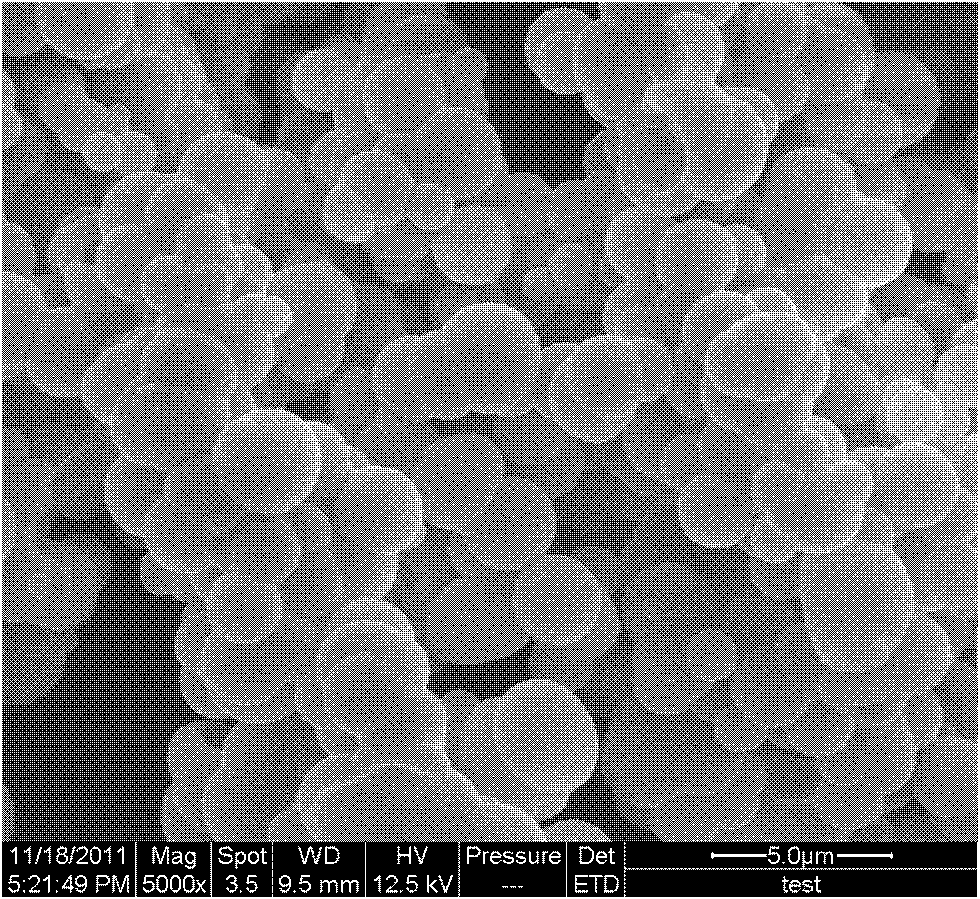

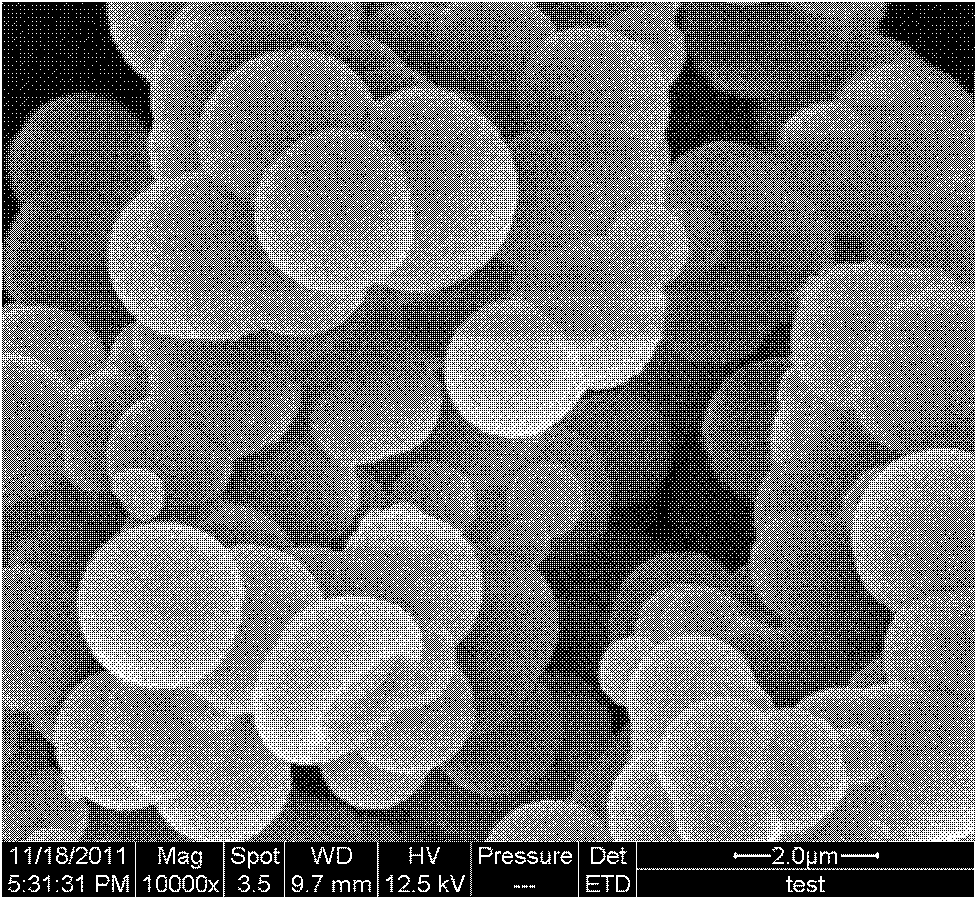

Preparation method of spherical beta-cyclodextrin/ melamine resin phase change energy storage materials

A technology of phase change energy storage materials and melamine resin, which is applied in the direction of microsphere preparation, heat exchange materials, chemical instruments and methods, etc., can solve the problem of high brittleness of wall materials, poor heat transfer performance of microcapsule phase change materials, phase The problem of low enthalpy change can achieve the effect of large phase change enthalpy, good coating effect and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation method of the spherical β-cyclodextrin / melamine resin phase-change energy storage material in this example adopts the in-situ polymerization method, which is specifically carried out according to the following steps: 1. A certain amount of formaldehyde The solution is placed in a three-necked flask with a stirrer, and triethanolamine solution is added dropwise until the pH value of the solution is 7.5-9, then melamine is added, and the solution is kept in a constant temperature water bath until the solution becomes clear to obtain a melamine resin solution; β-cyclodextrin is dissolved in In a certain amount of triethanolamine solution, obtain the alkali solution of β-cyclodextrin, control the amount of triethanolamine to make the pH value of the solution 7.5-9, heat it to 40-70°C, add it into the melamine resin solution and stir for 5 After ~10 minutes, pour it into a constant pressure dropping funnel to obtain a β-cyclodextrin / melamine resin prepolymer s...

Embodiment 2

[0017] Put 6.07g of formaldehyde solution in a three-neck flask with a stirrer and add triethanolamine solution dropwise until the pH value of the solution is 7.5-9, then add 3.05g of melamine, and keep a constant temperature water bath at 60°C until the solution becomes clear. Dissolve 0.6g of β-cyclodextrin in a certain amount of triethanolamine solution to obtain an alkaline solution of β-cyclodextrin, control the amount of triethanolamine so that the pH value is 7.5-9, heat it to the temperature of the water bath, and add it to the three bottle and stir for 5-10 minutes. Pour the solution in the three-neck bottle into the constant pressure dropping funnel to obtain the β-cyclodextrin / melamine resin prepolymer solution; add 0.75g OP-10 emulsifier and 50mL distilled water to 4.99g liquid paraffin and pass it through the laboratory The emulsifying machine is highly dispersed for 10-15 minutes to obtain the core material emulsion; put the core material emulsion in a three-neck...

Embodiment 3

[0019] Put 6.01g of formaldehyde solution in a three-necked flask with a stirrer and add triethanolamine solution dropwise until the pH of the solution is 7.5-9, then add 2.98g of melamine, and keep the water bath at 65°C until the solution becomes clear. Dissolve 0.6g of β-cyclodextrin in a certain amount of triethanolamine solution to obtain an alkaline solution of β-cyclodextrin, control the amount of triethanolamine so that the pH value is 7.5-9, heat it to the temperature of the water bath, and add it to the three bottle and stir for 5-10 minutes. Pour the solution in the three-neck bottle into the constant pressure dropping funnel to obtain the β-cyclodextrin / melamine resin prepolymer solution; add 0.91g OP-10 emulsifier and 50mL distilled water to 6.03g liquid paraffin and pass it through the laboratory The emulsifying machine is highly dispersed for 10-15 minutes to obtain the core material emulsion; put the core material emulsion in a three-necked bottle with a stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com