Mucilage production equipment and mucilage production method

A production equipment and glue technology, applied in the field of printing and dyeing, can solve the problems of affecting the emulsification effect, uneven product quality, slow emulsification process, etc., achieve good emulsification effect, improve mixing quality, and uniform emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

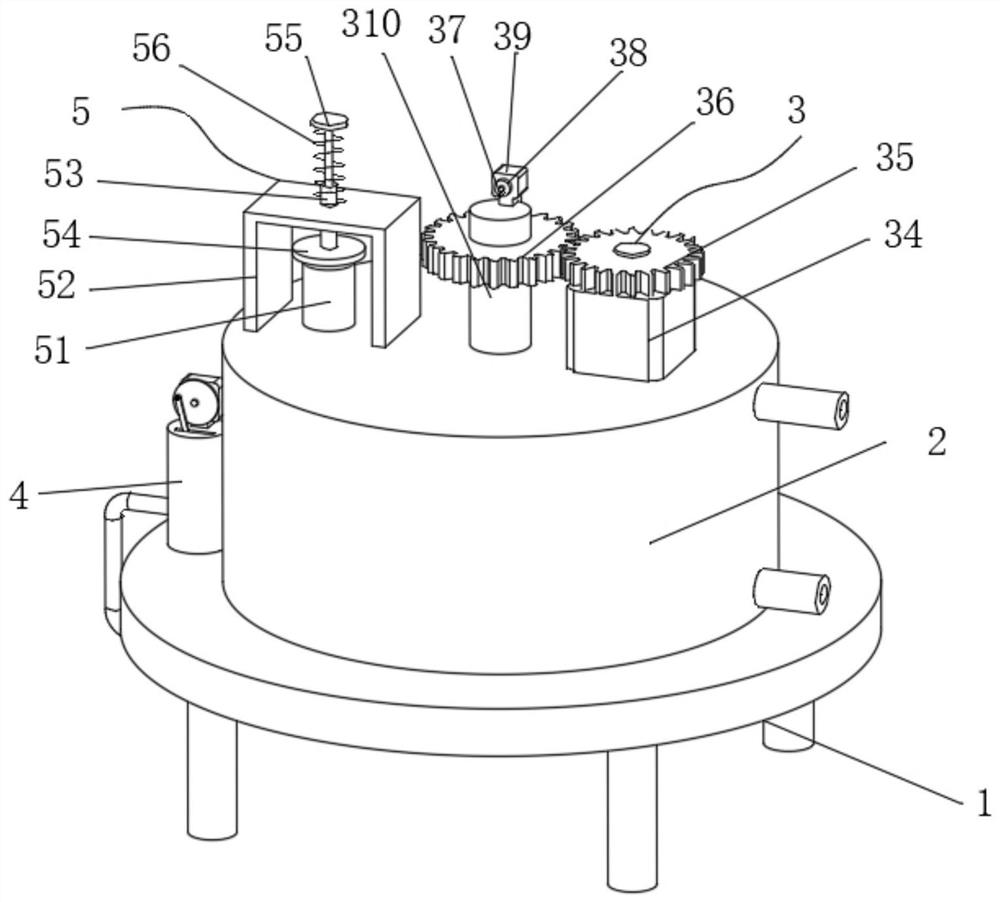

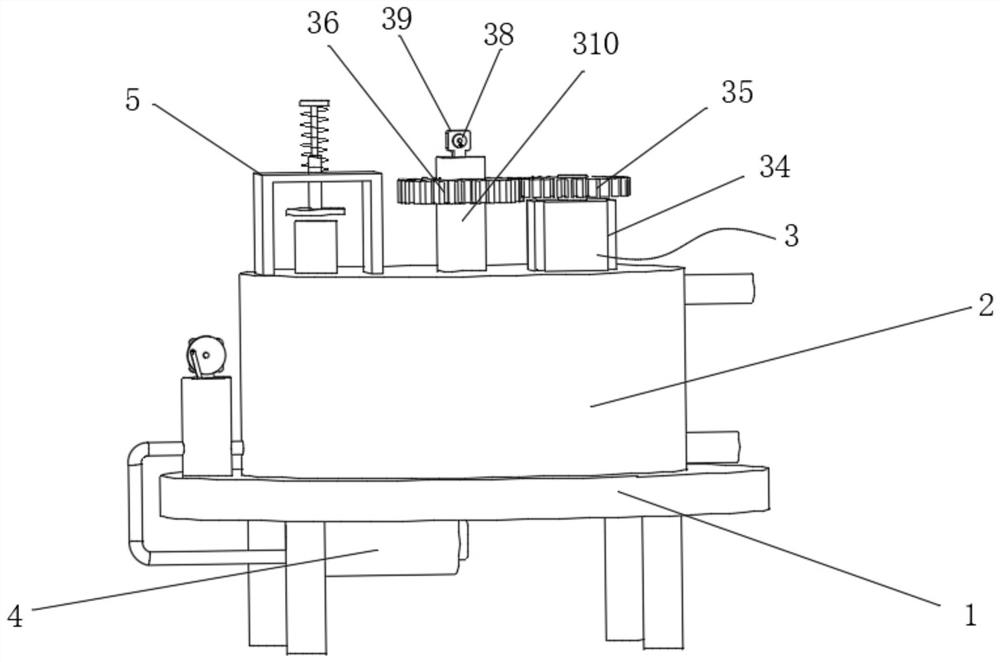

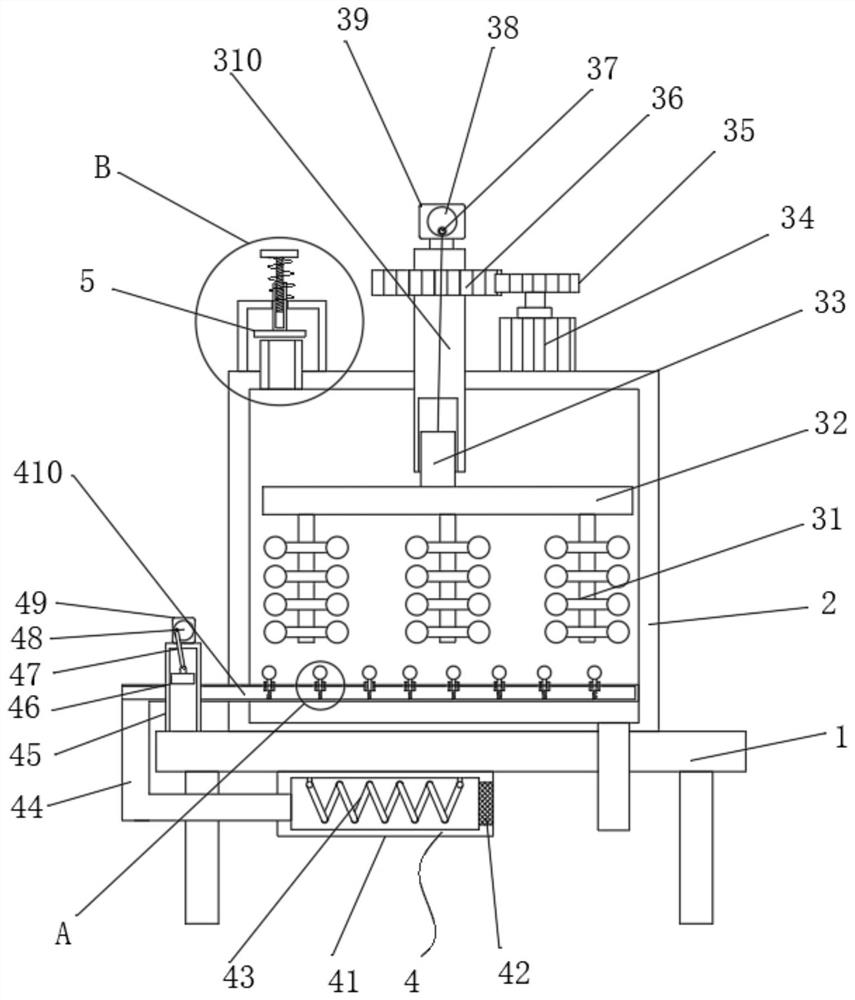

[0031]As an embodiment of the present invention, the vibrating emulsification structure 3 includes a vibrating rod 31, a vibrating plate 32, a matching insert rod 33, a rotating motor 34, a rotating gear 35, a matching gear 36, a positioning rod 37, a rotating disk 38, a vibrating Tampering motor 39 and rotating column 310. The rotating column 310 is vertically installed in the top side wall of the glue box 2. The bottom end of the rotating column 310 is provided with a rod hole, and the top end of the insertion rod 33 is matched with the rod hole Inside, the vibrating plate 32 is welded on the bottom end of the matching insert rod 33, and a plurality of vibrating rods 31 are welded side by side on the bottom side of the vibrating plate 32, and the matching gear 36 is sleeved on the top outside of the rotating column 310, and the rotating motor 34 Fittingly installed on the top side of the glue box 2 by bolts, the rotating shaft of the rotating motor 34 is equipped with a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com