Preparation method of compound additive for polycarbonate modification

A technology of composite additives and polycarbonate, which is applied in the field of preparation of composite additives in polycarbonate modification, can solve the problems of insufficient hydrolysis stability, poor scratch resistance, and UV resistance, etc. Achieve high use value, prolong service life and improve surface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

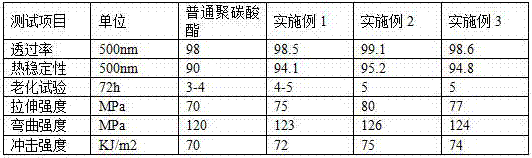

[0023] Embodiment one: preparation compound auxiliary agent: with the antioxidant of mass fraction 46 parts, the auxiliary antioxidant of mass fraction 46 parts, the ultraviolet absorber of mass fraction 6 parts and the fluorescent whitening agent of mass fraction 2 parts in high mixing The machine is fully mixed and stirred evenly, each component is granulated, and the obtained granules are sieved to obtain a composite additive for polycarbonate modification. See attached table 1 for the improvement of polycarbonate performance by the composite additive.

Embodiment 2

[0024] Embodiment two: preparation compound auxiliary agent: with the antioxidant of 40 parts of mass fractions, the auxiliary antioxidant of 40 parts of mass fractions, the ultraviolet absorber of 15 parts of mass fractions, the fluorescent whitening agent of 5 parts of mass fractions in high mixing The machine is fully mixed and stirred evenly, each component is granulated, and the obtained granules are sieved to obtain a composite additive for polycarbonate modification. See attached table 1 for the improvement of polycarbonate performance by the composite additive.

Embodiment 3

[0025] Embodiment three: preparation compound auxiliary agent: with the antioxidant of 44 parts of mass fractions, the auxiliary antioxidant of 44 parts of mass fractions, the ultraviolet absorber of 10 parts of mass fractions, the fluorescent whitening agent of 2 parts of mass fractions in high mixing The machine is fully mixed and stirred evenly, each component is granulated, and the obtained granules are sieved to obtain a composite additive for polycarbonate modification. See attached table 1 for the improvement of polycarbonate performance by the composite additive.

[0026] Schedule 1

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com