Lignin-based polyol, modified lignin-based polyurethane material, modified lignin-based polyurethane film, preparation method and application

A polyurethane material and polyurethane film technology, applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, anti-corrosion coatings, etc., can solve problems such as poor mechanical properties and thermal stability, and achieve improved heat resistance and light resistance Aging properties, good mechanical properties, effects of improving mechanical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

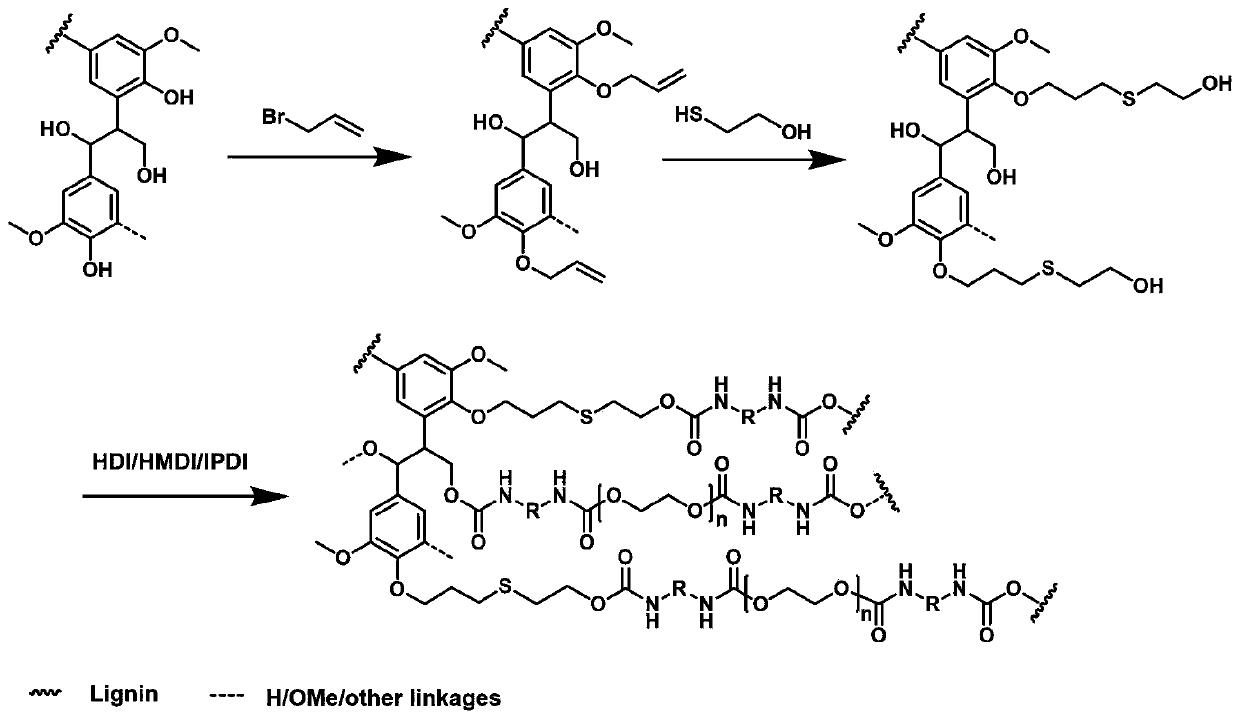

[0035] The invention provides a kind of preparation method of lignin-based polyol, comprising the following steps:

[0036] Mix lignin, sodium hydroxide solution, ethanol and allyl compound for allylation reaction to obtain allylated modified lignin;

[0037] The allylated modified lignin, the organic solvent and the mercapto compound are mixed, and the mercapto-ene click reaction is carried out to obtain the lignin-based polyol.

[0038] The invention mixes lignin, sodium hydroxide solution, ethanol and allyl compound to carry out allylation reaction to obtain allylated modified lignin.

[0039] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in this field.

[0040] In the present invention, the lignin preferably includes one or more of enzymatic lignin, alkali lignin and organic solvent lignin. In the present invention, the mass concentration of the sodium hydroxide solution is preferably 1-5%, m...

Embodiment 1

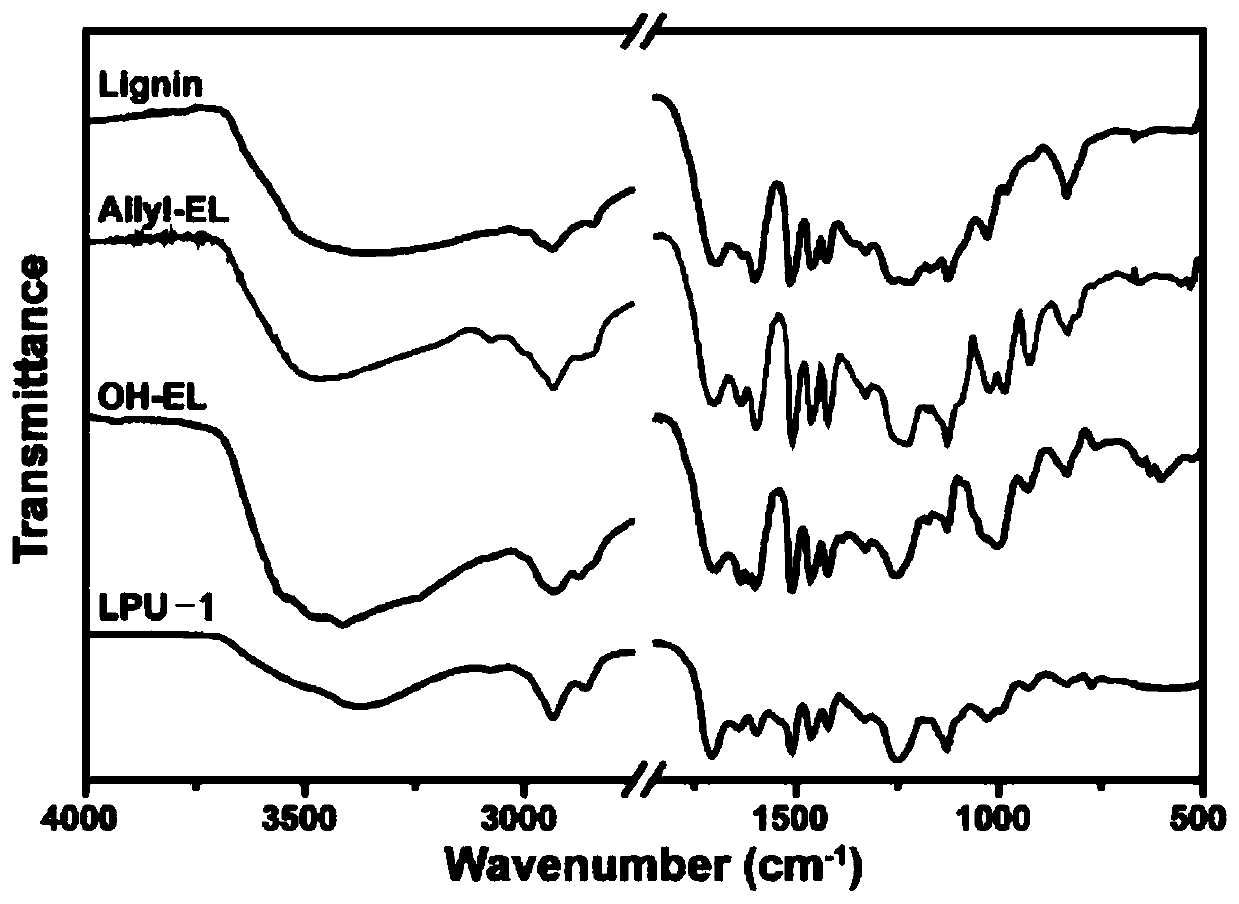

[0083] Weigh 10g of enzymatic lignin dissolved in NaOH solution and ethanol (the volume ratio of NaOH solution to ethanol is 1:1), add 7g of bromopropene, and carry out allylation reaction at 55°C for 24 hours Finally, the allylation reaction product was obtained. After the allylation reaction product was cooled to room temperature, an equal mass of ice-water mixture was added, and the pH value was adjusted to 2-3 with 1mol / L HCl, and the supernatant was filtered off overnight. liquid, put the solid filter residue in a vacuum oven, and after overnight at 50°C, crush it to obtain allylated modified lignin.

[0084] Weigh 10g of allylated modified lignin and dissolve it in THF, add 10g of mercaptoethanol, and carry out the mercapto-ene click reaction at 65°C. After 24 hours of reaction, the mercapto-ene click reaction product is obtained. The reaction product was cooled to room temperature, and an equal mass of deionized water was added, the product was precipitated and suction ...

Embodiment 2

[0095] The lignin-based polyol was prepared according to the method of Example 1.

[0096] Mix the modified lignin and HDI according to the ratio of isocyanate to 1.5, and dissolve it in absolute dry DMAC, put the reaction solution in a shaker at 250r / min and react for 30min to obtain a modified lignin-based polyurethane material, pour it into a glass sheet On the surface, the wet film thickness is 0.4mm, pre-cured at 60°C for 2 hours, the heating rate to 60°C is 0.5°C / min, and then heated to 120°C and cured for 2 hours, and the heating rate to 120°C is 0.5°C / min to obtain the modified lignin-based polyurethane film LPU-2 with a film thickness of 0.1 mm, which can be used to prepare sealing materials.

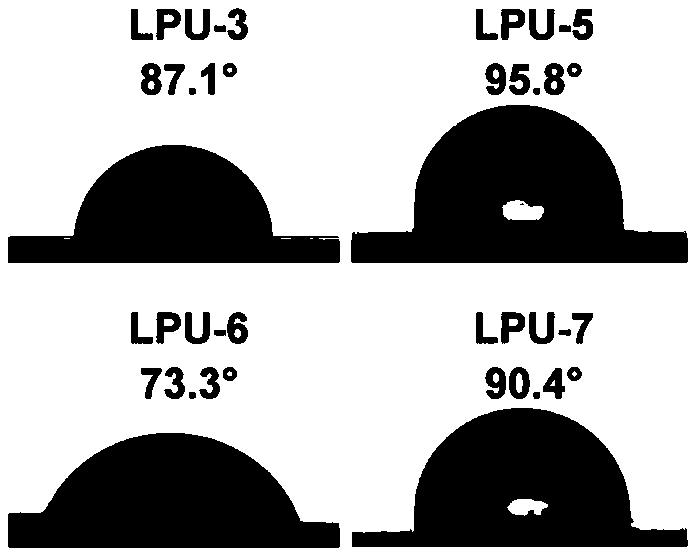

[0097] The performance of the modified lignin-based polyurethane film LPU-2 in Example 2 is tested, and the test results can be found in Figure 6-9 , Figure 11 And Table 2-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com