Fabric stiffening agent

A stiffening agent and initiator technology, which is applied in the field of acrylic silk protein sizing agent, can solve the problems of poor biodegradability and low strength of the serous film, and achieve the effects of easy storage and transportation, good wetting effect and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 prepares acrylic acid composite liquid:

[0025] 1) First add 100kg of water to the reactor, and then heat it to 75°C;

[0026] 2) add initiator (ammonium persulfate), and stop heating simultaneously;

[0027] 3) Stir while adding the prepared composite raw materials dropwise, and continue for about 60 minutes;

[0028] 4) Keep warm for 2 hours afterwards;

[0029] 5) Add 40kg of ammonia water, and then add 70kg of alcohol to obtain the acrylic compound liquid, which is set aside;

[0030] Step 3) The composite raw materials are: 10kg of vinyl acetate, 5kg of styrene; 90kg of methyl acrylate; 20kg of butyl acrylate; 15kg of methyl methacrylate;

Embodiment 2

[0031] Embodiment 2 prepares fibroin solution and stiffening agent finished product:

[0032] 1) Weigh a certain amount of 500g cocoon layer of the silk reeling head, place it in 10L of 0.5% sodium carbonate boiling solution and treat it for 20min to carry out degumming. Then take out the silk, wash it repeatedly with distilled water, wring it out, and dry it to obtain completely degummed silk, that is, silk protein fiber;

[0033] 2) Weigh 50 g of degummed silk protein fibers, place them in 1 L of calcium chloride boiling solution with a mass concentration of 60%, and treat them for about 4 minutes until the silk protein fibers are completely dissolved. Stir with a glass rod to obtain a fibroin / calcium chloride mixed solution. Filtrating the above mixed solution with gauze for rough extraction to obtain a salted silk protein solution;

[0034] 3) Mix the acrylic compound solution obtained in Example 1 and the silk protein solution obtained in step 3), and finally release an...

Embodiment 3

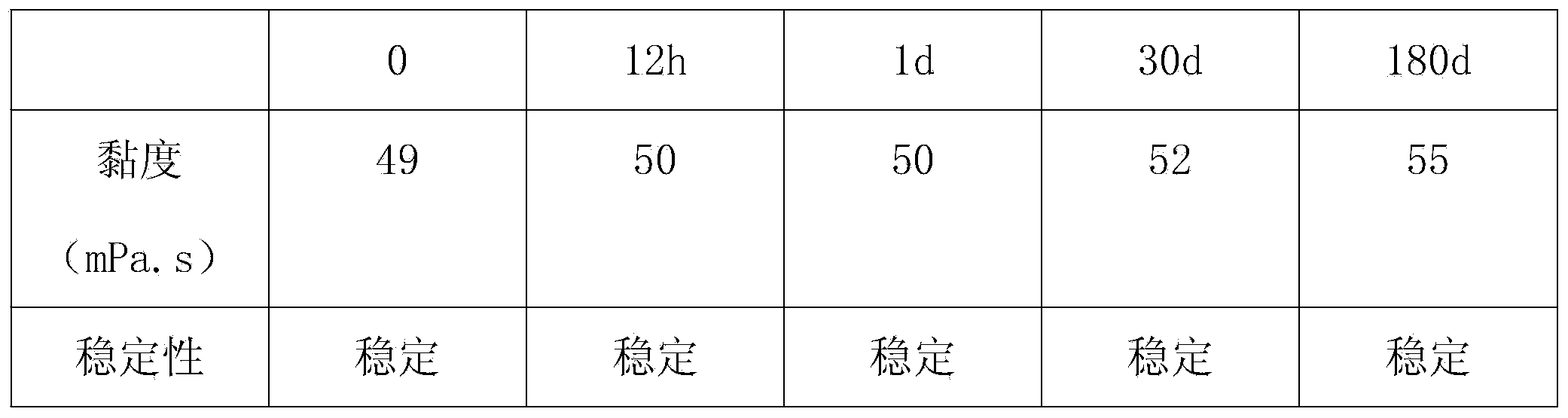

[0036] Embodiment 3: Stiffening agent viscosity and stability test

[0037] The stiffening agent obtained in Example 2 was used for testing.

[0038] Viscosity test: start after normal temperature, and test the change of viscosity on the viscometer at regular intervals.

[0039] Stability test: mainly through the objective observation method, after room temperature, observe whether the slurry is delaminated and the delamination ratio (upper layer than lower layer) at regular intervals.

[0040] Table 1 Stiffener viscosity and stability test

[0041]

[0042] It can be seen from Table 1 that the stiffening agent obtained by the present invention has moderate viscosity, is easy to use, and has excellent stability, and there is no obvious delamination after 180 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com