Anti-light-ageing reinforcement material of colored relics and preparation method of reinforcement material

A technology for anti-light aging and reinforcement materials, applied in the direction of coating, etc., can solve the problems of affecting the protection effect of painted cultural relics, poor light aging resistance of B72, yellowing and brittleness, etc., to achieve long life, increased anti-light aging ability, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of anti-light aging reinforcement materials

[0037] Weigh 1.25g nano-SiO 2 Add 100mL of absolute ethanol / deionized water mixed solvent with a volume ratio of 85 / 15, add 0.0125g KH550 and 0.0375g OP-10 to prepare solution A. Weigh 2g of B72 and dissolve it in 8g of ethyl acetate to prepare solution B.

[0038] Solution A was ultrasonically dispersed at 60 °C for 120 min. Take 12.8mL of the above-mentioned solution A after ultrasonic dispersion and add it to 10g of solution B to obtain the SiO 2 -B72 composite anti-photoaging reinforcement material for painted cultural relics. Apply the above reinforcement material evenly on the glass slide to form a film, paint on the surface of the painted sample block and then repeat the brushing once, and place the treated sample at room temperature for 1 week before use;

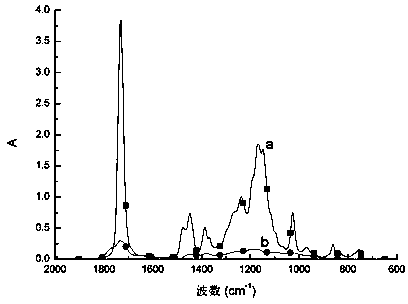

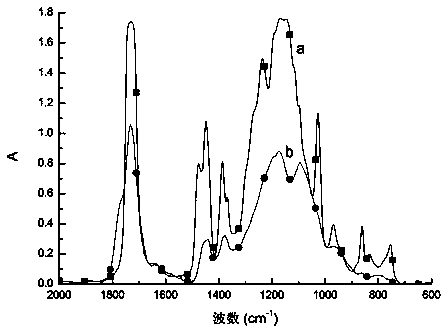

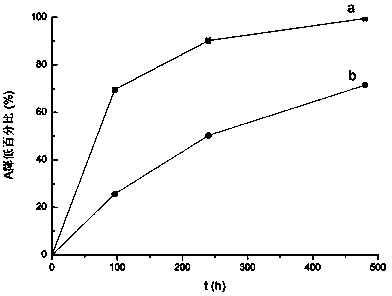

[0039] (2) Anti-light aging performance test

[0040] Place the prepared film material and painted sample block at a distance of 2cm from the...

Embodiment 2

[0066] Similar to the preparation method of Example 1, the waterproof material described in Table 3 can be prepared.

[0067]

Embodiment 3

[0069] Similar to Example 1, change the amount of SiO in the solution by changing the amount of solution A and solution B added 2 concentration, the experimental results are shown in Table 4.

[0070]

[0071] As can be seen from Table 4, the material of the present invention is significantly improved compared with the photoaging performance of B72, and the degree of improvement of the photoaging performance of the material of the present invention is comparable to that of SiO 2 Concentration related, and SiO 2 The higher the concentration, the better the effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com