Bidirectional easy-to-tear PE film and preparation method thereof

A casting and outer layer technology, applied in the field of polymer chemistry, can solve the problem of easy tearing of polyethylene film without paying attention to it, achieve high composite strength and light aging resistance, good uniformity, improve mechanical properties and light aging resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 A kind of bidirectional easy-tear cast PE film

[0056] The formula is as follows in parts by weight:

[0057] Example 1

inner layer

inner layer

outer layer

10

10

10

Titanium dioxide

10

10

10

1.5

1.5

1.5

silica

0.8

0.8

0.8

Antioxidant 1098

0.8

0.8

0.8

Light Stabilizer UV-419

1.5

1.5

1.5

3

3

3

2

2

2

Sodium carboxymethyl cellulose

0.8

0.8

0.8

0.2

0.2

0.2

Blend of titanate coupling agent and silane coupling agent

1

1

1

LLDPE

10

10

10

acetate fiber

0.5

0

0

PP

0

2

0

COC

0

1

0

m-LLDPE

0

0

1

0

0

1

HDPE

55

55

55

[0058] Wherein, the average particle size of th...

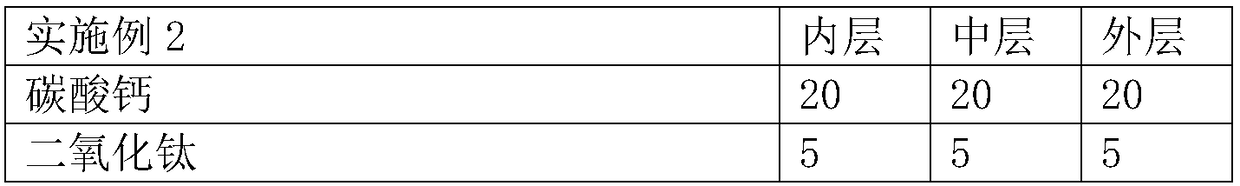

Embodiment 2

[0064] Embodiment 2 A kind of bidirectional easy-tear cast PE film

[0065] The formula is as follows in parts by weight:

[0066]

[0067]

[0068] Wherein, the average particle size of the nano-magnesium oxide is 55 nm; the weight ratio of the titanate coupling agent and the silane coupling agent in the blend of the titanate coupling agent and the silane coupling agent is 3:1.

[0069] The preparation method is basically the same as Example 1, and the difference with Example 1 is:

[0070] In steps (1), (2) and (3), the mixing time in the mixer is 30 min; the temperature of banburying is 160° C.;

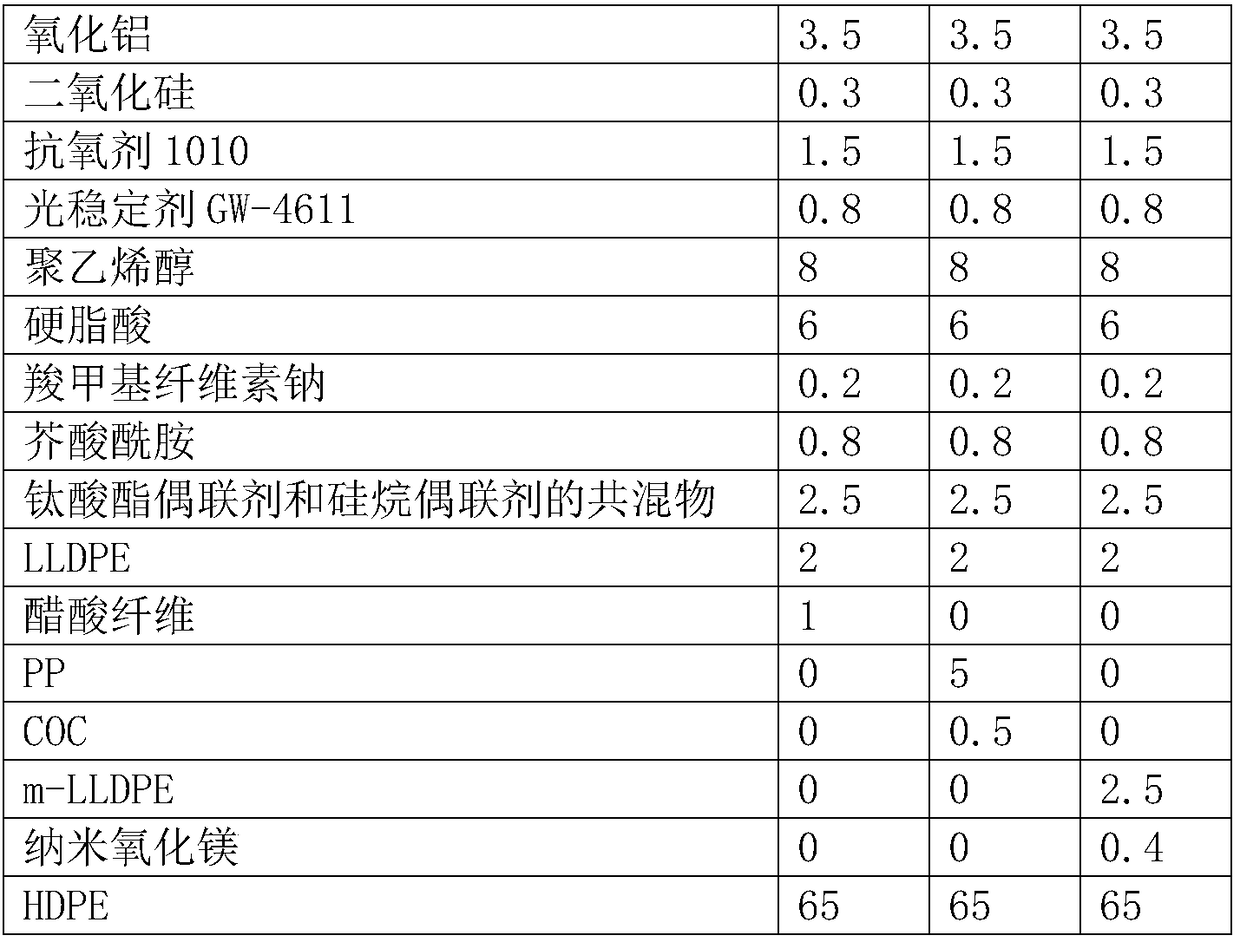

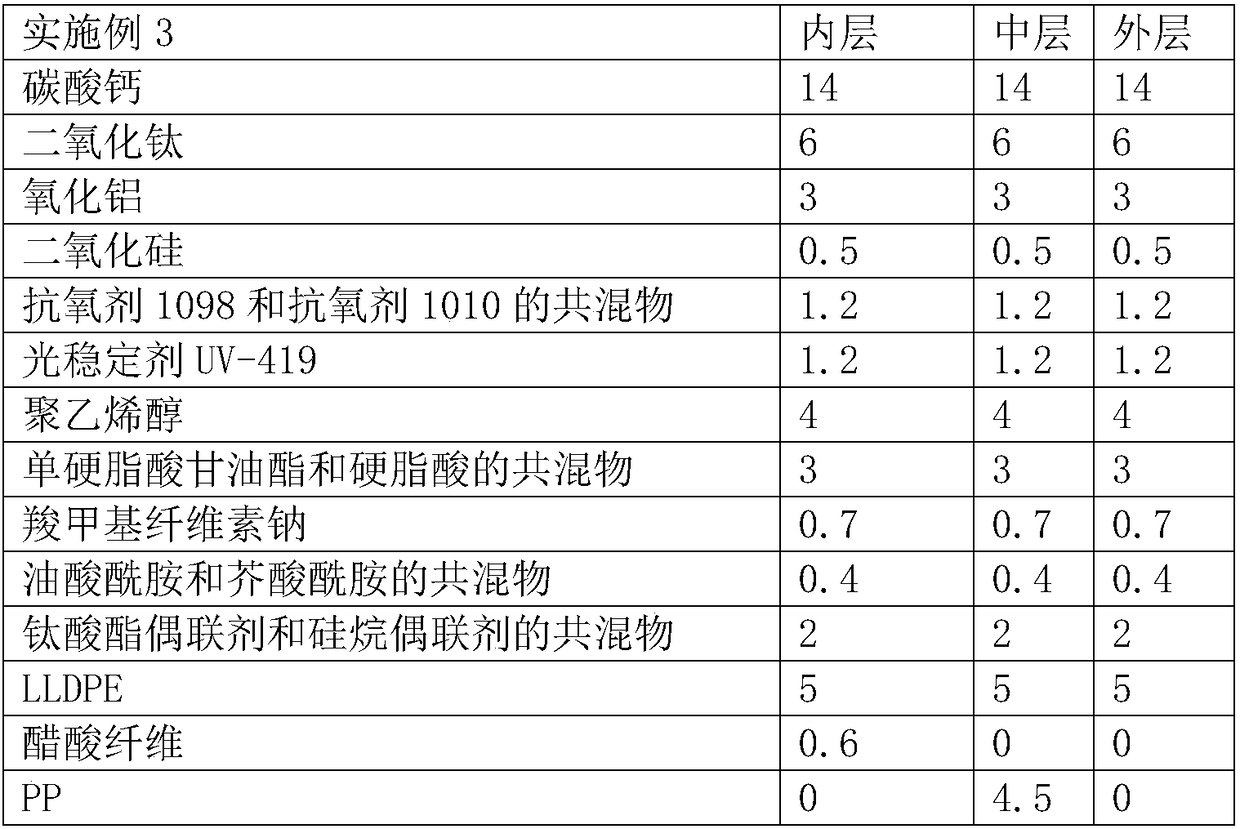

Embodiment 3

[0071] Embodiment 3 A kind of bidirectional easy-tear cast PE film

[0072] The formula is as follows in parts by weight:

[0073]

[0074]

[0075] Wherein, the average particle size of the nano-magnesium oxide is 50 nm; the weight ratio of the titanate coupling agent and the silane coupling agent in the blend of the titanate coupling agent and the silane coupling agent is 1:1.

[0076] The preparation method is basically the same as Example 1, and the difference with Example 1 is:

[0077] In steps (1), (2) and (3), the mixing time in the mixer is 25min; the temperature of Banbury is 145°C; the draw ratio is controlled to be 1.3:1, that is, it is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com