Inorganic bio-based ultraviolet aging-resistant flame retardant and application thereof in textiles

An anti-photoaging, bio-based technology, applied in the field of flame retardant, can solve the problems of poor heat resistance, low melting point of salicylic acid, and rarely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

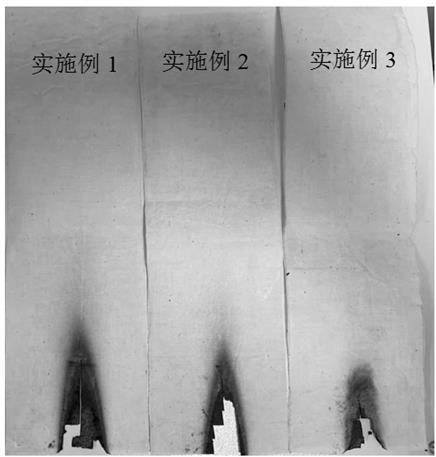

Examples

Embodiment 1

[0026] Weigh 10g of urea into a crucible, put it into an environment with a heating rate of 10°C / min, raise the temperature to 540°C, and keep it for 5h to obtain g-C 3 N 4 ;According to the mass ratio 1:1000, take g-C respectively 3 N 4 and deionized water, mix, ultrasonic 24h, take supernatant, get g-C 3 N 4 anionic suspension. According to the mass ratio of 1:49, weigh polyethyleneimine and deionized water respectively, mix them, stir at a speed of 400rpm for 12h, add HCl solution with a molar volume concentration of 1mol / L, and obtain polyethyleneimine with a pH value of 8 cationic solution. According to the mass ratio of 1:49, weigh phytic acid and deionized water respectively, mix them, stir at 400 rpm for 12 hours, then add NaOH solution with a molar volume concentration of 1 mol / L to obtain a phytic acid anion solution with a pH value of 7. According to the mass ratio of 1:5:25, respectively take phosphor, polyvinylpyrrolidone and absolute ethanol, mix and stir f...

Embodiment 2

[0029] Weigh 10g of urea into a crucible, put it into an environment with a heating rate of 10°C / min, raise the temperature to 550°C, and keep it for 6 hours to obtain g-C 3 N 4 ; According to the mass ratio 2: 1000, take g-C respectively 3 N 4 and deionized water, mix, ultrasonic 24h, take supernatant, get g-C 3 N 4 Anionic suspension: According to the mass ratio of 2:49, take polyethyleneimine and deionized water respectively, mix them, stir at a speed of 500rpm for 12h, add HCl solution with a molar volume concentration of 1mol / L, and obtain polyethylene with a pH of 7 imine cation solution. According to the mass ratio of 2:49, take phytic acid and deionized water respectively, mix them, stir at 450 rpm for 12 hours, then add 1 mol / L NaOH solution to obtain a phytic acid anion solution with a pH of 7. According to the mass ratio of 1:5:25, respectively take phosphor, polyvinylpyrrolidone and absolute ethanol, mix and stir for 24 hours to obtain a coating solution;

[...

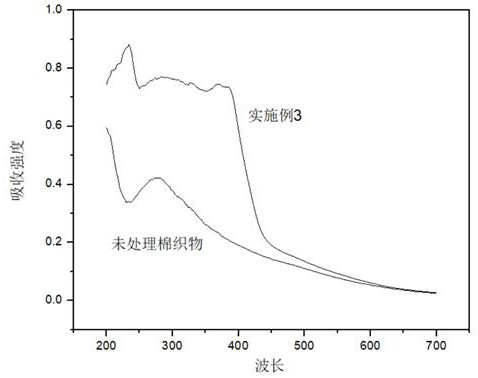

Embodiment 3

[0032] Weigh 10g of urea in a crucible, put it into an environment with a heating rate of 10°C / min, raise the temperature to 545°C, and keep it for 5.5h to obtain g-C 3 N 4 ; According to the mass ratio of 1.5: 1000, take g-C respectively 3 N 4 and deionized water, mix, ultrasonic 24h, take supernatant, get g-C 3 N 4 anionic suspension. According to the mass ratio of 1.5︰49, take polyethyleneimine and deionized water respectively, mix them, stir at a speed of 450rpm for 18h, add HCl solution with a molar volume concentration of 1mol / L, and obtain a polyethyleneimine cationic solution with a pH of 7.5 . According to the mass ratio of 1.5:49, take phytic acid and deionized water respectively, mix them, stir at 500 rpm for 18 hours, then add NaOH solution with a molar volume concentration of 1 mol / L to obtain a phytic acid anion solution with a pH of 6.5. According to the mass ratio of 1:5:25, respectively take phosphor powder, polyvinylpyrrolidone and absolute ethanol, mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com