Phosphorus-nitrogen-silicon compound containing triazine ring and its preparation method

A technology of silicon compound and triazine ring, which is applied in the field of phosphorus-nitrogen-silicon compound and its preparation, can solve the problems of high energy consumption, high addition amount, complex synthesis process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of the phosphorus-nitrogen-silicon compound containing triazine ring is:

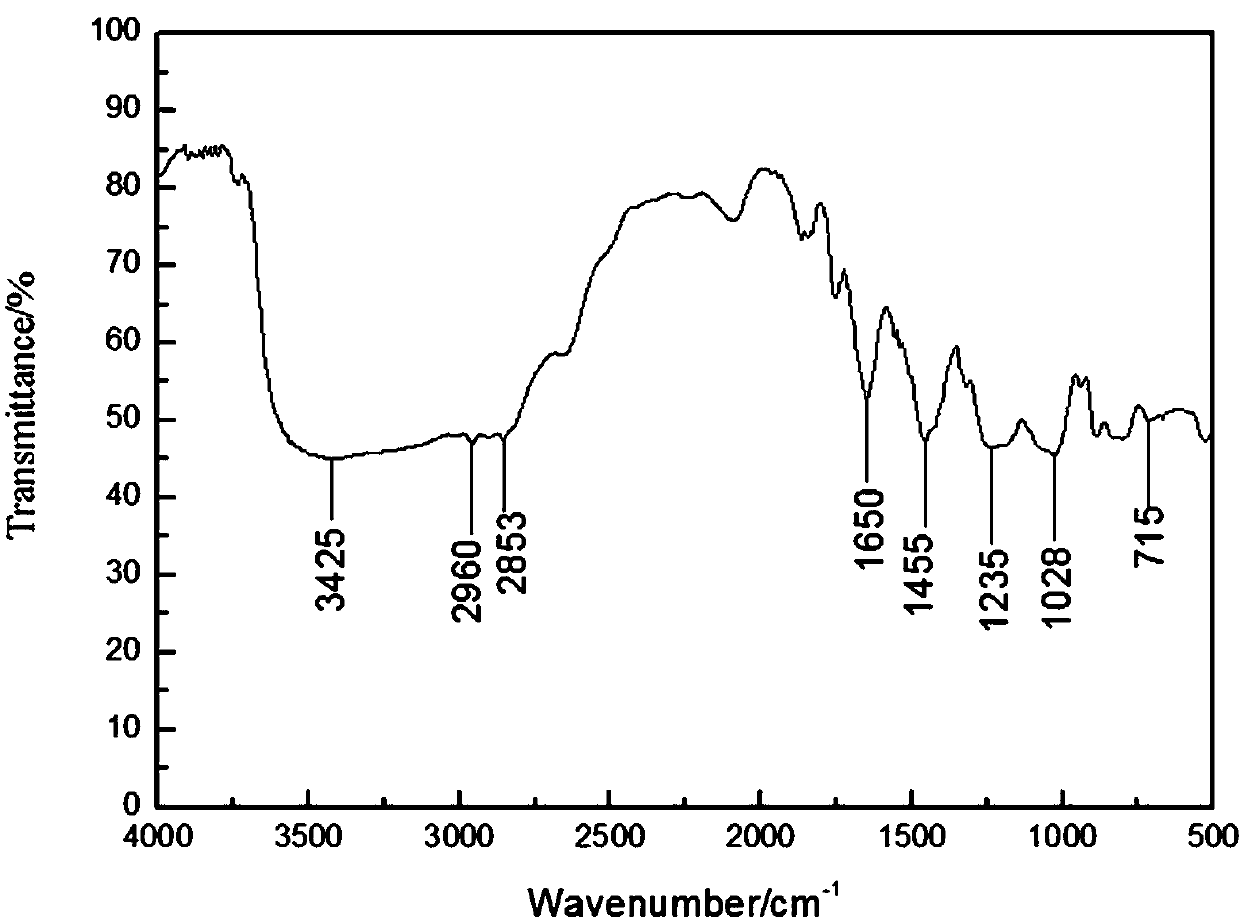

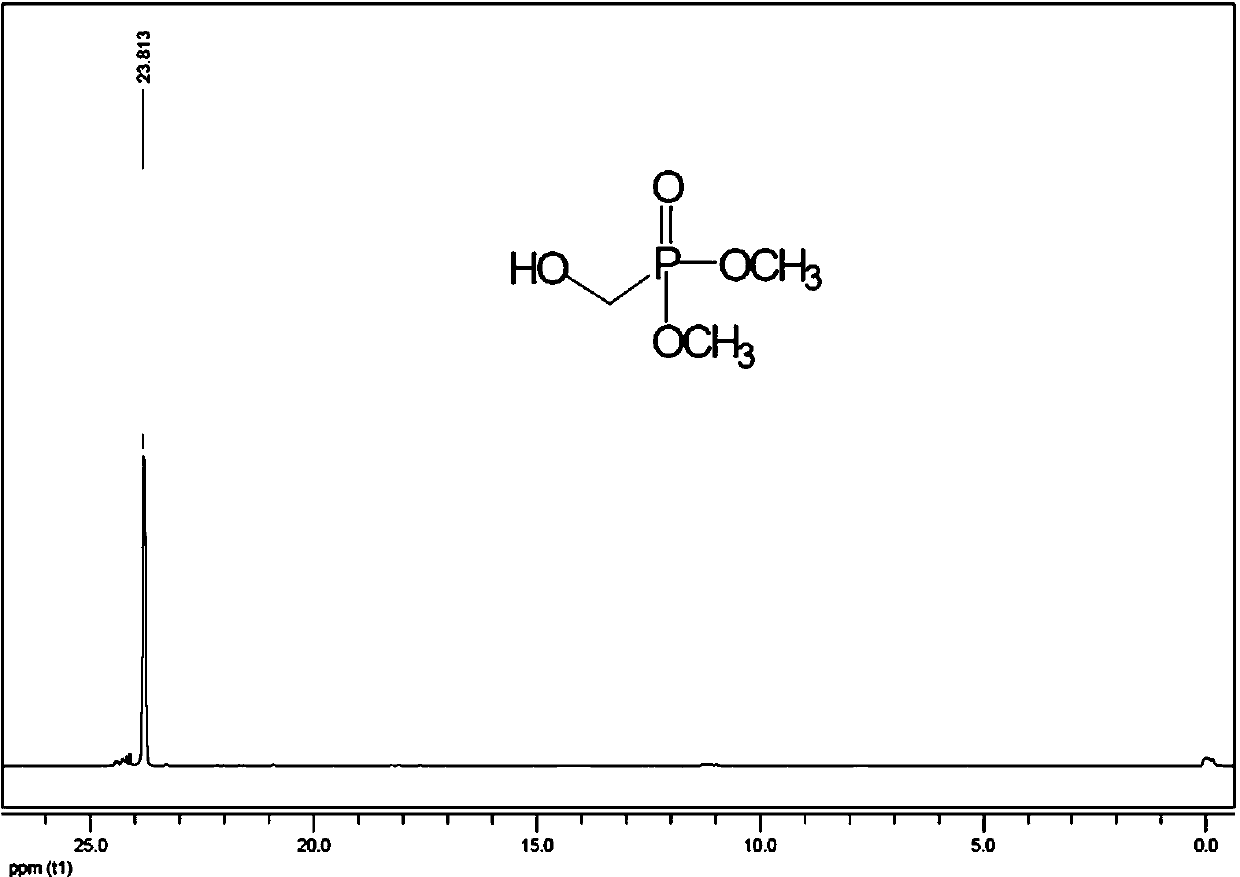

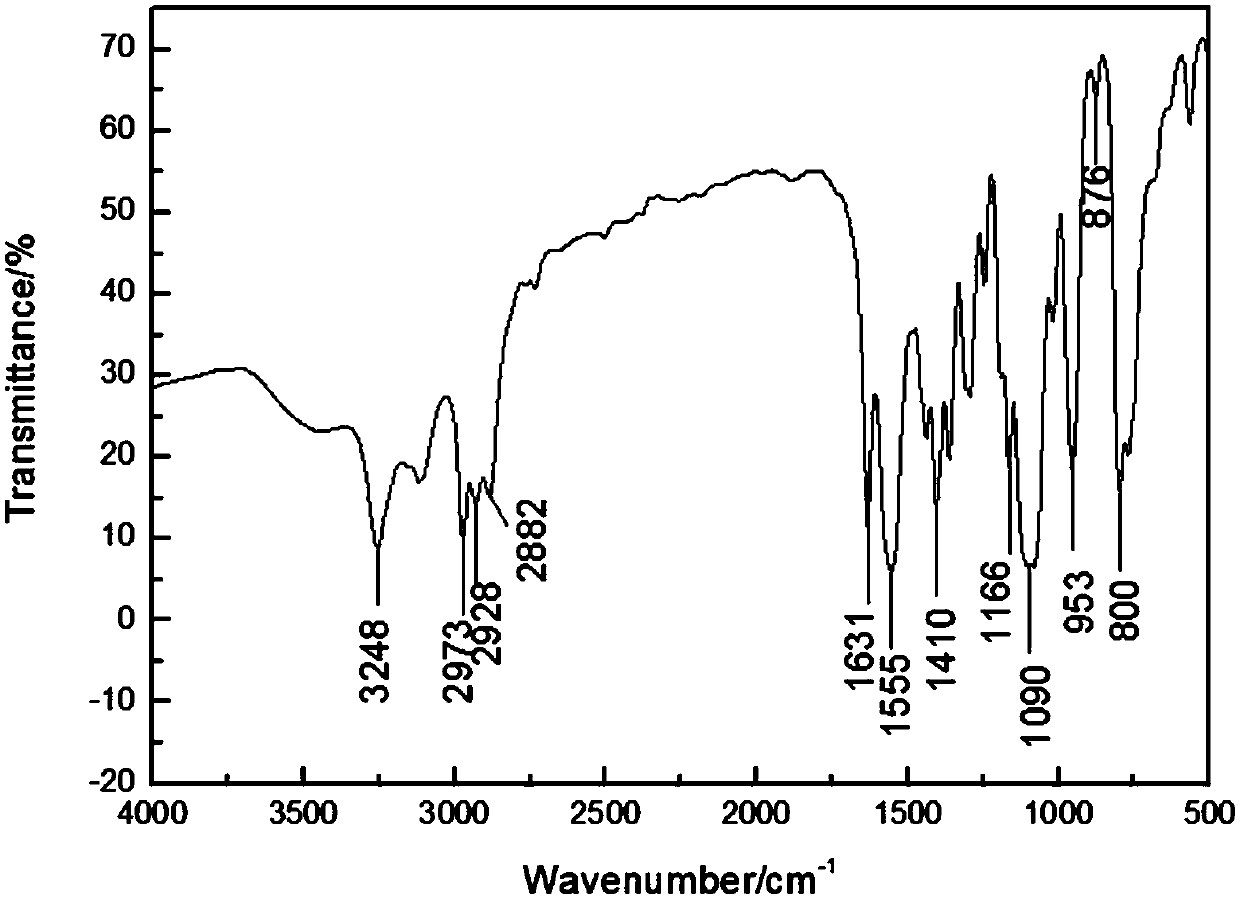

[0046] In the first step, 1.75g (55mmol) of paraformaldehyde was dissolved in 50mL of methanol, 0.63g (4.54mmol) of potassium carbonate solid was added, the solution was cooled to 0°C, and 5.0g (45.4mmol) of diphosphite was added dropwise while stirring Methyl ester, then warmed up to room temperature, potassium carbonate was filtered off after 1h, and methanol was removed from the filtrate under reduced pressure to obtain a colorless oil, which was Intermediate I;

[0047] In the second step, dissolve 3.69g (0.02mol) cyanuric chloride in 70mL acetone, stir well, keep the solution temperature between 0-5°C, slowly add 5.6mL (0.024mol) γ-aminopropyl triethyl Oxysilane, while adding sodium carbonate aqueous solution dropwise to neutralize the hydrogen chloride produced, adjust the pH value to 7, react for 1h, remove the salt by suction filtration, remove the acetone from th...

Embodiment 2

[0050] The preparation method of the phosphorus-nitrogen-silicon compound containing triazine ring is:

[0051] In the first step, 1.75g (55mmol) of paraformaldehyde was dissolved in 50mL of methanol, 0.63g (4.54mmol) of potassium carbonate solid was added, the solution was cooled to 0°C, and 5.0g (45.4mmol) of diphosphite was added dropwise while stirring Methyl ester, then warmed up to room temperature, potassium carbonate was filtered off after 1h, and methanol was removed from the filtrate under reduced pressure to obtain a colorless oil, which was Intermediate I;

[0052] In the second step, dissolve 3.69g (0.02mol) cyanuric chloride in 70mL acetonitrile, stir well, keep the solution temperature between 0-5°C, slowly add 4.7mL (0.02mol) γ-aminopropyl triethyl At the same time, dropwise add sodium hydroxide aqueous solution to neutralize the hydrogen chloride produced, adjust the pH value to 6, react for 2 hours, remove the salt by suction filtration, remove acetonitrile...

Embodiment 3

[0055] The preparation method of the phosphorus-nitrogen-silicon compound containing triazine ring is:

[0056] In the first step, 6.61g (0.22mol) of paraformaldehyde was dissolved in 200mL of methanol, 2.76g (0.02mol) of potassium carbonate solid was added, the solution was cooled to 0°C, and 22.0g (0.2mol) of phosphorous acid was added dropwise while stirring Dimethyl ester, then warmed up to room temperature, potassium carbonate was filtered off after 1h, and methanol was removed from the filtrate under reduced pressure to obtain a colorless oily substance, which was intermediate Ⅰ;

[0057] In the second step, dissolve 3.69g (0.02mol) cyanuric chloride in 70mL tetrahydrofuran, stir well, keep the solution temperature between 0-5°C, slowly add 5.6mL (0.024mol) γ-aminopropyl triethyl Oxysilane, while adding dropwise sodium bicarbonate aqueous solution to neutralize the hydrogen chloride produced, adjust the pH value to 7, react for 1.5h, remove the salt by suction filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com