Preparation method and application of inorganic hybrid flame retardant with high thermal stability

A technology with high thermal stability and flame retardant, applied in the direction of phosphorus oxyacid, hypophosphorous acid, etc., can solve the problems of difficult dispersibility, poor comprehensive flame retardant performance, etc., and achieve good comprehensive flame retardant performance and good comprehensive flame retardant performance. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

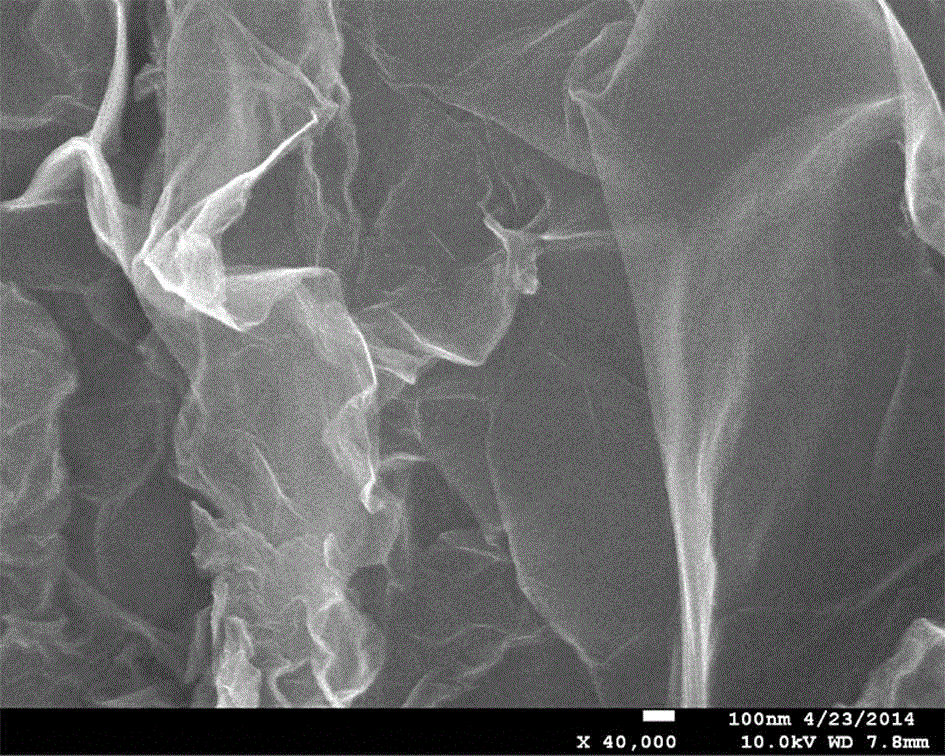

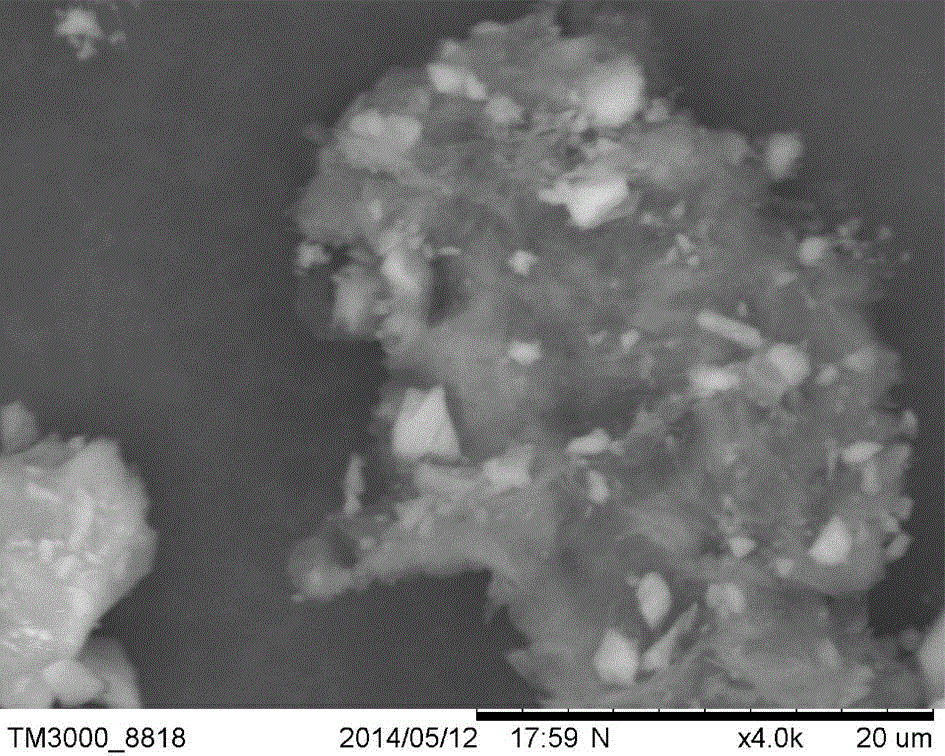

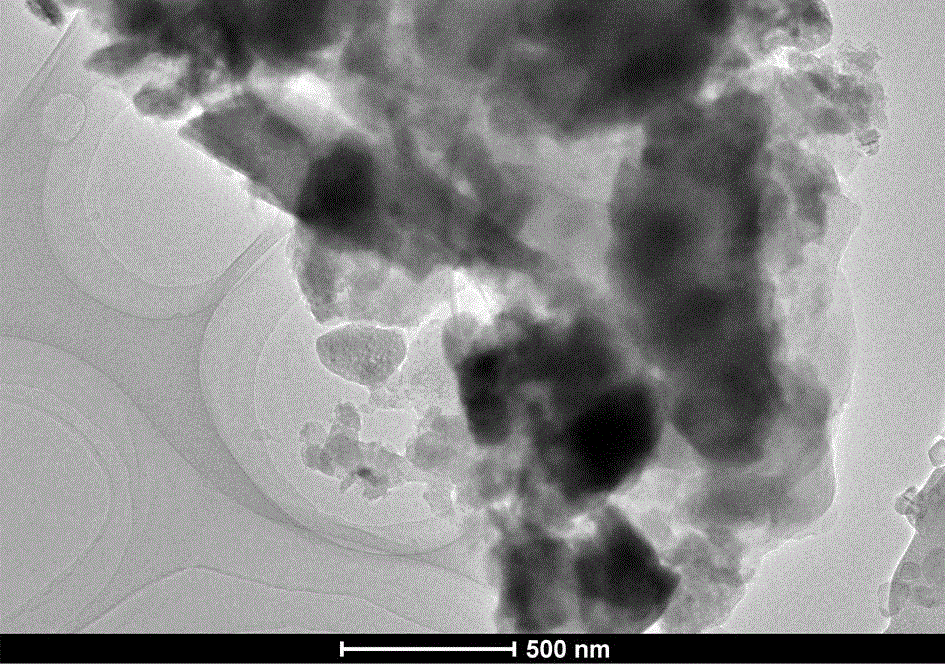

[0032] Dissolve 120mg of graphite oxide (GO) in 400mL of distilled water and ultrasonically disperse to obtain a concentration of 0.3mg·mL -1 Graphene oxide suspension; 4.83g AlCl 3 ·6H 2 O (0.02mol) was dissolved in the above 400mL graphene oxide suspension so that the concentration of aluminum salt was 50mmol L -1 , stirred at 25°C for 30min to obtain a mixed solution; add 6.36g of NaH to the above mixed solution 2 PO 2 ·H 2 O (0.06mol) to obtain a reaction solution; pour this reaction solution into a polytetrafluoroethylene reactor, transfer the reactor to an oven, set the reaction temperature to 180°C, and set the reaction time to 3h; the reaction is over Finally, the reaction solution was cooled to room temperature, subjected to suction filtration, water washing, and alcohol washing, and the obtained solid was put into a vacuum oven at a drying temperature of 50°C for 12 hours to obtain an inorganic hybrid flame retardant.

[0033] Taking Example 1 as an example, the...

Embodiment 2

[0035] Dissolve 200mg of graphite oxide (GO) in 400mL of distilled water and ultrasonically disperse to a concentration of 0.5mg·mL -1 Graphene oxide suspension; 26.66g Al 2 (SO 4 ) 3 18H 2 O (0.04mol) was dissolved in the above 400mL graphene oxide suspension so that the concentration of aluminum salt was 0.1mol L -1 , stirred at 25°C for 30min to obtain a mixed solution; add 12.72g of NaH to the above mixed solution 2 PO 2 ·H 2 O (0.12mol) to obtain a reaction solution, pour the reaction solution into a polytetrafluoroethylene reactor, transfer the reactor to an oven, set the reaction temperature to 180°C, and set the reaction time to 3h. After the reaction, the reaction solution was cooled to room temperature, filtered, washed with water, and washed with alcohol, and the obtained solid was put into a vacuum oven at a drying temperature of 50°C for 12 hours to obtain an inorganic hybrid flame retardant.

Embodiment 3

[0037] Dissolve 120mg of graphite oxide (GO) in 400mL of distilled water and ultrasonically disperse to obtain a concentration of 0.3mg·mL -1 Graphene oxide suspension; 30.01g Al(NO 3 ) 3 9H 2 O (0.08mol) was dissolved in the above 400mL graphene oxide suspension so that the concentration of aluminum salt was 0.2mol L -1 , stirred at 25°C for 30min to obtain a mixed solution; add 25.44g of NaH to the above mixed solution 2 PO 2 ·H 2 O (0.24mol) to obtain a reaction solution; pour this reaction solution into a polytetrafluoroethylene reactor, transfer the reactor to an oven, set the reaction temperature to 180°C, and set the reaction time to 3h; the reaction ends Finally, the reaction solution was cooled to room temperature, subjected to suction filtration, water washing, and alcohol washing, and the obtained solid was put into a vacuum oven at a drying temperature of 50°C for 12 hours to obtain an inorganic hybrid flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com