Synthesis method of ultraviolet light absorber for water-based coiled material finish paint

A synthesis method and ultraviolet technology, applied in radiation-absorbing coatings, preparation of carboxylic acid halides, coatings, etc., can solve problems such as poor compatibility, migration on the surface of the coating film, and difficulty in dissolving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

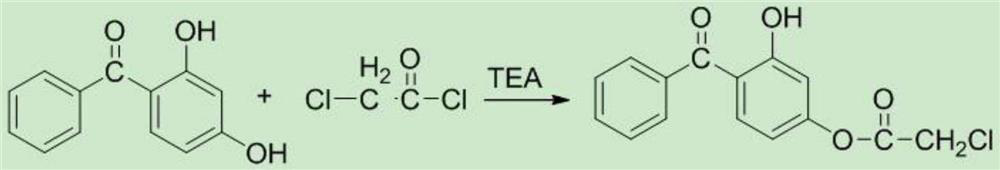

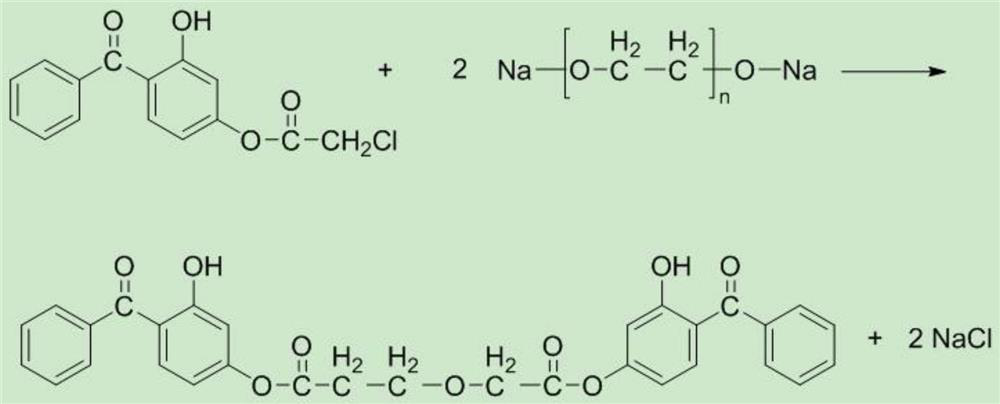

[0026] Embodiment 1, [PhCO(C 6 h 4 )(2-OH)(4-OCO)] 2 CH 2 (OCH 2 CH 2 ) 13 Synthesis

[0027]Add 60g polyethylene glycol-600 (0.1mol) and toluene into a round bottom flask equipped with a stirring bar, a reflux condenser and a thermometer, and use toluene to bring water out of the polyethylene glycol. Under the protection of nitrogen, heat to 115°C, add enough sodium metal, and react for about 18 hours until the solution turns dark brown, remove the remaining sodium metal, and obtain sodium polyethylene glycol-600 toluene solution.

[0028] Weigh 12.2g of PhCO(C 6 h 4 )(2-OH)(4-OCOCH 2 Cl) (0.042mol) was placed in a 250mL three-necked round-bottomed flask equipped with a stirrer, a thermometer, and a reflux condenser, and a certain amount of toluene was added. After fully stirring and dissolving, the temperature was raised to 100°C. Under nitrogen protection, the The prepared sodium polyethylene glycol-600 toluene solution was slowly dripped in, and the dripping was ...

Embodiment 2

[0029] Embodiment 2, [PhCO(C 6 h 4 )(2-OH)(4-OCO)] 2 CH 2 (OCH 2 CH 2 ) 22 Synthesis

[0030] Add 100g polyethylene glycol-1000 (0.1mol) and toluene into a round bottom flask equipped with a stirring bar, a reflux condenser and a thermometer, and use toluene to bring water out of the polyethylene glycol. Under the protection of nitrogen, heat to 115°C, add enough sodium metal, and react for about 18 hours until the solution turns dark brown, remove the remaining sodium metal, and obtain sodium polyethylene glycol-1000 toluene solution.

[0031] Weigh 12.2g of PhCO(C 6 h 4 )(2-OH)(4-OCOCH 2 Cl) (0.042mol) was placed in a 250mL three-necked round-bottomed flask equipped with a stirrer, a thermometer, and a reflux condenser, and a certain amount of toluene was added. After fully stirring and dissolving, the temperature was raised to 100°C. Under nitrogen protection, the The prepared sodium polyethylene glycol-1000 toluene solution was slowly dripped in, and the dripping...

Embodiment 3

[0032] Embodiment 3, [PhCO(C 6 h 4 )(2-OH)(4-OCO)] 2 CH 2 (OCH 2 CH 2 ) 45 Synthesis

[0033] Add 100g polyethylene glycol-2000 (0.05mol) and toluene into a round bottom flask equipped with a stirring bar, a reflux condenser and a thermometer, and use toluene to bring water out of the polyethylene glycol. Under the protection of nitrogen, heat to 115°C, add enough sodium metal, and react for about 18 hours until the solution turns dark brown, remove the remaining sodium metal, and obtain sodium polyethylene glycol-2000 toluene solution.

[0034] Weigh 6.1g of PhCO(C 6 h 4 )(2-OH)(4-OCOCH 2 Cl) (0.021mol) was placed in a 250mL three-necked round-bottomed flask equipped with a stirrer, a thermometer, and a reflux condenser, and a certain amount of toluene was added. After fully stirring and dissolving, the temperature was raised to 100°C. Under nitrogen protection, the The prepared sodium polyethylene glycol-2000 toluene solution was slowly dripped in, and the dripping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com