Wax printing dye and wax printing method

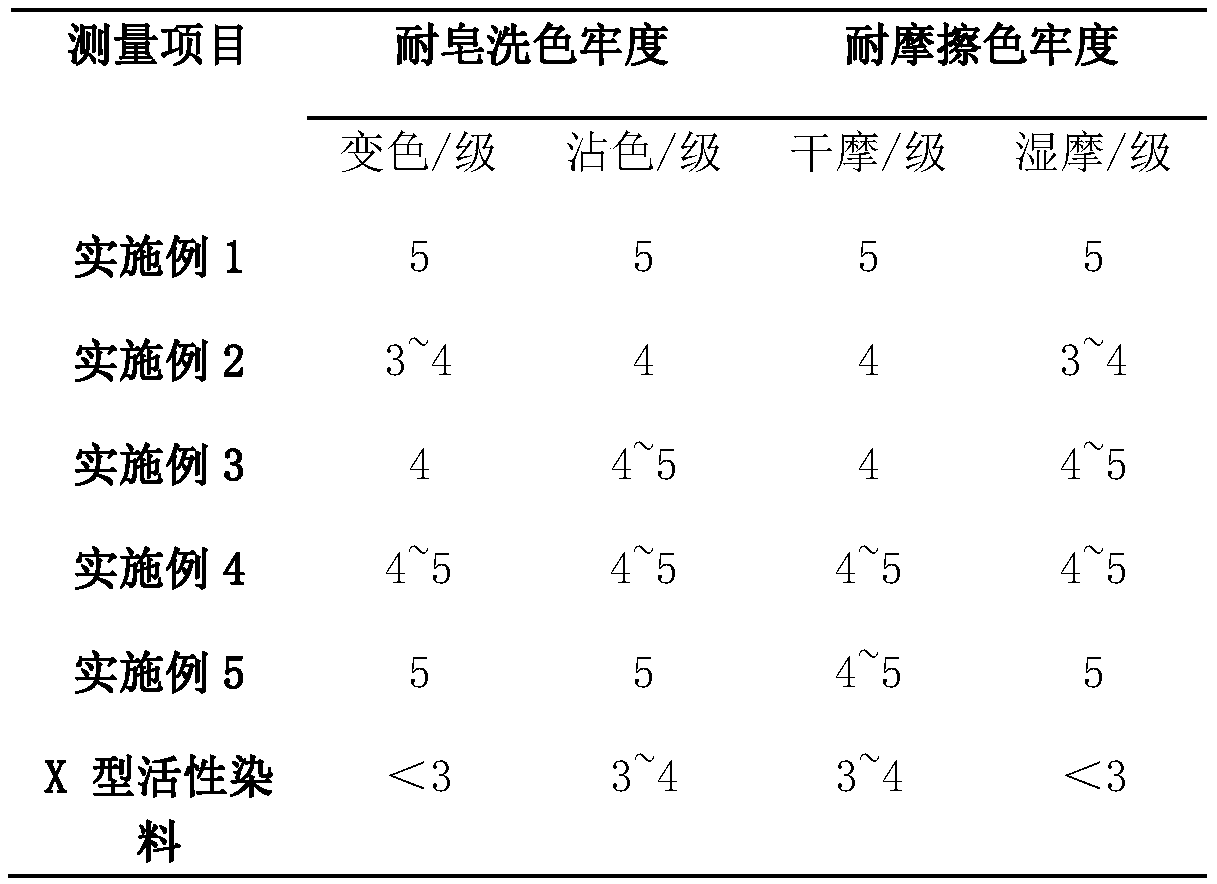

A dye and batik technology, applied in the field of batik, can solve the problems of low washing fastness, high price, incomplete chromatogram, etc., and achieve the effects of improving color fastness and uniformity, improving light aging resistance, and accelerating dyeing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] For the following, through the description of the examples, the specific implementation of the present invention, such as the manufacturing process involved, the operation and use method, etc., will be described in further detail, so as to help those skilled in the art to have a more complete concept of the invention and the technical solution of the present invention. , accurate and in-depth understanding.

[0018] In order to solve the problems of poor color fastness and uneven dyeing of dyes in the prior art, the invention provides a kind of batik dye, comprising the following components, 8-10% (owf) of dyes, 20-45g / L of sodium sulfate, soda ash 25-50g / L, tea polyphenols 40-60g / L, and the wax liquid mass percentage in the dye is 65-85%.

[0019] Provide a kind of batik method simultaneously, comprise the following steps,

[0020] Fabric pretreatment: Soak the fabric in normal temperature water for 10-20 minutes, then add softener to the water and heat the water to 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com