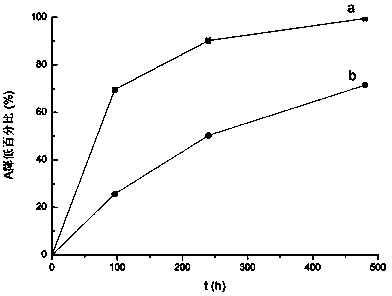

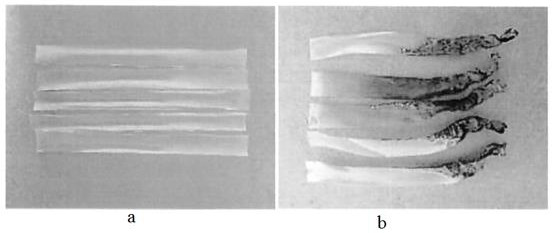

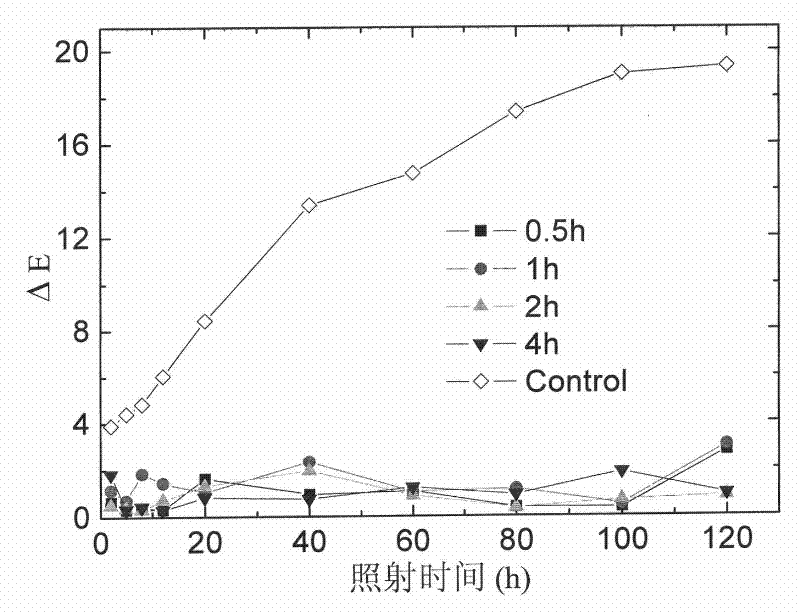

Anti-light-ageing reinforcement material of colored relics and preparation method of reinforcement material

The invention discloses an anti-light-ageing reinforcement material of colored relics. The reinforcement material is prepared from the following components in parts by weight: 500-1,200 parts of silicon dioxide, 6,000-20,000 parts of B72, 5-40 parts of polyethylene glycol octylphenol ether, 4-20 parts of aminopropyl triethoxy silane, 5,000-80,000 parts of a 85%-95% ethanol aqueous solution and 30,000-200,000 parts of ethyl acetate. Compared with a common reinforcement material B72 of the colored relics, the anti-light-ageing reinforcement material is relatively long in service life and relatively high in stability, especially, the light ageing resistance is remarkably improved, and a preparation process of the anti-light-ageing reinforcement material is simple and convenient to perform.

Owner:NORTHWEST UNIV

Preparation method of aerogel composite material for degrading organic matters

InactiveCN109201011AEasy to recycleAchieve adsorptionWater/sewage treatment by irradiationOther chemical processesCelluloseUltraviolet lights

The invention discloses a preparation method of an aerogel composite material for degrading organic matters. The preparation method comprises carbon nitride preparation, titanium dioxide and carbon nitride compounding, cellulose modification and aerogel preparation, wherein the cellulose modification step is as follows: adjusting the pH of a H2O2 solution to 11-12 by using a NaOH solution, drying,crushing, adding sieved natural saw dust into the H2O2 solution, carrying out constant-temperature oscillation reaction for 10-15 hours, adding 3-alpha-furylacrylic acid accounting for 1-5% of the mass of the saw dust and 3-chloro-2-hydroxypropyl trimethyl ammonium chloride accounting for 0.5-1% of the mass of the saw dust, and reacting for 4-6 hours under ultraviolet light to obtain a modified saw dust cellulose solution. The preparation process is simple, raw material sources are rich, the large-scale production is facilitated, and the prepared aerogel composite material has a large specific surface area, and has the advantages of being high in adsorption property, high in organic substance degradation efficiency, long in service life, green and environment-friendly and the like.

Owner:潘钕

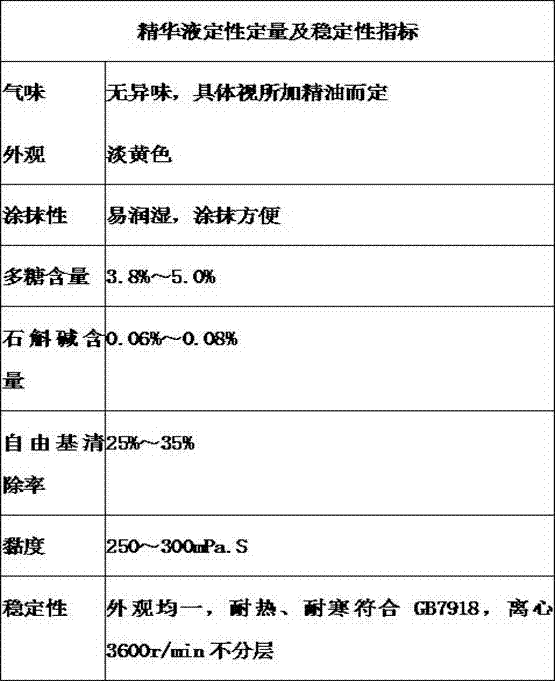

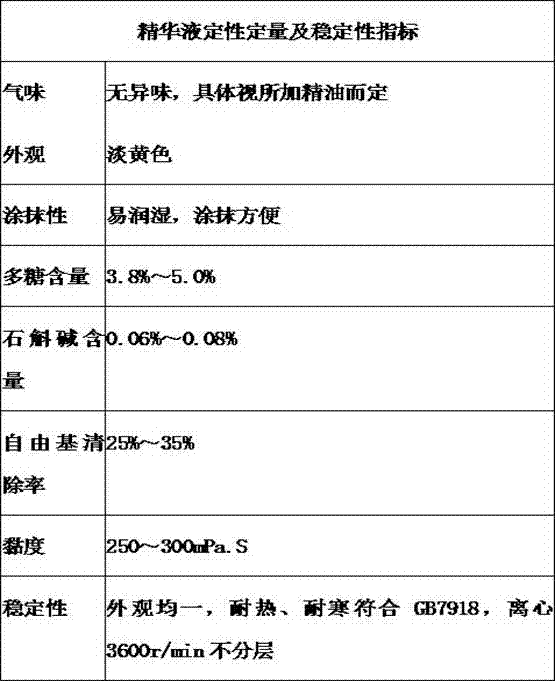

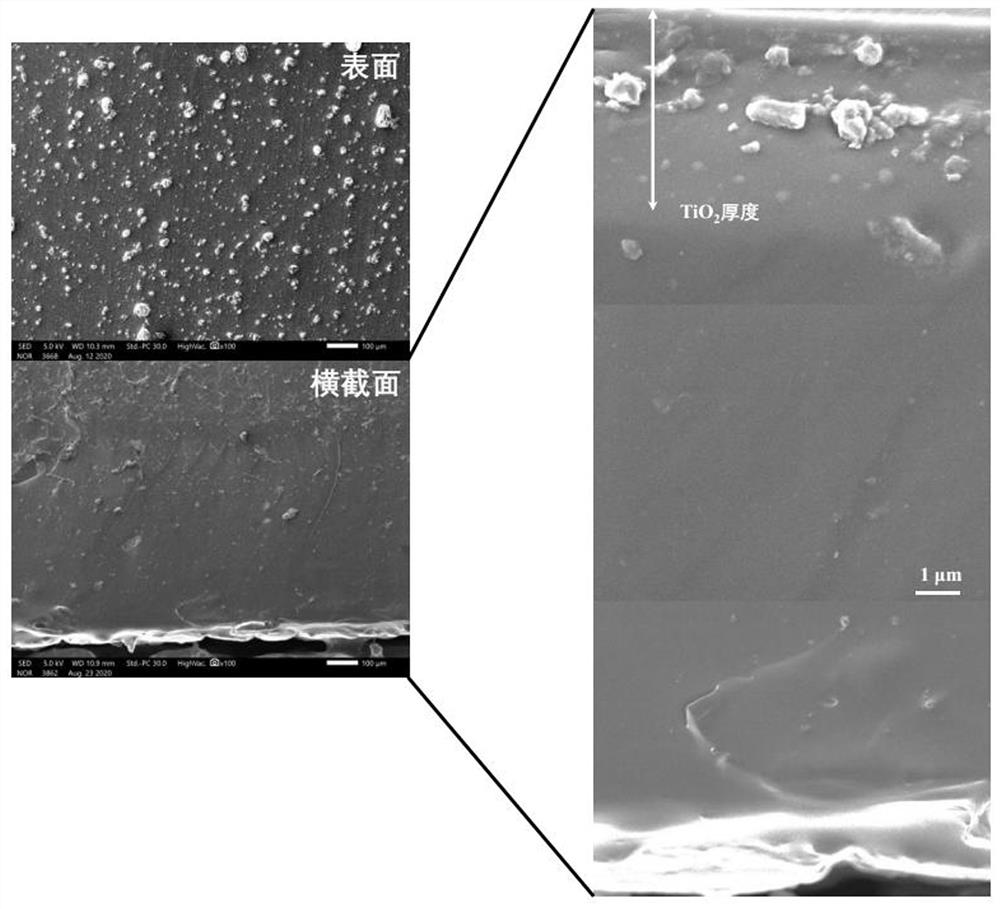

Preparation method of dendrobium polysaccharides and dendrobine ethosomes and cosmetic

InactiveCN106963712AImprove antioxidant capacityInhibit inflammationCosmetic preparationsToilet preparationsALPHA-ARBUTINIrritation

The invention discloses a cosmetic which comprises the following components in percentage by weight: 20-35% of dendrobium polysaccharides, 10-15% of glycerinum, 0-2 of ceramide, 42-65% of ultrapure water, 0.3-1% of dendrobine ethosomes, 0-2% of natural vitamin E, 0-1% of trans-resveratrol, 0-1% of vitamin C palmitate, 0-1% of alpha-arbutin and 0.1-1% of plant essential oil. The invention further provides a preparation method of the dendrobium polysaccharides and the dendrobine ethosomes in the cosmetic. The invention solves the technical problem of 'providing a cosmetic with dendrobium extracts (the dendrobium polysaccharides and the dendrobine ethosomes)', and the cosmetic disclosed by the invention has effects of ultraviolet resistance and oxidation resistance, meanwhile has effects of whitening skin and lightening stain, and moreover is purely natural and free of irritation.

Owner:宁波百岚德加进出口有限公司

Environment-friendly flame-retardant rubber floor and manufacturing method thereof

InactiveCN107090106AImprove wear resistanceUniform colorCovering/liningsFlat articlesStearic acidAccelerant

The invention discloses environment-friendly flame-retardant rubber floor. The environment-friendly flame-retardant rubber floor is prepared from the following raw materials in parts by weight: 20-30 parts of butadiene styrene rubber, 50-60 parts of acrylonitrile-butadiene rubber, 6-8 parts of titanium dioxide, 4-6 parts of a vulcanizing agent, 1-3 parts of zinc oxide, 0.5-2 parts of stearic acid, 4-6 parts of white carbon black, 0.8-1.4 parts of an accelerant, 1-2 parts of a weather resistant, 3-5 parts of antimonous oxide, 5-7 parts of a flame retardant, 1-3 parts of an antistatic agent and 20-30 parts of reinforcing filler. The rubber floor disclosed by the invention has the advantages of stronger wear resistance, static electricity resistance, low smoke, low toxicity, low corrosion, good flame resistance, high tensile strength, good skid resistance, good resilience and the like. A manufacturing method for the rubber floor adopts safe and reliable raw material components, is harmless on environment, adopts easily available raw materials, is relatively low in cost, is simple in process, is easy to operate and realize industrial production, and has relatively high practical value and a good application prospect.

Owner:合肥市老海新材料有限公司

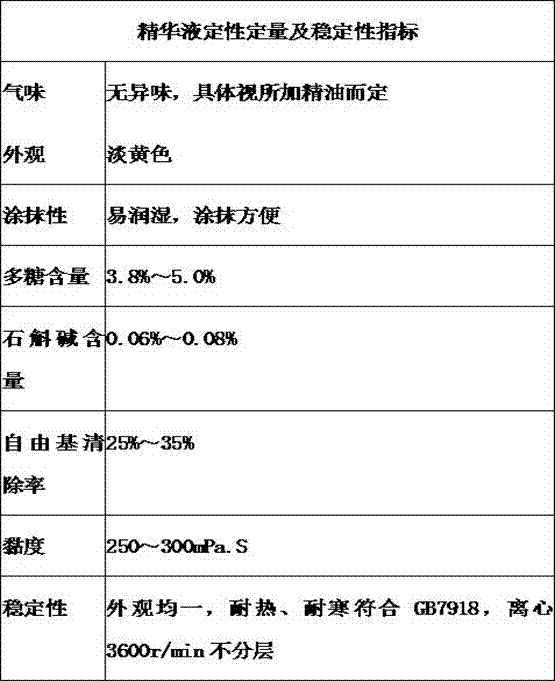

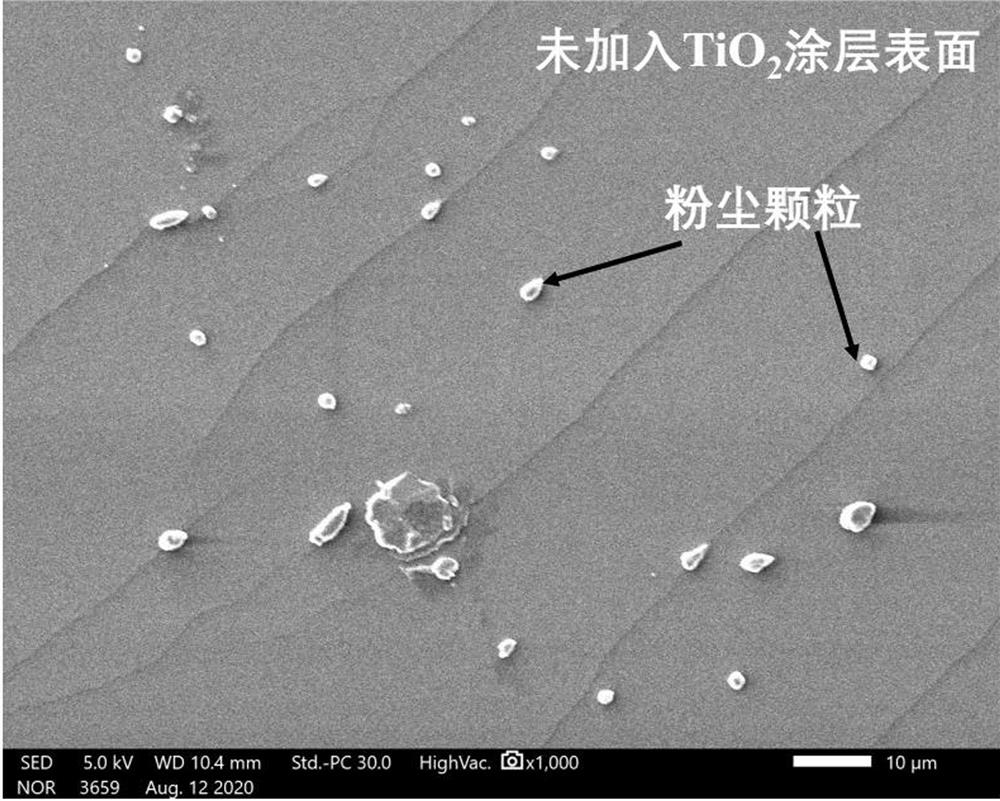

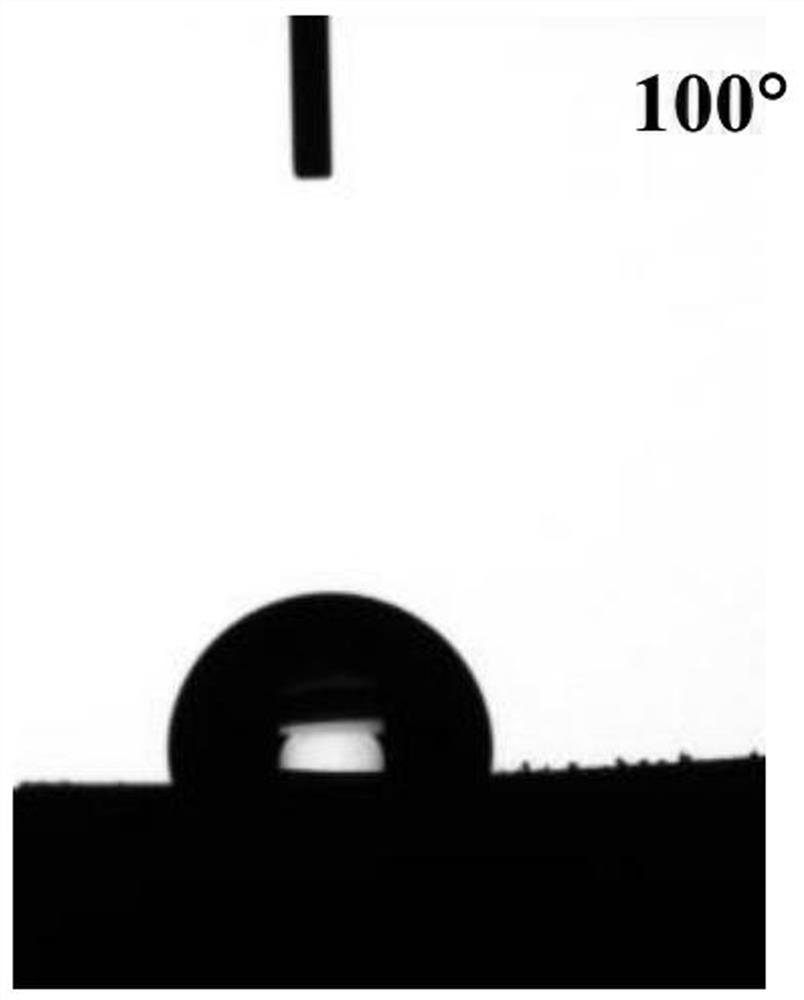

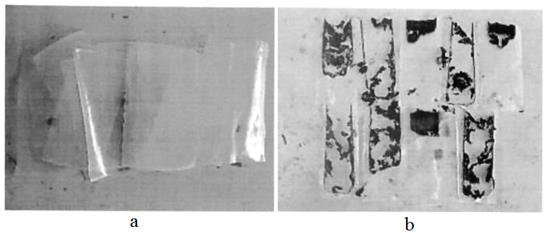

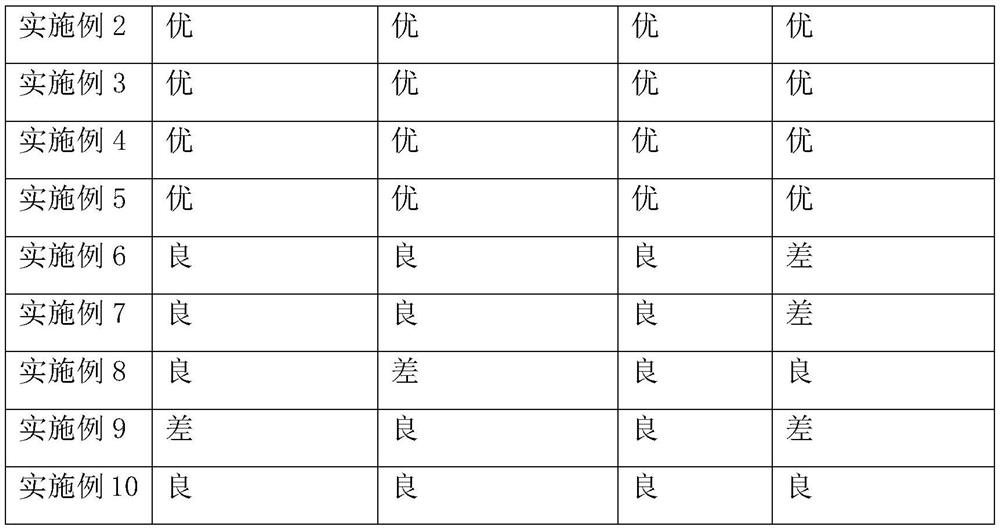

Preparation method of durable hydrophobic anti-photoaging stone cultural relic sealing and protecting coating

The invention belongs to the technical field of preparation of a novel anti-photoaging stone cultural relic coating, and provides a preparation method of a durable hydrophobic anti-photoaging stone cultural relic sealing coating in order to overcome the defects that an existing anti-photoaging stone cultural relic sealing coating is poor in durability, prone to pollution, poor in anti-photoaging performance, low in strength and the like. According to the invention, fluorosilane and nano TiO2 are added into an isopropanol solution, and ultrasonic dispersion is carried out; a mixed solution of PDMS and a curing agent are prepared; and the fluorosilane grafted nano TiO2 is dried, the dried fluorosilane grafted nano TiO2 is added into a PDMS mixed solution, ultrasonic dispersion is carried out, the surface of the stone cultural relic is coated with the obtained product, vacuumizing is carried out, and curing is performed to obtain the durable hydrophobic anti-photoaging stone cultural relic sealing and protecting coating. Due to the fact that the nano TiO2 with the light shielding performance is enriched on the surface, the light aging resistance is improved. The fluorosilane-modifiednano TiO2 migrated to the surface reduces the surface energy of the coating, thereby enhancing the hydrophobicity. The preparation method is simple and easy to implement, short in period, suitable forlarge-scale production and applied to stone cultural relic protection.

Owner:TAIYUAN UNIV OF TECH

Anti-aging cable sheath material

PendingCN107383447AStrong heat aging resistanceImproves photoaging performanceRubber insulatorsPolyvinyl chlorideButadiene-styrene rubber

The invention discloses an anti-aging cable sheath material. The anti-aging cable sheath material comprises the following materials in parts by weight: 80-100 parts of natural rubber, 50-60 parts of butadiene styrene rubber, 15-20 parts of butyronitrile rubber, 15-30 parts of chlorosulfonated polyethylene rubber, 20-30 parts of polyvinyl chloride resin, 5-18 parts of aluminium-plated glass microbead, 6-12 parts of barium petroleum sulfonate, 2-8 parts of calcium-sulfate whisker powder, 12-25 parts of carbon black, 5-10 parts of zinc oxide, 5-10 parts of sulfur, 8-15 parts of N-isopropyl-N'-phenyl p-phenylenediamine, 4-10 parts of N-phenyl-2-naphthylamine, 5-10 parts of titanium dioxide, 4-12 parts of phenyl salicylate, 5-8 parts of an ultraviolet absorbent UV-P, 6-12 parts of an ultraviolet absorbent UV-O, 5-10 parts of a light stabilizer GW-540, 5-10 parts of a light stabilizer GW-544, 20-30 parts of a filler and 1-3 parts of a plasticizing agent. The anti-aging cable sheath material disclosed by the invention has the advantages that by matching of the natural rubber, the butadiene styrene rubber, the butyronitrile rubber, the chlorosulfonated polyethylene rubber and the polyvinyl chloride resin with a proper matching ratio and addition of all other materials, a finished product has stronger anti-heat-aging, anti-oxidative-aging and anti-light-aging properties.

Owner:安徽卓越电力设备有限公司

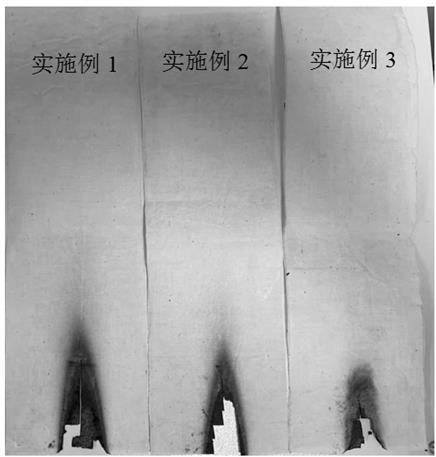

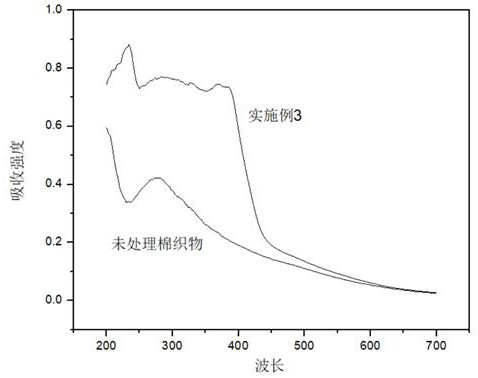

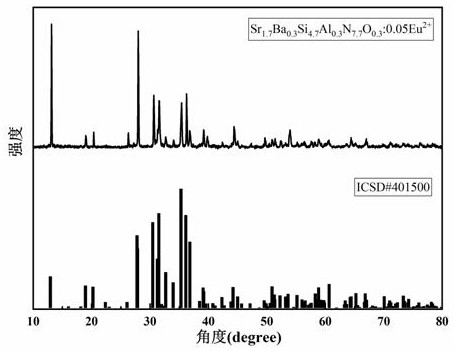

Inorganic bio-based ultraviolet aging-resistant flame retardant and application thereof in textiles

PendingCN113186727ASuppress afterburnImprove charcoal abilityHeat resistant fibresVegetal fibresPolyesterWoven fabric

The invention discloses an inorganic bio-based ultraviolet aging-resistant flame retardant and application thereof in textiles. The flame retardant comprises a g-C3N4 anion suspension solution prepared from urea, a polyethyleneimine cation solution prepared from polyethyleneimine and deionized water, and a phytic acid anion solution prepared from phytic acid and deionized water. Fluorescent powder, polyvinylpyrrolidone and absolute ethyl alcohol are mixed, and stirring is performed to obtain a coating solution; and a cotton fabric is alternately soaked in the polyethyleneimine cation solution and the g-C3N4 anion solution and then is alternately soaked in the polyethyleneimine cation solution and the phytic acid anion solution, then the coating solution is uniformly applied, and drying is performed to obtain an ultraviolet aging-resistant and flame-retardant cotton fabric. According to the flame retardant, an inorganic bio-based hybrid self-assembly coating is constructed, so that the afterflame of a polyester-cotton fabric is effectively inhibited, and the char forming capacity of the cotton fabric is improved. Ultraviolet rays are effectively absorbed through the fluorescent powder, so that the ultraviolet aging resistance of the fabric is enhanced.

Owner:LANZHOU UNIVERSITY

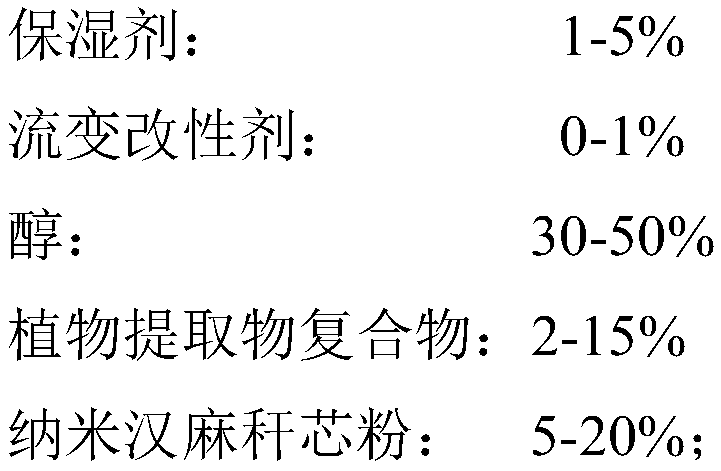

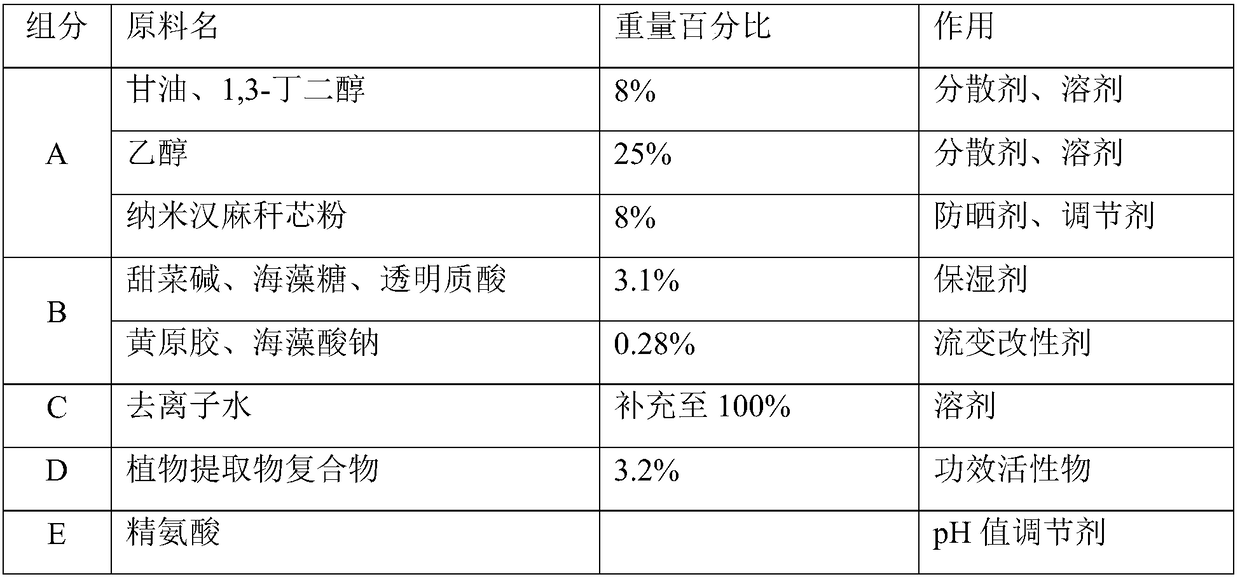

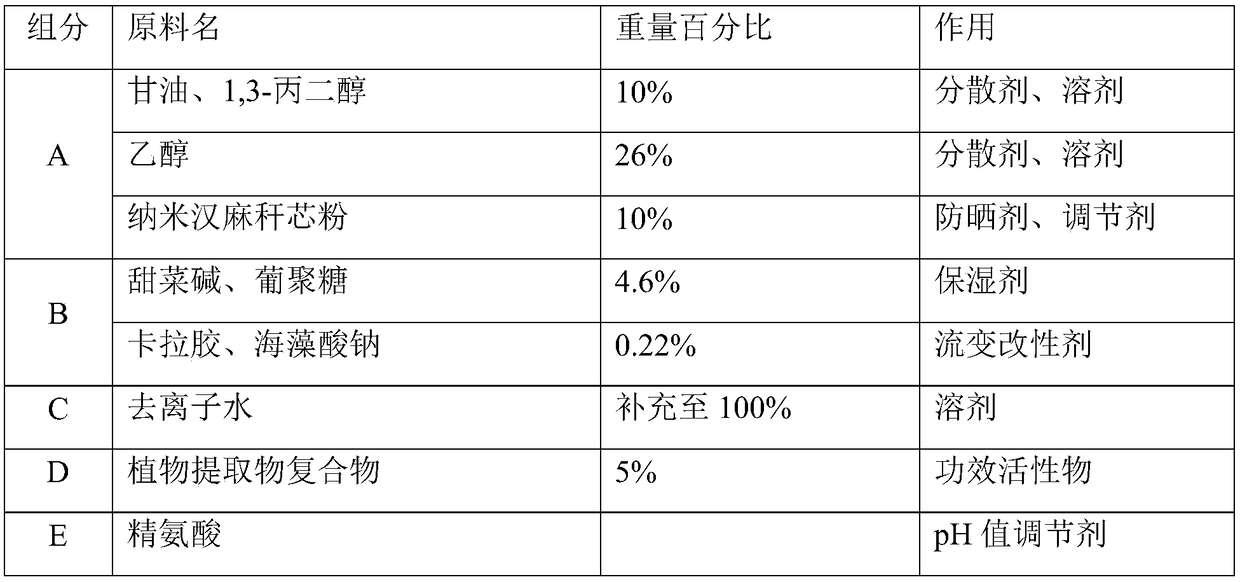

Natural plant sunscreen composition as well as preparation method and application thereof in sunscreen products

InactiveCN109303748AEffective protectionSpeed up the repair processCosmetic preparationsToilet preparationsIlex kudingchaAlcohol

The invention discloses a natural plant sunscreen composition as well as preparation method and application thereof in sunscreen products. The composition is prepared from the following components inpercentage by weight: 1-5% of moisturizer, 0-1% of rheology modifier, 30-50% of alcohol, 2-15% of plant extract compound and 5-20% of nano hemp stalk core powder; the plant extract compound is prepared from an ilex kudingcha extract, a radix scutellariae extract, a fructus rosae roxburgniae extract, a lespedeza extract, a saffron crocus extract and a flos sophorae immaturus extract. Since all components are derived from natural plants, the sunscreen composition disclosed by the invention is safe and mild, realizes an effective protection effect against ultraviolet light and a function of improving skin repairing and light aging resistance, and feels moisturized, smooth and fresh without greasiness.

Owner:广州丽丰化妆品制造有限公司

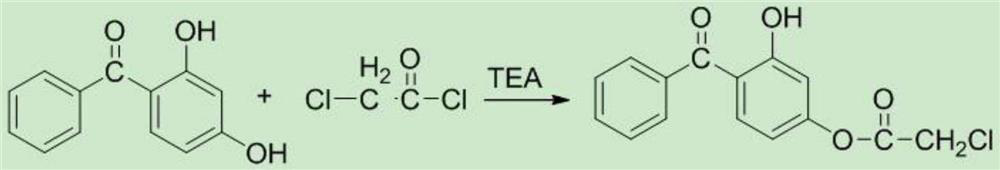

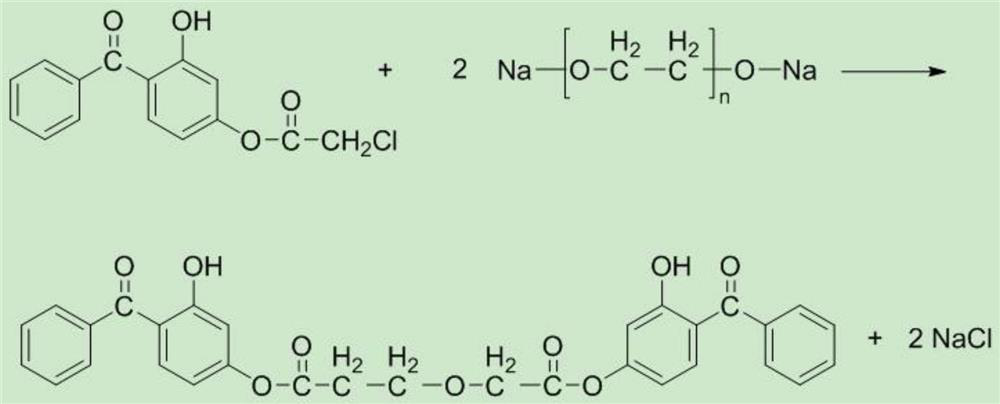

Synthesis method of ultraviolet light absorber for water-based coiled material finish paint

PendingCN112795282ASoluble in waterGood water solubilityPreparation from carboxylic acid halidesRadiation-absorbing paintsUltraviolet lightsPolyethylene glycol

The invention provides a synthesis method of an ultraviolet light absorber for water-based coiled material finish paint, and particularly relates to the technical field of polymer synthesis and paints. The method comprises the steps: S1, taking 2,4-dihydroxybenzophenone (UV-0) as a parent body, introducing an active reaction group through molecular design, and preparing a reaction type benzophenone monomer; and S2, enabling the active monomer containing the benzophenone structure in the S1 to react with sodium polyethylene glycol with different molecular weights so as to obtain a target product. The water solubility of the ultraviolet light absorber can be effectively improved; and the compatibility of the ultraviolet light absorber and base resin can be improved, the defects that a traditional benzophenone ultraviolet light absorber is insoluble in water, poor in compatibility, prone to migration and the like are overcome, and when the ultraviolet light absorber is used in cooperation with the water-based coiled material finish paint, the light aging resistance of a coating film can be effectively improved.

Owner:万博新材料科技(南通)有限公司

ABS material and preparation method thereof

InactiveCN108641275AGood weather resistanceImprove mechanical propertiesHindered amine light stabilizersEmulsion polymerization

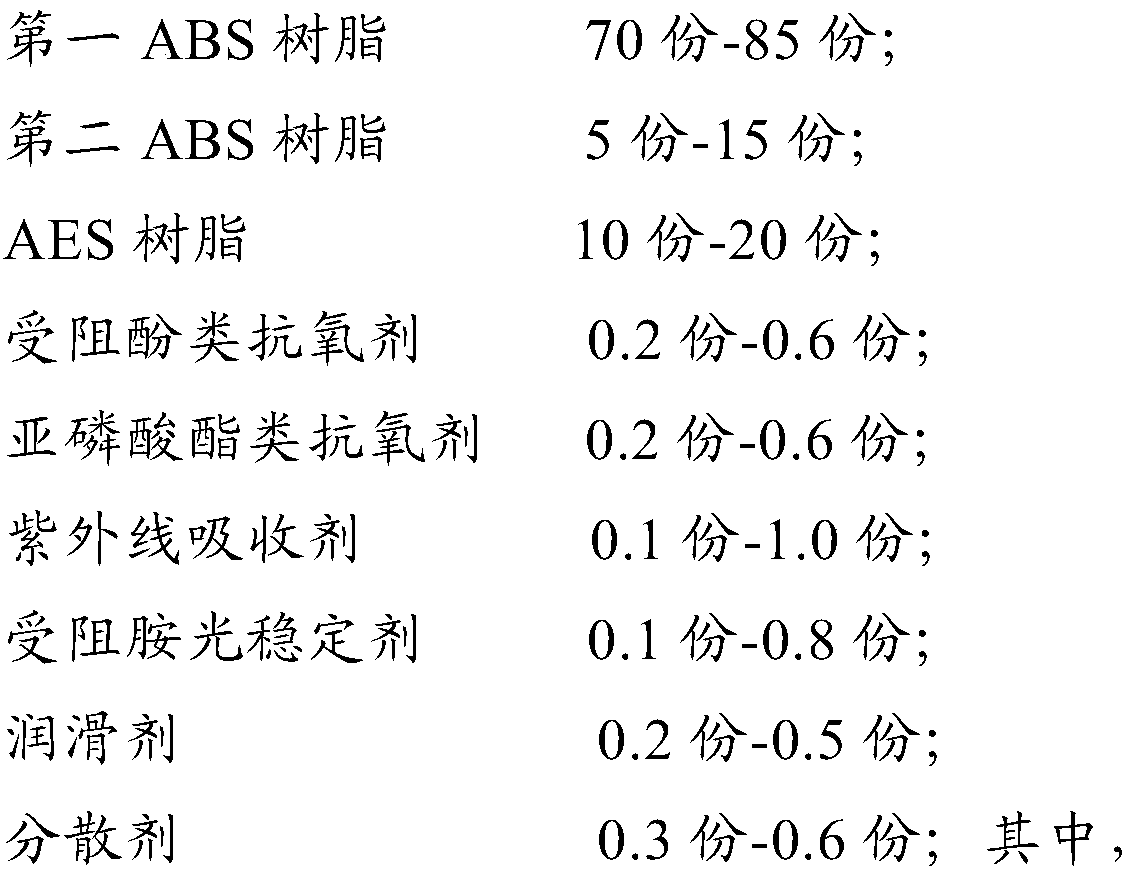

The invention discloses an ABS material and a preparation method thereof. The ABS material is prepared from, by weight, 70-85 parts of first ABS resin, 5-15 parts of second ABS resin, 10-20 parts of AES resin, 0.2-0.6 part of hindered phenol antioxidant, 0.2-0.6 part of phosphite antioxidant, 0.1-1.0 part of ultraviolet light absorber, 0.1-0.8 part of hindered amine light stabilizer, 0.2-0.5 partof lubricating agent and 0.3-0.6 part of dispersing agent; the first ABS resin is synthesized ABS resin by using a continuous bulk method, and the second ABS resin is the synthesized ABS resin by using a emulsion polymerization method. By utilizing synergistic effects among all the components, the method improves the weather-proof performance and mechanical performance of the ABS material.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Anti-photoaging latex foaming product and manufacturing method thereof

PendingCN112662025AImproves photoaging performanceExtended service lifePolymer scienceUltraviolet lights

The invention provides an anti-photoaging latex foaming product and a manufacturing method thereof. The product comprises the following components in parts by weight: 100-0 parts of natural latex NR with solid content of 60%, 0-100 parts of styrene-butadiene latex SBR with solid content of more than 60%, 7.0-8.5 parts of vulcanizing bag with solid content of 50%, 0.65-1.3 parts of DPG dispersion with solid content of 50%, 2.3-5.8 parts of potassium oleate with solid content of 20%, and 0.75-1.35 parts of castor oil soup liquid with solid content of 20%, and 0.4-0.8 parts of a composite anti-photoaging agent dispersion with the solid content of 50% and a proper amount of a pH regulator. The combined anti-photoaging agent dispersion is mainly prepared from a phenolic antioxidant, an ultraviolet light absorber and a light stabilizer. By adding the combined anti-photoaging agent dispersoid into the formula, the obtained latex foaming product can greatly improve the anti-photoaging performance.

Owner:JIANGSU AIDEFU LATEX PROD

Preparation method of exterior wall heat-insulating coating capable of resisting pulverizing and falling

The invention relates to a preparation method of an exterior wall heat-insulating coating capable of resisting pulverizing and falling, and belongs to the technical field of preparation of building materials. The preparation method comprises the following steps: grinding raw materials comprising coal ash rich in calcium, aluminum ions and siliceous salt, sandstone and imvite to obtain a sieving powder, cultivating oil-producing algae by taking waste water of a sugar refinery as a culture liquid, blending and fermenting the oil-producing algae, egg white and orange juice to obtain a fermented material, continuously fermenting the fermented material and the sieving powder for the second time, and finally preparing the exterior wall heat-insulating coating capable of resisting pulverizing andfalling by taking fermentation filter residues as a main material and cooperating with other auxiliary materials. The exterior wall heat-insulating coating capable of resisting pulverizing and falling has a high waterproof property, high durability and high adhesive strength, has low probability of pulverizing and falling and has a wide application prospect.

Owner:赵建平

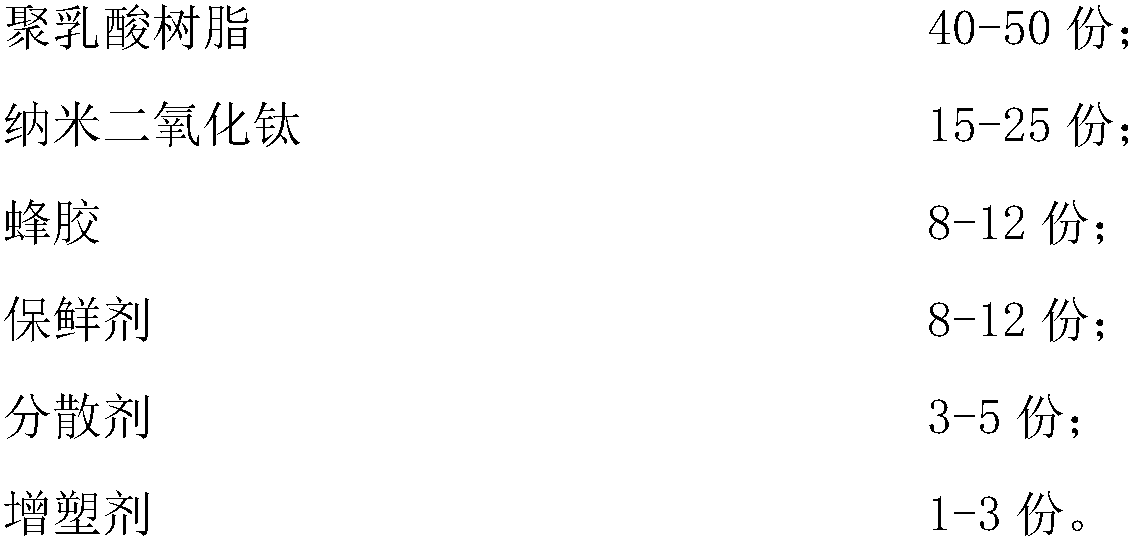

Environment-friendly preservation bag for beef jerky and preparation method of bag

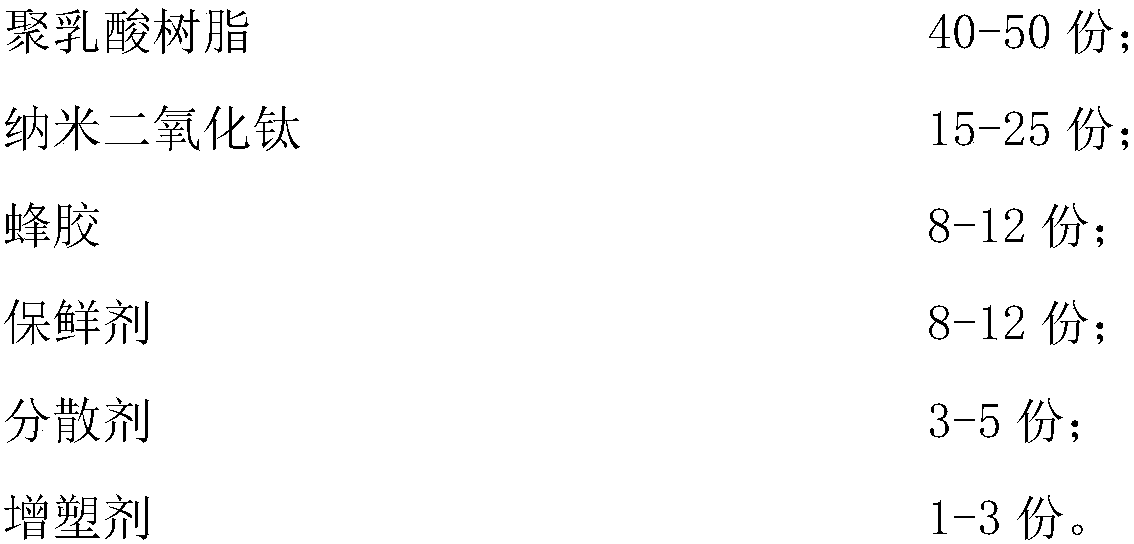

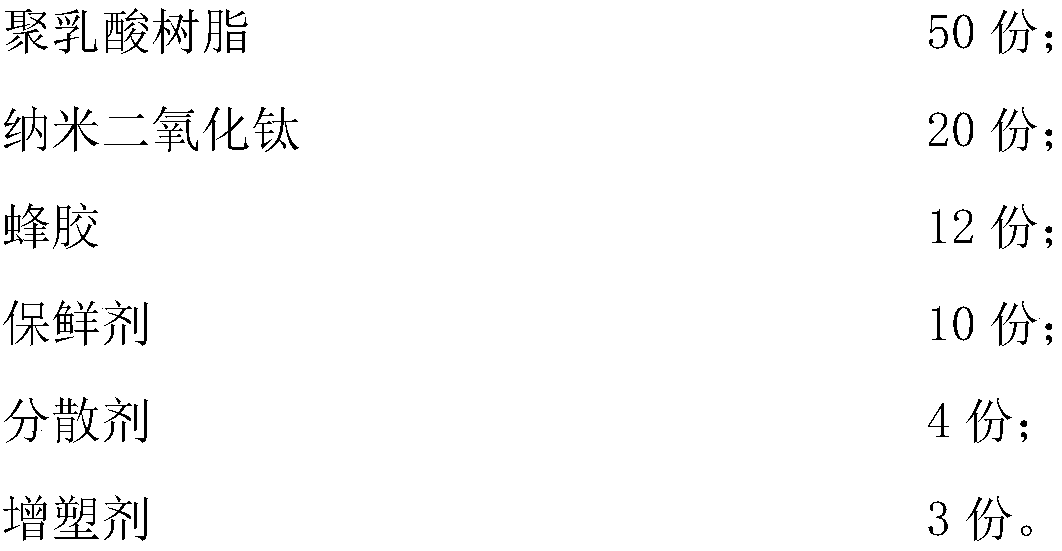

The invention discloses an environment-friendly preservation bag for beef jerky and a preservation method of the bag. The environment-friendly preservation bag takes polylactic resin as a base material, nano titanium is added for enhancing the polylactic resin, added propolis has an antibacterial function, the preservation function of the preservation bag is improved, an added preservative tea polyphenol has an antioxidant function, melt blending and extrusion palletization are adopted, extrusion and film blowing are performed, and the prepared preservation bag has the advantages of being biodegradable, environmentally friendly, antibacterial and simple to prepare.

Owner:安徽五源食品有限公司

Composite degradable polymer with strong ductility and preparation method thereof

PendingCN114763430AImprove tensile strength, impact strengthImprove compatibilityPolymer chemistryCompatibilization

The invention provides a high-ductility composite degradable polymer and a preparation method thereof. The high-ductility composite degradable polymer is prepared from the following raw materials in parts by weight: 1-99 parts of PHBV, 1-99 parts of PPCP, 0.1-20 parts of a compatibilizer and 0.1-15 parts of functional materials. According to the composite degradable polymer disclosed by the invention, by regulating and controlling the adding proportion of the PPCP and the PHBV and combining the specific compatibilizer and various specific functional aids, the production cost is reduced, the crystallization degree of a composite copolymer is reduced, the mechanical property of the composite degradable polymer is improved, and the compatibility, the thermal stability and the light aging resistance of the polymer are improved; the application of the composite copolymer in films, sheets, injection molding products and foaming products is improved, and the method is suitable for large-scale industrial production.

Owner:SHANDONG LECSIN GREEN TECH CO LTD

Preparation method of bio-based flame-retardant and light-aging-resistant PVA (Polyvinyl Alcohol) composite material

ActiveCN113185873AWide variety of sourcesAdd lessFireproof paintsLuminescent paintsAcetic acidPolyvinyl alcohol

The invention discloses a preparation method of a bio-based flame-retardant and light-aging-resistant PVA (polyvinyl alcohol) composite material, which comprises the following steps: dispersing polyvinyl alcohol in deionized water, heating, stirring and cooling to obtain PVA dispersion liquid; adding glacial acetic acid and chitosan powder, and stirring at room temperature until the chitosan powder is completely dissolved; adding phytic acid, stirring and performing ultrasonic treatment to obtain a bio-based flame-retardant PVA solution; adding fluorescent powder, stirring at room temperature, and performing ultrasonic treatment to obtain a mixed solution; and transferring the mixed solution into a mold, drying, and demolding to obtain the bio-based flame-retardant and light-aging-resistant PVA composite material. The composite material prepared by the preparation method has excellent flame retardant property, mechanical property, ultraviolet absorption property and the like, the influence of ultraviolet on PVA (Polyvinyl Alcohol) can be reduced, the service life is prolonged, and the light aging resistance is improved.

Owner:LANZHOU UNIVERSITY

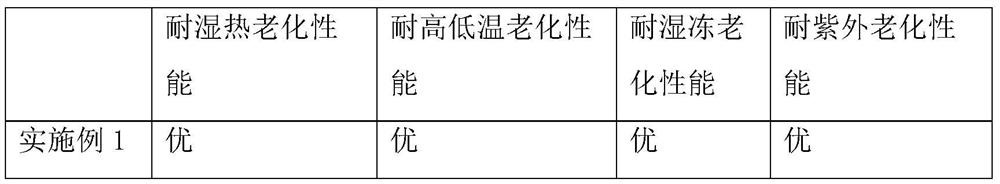

High and low temperature resistant long-life solar photovoltaic backboard and preparation process thereof

ActiveCN112812433AImprove firmness and stabilityExtended service lifeFinal product manufactureSynthetic resin layered productsPolyolefinEngineering

A high and low temperature resistant long-life solar photovoltaic backboard at least comprises an outer layer and an inner layer connected with the outer layer from top to bottom, wherein the preparation raw materials of the outer layer at least comprise, by weight, 20-80 parts of first polyolefin and 1-10 parts of water-insoluble solid inorganic matter, and the preparation raw materials of the inner layer at least comprise, by weight, 20-80 parts of second polyolefin; the outer layer and the inner layer are integrally formed through a co-extrusion technology and fusion, so that the overall firmness and stability of the solar photovoltaic back plate are improved, the solar photovoltaic back plate does not have the risks of cracking and delaminating even if the solar photovoltaic back plate is in an external cracking environment for a long time, and the service life of the solar photovoltaic back plate is prolonged. With the polyolefins as a main raw material, so that the environmental protection property of the solar photovoltaic backboard is improved, and the production concept of green development is compounded. By adding the solid inorganic matter in the outer layer of the solar photovoltaic backboard, the high and low temperature resistance and wear resistance of the solar photovoltaic backboard are improved, and the service life of the solar photovoltaic backboard is prolonged.

Owner:浙江中聚材料有限公司

Natural lignocellulose material with modified zinc oxide and preparation method thereof

The invention relates to a natural lignocellulose material with modified nano zinc oxide and a preparation method thereof. The method prepares the natural lignocellulose material with modified nano zinc oxide by impregnating natural lignocellulose material with zinc salt solution by means of constant pressure, vacuum or vacuum pressure, and then conducting heat treatment on the material obtained through impregnation at the temperature of 70-120 DEG C for 1-6h. Being simple and effective, the preparation method not only maintains the color, texture and structure of natural lignocellulose material totally, but also improves the resistance to photochromism by 10-20 times and improves mildewproof performance by 25-30 times and changes unavailable antibacterial performance to over 99 percent sterilization rate of colibacillus, candida albicans and other strains. The natural lignocellulose material with modified nano zinc oxide can be widely applied outdoors, and in indoor basements, hospitals and other places that have high requirement on the anti-aging, mildewproof and antibacterial performances of the material.

Owner:国际竹藤网络中心

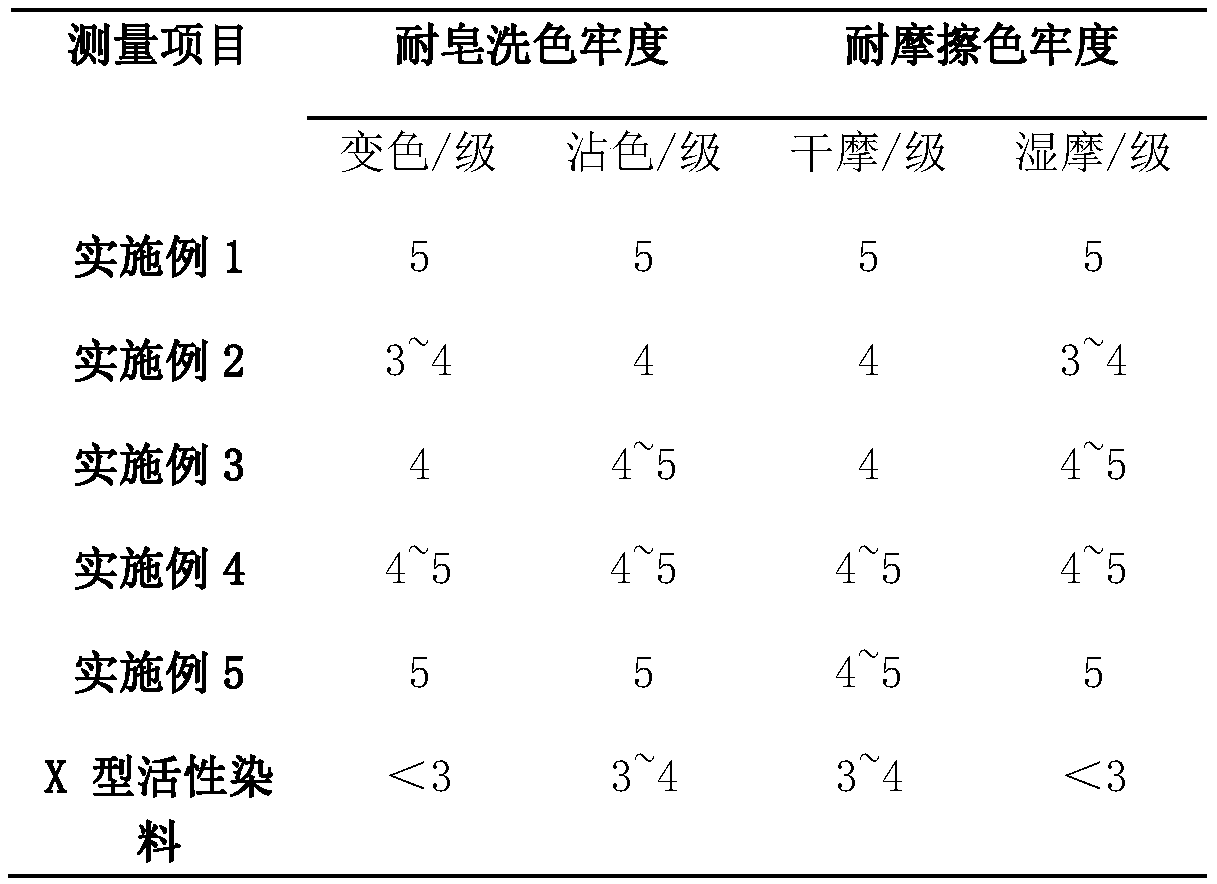

Wax printing dye and wax printing method

InactiveCN110761088AChange color fastnessHigh color fastnessDyeing processColour fastnessPolymer science

The invention discloses a wax printing dye and a wax printing method. A substance containing a bis(monochlorotriazine) active group or monochlorodiazine active group is used as a colorant, mixed wax liquid is adopted, dyeing color fastness is changed, and tea polyphenols are added into the dye in order to improve the light aging resistance of dyeing colors. A fabric is smoothened and pretreated inthe dyeing process, a substance base is provided for natural and fine wax stripes in a follow-up wax printing process, the pretreated fabric is placed into the dye and dyed under the action of ultrasound, movement of dye molecules is facilitated by the action of ultrasound, dyeing is accelerated, and dyeing color fastness and uniformity are improved.

Owner:张家界乖幺妹土家织锦开发有限公司

Light aging resistant polyurethane plastic track and preparation method thereof

InactiveCN106398187AImproves photoaging performanceIncrease elasticityMethylene diphenyl diisocyanateStearic acid

Disclosed is a light aging resistant polyurethane plastic track. The light aging resistant polyurethane plastic track is prepared from paraformaldehyde, dimethylethanolamine, methylbenzene, rosin, aziridine, hydrogen peroxide, formic acid, phosphoric acid, ethylene glycol dimethacrylate, titanium dioxide rutile, nano barium sulfate, gamma-ammonia propyl triethoxy silane, poly butyl bisphenol, acrylonitrile-butadiene-styrol copolymer, iron oxide green, stearic acid lactic acid zinc, dibutyl phthalate, triethyl citrate, diethyl dithiocarbamate zinc, polypropylene glycol, methylene diphenyl diisocyanate, a 8-10%NaOH solution and deionized water. The polyurethane plastic track has the advantages of being good in elasticity, wearproof, antiskid, attractive in color, clean in site, easy to maintain and manage, free from affection of weather and the like.

Owner:安徽潜源教学设备有限公司

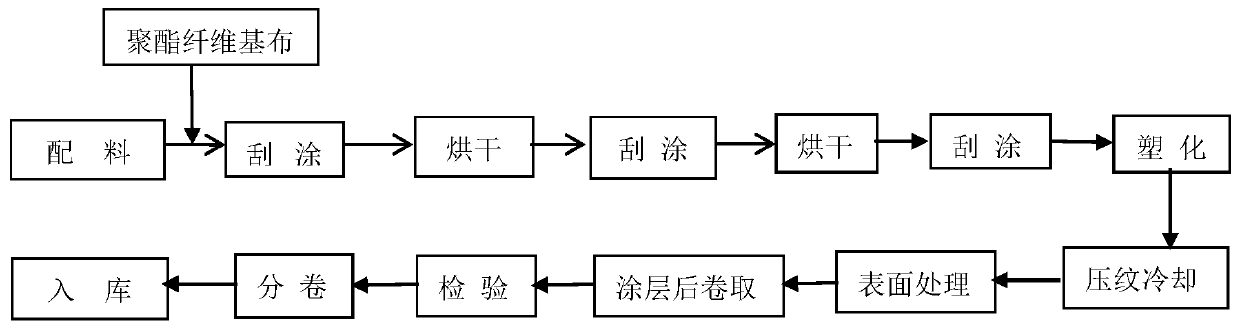

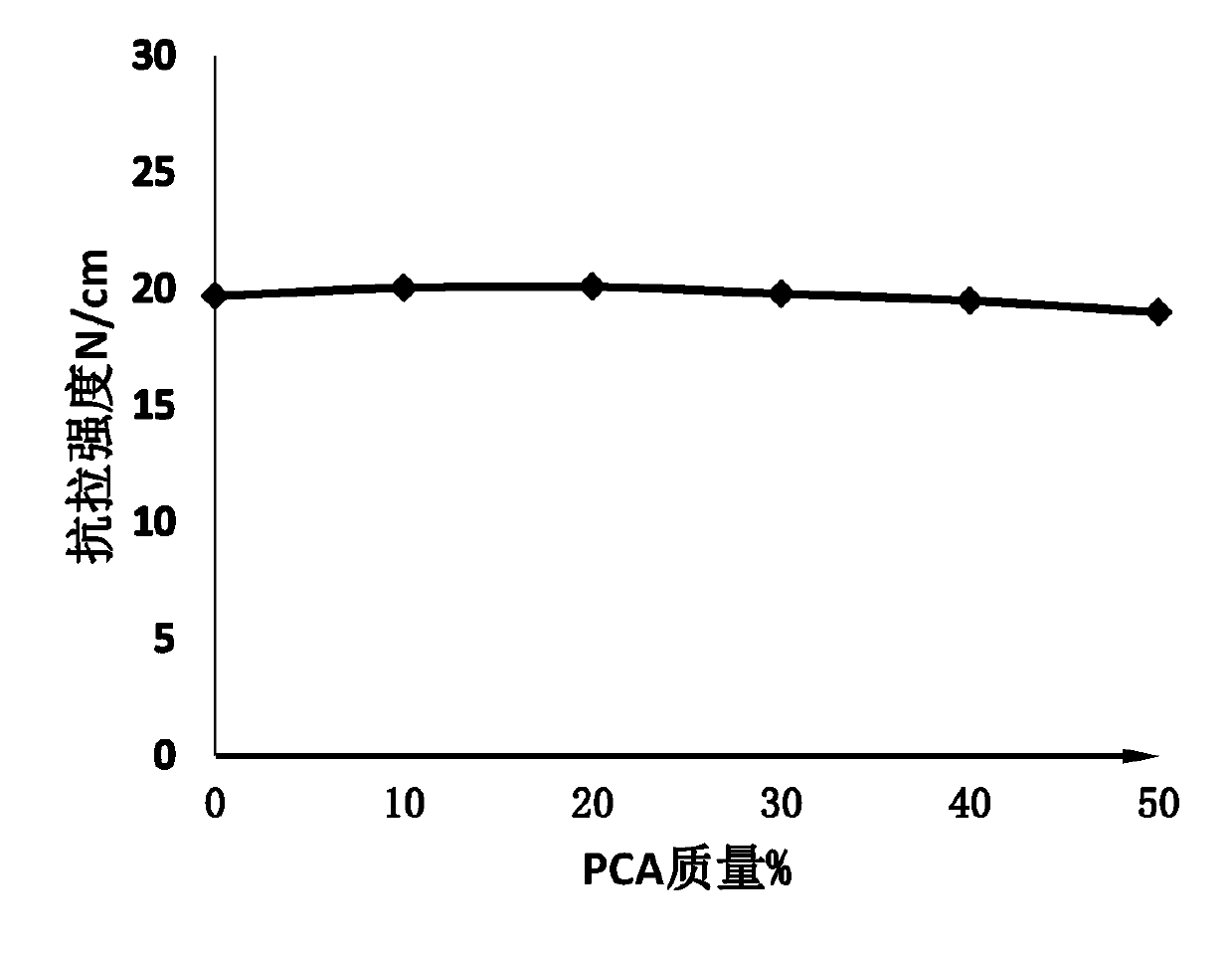

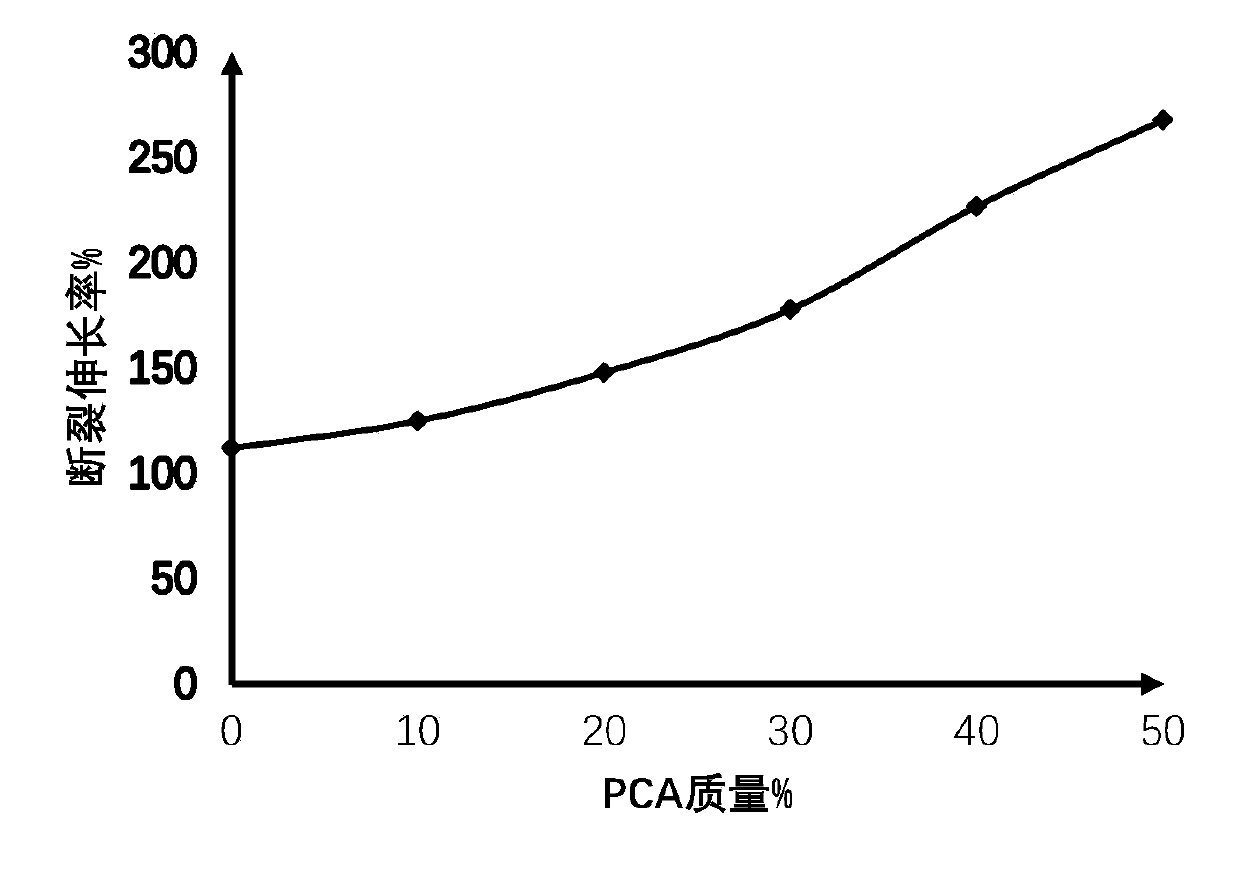

PVC/PCA composite coating fabric of sanitary tent and processing technology of PVC/PCA composite coating fabric

ActiveCN111501369AHigh peel strengthIncreased durabilityConstructions elementsVehicle componentsPolymer sciencePlasticizer

The invention relates to tent fabric, in particular to PVC / PCA composite coating fabric of a sanitary tent and a processing technology of the PVC / PCA composite coating fabric. The PVC / PCA composite coating fabric of the sanitary tent is prepared from, by weight, 50-100 parts of PVC paste resin, 0-50 parts of copolymer resin, 40-80 parts of an environment-friendly plasticizer, 0-30 parts of a cold-resistance plasticizer, 2-4 parts of an environment-friendly compound stabilizer, 10-30 parts of a flame retardant, 0-4 parts of a mildew preventive, 0-5 parts of a light stabilizer, 0-40 parts of a filler and 0-8 parts of a binder, wherein the copolymer resin is chloroethylene / vinyl acetate / acrylate terpolymer resin (PCA), and the sum of weights of the PVC paste resin and copolymer resin is 100 parts. According to the PVC / PCA composite coating fabric, the use of a large quantity of the low-molecular-weight plasticizer is avoided, and the fabric has excellent wear resistance, folding resistance and low-temperature resistance while the cold-resistance plasticizer is not used or the usage amount of the plasticizer is lowered.

Owner:ZHEJIANG FEIHU NEW MATERIAL CO LTD

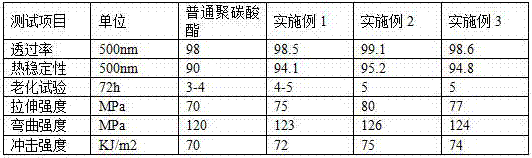

Preparation method of compound additive for polycarbonate modification

InactiveCN106947234AImprove antioxidant capacityImproves photoaging performanceBenzoxazoleAntioxidant

The invention discloses a preparation method of a compound additive for polycarbonate modification. The compound additive is prepared from the following components in parts by weight: 40-50 parts of an antioxidant, 40-50 parts of an auxiliary antioxidant, 10-15 parts of an ultraviolet light absorber and 1-5 parts of a fluorescent brightener, wherein the antioxidant is hindered phenols; the auxiliary antioxidant is dipropyl thionate or phosphites; the ultraviolet light absorber is triazine or benztriazoles; and the fluorescent brightener is benzoxazole. The additives are blended to obtain the compound additive in polycarbonate modification. According to the compound additive, the oxidation resistance, the heat stability and the photoaging resistance of polycarbonate can be improved.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

Special filler for cold-resistant ultraviolet-resistant high-pressure rubber tubes and preparation method thereof

The invention relates to a special filler for cold-resistant ultraviolet-resistant high-pressure rubber tubes, which is prepared from the following raw materials in parts by weight: 5-8 parts of attapulgite, 3-5 parts of meerschaum, 1-2 parts of vanadium pentoxide, 13-15 parts of ferrocene, 2-3 parts of barium stearate, 2-3 parts of polyamide wax micropowder, 2-3 parts of phytic acid, 2-3 parts of triethanolamine, 2-3 parts of triglycol diisooctoate, 50-55 parts of fly ash, a right amount of 4-6% hydrochloric acid, a right amount of water and 15-20 parts of assistant. By adding the ferrocene, the filler has ultraviolet resistance and higher photoaging resistance; by adding the triglycol diisooctoate, the cold resistance of the rubber tube can be enhanced; by using the fly ash, the cost is lowered, and the filler has favorable reinforcing performance; and the assistant can enhance the dispersity and reinforcing performance of the filler and enhance the strength and impact toughness of the high-pressure rubber tube, so that the rubber tube can not easily bubble or deform.

Owner:HEFEI HEAN MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com