Identical reaction kettle reel-to-reel plasma ultrasonic supercritical non-aqueous dyeing

An anhydrous dyeing and reaction kettle technology, applied in dyeing method, vibration treatment, treatment of textile material containers, etc., can solve problems such as inability to solve the problem of textile surface pretreatment, inability to meet the requirements of safety, and the system works continuously at a uniform speed. Achieve the effect of shortening dyeing time, improving production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

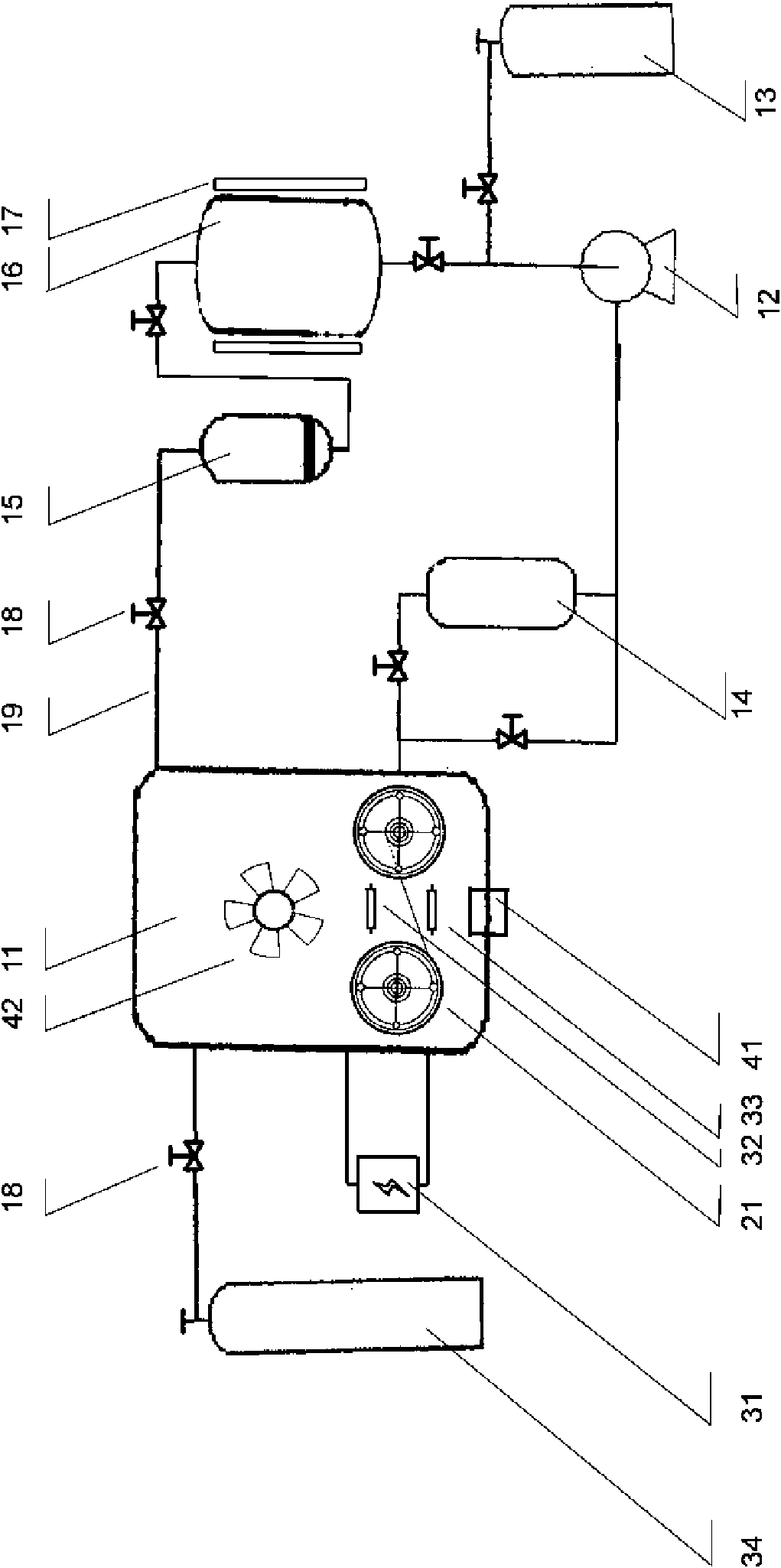

[0019]Embodiment 1, the same reactor roll-to-roll plasma ultrasonic supercritical textile anhydrous dyeing, the greige cloth is packed into the roll-to-roll or shaft-to-shaft winding device (21) in the reactor, with a vacuum pump (preferably a Luo with a large air extraction capacity) Vacuum pump) vacuumizes the airtight reaction kettle (11) made of high-pressure resistant transparent glass (to about 10Pa), feeds oxygen into the reaction kettle (11) from the gas cylinder (34), and gives the reaction kettle (11) The upper electrode (32) and the lower electrode (33) of the inner plasma generator (31) are energized, the plasma parameters are measured by a Langmuir (Langmuir) probe, and the reel-to-reel or reel-to-reel winding device (21) is turned on to enable The textile starts to be wound at a constant speed, and the surface of the textile is modified by capacitively coupled low-pressure glow discharge. The plasma reaction is stopped after the power is turned off, and a small am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com