Patents

Literature

82results about How to "Emulsified evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

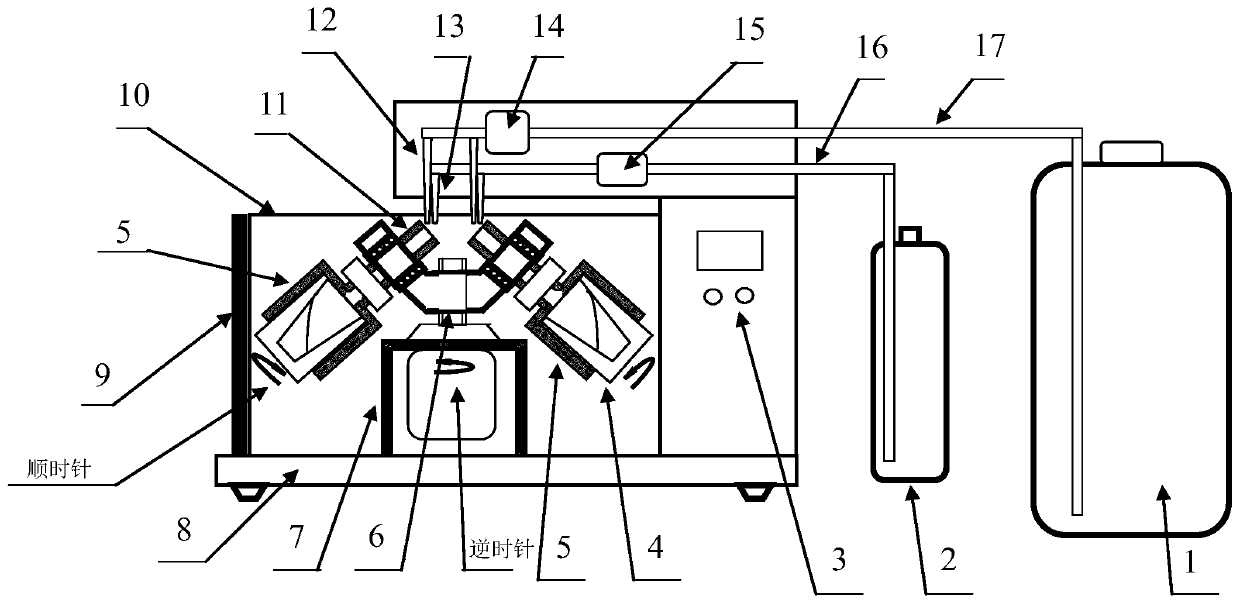

Identical reaction kettle reel-to-reel plasma ultrasonic supercritical non-aqueous dyeing

InactiveCN101555665AFast anhydrous dyeing rateImprove solubilityTextile treatment containersPhysical treatmentUltrasonic sensorExhaust valve

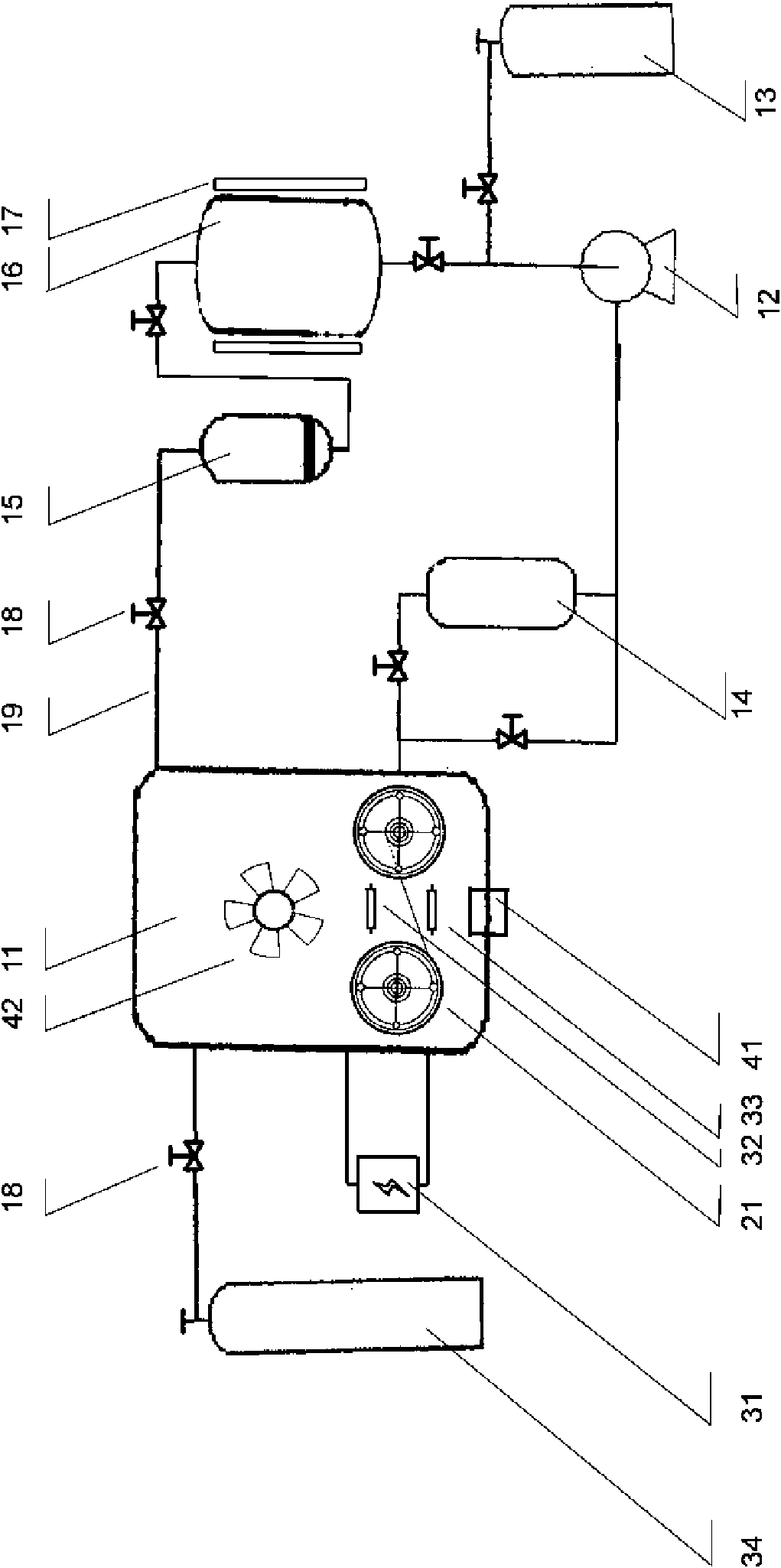

The invention discloses an identical reaction kettle reel-to-reel plasma ultrasonic supercritical non-aqueous dyeing system, comprising a general control console, a carbon dioxide storage bottle, a high-pressure pump, a dye tank, a heat exchange device, a reaction kettle, a dye recycling tank, a filter, a condenser, a liquid carbon dioxide storage tank, a flow meter, a valve and a pipeline, and characterized in that the reaction kettle is provided with an upper electrode and a lower electrode of a plasma generator, an exhaust valve and a vacuum pump, is internally provided with one or a plurality of groups of reel-to-reel or axis-to-axis wind and relative motors, is also internally provided with one or a plurality of groups of agitating devices and relative motors, and is embedded with an ultrasonic transducer connected with an ultrasonic wave generation device. The plasma realizes the modification for the surface of material, the ultrasonic wave disperses the dyes uniformly, the supercritical carbon dioxide realizes non-aqueous dyeing, and the reel-to-reel way realizes non-intermittent continuous industry production. The invention can meet the most rigorous environment-friendly demand and product safety demand.

Owner:冷博

Whitening and anti-wrinkle alligator oil skin-care product and preparation method thereof

ActiveCN103462829AGet rid of acne scarsLighten dark spotsCosmetic preparationsToilet preparationsAnti wrinkleChemistry

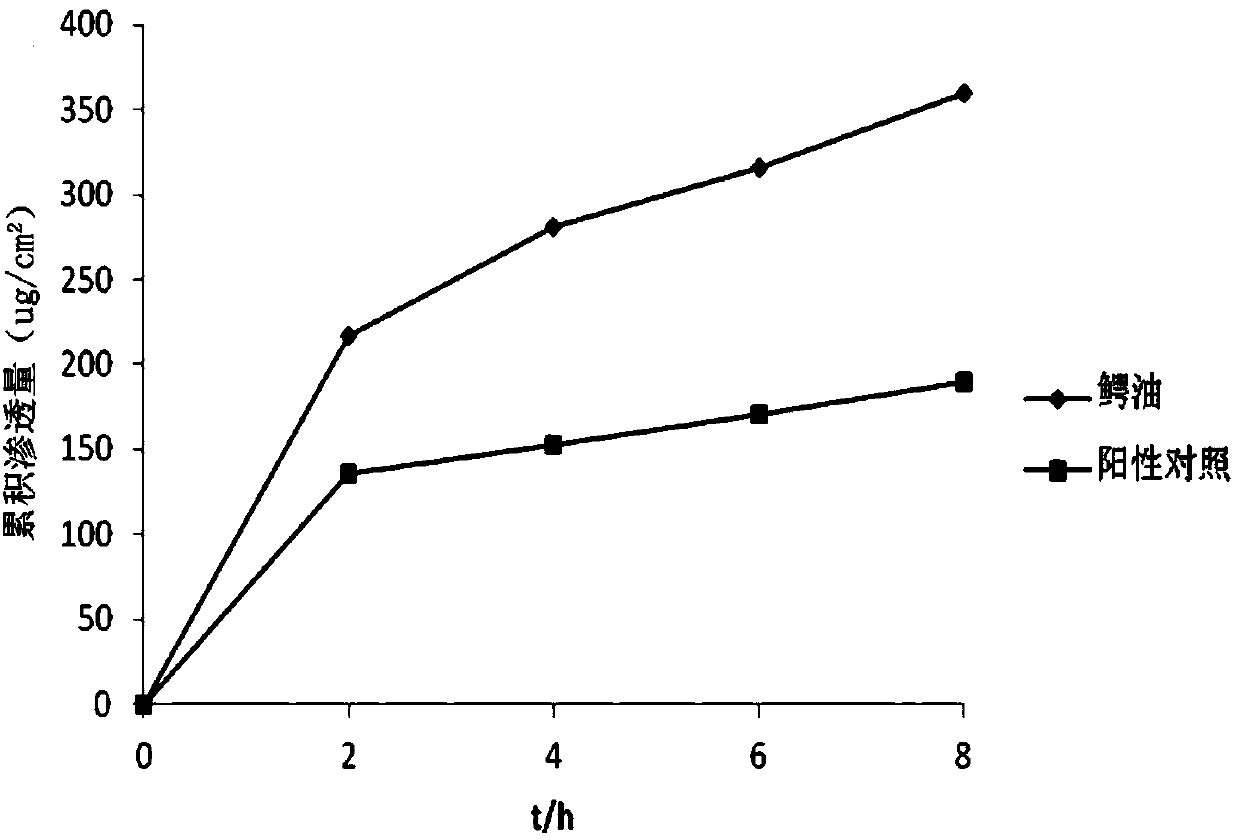

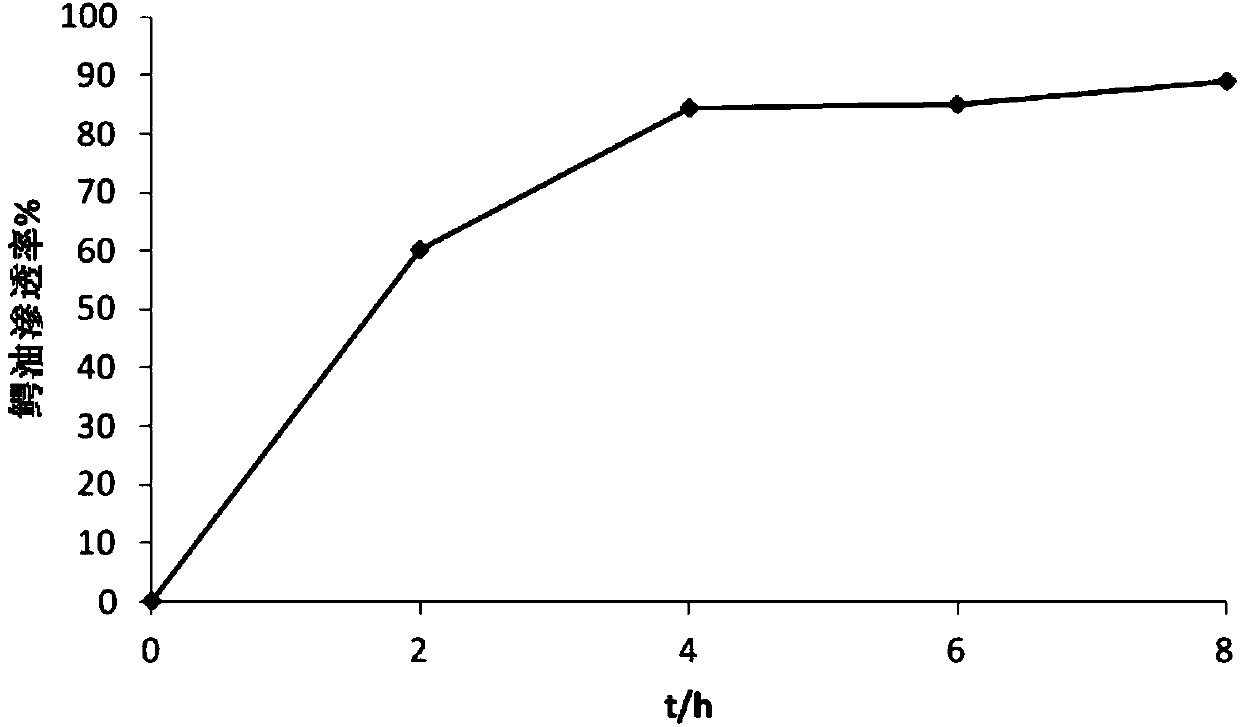

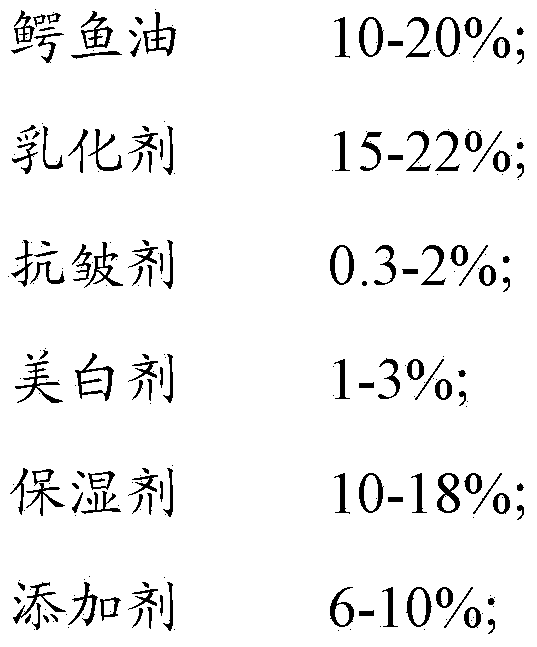

The invention relates to a whitening and anti-wrinkle alligator oil skin-care product and a preparation method thereof. The whitening and anti-wrinkle alligator oil skin-care product comprises the following components in percentage by weight: 10-20% of alligator oil, 15-22% of emulsifying agents, 0.3-2% of anti-wrinkling agents, 1-3% of whitening agents, 10-18% of moisturizing agents, 6-10% of additives, and the balance being water. The whitening and anti-wrinkle alligator oil skin-care product has the efficacies on whitening the skin, moisturizing and preventing wrinkles, has a good cleaning-up effect on black brown spots generated by solar ultraviolet irradiation, keeps the skin moisture, prevents the wrinkles caused by dry skin and improves the skin elasticity.

Owner:GUANGZHOU TUOLONG BIOTECH DEV

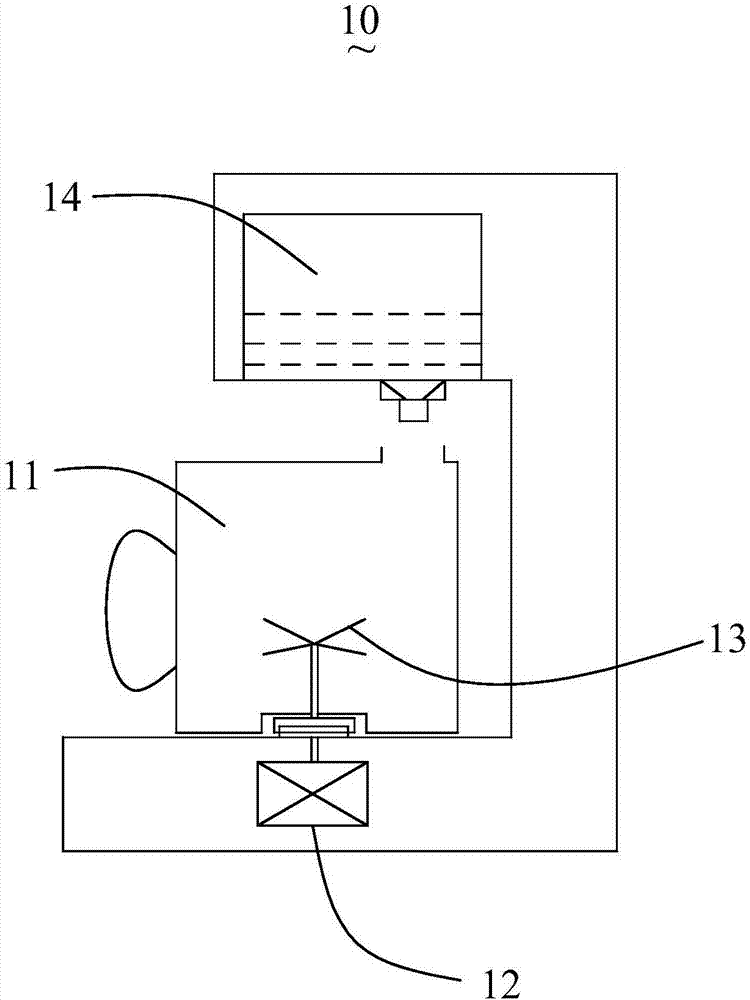

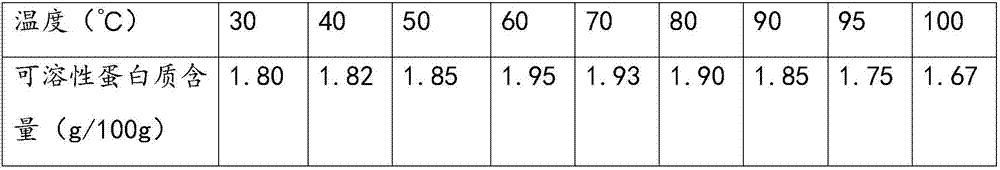

Soybean milk making method free of false boiling and soybean milk machine adopting method

ActiveCN107396976ADelicate and smooth tasteImprove surface activityBeverage vesselsMilk substitutesSlurryEnzyme

Owner:JOYOUNG CO LTD

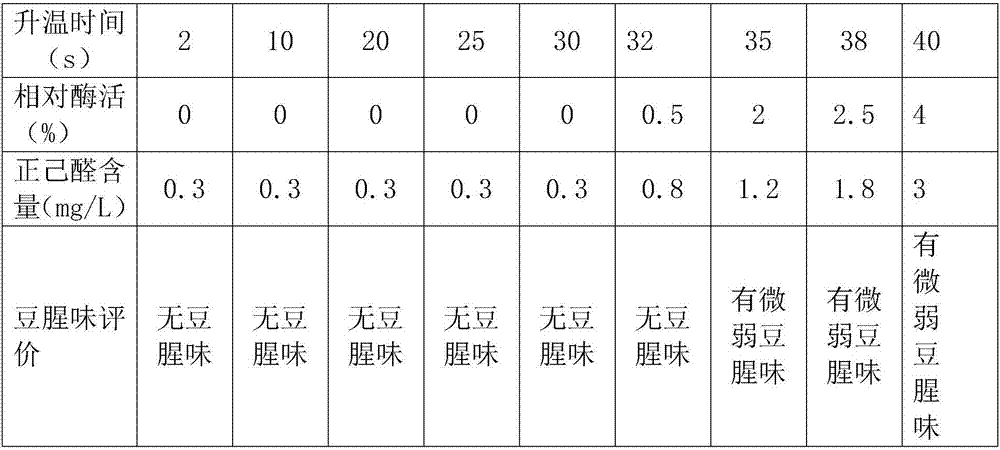

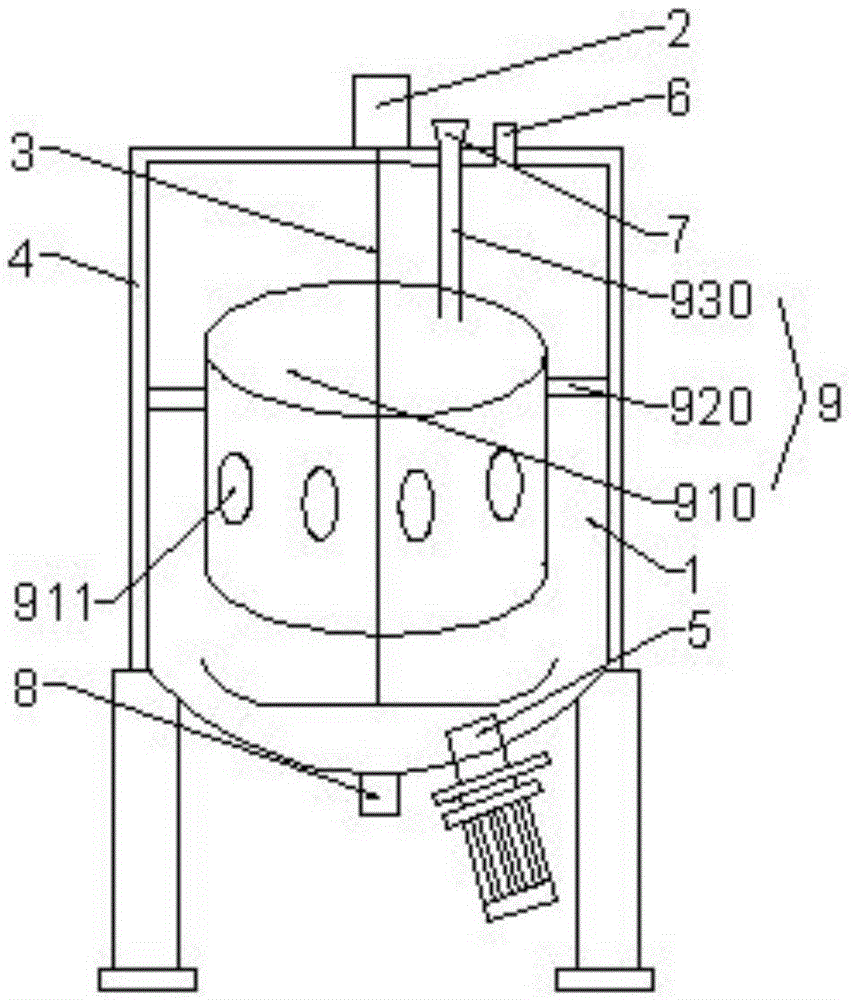

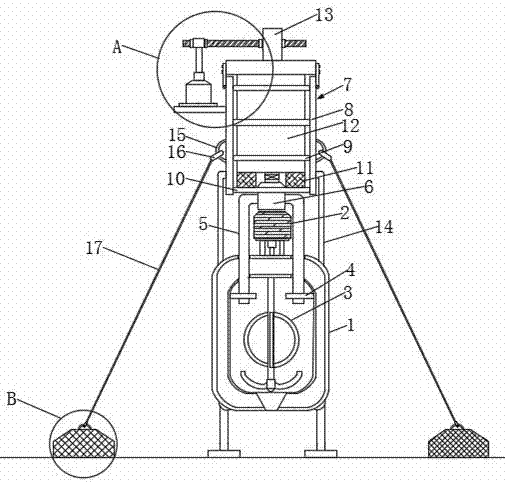

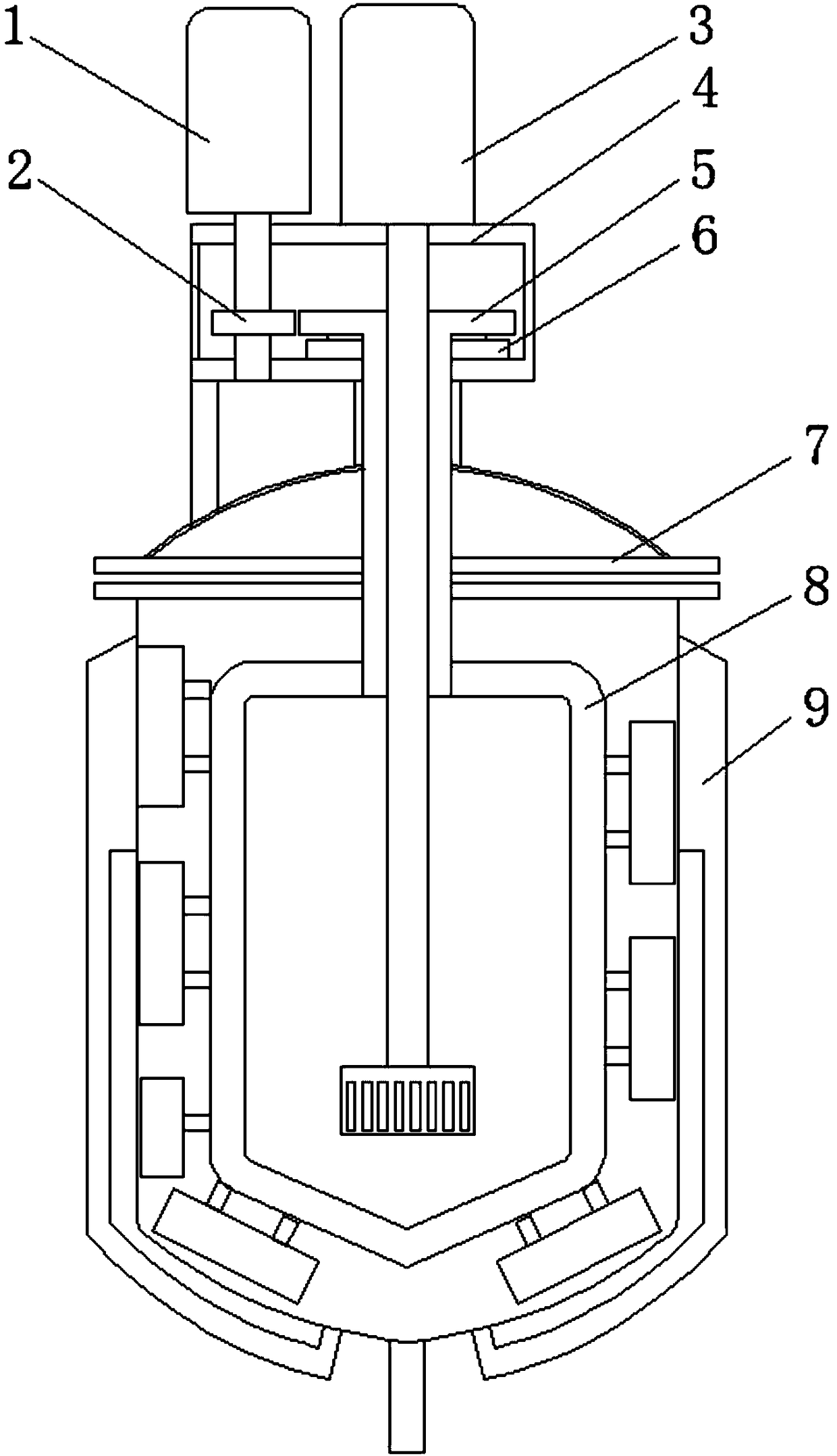

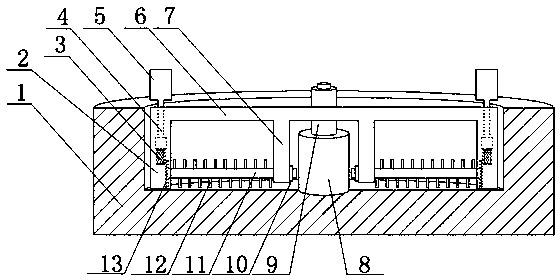

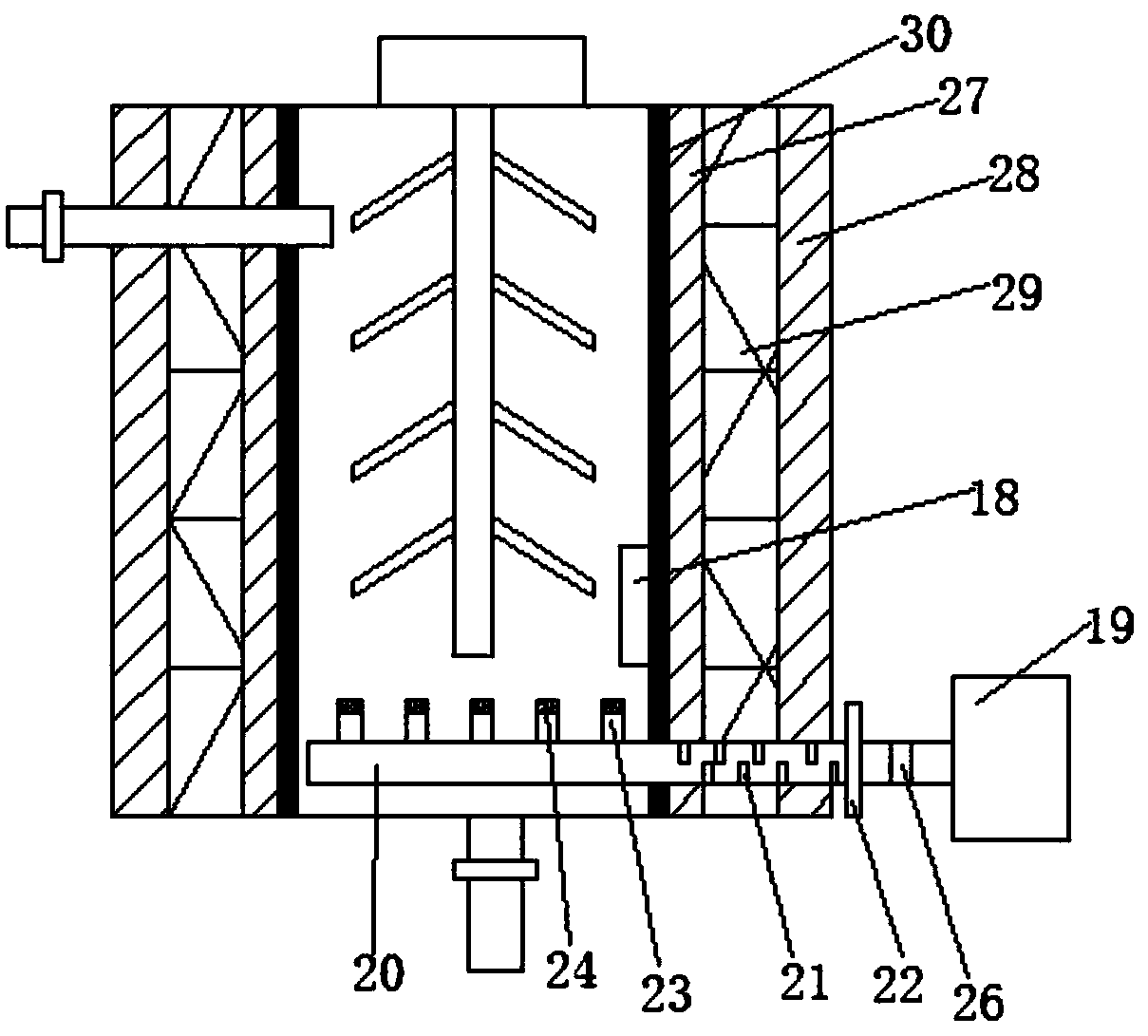

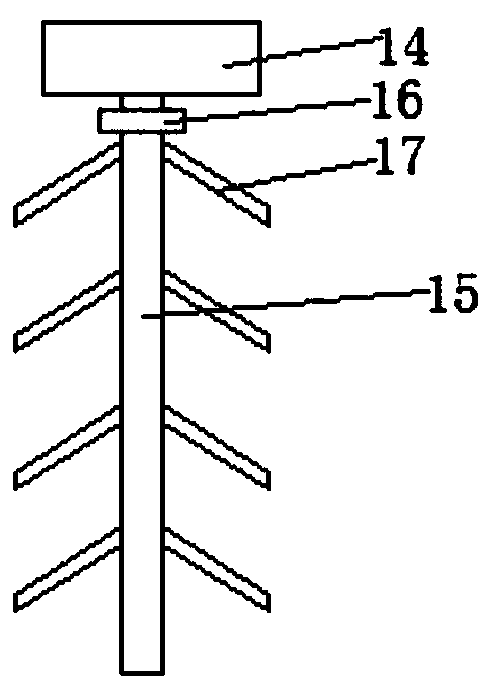

Reactor for preparing high-viscosity silicone oil emulsion

InactiveCN103623762AEasy to moveDoes not change the flow patternRotary stirring mixersChemical/physical/physico-chemical stationary reactorsEngineeringSilicone oil

The invention belongs to the technical field of novel silicone oil emulsion preparation, and in particular relates to a reactor for preparing high-viscosity silicone oil emulsion. The reactor is characterized by consisting of a container main body, a jacket, a main stirrer and a wall-scraping stirrer. Materials generate a flow field by virtue of the rotation of the main stirrer. Since the main stirrer is provided with three layers of blades in different rotating directions, the materials flow up from the bottom of a container and are pressed down by the reversed blades at a liquid level part. An oil phase and a water phase form shearing for emulsification, and the blades are large in size and are particularly suitable for preparing the high-viscosity silicone oil emulsion. The wall-scraping stirrer can scrape the poorly-emulsified materials which are adhered to the wall surface along the inner wall of the container to enable the materials to enter the main stirrer for emulsification; the wall-scraping stirrer is attached to the inner wall of the container, so that the flow pattern of the flow field of the main stirrer cannot be changed; the container is provided with a sealing head with a flat bottom and a circular-arc-shaped straight edge, so that high-viscosity materials can conveniently flow up, and the emulsification uniformity is realized. The particle size distribution of the high-viscosity silicone oil emulsion prepared by the reactor is narrow. The reactor is particularly suitable for preparing large-particle-size oil-in-water (O / W) emulsion and can be applied to the reaction process of other high-viscosity material systems.

Owner:JIANGNAN UNIV

Compound clobetasol propionate and tretinoin ointment

ActiveCN102641275AExcellent emulsifierStable traitsHydroxy compound active ingredientsAerosol deliveryTretinoinDisease

The invention provides a compound clobetasol propionate and tretinoin ointment which comprises clobetasol propionate, tretinoin and octodecyl alcohol. The ointment can still keep a homogeneous system at high temperature of 40 DEG C, or even 60 DEG C, two-phase separation cannot occur, and the problem of uneven content of the preparation at high temperature can be effectively avoided. The ointmentis mainly used for treating psoriasis vulgaris, dermatitis, eczema, etc.

Owner:JIANGSU SEMPOLL PHARMA

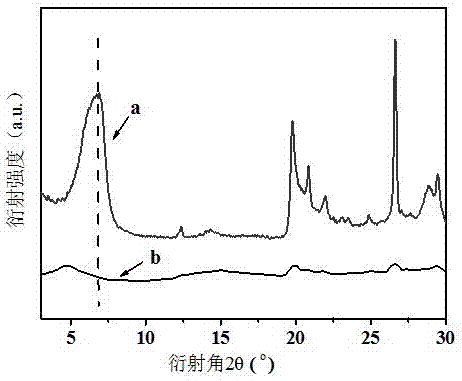

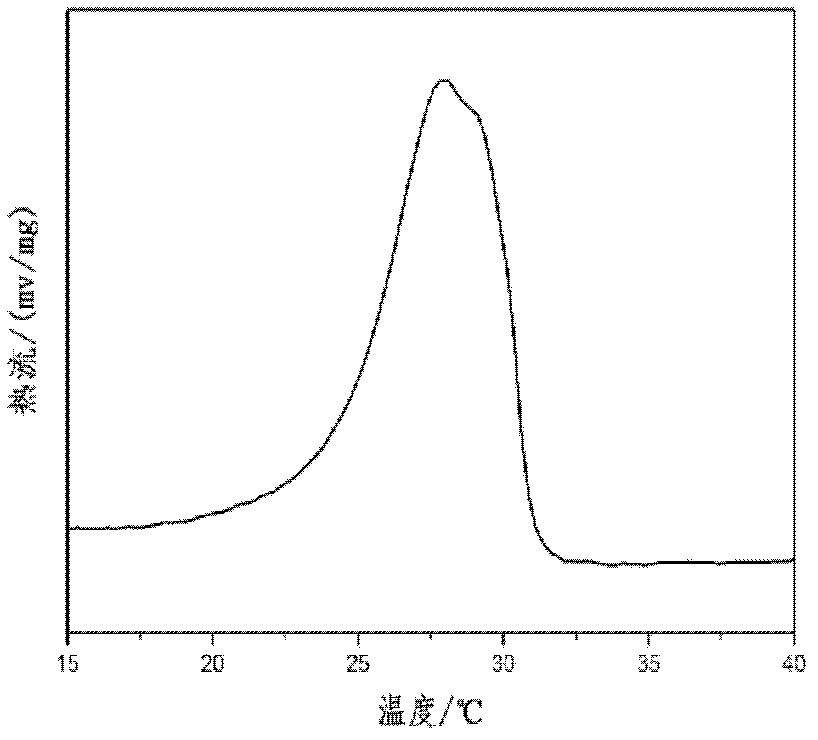

Preparation method of spherical beta-cyclodextrin/ melamine resin phase change energy storage materials

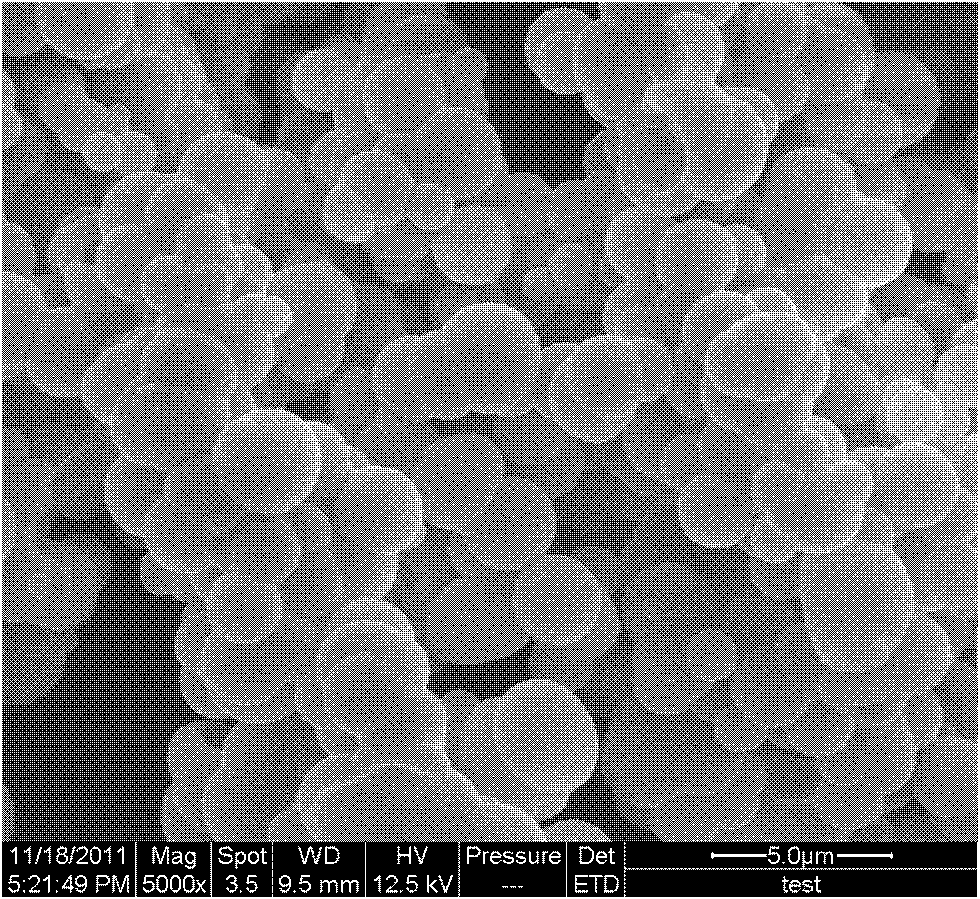

InactiveCN102527305AEmulsified evenlyIncrease coverageHeat-exchange elementsMicroballoon preparationWater bathsParaffin wax

The invention provides a preparation method of spherical beta-cyclodextrin / melamine resin phase change energy storage materials and relates to a method using a heat effect generated by phase change materials during solid-liquid (or liquid-solid) phase change in the phase change temperature range to reach the goals of absorbing, storing or releasing heat energy. According to the method, beta-cyclodextrin / melamine resin is used as wall materials, liquid paraffin wax is used as core materials, firstly, emulsified core materials are added into a reaction vessel, water bath heating and stirring are carried out, then, uniformly stirred beta-cyclodextrin / melamine prepolymer solution is added into the reaction vessel drip by drip, the in-situ polymerization reaction is carried out through controlling the reaction conditions, and the spherical phase change energy storage materials are obtained through heat insulation, cooling, filtering and vacuum drying. The phase change materials prepared by the method provided by the invention are in the spherical shape, the covering rate on the core materials can reach 79.67 percent to the maximum degree, and the enthalpy can reach 117.57J / g to the maximum degree. The phase change materials prepared by the method can be applied to the field of temperature regulation buffer material preparation and have good application prospects in phase change self regulation temperature aspects.

Owner:NORTHEAST FORESTRY UNIVERSITY

High adhesion coating for aluminum charger housing

InactiveCN106752817AGood adhesionWell mixedPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxySodium Bentonite

The invention discloses a high adhesion coating for an aluminum charger housing. The raw materials of the high adhesion coating for the aluminum charger housing comprise polyurethane, acrylic emulsion, styrene-acrylic emulsion, chlorosulfonated polyethylene, acrylic resin, modified epoxy resin, methyl hydroxyethyl cellulose, methyl ethyl ketone, ethyl acetate, ethyl cellulose, mica powder, diatomite, nano-zinc oxide, fine ceramic powder, molybdenum disulfide, nano-montmorillonite, nanometer aluminum hydroxide, organic bentonite, modified castor oil, a titanate coupling agent, citrate, a defoaming agent, an adhesion promoter and a curing agent. The high adhesion coating for the aluminum charger housing, disclosed by the invention, has excellent adhesion performance.

Owner:天长市优信电器设备有限公司

A preparation method and device for personalized nano-ice cream

Provided is a preparation method and device of personalized nano ice cream. Liquid nitrogen and ice cream raw materials are injected into a material container installed in a rotating-revolving mixer in a jet mode, the container containing the liquid nitrogen and ice cream raw materials performs high-speed revolution and rotation in a revolution track through the rotating-revolving mixer. Therefore, revolution energy having powerful accelerated speed is produced, meanwhile rotation makes the materials in the container to produce convection, accordingly full stirring, dispersion and defoaming within short time are achieved, and uniformly distributed nano ice crystals are efficiently formed. High-speed revolution and rotation mixing make the milk fat globules in the ice cream raw materials smaller and more uniformly emulsified, and finally a stable nano ice crystal-milk fat globule-microbubble structure is formed. The material container utilizes a container adapter for placement, common ice cream can be placed in a machine for direct processing, and container cleaning and waste are completely avoided. The production process is simple and stable, no stabilizer nor emulgator is needed in the preparation process, and the made ice cream has a fine and smooth taste and strong milk fragrance and is more natural.

Owner:笑傲天宫航天生物科技沧州有限公司

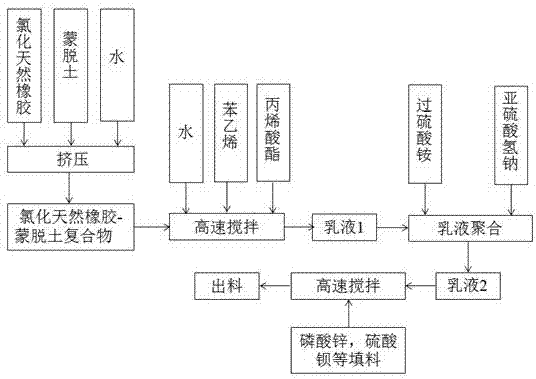

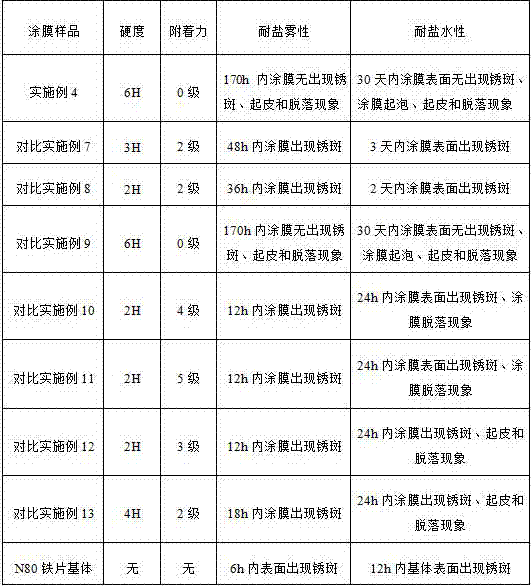

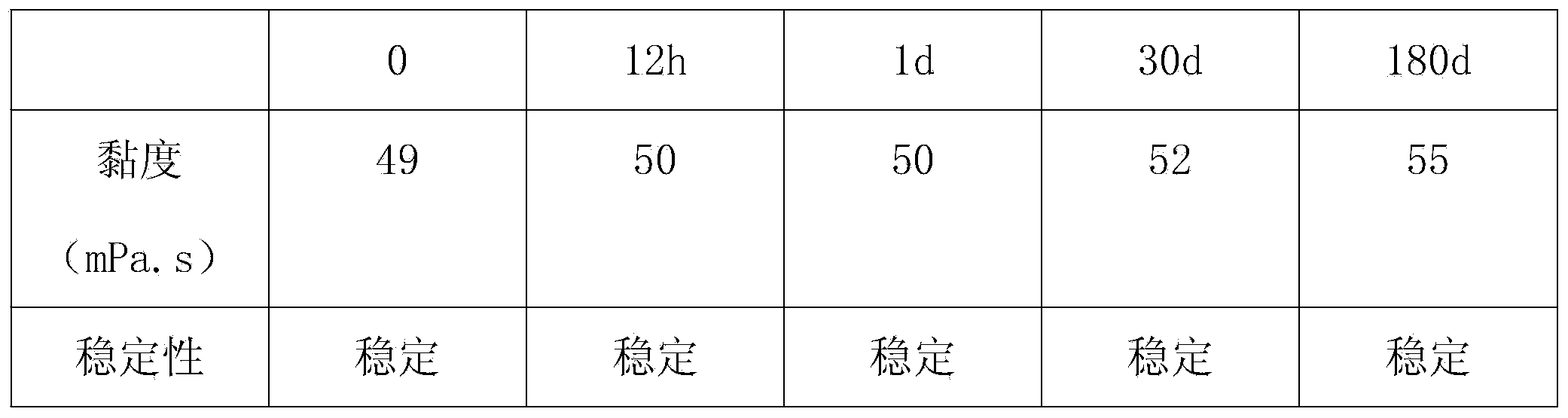

Organic-inorganic compound chlorinated natural rubber emulsion and preparation method thereof

ActiveCN107474637AGood corrosion resistanceEvenly dispersedRubber derivative coatingsAnti-corrosive paintsEmulsionNatural rubber

The invention provides an organic-inorganic compound chlorinated natural rubber emulsion and preparation method thereof. The preparation method comprises the steps of firstly preparing a chlorinated natural rubber-sodium-base-montmorillonite organic-inorganic compound, mixing and stirring acrylate, styrene, water and the chlorinated natural rubber-sodium-base-montmorillonite organic-inorganic compound in a proper proportion, so as to obtain a stable emulsion, adding oxidation-reduction initiators, namely ammonium persulfate and sodium sulfite into the emulsion so as to initiating polymerization between acrylate on particles of the chlorinated natural rubber-sodium-base-montmorillonite organic-inorganic compound and styrene monomers, and adding a proper amount of zinc phosphate and barium sulfate, so as to obtain the organic-inorganic compound chlorinated natural rubber emulsion.

Owner:瑞易德新材料股份有限公司

Fabric stiffening agent

The invention discloses a fabric stiffening agent. The fabric stiffening agent is prepared by the following steps: (1) adding 100kg of water into a reaction still and heating to 75 DEG C; (2) adding an initiator (namely ammonium persulfate) while stopping heating; (3) dropwise adding the prepared composite raw material while stirring for about 60min; (4) preserving heat for 2 hours; (5) adding ammonium hydroxide, and then adding ethyl alcohol to obtain acrylic acid composite liquid for later use; (6) preparing a salt hydrolyzed silk protein solution; and (7) mixing the acrylic acid composite liquid obtained in the step (5) and the silk protein solution obtained in the step (6) to obtain the finished product.

Owner:湖州天鑫皮革涂饰剂厂

Preparing method of profiled hogskin recombination with chippy hogskin

InactiveCN101015357AGood for healthEmulsified evenlySausage casingsFood preparationFood gradePhosphate

The invention discloses a making technique of moulded pigskin recombined by broken pigskin, which comprises the following steps: cleaning broken pigskin; sterilizing; acidifying the broken pigskin; cutting the broken pigskin into particle shape; extracting protein from broken pigskin; filtering albumen glue; adding edible sodium hydroxide solution, glucose, glutamine transmitting enzyme, laurate monoglyceride, potassium sorbate and phosphate into albumen glue; casting albumen glue into mould; transmitting into moulding chamber; fetching the pigskin out of mould with usage at 100%. The invention utilizes glutamine transmitting enzyme to form dense spatial network structure as recombinant pigskin, which reinforces the water retention property of pigskin effectively.

Owner:TIANJIN DAHAI IND DEV

Enzyme slimming cream and preparation method thereof

ActiveCN105232370AFast processFulfil requirementsCosmetic preparationsTransportation and packagingSide effectPalmitates

The invention discloses an enzyme slimming cream and a preparation method thereof. The enzyme slimming cream is prepared from 1-10 parts of orbignya oleifera seed oil, 1-5 parts of crambe abyssinica seed oil, 2-8 parts of caprylic / capric triglyceride, 2-8 parts of palmitate, 1-9 parts of dimethylcydosiloxane, 1-9 parts of polydimethylsiloxane, 0.05-0.4 part of propylparaben, 0.05-0.3 part of carbomer, 1-15 parts of glycerine, 1-15 parts of propanediol, 50-80 parts of deionized water, 0.05-0.3 part of triethanolamine, 0.01-0.05 part of water-borne preservative and 4-10 parts of plant fat-burn mixture. The preparation method includes adding oil-soluble mixture of the raw materials into water-soluble mixture to achieve emulsifying, cooling emulsified mixture, then adding fat-burn mixture into the emulsified mixture and uniformly stirring to obtain the enzyme slimming cream. The enzyme slimming cream prepared by the method has quick action and zero toxic and side effects without any harm to normal metabolism of human bodies.

Owner:HUBEI MULAN TONGDA TECH

Scoparone missible oil acaricide and preparation method thereof

The invention discloses a scoparone missible oil acaricide and a preparation method thereof, and belongs to the technical field of pesticides. The acaricide comprises scoparone, a solvent, an emulsifier and a filling agent, the mass percents of the solvent, the emulsifier and the filling agent is (35-60): (8-12): (40-50), and the mass percentage of the scoparone and the emulsifier is 1: 2. The preparation method comprises the following steps: (1) taking raw materials for later use; (2) adding scoparone into a solvent, and uniformly stirring to obtain a mixed solution; and (3) adding the emulsifier into the mixed solution, stirring uniformly, adding the filling agent, and mixing and stirring uniformly. The prepared acaricide has good dispersibility in water and uniform emulsification, belongs to an environment-friendly natural acaricide, has little harm to human bodies and environments, can be decomposed, and is stable in hot storage and cold storage and easy to store.

Owner:SOUTHWEST UNIVERSITY

Sunscreen skin-moisture cream containing chinese herbal medicine and myocastor coypus oil

The present invention provides a sun protection skin-moistening cream containing Chinese medicinal materials and other oil. Said invented sun protection skin-moistening cream at least contains the Chinese medicinal materials of pear powder hydrolysate, royal jelly, coix seed extract, platycodon root extrat and poria extract, etc. and the components of otter oil and artificial synthetic oil, so that said invented sun protection skin-moistening cream contains the components of fatty acid-linolic acid linolenic acid, several vitamins, allantoin and components of promoting blood circulation and protecting skin which are necessary for human body, therefore said invention has the excellent effect for sun protection and moistening skin. Besides, said invention also can be used in the winter, it can be used for preventing and curing hand and foot xerochase. Said invention also has the good effect for curing pimple.

Owner:陈立炘

Low-viscosity anticorrosive metal antirust agent

InactiveCN107043563AWell mixedImprove anti-corrosion performanceAnti-corrosive paintsMaleic anhydrideZinc Acetate Dihydrate

The invention discloses a low-viscosity anticorrosive metal antirust agent. The low-viscosity anticorrosive metal antirust agent comprises sodium gluconate, dimethyl fumarate, dibutyltin dilaurate, sodium hexametaphosphate, sodium dodecyl sulfate, water-soluble silicone oil, triethanolamine, sodium molybdate, an organic phosphonic acid, sodium benzoate, carboxylic acid amine, boric acid amine, diglycolamine, maleic anhydride, m-phthalic acid anhydride, zinc acetate, terephthalic acid, itaconic acid, cobaltous naphthenate, sodium tungstate, anhydrous sodium carbonate, nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, fatty acid methyl ester ethoxylate calcium sulfonate, dodecylbenzene sulfonic acid, a modifying lubricant, a modifying anticorrosion auxiliary agent, a modifying curing agent, an adhesive promoter, and water. The low-viscosity anticorrosive metal antirust agent is low in viscosity, and excellent in anticorrosive and antirust capacity.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

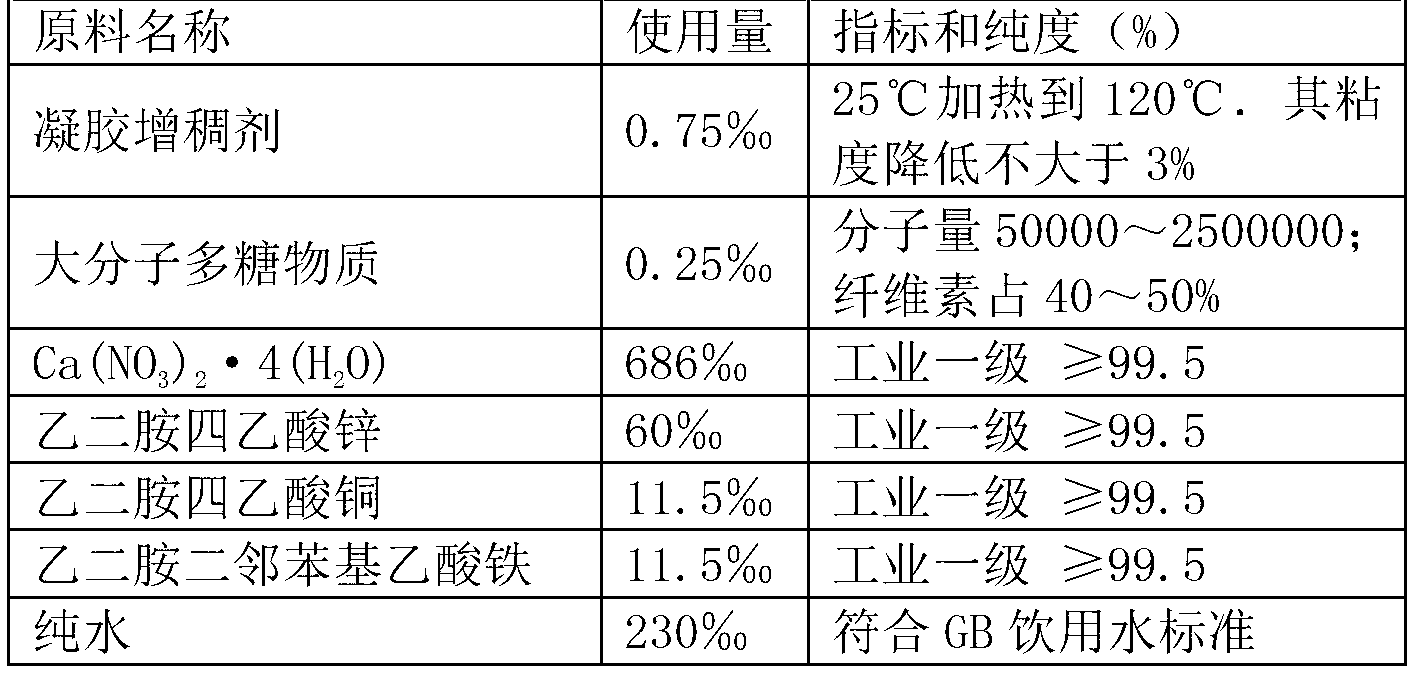

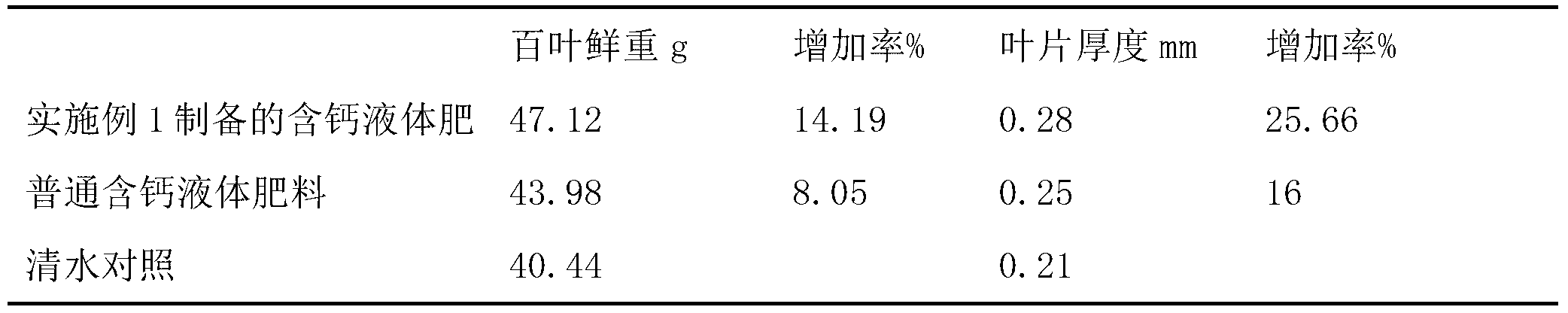

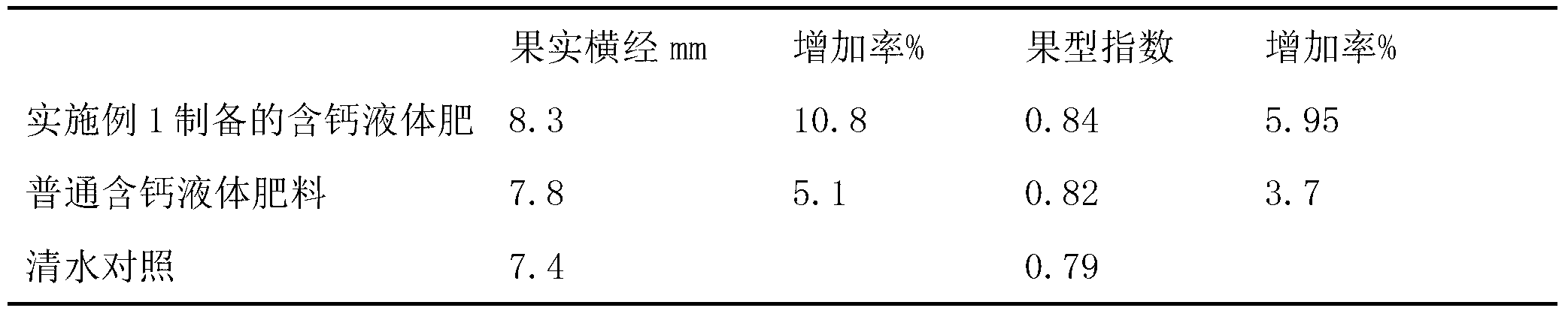

Calcium-containing liquid manure and preparation method thereof

ActiveCN103319263AImprove solubilityHigh in calciumFertilizer mixturesHigh concentrationEthylenediamine

The invention discloses calcium-containing liquid manure. The calcium-containing liquid manure comprises the following components in percentage by weight: 0.50-1.00 per mill of gel thickening agent material, 0.20-0.30 per mill of macromolecule polysaccharide material, 650-70 per mill of Ca(NO3)2.4(H2O), 50-70 per mill of ethylenediamine tetraacetic acid zinc, 10.0-13.0 per mill of ethylenediamine tetraacetic acid zinc copper, 10.0-13.0 per mill of ethylenediamine di-o-phenyl ferric acetate and the balance of water. The calcium-containing liquid manure disclosed by the invention forms a stable solvent by adopting a colloid chemical technology, the solubility of calcium ions can be increased, the calcium-containing liquid manure has good solubility and high calcium nutrient content, is rich in trace elements and reasonable in proportioning and has the characteristics of non-precipitation, non-crystallization, non-water releasing, non-generation of gas and the like, and therefore, the calcium-containing liquid manure is a high-concentration quick-acting fluid calcium fertilizer and can be used through leaf surface spraying and drip fertigation.

Owner:中化(临沂)作物营养有限公司

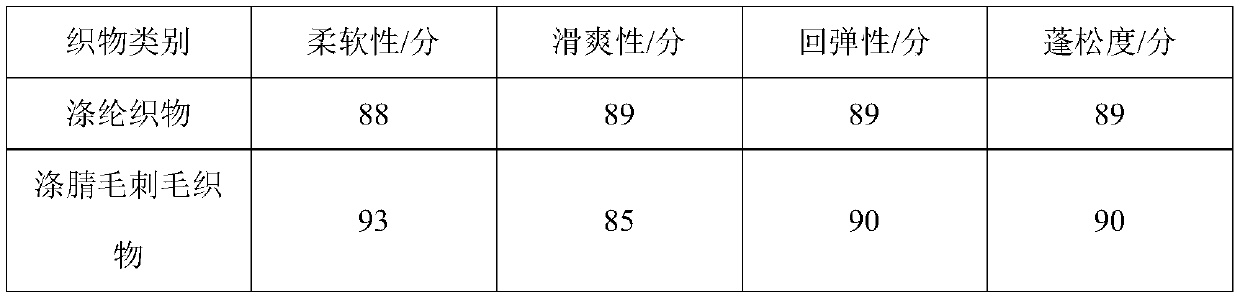

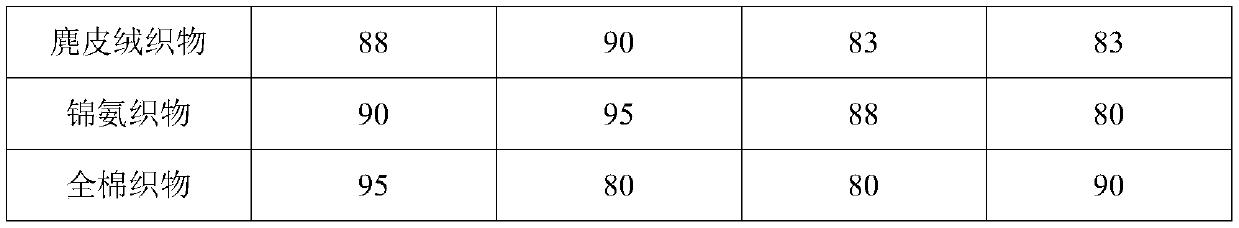

High-safety non-yellowing viscoelastic softening finishing agent and preparation method thereof

ActiveCN110820352AImprove stabilityFeel smoothBiochemical fibre treatmentGrip property fibresCelluloseOrganic acid

The invention relates to the technical field of softening finishing agents, in particular to a high-safety non-yellowing viscoelastic softening finishing agent and a preparation method thereof. The softening finishing agent comprises the following components in parts by weight: 15-25 parts of silicone oil, 8-12 parts of polyvinyl alcohol, 1-2 parts of hydroxymethyl cellulose, 1-3 parts of an antibacterial agent, 5-10 parts of an emulsifier, 1-2 parts of organic acid, 1-2 parts of an aloe extract, 3-8 parts of a solvent and 10-15 parts of water. The high-safety non-yellowing viscoelastic softening finishing agent has the advantages of good hand feeling, good hydrophilicity, high stability and no influence on the whiteness of a fabric.

Owner:多恩生物科技有限公司

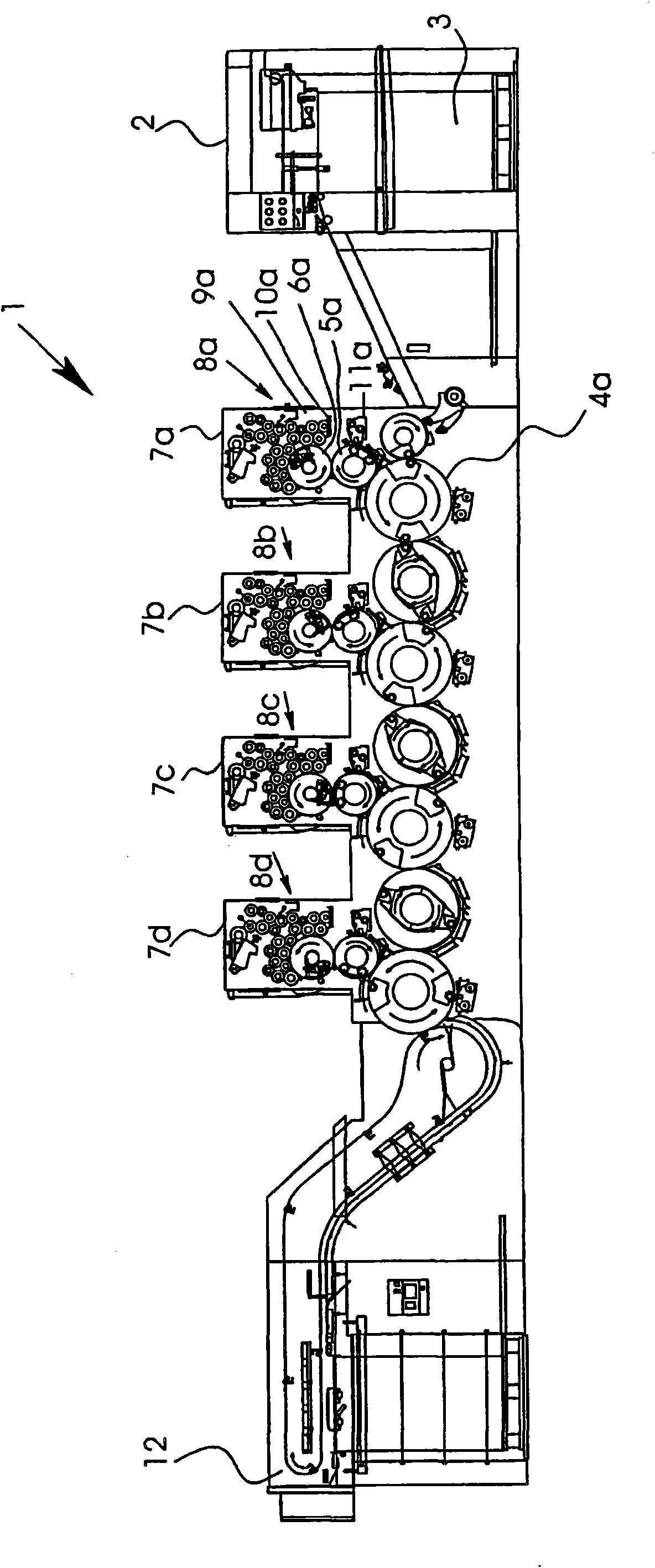

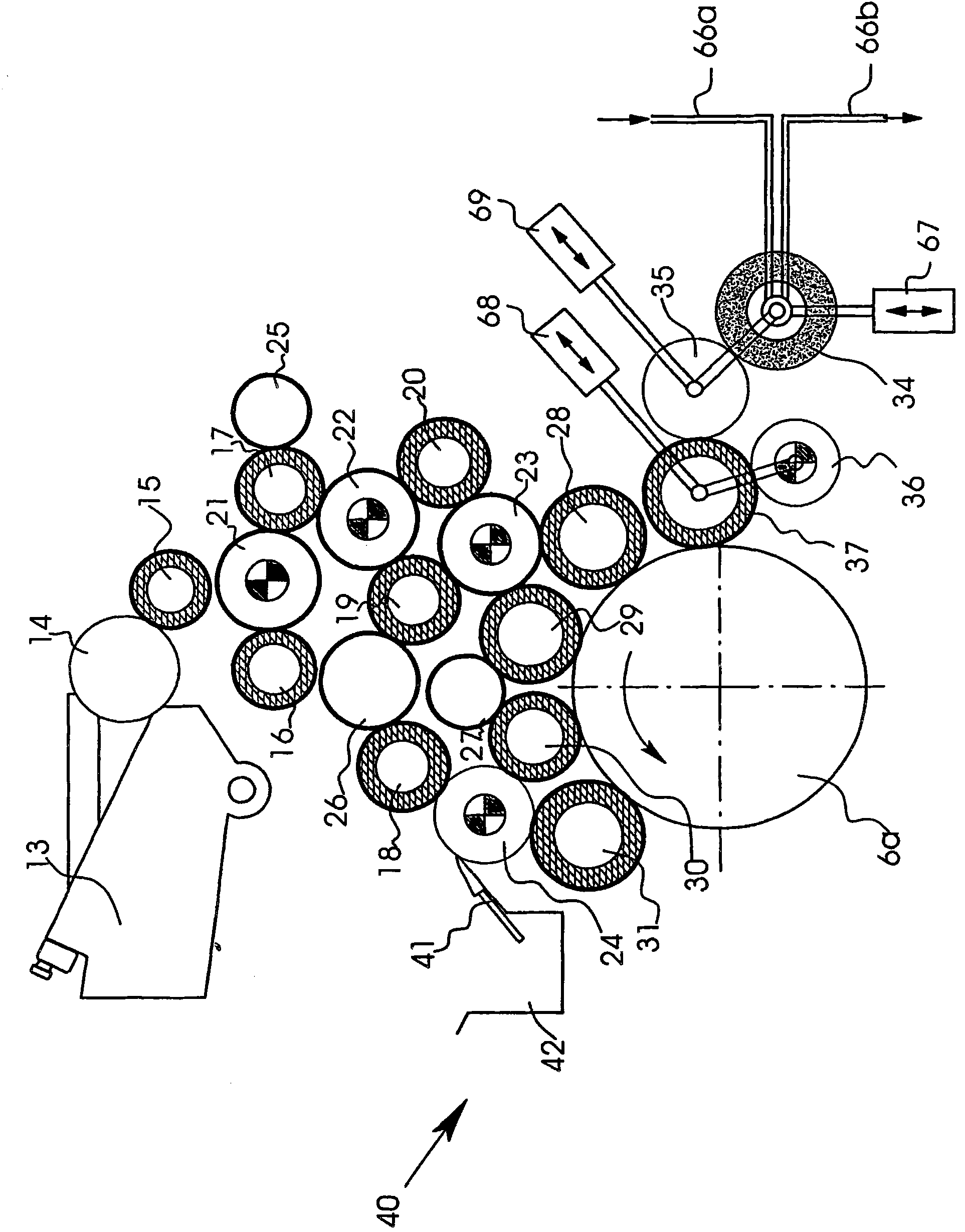

Rotary flat-bed printing machine

InactiveCN101888929AGuaranteed functionAvoid tintRotary lithographic machinesEngineeringPrinting press

The invention relates to a rotary flat-bed printing machine having an inking unit with a plurality of inking rolls and a dampening unit with a plurality of dampening rolls, wherein one of the dampening rolls (34) has a porous surface from which the dampening agent exits. In the dampening agent flow, between the dampening roll (34) having the porous surface and the plate cylinder (6a), at least two further rolls (35, 37) are arranged.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Scrub-resistant and waterproof quartzite composite material for cupboard tabletop

InactiveCN107244832AGood scrub resistanceImprove waterproof performanceAcrylic resinIsophorone diisocyanate

The invention discloses a scrub-resistant and waterproof quartzite composite material for a cupboard tabletop. The composite material is prepared from the raw materials: calcined quartzite sand, hydroxy acrylic resin, aqueous saturated polyester resin, hydroxy acrylic resin, hexamethoxymethyl melamine resin, organosilicone modified alkyd resin, amino resin, ternary vinyl chloride-vinyl acetate copolymer, N-methyl pyrrolidone, polyvinyl acetate, cellulose acetate butyrate, an isocyanate curing agent, an accelerant, pigments, isophorone diisocyanate, dibutyl tin dilaurate, a silane coupling agent KH-560, a scrub-resistant filler and a waterproof filler. The composite material disclosed by the invention is applied to the cupboard tabletop and has excellent scrub-resistant and waterproof performance.

Owner:宿松圣峰装饰材料有限公司

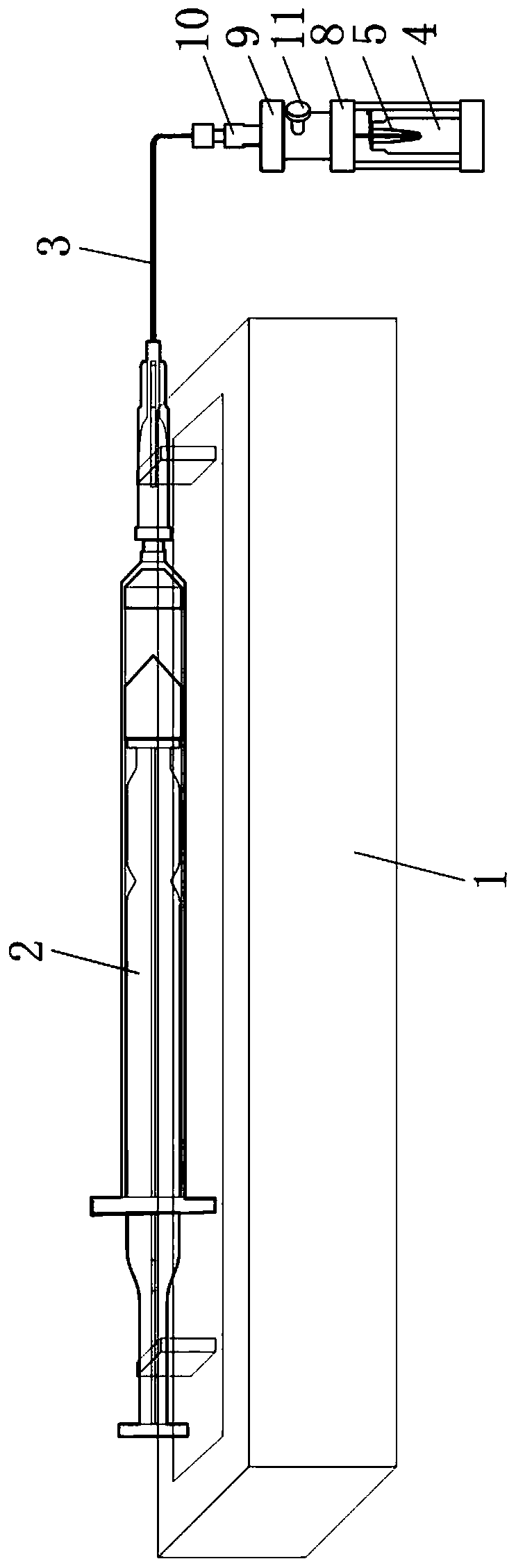

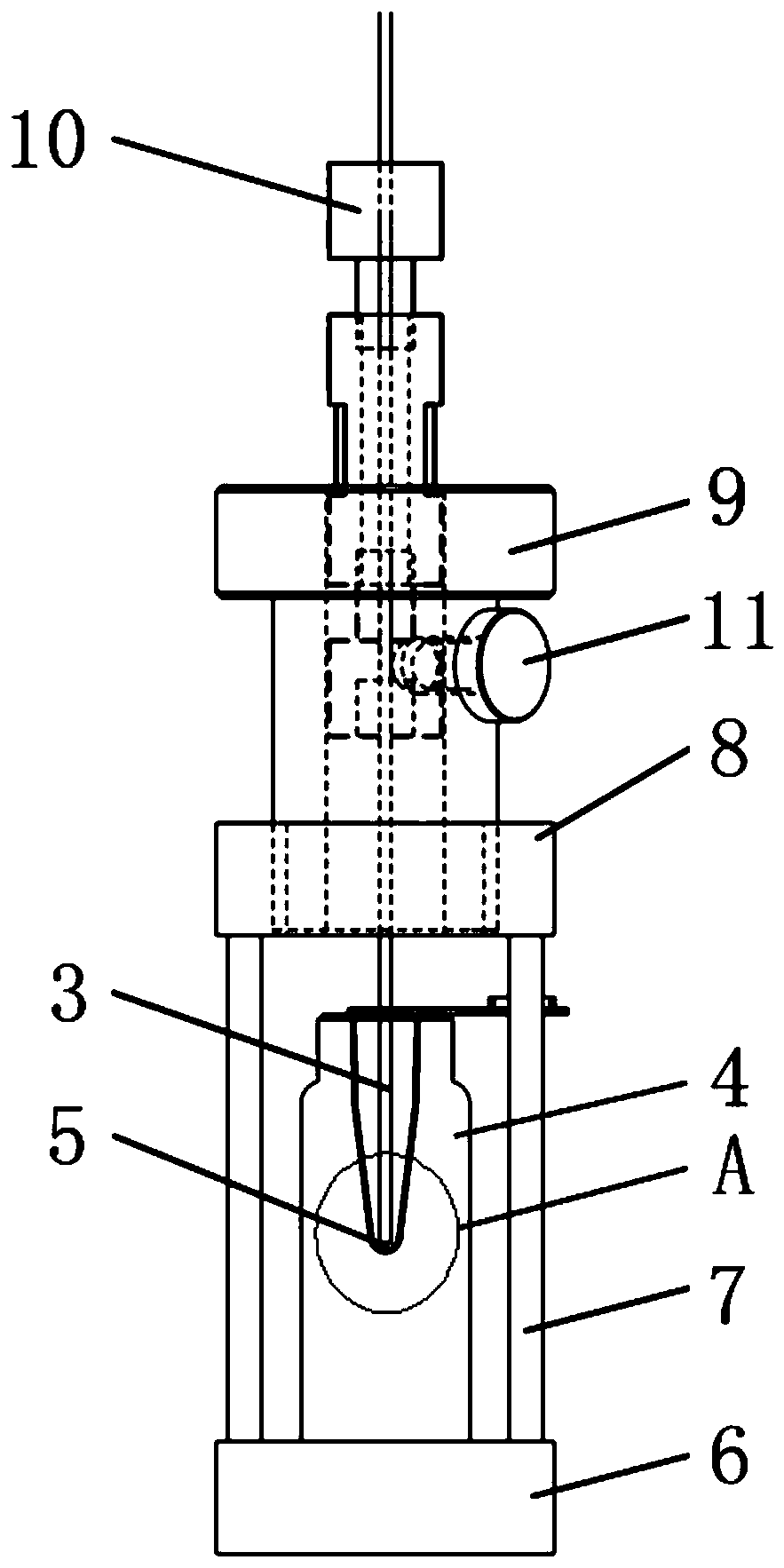

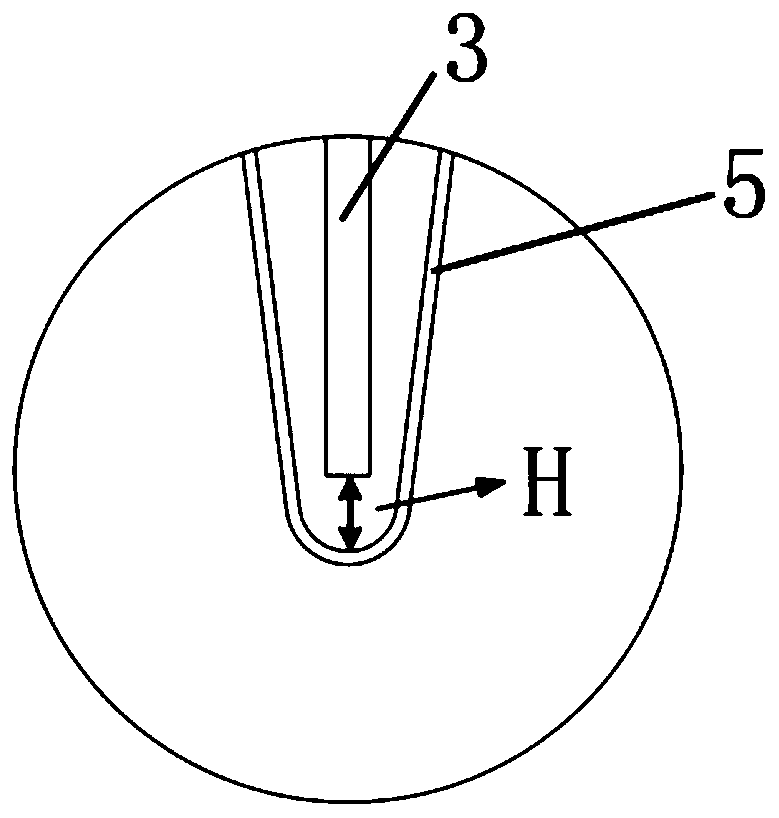

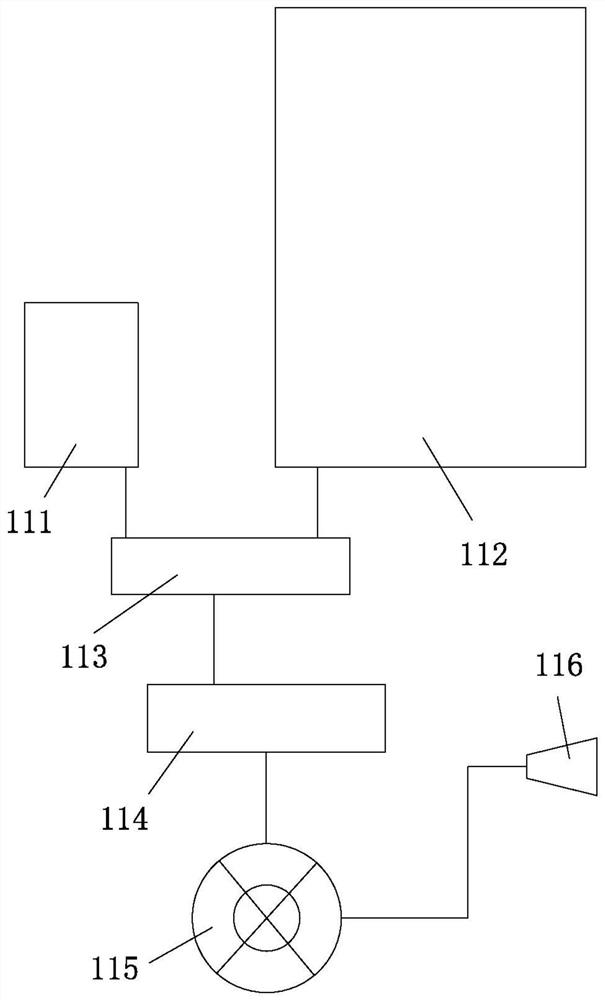

Digital PCR device and single-pump droplet generation system thereof

InactiveCN110841734AControl Size ParametersAvoid destructionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSystem structure

The invention discloses a single-pump droplet generation system, the single-pump droplet generation system comprises a single pump, a water phase injector connected with the output end of the single pump and used for injecting a water phase, a flow guide pipe communicated with an injection head of the water phase injector, an adjusting mechanism used for clamping the flow guide pipe and adjustingthe height of the tail end of the flow guide pipe, a liquid collecting bottle and a centrifugal pipe arranged in the liquid collecting bottle and used for containing an oil phase. And the tail end ofthe flow guide pipe extends into the centrifugal pipe, and a preset distance for generating liquid drops with preset sizes is kept between the tail end of the flow guide pipe and the bottom end of thecentrifugal pipe. Thus, the single pump is used as a power source to drive the water phase injector to inject the water phase into the flow guide pipe, and then the oil phase is contained in the centrifugal pipe, so that the injected water phase and the oil phase are mixed to generate droplets required by a reaction, and on the basis of smoothly generating digital PCR droplets, the space occupation of equipment and the system structure complexity can be reduced; meanwhile, the research cost is reduced. The invention also discloses a digital PCR device, which has the beneficial effects as described above.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Tremella composite flocking adhesive

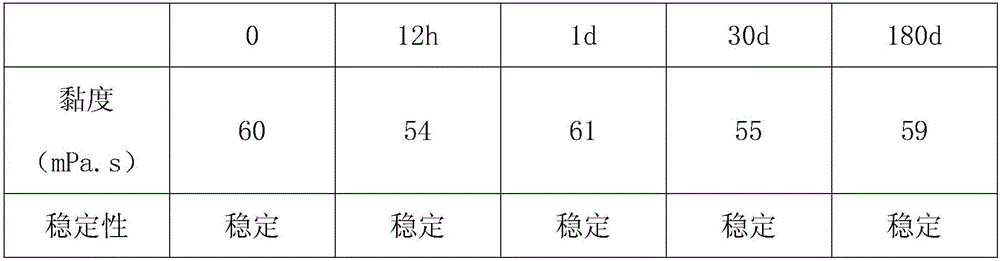

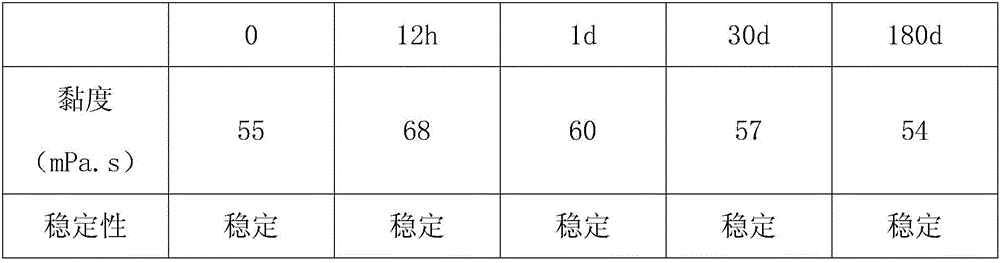

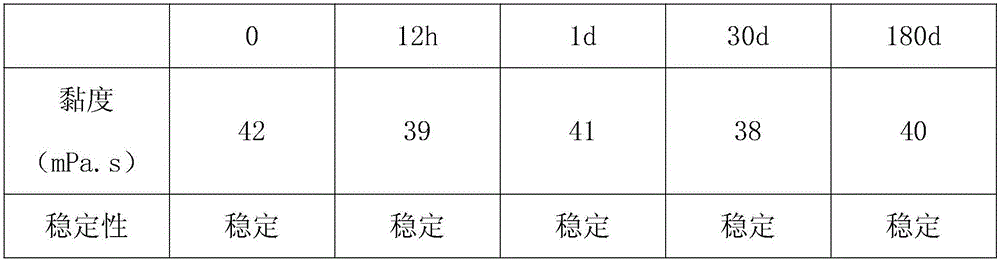

ActiveCN106085300ALow viscosityImprove stabilityMonocarboxylic acid ester polymer adhesivesPolysaccharide adhesivesAdhesiveFiltration

The invention discloses a tremella composite flocking adhesive. A preparation method of the adhesive includes the steps: preparing acrylic composite solution for standby application; weighing 500g of dry tremella, placing the dry tremella in 10L of 0.3% mycose solution, standing for 18-20 hours, taking out the thoroughly soaked tremella, uniformly grinding the tremella, weighing 100g of the grinded soaked tremella, treating the grinded soaked tremella in 1L of calcium chloride boiling solution with mass concentration 60% for about 50-80 minutes until dissolving most of the grinded soaked tremella, stirring the grinded soaked tremella by a glass rod during treatment, and coarsely extracting the mixed solution by wick filtration to obtain tremella extracting solution; mixing the acrylic composite solution and the tremella extracting solution well, and finally discharging and packaging a finished product.

Owner:蚌埠行时知识产权运营有限公司

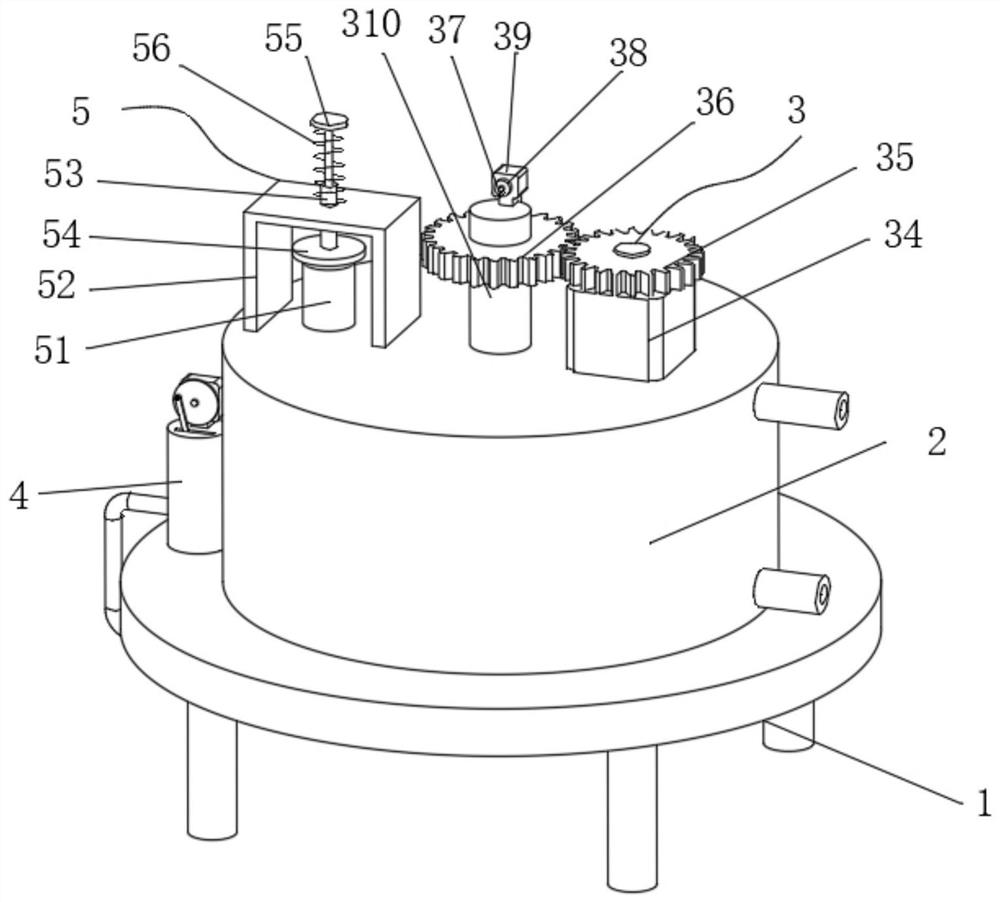

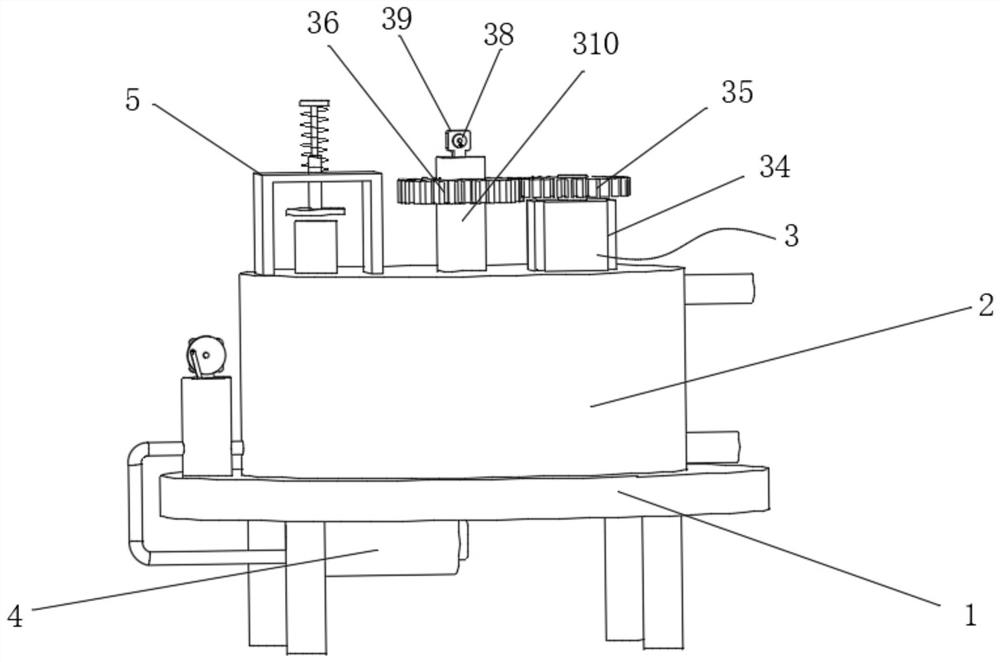

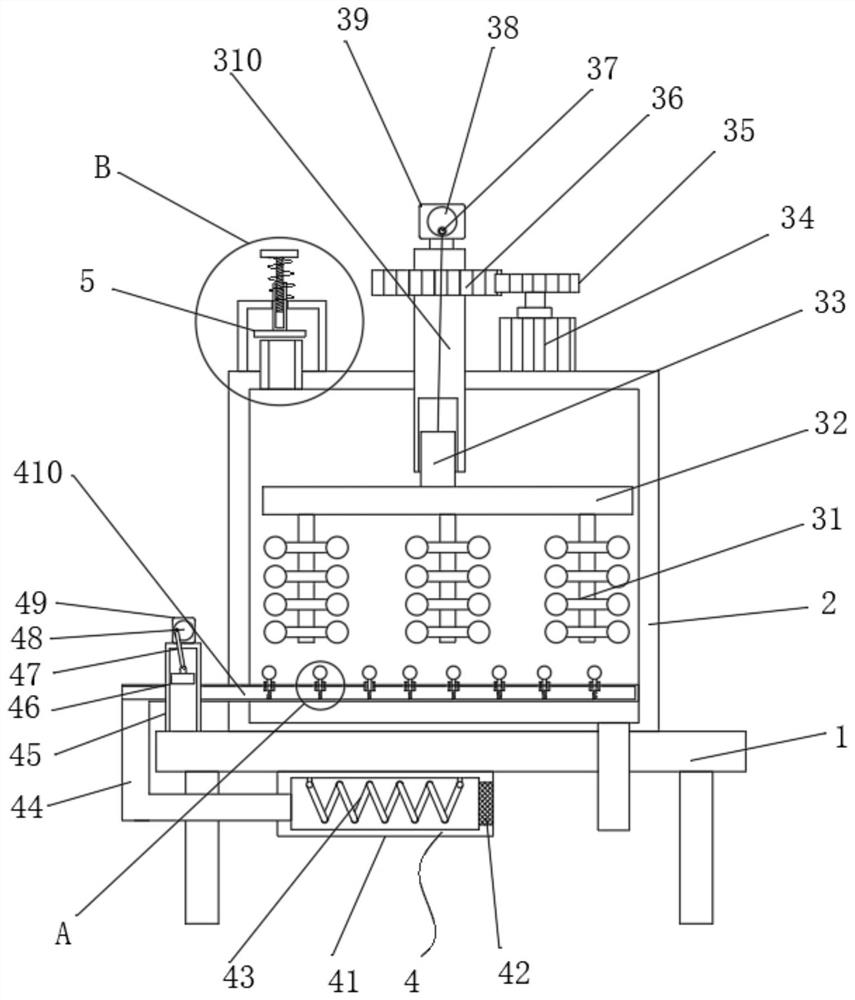

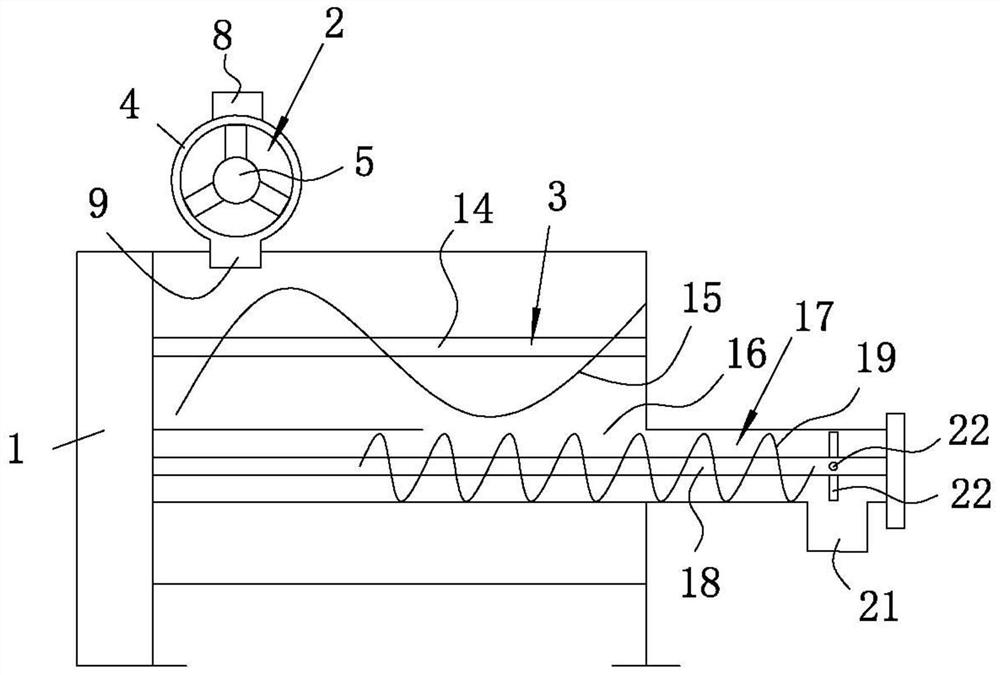

Mucilage production equipment and mucilage production method

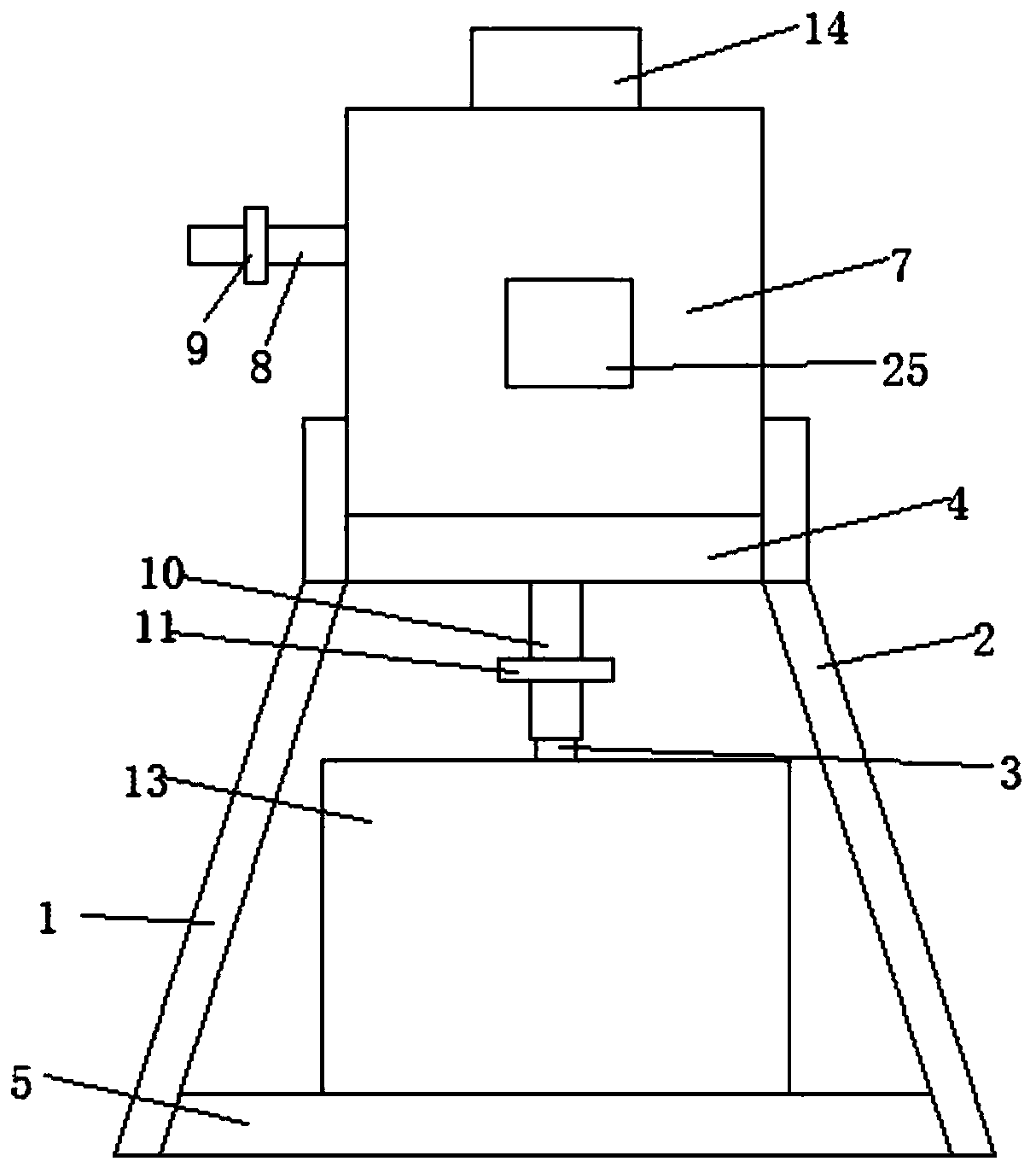

PendingCN112295430ARealize pullImprove the heating effectTransportation and packagingMixing methodsReciprocating motionElectric machinery

The invention discloses mucilage production equipment and a mucilage production method. The mucilage production equipment comprises a base, a gluing box, a vibration emulsification structure, an air inlet heating structure and a pressure relief structure, the gluing box is installed on the top side of the base, the vibration emulsification structure is installed in the gluing box, and the air inlet heating structure is installed at the bottom of the gluing box; the pressure relief structure is installed at the top of the gluing box, through the vibration emulsification structure, in the rotating process, a vibration motor works, a rotating disc is driven to rotate, a steel wire rope is pulled under cooperation of a positioning rod, vertical reciprocating motion of an insertion rod in a rodhole is achieved, vibration emulsification of mucilage is achieved under cooperation of a vibration rod, and stirring and vibration can be conducted at the same time, the emulsifying efficiency is greatly improved, meanwhile, stirring dead angles are avoided, it is guaranteed that mucilage is emulsified evenly, through air heating, it can be guaranteed that heat has a larger contact surface withthe mucilage, the heat exchange process is achieved more quickly, the heating effect of the mucilage is improved, and the mixing quality of the mucilage is improved.

Owner:JIANGMEN SINOBLE TECH SHARES CO LTD

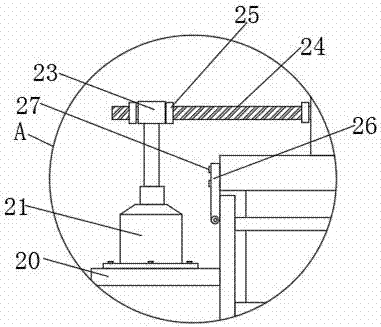

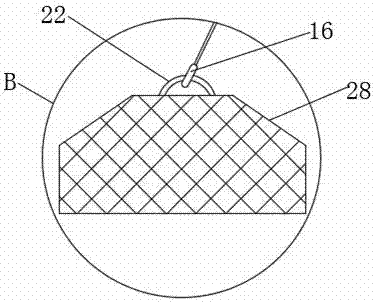

Cosmetic emulsifying machine with automatic filling mechanism

PendingCN107875904AReasonable structural designEasy to addRotary stirring mixersTransportation and packagingEngineeringDrive motor

The invention discloses a cosmetic emulsifying machine with an automatic filling mechanism. The cosmetic emulsifying machine comprises an emulsifying reactor, wherein a driving motor is fixedly arranged in the middle of the upper end of the emulsifying reactor; a stirring shaft is connected to the lower end of an output shaft of the driving motor; the stirring shaft is positioned inside the emulsifying reactor; a stirring mechanism is arranged on the stirring shaft; L-shaped feed pipes are inserted into two sides in the middle of the upper end of the emulsifying reactor in a penetrated manner;a separating chamber is formed inside a separating cylinder; the L-shaped feed pipes are communicated with the separating chamber; a storage barrel mounting rack is arranged above the separating cylinder; and a storage barrel is arranged in the storage barrel mounting rack. According to the cosmetic emulsifying machine with the automatic filling mechanism, the feeding process can be convenient, the automation capability is high, the manual labor and labor force are saved, and the cosmetic emulsifying machine is uniform in feeding and high in efficiency. Therefore, the cosmetic emulsifying machine is more stable in operation, any shaking or dumping phenomenon is difficultly caused, and the safety is high; and emulsification is uniform.

Owner:黄阿凤

High-shear emulsifying and wall-scraping stirring device

The invention relates to a high-shear emulsifying and wall-scraping stirring device. The device comprises a reaction tank, a high-shear emulsifier, a wall-scraping stirring assembly and a stirring speed reducing motor, wherein the wall-scraping stirring assembly is arranged in the reaction tank and is connected with the stirring speed reducing motor; the high-shear emulsifier comprises an emulsifying motor and an emulsifier rotating shaft movably connected with the emulsifying motor; the wall-scraping stirring assembly comprises a stirring rotating shaft; and the emulsifier rotating shaft penetrates through the axis center of the stirring rotating shaft. Compared with the prior art, the high-shear emulsifying and wall-scraping stirring device has the advantages that the emulsifying and stirring processes are simultaneously carried out, the structure is compact, no dead corner exists in the stirring process, the mixing is relatively uniform, and the like.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

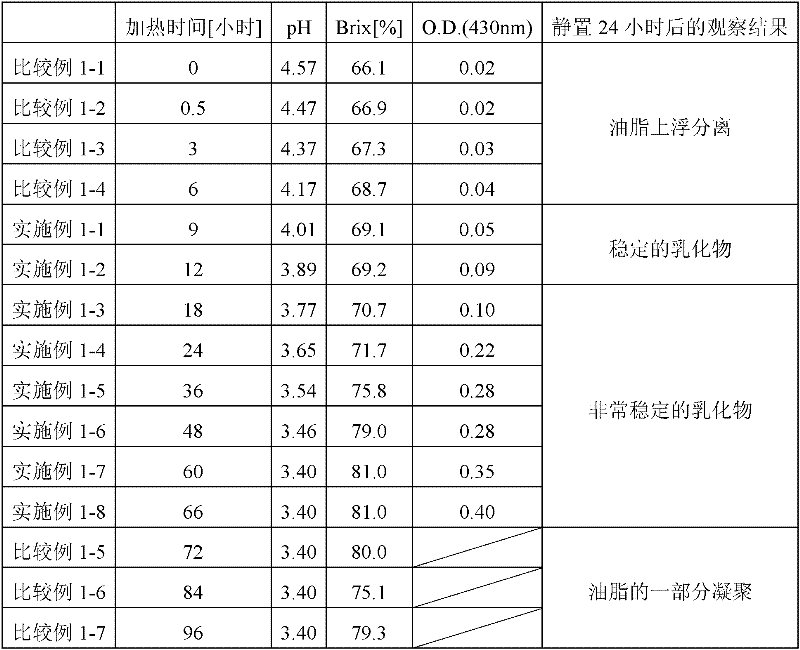

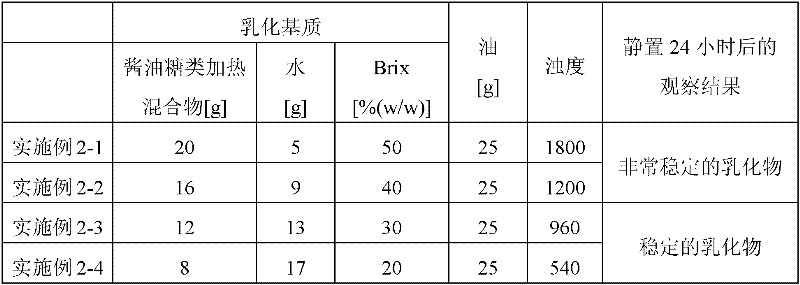

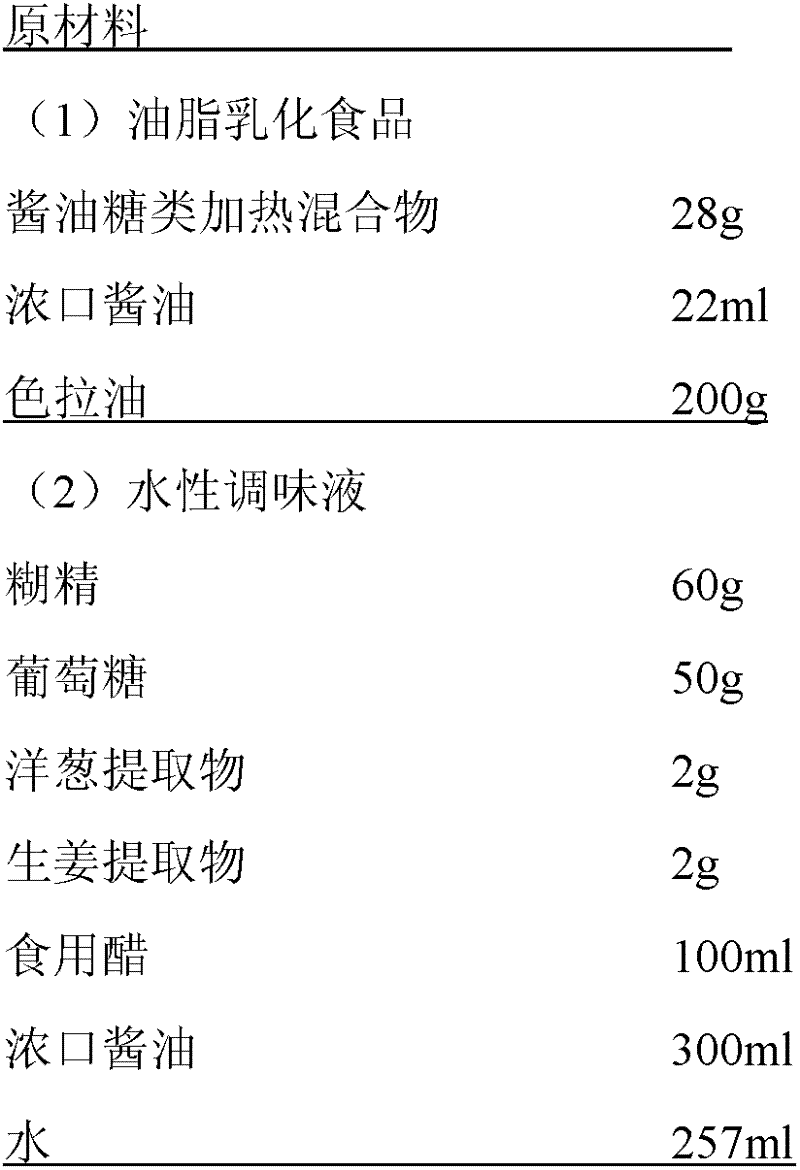

Heated mixture of soy sauce and sugar, and fatty food

ActiveCN102413705AWon't separateGood emulsifying effectFood preparationEdible oils/fats with aqeous phasePaint thinnerEmulsion

Disclosed is a heated (soy sauce)-sugar mixture, which is produced by heating an aqueous mixed solution of a soy sauce and a sugar, and shows an absorbance of 0.05 to 0.40 at 430 nm when prepared into a 0.1% (w / w) aqueous diluted solution. Also disclosed is a fatty food which is prepared by adding an oil or fat to the heated (soy sauce)-sugar mixture to emulsify or solubilize the oil or fat. The heated (soy sauce)-sugar mixture is useful as a substitute for an emulsifying agent or a surfactant. The heated (soy sauce)-sugar mixture can be used for the production of a fatty food in which an emulsifying property cannot not deteriorated by the change in pH, heat or the like, without the need of using any emulsion stabilizer or surfactant. The fatty food has such characteristic properties that the separation of the oil or fat does not occur and the oil or fat can be emulsified or solubilized therein stably.

Owner:KIKKOMAN CORP

Application method of beating machine

InactiveCN103721597AEasy to useSimple structureMixing methodsRotary stirring mixersRotational axisMotor drive

The invention discloses an application method of a beating machine. The application method comprises the following steps: A, firstly, a block-shaped or pie-shaped organic bio-fertilizer after compost maturity and filter-press is cut into block-shaped materials with sizes about 10*10 cm, then the cut materials are added into a beating tank, and water or an emulsion in a certain proportion is poured in; B, a rotary motor is switched on, an output shaft of the rotary motor drives a rotary shaft to rotate, and then a rotary frame, external beating shaft columns and internal beating shaft columns are driven to rotate with the rotary shaft as a circle center; C, power supply of emulsification motors is further switched on, output shafts of emulsification motors drives gear shafts to rotate, then gear plates meshed with the gear shafts are driven to rotate and drive beating shaft to rotate, and beating teeth on two sides of each beating shaft perform beating and emulsifying operation on the mixed materials; and D, after the beating operation is finished, the organic bio-fertilizer after beating and emulsifying is sucked out of the beating tank by suction equipment. The invention has the advantages that the application method is simple; and a used product has simple structure, high strength, high emulsification speed, high production efficiency and uniform emulsification without caking.

Owner:刘成涛

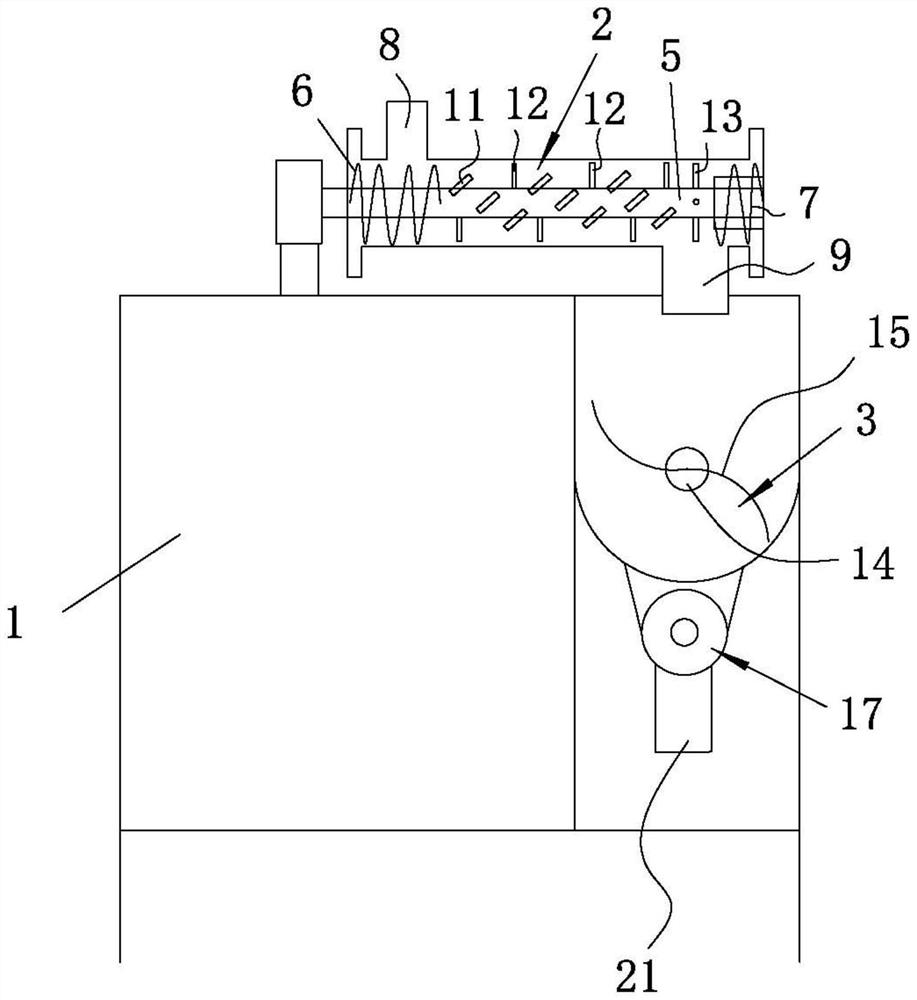

High-speed continuous material mixing equipment

PendingCN113083059AImprove mixing efficiency and mixing yieldEmulsified evenlyRotary stirring mixersTransportation and packagingProcess engineeringPeristaltic pump

The invention relates to the technical field of material mixing, and particularly discloses high-speed continuous material mixing equipment which comprises a rack, a material mixing machine arranged on the rack and a first stirring and conveying unit. The equipment comprises an oil containing part, a water containing part, a peristaltic pump unit, an emulsifier, a power pump and an atomizing nozzle, wherein the peristaltic pump unit pumps oil contained in the oil containing part and water contained in the water containing part into the emulsifier for emulsification treatment to form emulsified liquid; the power pump pumps out emulsified liquid in the emulsifier, the emulsified liquid forms atomized liquid through the atomizing nozzle, the atomized liquid is sprayed into the material mixing machine to be mixed with materials, and the material mixing machine mixes and stirs the materials and the atomized liquid sprayed by the atomizing nozzle; the accurate proportioning of oil and water is realized by virtue of the peristaltic pump unit, the oil and water are emulsified more uniformly by virtue of the emulsifier, the atomized uniform spraying and no particle of an oil-water mixed solution are realized by virtue of the power pump and the atomizing nozzle, the uniform mixing of oil, water and materials is realized by virtue of the material mixing machine, and the uniformly mixed materials are automatically output by the conveying unit. The mixing efficiency and the mixing yield are improved.

Owner:陈子欣

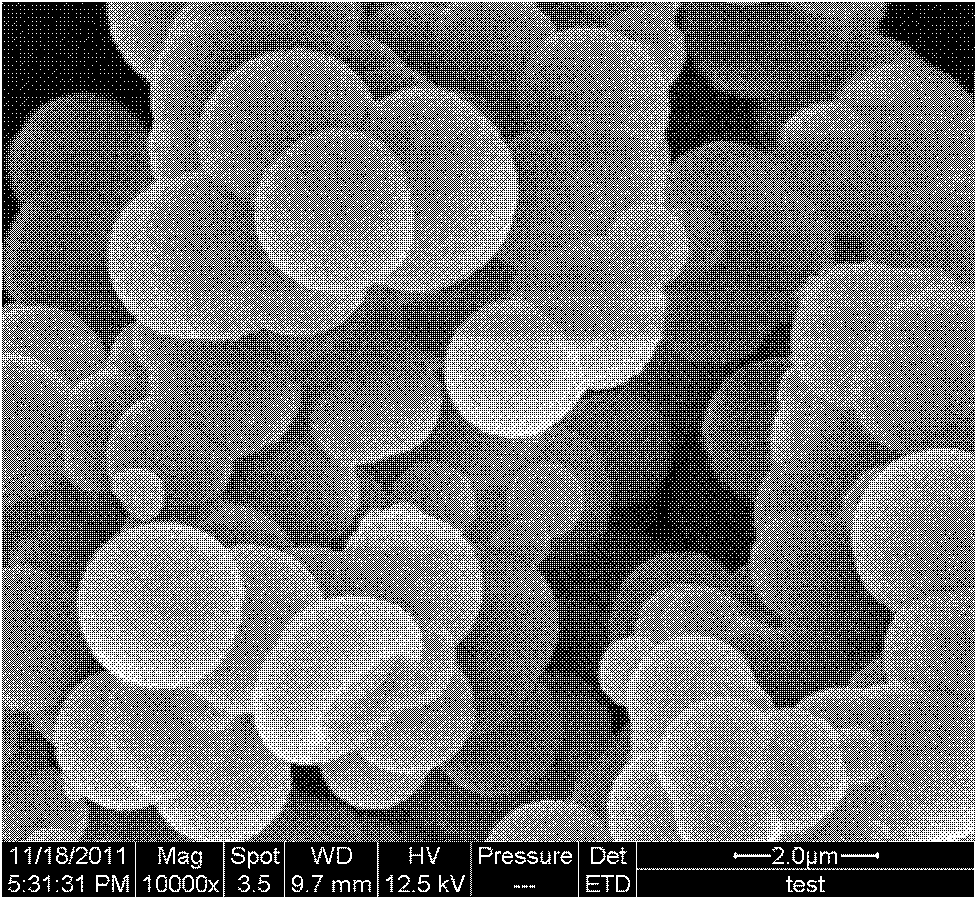

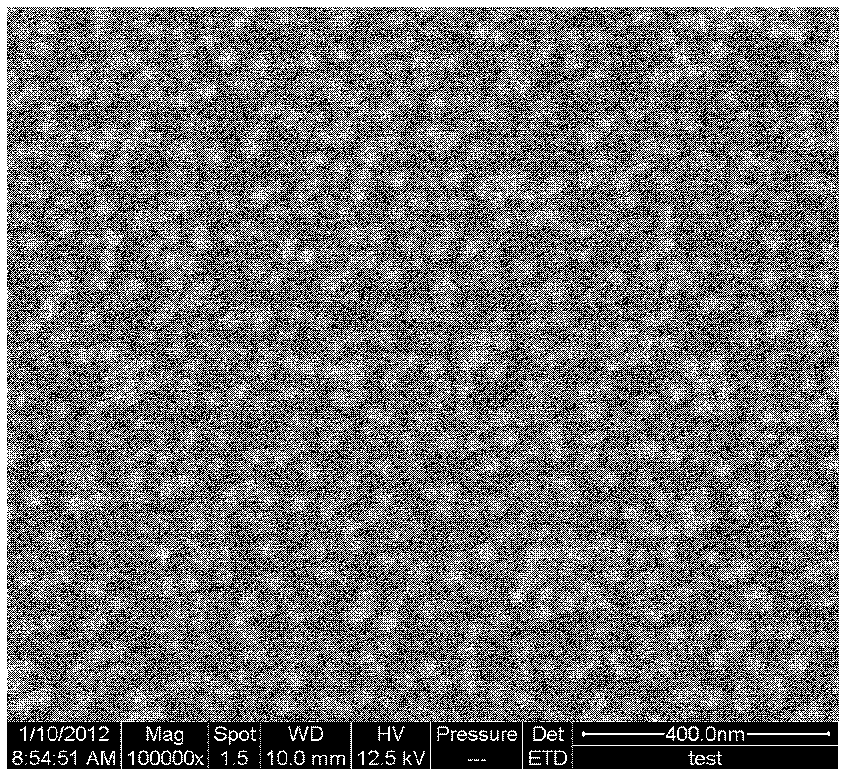

Preparation method of spherical carboxymethyl cellulose/melamine resin nano phase change energy storage material

InactiveCN102604600AImprove toughnessEmulsified evenlyHeat-exchange elementsMicroballoon preparationParaffin waxIn situ polymerization

The invention provides a preparation method of a spherical carboxymethyl cellulose / melamine resin nano phase change energy storage material, relating to a method for absorbing or releasing heat energy by virtue of a heat effect produced during solid-liquid (or liquid-solid) phase conversion on a material when ambient temperature deviates from phase change temperature. According to the invention, the carboxymethyl cellulose / melamine resin is taken as a wall material of a nano capsule, and solid paraffin is taken as a core material; and in situ polymerization reaction is carried out by controlling reaction conditions, thus the spherical phase change energy storage nano capsule material is obtained. The phase change energy storage nano capsule material prepared by the invention is a sphere with the diameter of being about 50nm, 60.1% of core material can be contained in 1g of capsule material at most, enthalpy value can reach up to 81.6J / g at most, and capsule damage rate is 12.6% at lowest. The phase change energy storage material prepared by the invention has a wide application prospect in the fields of industrial and civil construction heating, energy conservation of air conditioner and recycling of waste heat.

Owner:NORTHEAST FORESTRY UNIVERSITY

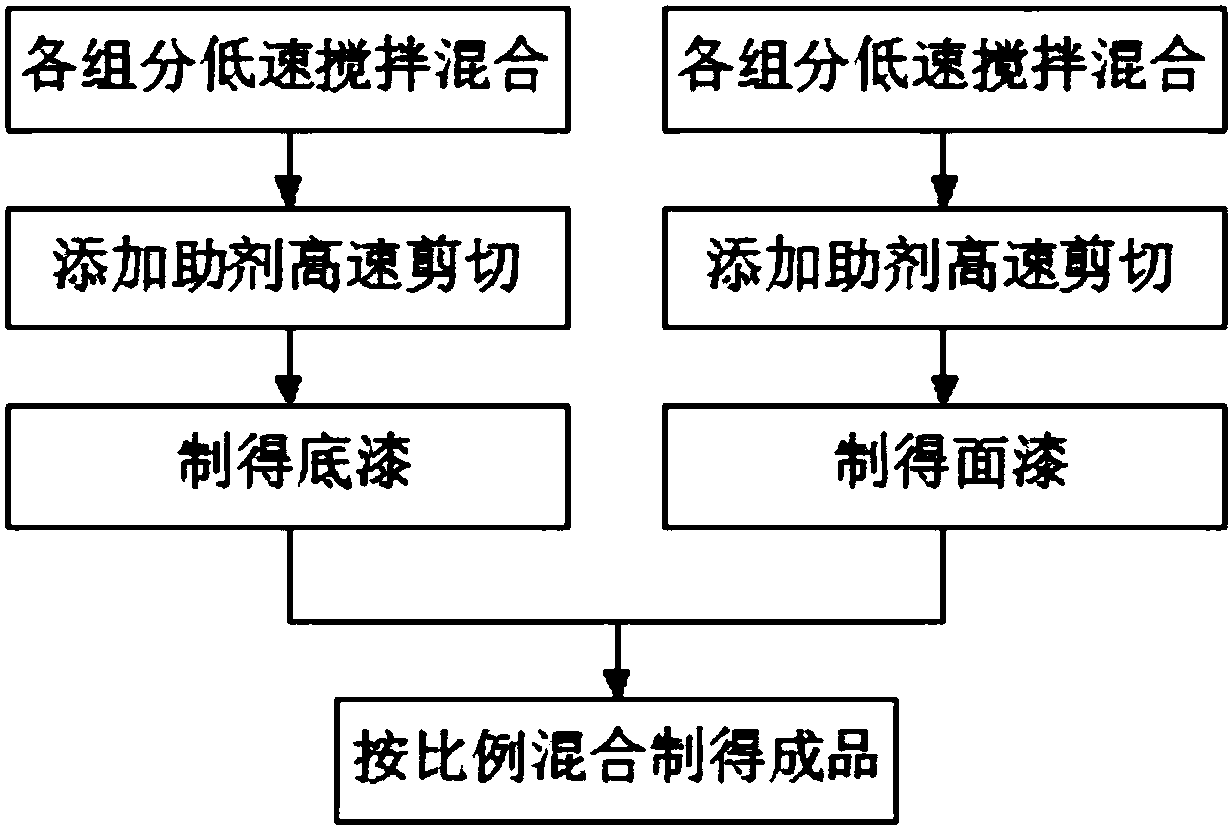

Special waterborne epoxy floor paint as well as preparation method and application thereof

InactiveCN108102439AImprove construction periodShorten the construction periodCement coatingsPolyester coatingsEpoxyCellulose

The invention discloses special waterborne epoxy floor paint as well as a preparation method and an application thereof in the technical field of paint. The special waterborne epoxy floor paint contains primer and finish paint, wherein the primer is prepared from components in parts by weight as follows: 50-100 parts of cement, 200-300 parts of sand, 100-200 parts of heavy calcium carbonate, 60-80parts of polymer emulsion, 10-20 parts of a water reducing agent and 5-10 parts of carboxyethyl cellulose; the finish paint is prepared from components in parts by weight as follows: 200-400 parts ofwaterborne resin, 200-300 parts of modified whole acrylate emulsion, 40-60 parts of a curing agent, 20-40 parts of a dispersant, 80-100 parts of filler, 30-50 parts of a flatting agent, 40-60 parts of modified polyvinyl alcohol thickener, 30-40 parts of a defoaming agent and 70-80 parts of a wetting agent. After the two components are mixed, the construction period is long, the surface of the floor paint can be hardened rapidly after construction, the construction period of the floor paint is shortened, and construction speed is increased.

Owner:中山市榄商置业发展有限公司

Building decoration paint stirring device

InactiveCN109012256AWell mixedEmulsified evenlyMixing methodsTransportation and packagingArchitectural engineeringControl valves

The invention discloses a building decoration paint stirring device which comprises a support assembly, a stirring assembly and a heating assembly. The support assembly comprises three support columnswith an inclined structure, the top ends and the bottom ends of the support columns I, II and III are respectively fixedly connected with support plates, the support plates comprise an upper supportplate and a lower support plate, wherein the upper support plate and the lower support plate both have a circular structure, a through hole is formed in the middle portion of the upper support plate,the bottom of a stirring drum of the stirring assembly is fixed to the upper support plate, a stirring member is disposed on the stirring drum, a feeding pipe is connected to the top of the stirring drum, a discharging pipe is connected to the bottom of the stirring drum, the discharging pipe passes through the through hole of the upper support plate, and the heating assembly includes a temperature sensor, an electric heater, a blast pipe, an air blower, an air outlet, a spacer net, and a control valve. The building decoration paint stirring device allows paint to be more uniformly stirred.

Owner:WUHU SANSHAN LONGCHENG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com