Method for preparing supercritical hydrotalcite grafted with flame retardant

A supercritical, flame retardant technology, applied in the production of bulk chemicals, treatment of dyed low molecular organic compounds, fibrous fillers, etc., can solve the problems of unfriendly environment, poor extraction resistance, low thermal stability, etc. The effect of improving dispersibility and comprehensive mechanical properties, greatly improving aging resistance, and improving thermal degradation and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

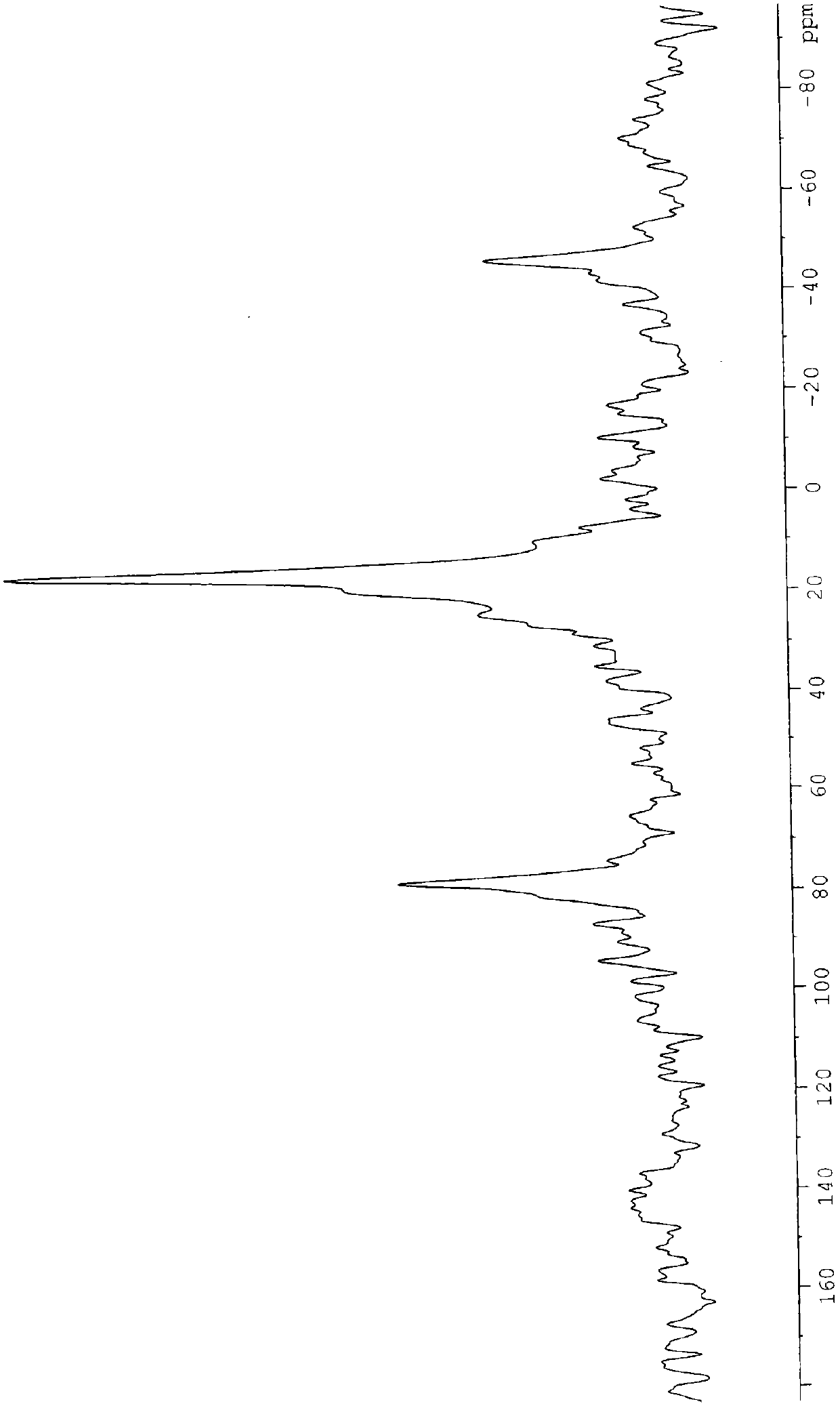

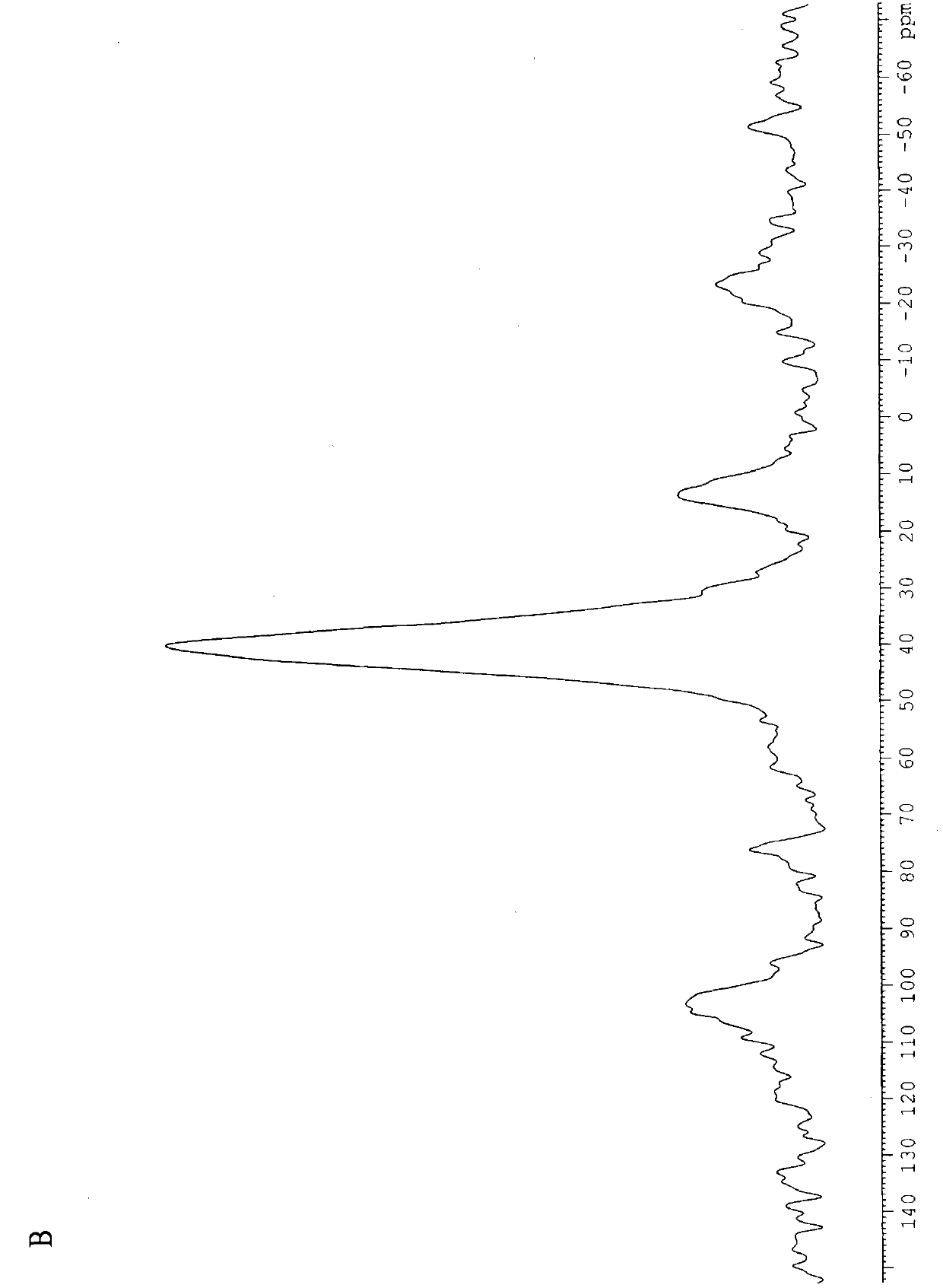

[0031] Silane coupling agent chemical grafting treatment of hydrotalcite: Weigh 5 grams of the above-mentioned hydrotalcite, 0.5 grams of γ-(methacryloyloxy)propyltrimethoxysilane, and 0.45 grams of DOPO into the supercritical reactor, and feed Supercritical carbon dioxide, continuous stirring and reaction for 5 hours, then release the pressure to obtain the surface-grafted DOPO hydrotalcite.

[0032] Wherein γ-(methacryloyloxy)propyltrimethoxysilane accounts for 4wt% of the hydrotalcite total amount of surface-grafted γ-(methacryloyloxy)propyltrimethoxysilane and DOPO, and DOPO accounts for surface-grafted Branch γ-(methacryloyloxy)propyltrimethoxysilane and DOPO account for 2 wt% of the total amount of hydrotalcite, and the balance is hydrotalcite.

Embodiment 2

[0034] Adopt and embodiment 1 substantially identical method, but the hydrotalcite particle size used in the present embodiment is 100 μ m, and the silane coupling agent of use is gamma-(methacryloxy) propyl monomethoxysilane, can A hydrotalcite grafted with DOPO on the surface by γ-(methacryloyloxy)propyl monomethoxysilane was obtained. Wherein γ-(methacryloyloxy)propyl monomethoxysilane accounts for 0.7wt% of the hydrotalcite total amount of surface grafted γ-(methacryloyloxy)propyl monomethoxysilane and DOPO, DOPO It accounts for 0.5wt% of the total amount of hydrotalcite grafted with γ-(methacryloxy)propyl monomethoxysilane and DOPO on the surface, and the balance is hydrotalcite.

Embodiment 3

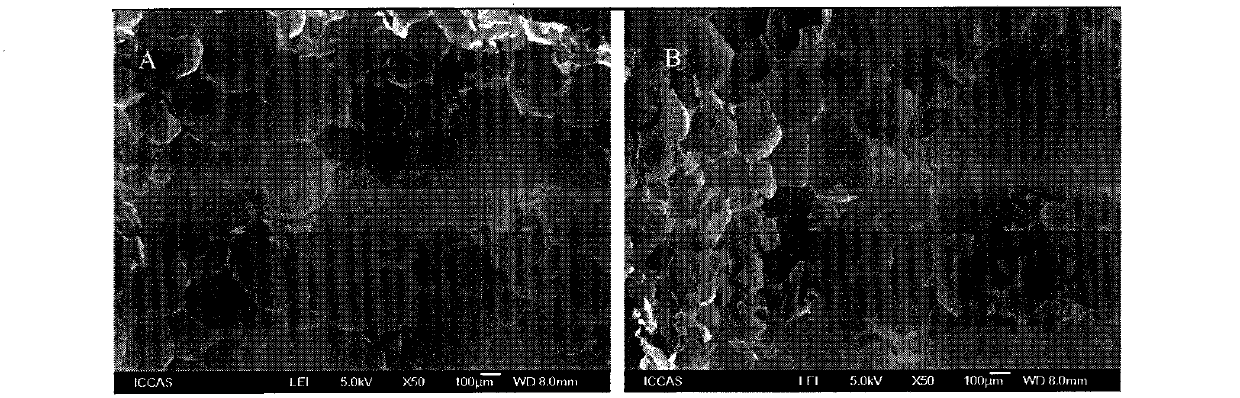

[0036] The product prepared in Example 1 and unmodified hydrotalcite were used as fillers respectively, and were respectively added to the polyurethane foam material, and prepared into samples of a certain shape for performance characterization:

[0037] The hydrotalcites grafted with DOPO on the surface and the unmodified hydrotalcites were respectively added to the polyurethane raw materials to prepare polyurethane foam materials, and the composite materials of polyurethane / hydrotalcite grafted with DOPO and the composite materials of polyurethane / hydrotalcite were respectively obtained. with pure polyurethane. The materials prepared from the above three materials were subjected to the oxygen index combustion performance test (JF-3, Nanjing Jiangning District Analytical Instrument Factory) according to GB / T2406. The limiting oxygen indices of the above composite materials are shown in Table 1.

[0038] Table 1 Limiting oxygen index of polypropylene-based composites with dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com