Special waterborne epoxy floor paint as well as preparation method and application thereof

An epoxy floor paint, water-based technology, applied in the field of paint, can solve the problems of short construction period, slow hardness, uneven emulsification, etc., and achieve the effect of long construction period, speeding up construction speed, and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention provides a special waterborne epoxy floor paint, including a primer and a topcoat. The primer is composed of the following components by weight: 50 parts of cement, 200 parts of sand, 100 parts of heavy calcium carbonate, polymer 60 parts of emulsion, 10 parts of water reducing agent, 5 parts of carboxyethyl cellulose;

[0024] The topcoat is composed of the following components by weight: 200 parts of polyester resin, 200 parts of modified all-acrylate emulsion, 40 parts of isophorone diamine, 20 parts of modified polycarboxylate ammonium salt, 80 parts of titanium dioxide Parts, 30 parts of leveling agent, 40 parts of modified polyvinyl alcohol thickener, 30 parts of defoamer, 70 parts of fatty acid ester sulfate.

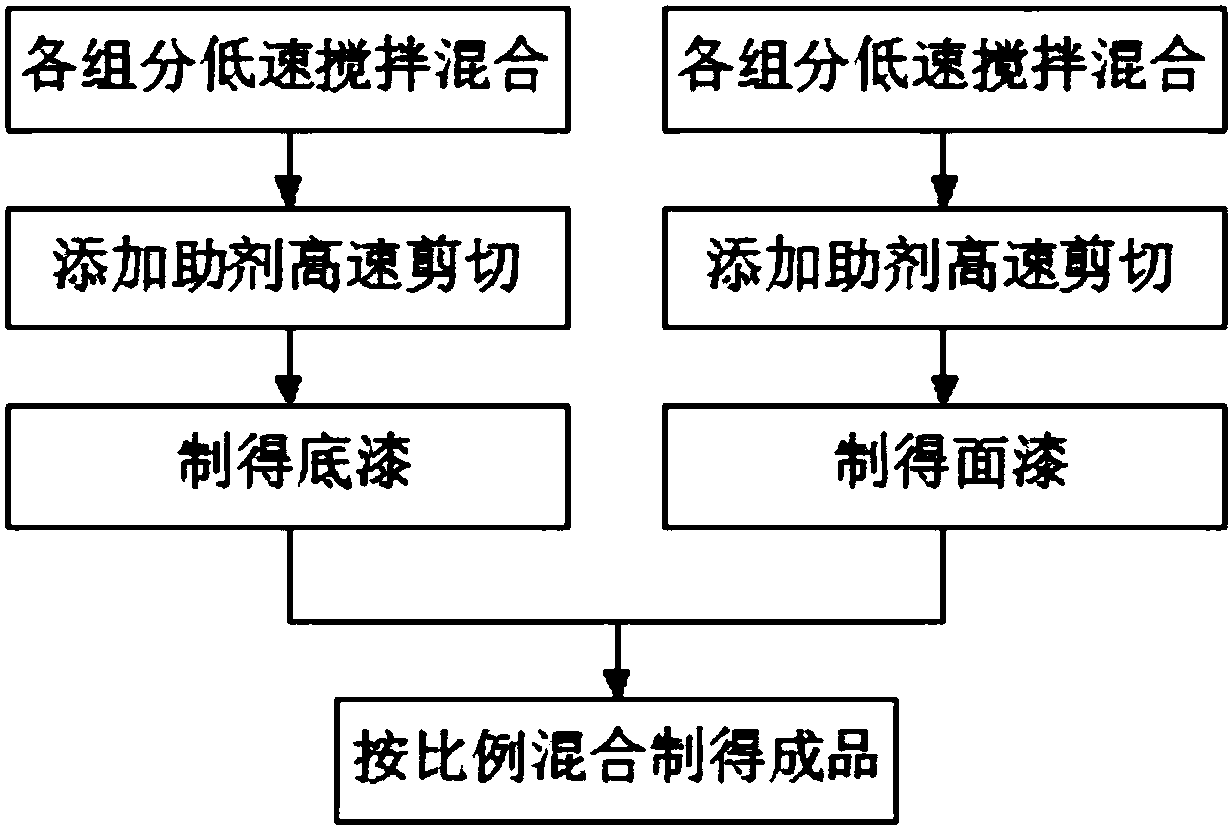

[0025] The invention also provides a method for preparing a special waterborne epoxy floor paint, which specifically includes the following steps:

[0026] S1: Put the cement, sand, heavy calcium carbonate and polymer emulsion into the mixe...

Embodiment 2

[0033] The present invention provides a special waterborne epoxy floor paint, including a primer and a topcoat. The primer is composed of the following components by weight: 100 parts of cement, 300 parts of sand, 200 parts of heavy calcium carbonate, and polymer 80 parts of organic emulsion, 20 parts of water reducing agent, 10 parts of carboxyethyl cellulose;

[0034] The topcoat is composed of the following components by weight: 400 parts of phenolic resin, 300 parts of modified all-acrylate emulsion, 60 parts of cyclohexanediamine, 0 parts of modified polyacrylate, 100 parts of quartz sand, leveling agent 50 parts, 60 parts of modified polyvinyl alcohol thickener, 40 parts of defoamer, 80 parts of alkylphenol polyoxyethylene ether.

[0035] The invention also provides a method for preparing a special waterborne epoxy floor paint, which specifically includes the following steps:

[0036] S1: Put the cement, sand, heavy calcium carbonate and polymer emulsion into the mixer, add an...

Embodiment 3

[0043] The present invention provides a special waterborne epoxy floor paint, including a primer and a topcoat. The primer is composed of the following components by weight: 60 parts of cement, 200 parts of sand, 150 parts of heavy calcium carbonate, and polymer 70 parts of emulsion, 15 parts of water reducing agent, 7 parts of carboxyethyl cellulose;

[0044] The topcoat is composed of the following components by weight: 300 parts of acrylic resin, 300 parts of modified all-acrylate emulsion, 50 parts of polyamide, 30 parts of modified polycarboxylate ammonium salt, 90 parts of barium sulfate powder, leveling 40 parts of modified polyvinyl alcohol thickener, 35 parts of antifoaming agent, and 75 parts of polyoxyethylene modifier.

[0045] The invention also provides a method for preparing a special waterborne epoxy floor paint, which specifically includes the following steps:

[0046] S1: Put the cement, sand, heavy calcium carbonate and polymer emulsion into the mixer, add an appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com