Natural lignocellulose material with modified zinc oxide and preparation method thereof

A technology of lignocellulose and zinc oxide modification, which is applied in the field of composite materials to achieve the effect of improving the resistance to light discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

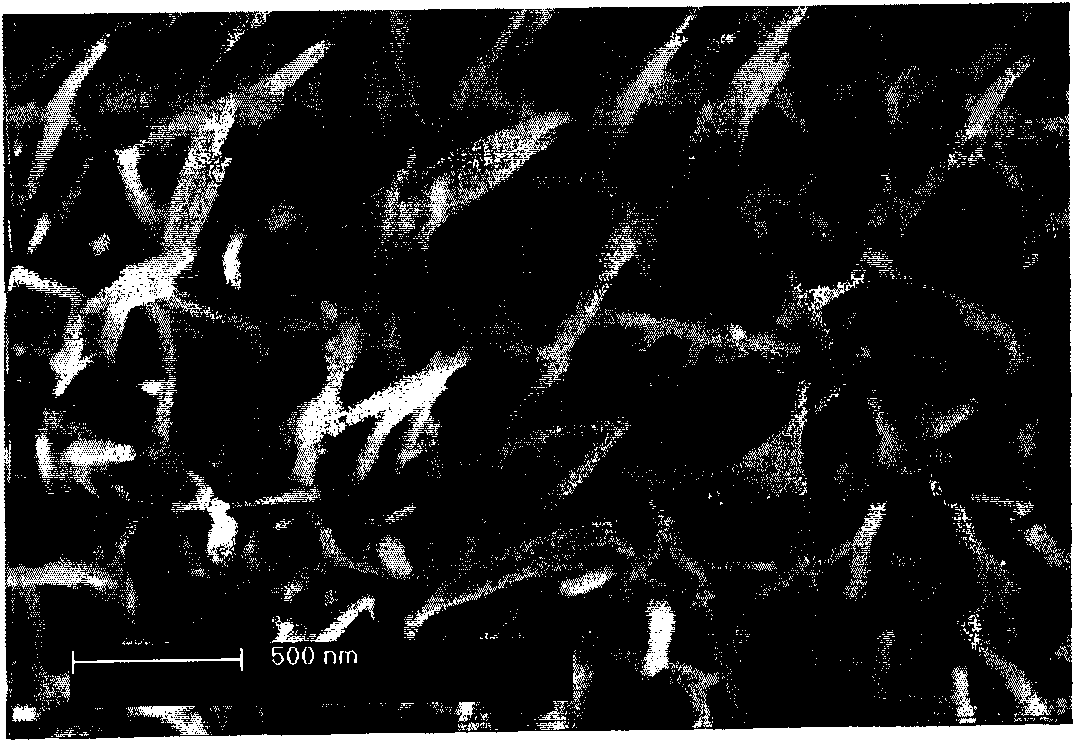

[0036] Take bamboo as the processing object, and process it according to the following steps:

[0037](1) preparation molar concentration is the ethanolic solution of zinc acetate dihydrate of 0.015mol / L, and the pH value is adjusted to 12.5 with potassium hydroxide solution;

[0038] (2) Under room temperature conditions, the solution prepared by (1) is impregnated into the inside of the bamboo by vacuum pressurization method (vacuumizing and then pressurizing the liquid), the impregnation time is 4h, and the wet state weight gain rate is 90%. , and then dried at 100°C for 3 hours, repeated 3 times;

[0039] (3) Zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) growth solution, the pH value of the solution is controlled at 6.8 with ammonia water, and the storage temperature is 3-5° C.;

[0040] (4) Under the conditions of 5° C. and normal pressure, inject the growth liquid into the inside of the sample after (3) treatment, so that the wet weight gain rate after treatment is ...

Embodiment 2

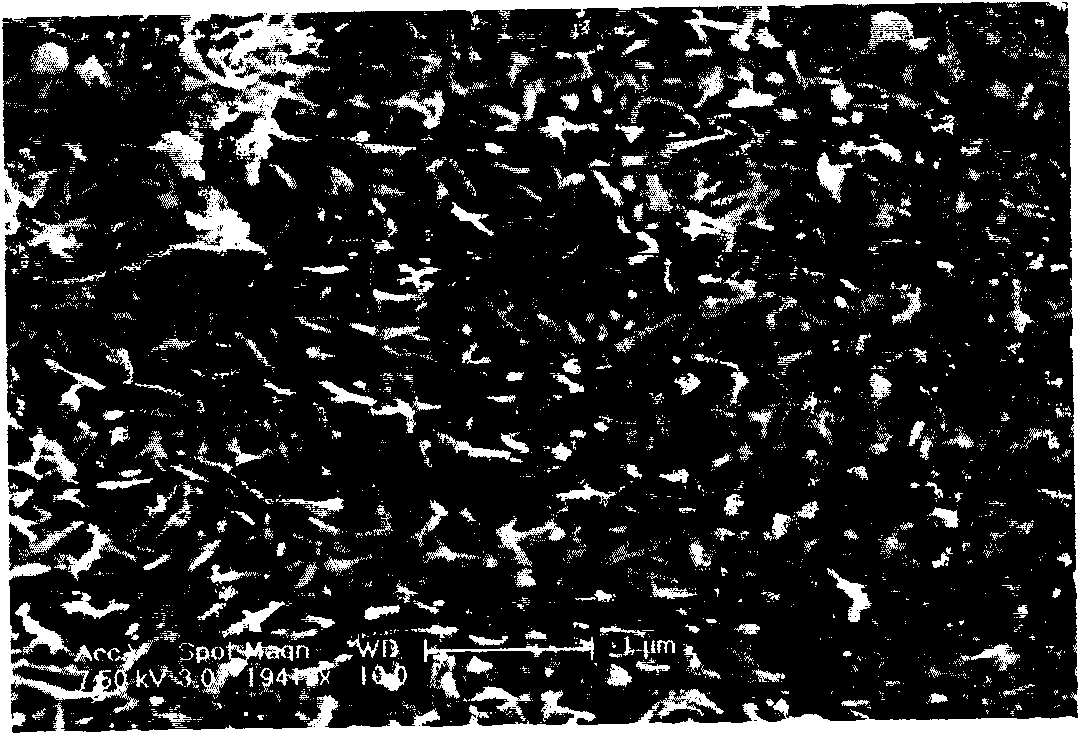

[0047] Timber is the processing object, and it is processed according to the following steps:

[0048] (1) preparation molar concentration is the ethanolic solution of zinc acetate dihydrate of 0.01mol / L, and the pH value is adjusted to 11 with potassium hydroxide solution;

[0049] (2) At room temperature, the seed solution prepared in (1) is impregnated into the interior of the wood by vacuum method, the impregnation time is 2 hours, the wet state weight gain rate is above 100%, and then dried at 100°C for 3 hours , repeated 3 times;

[0050] (3) Zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] growth solution, the pH value of regulating solution with ammonia water is controlled at 6.8;

[0051] (4) Under the condition of room temperature, the growth solution is injected into the inside of the sample after the treatment in (3) by vacuum pressurization method, so that the wet weight gain rate after treatment is about 120%.

[0052] (5) Immediately after taking out the trea...

Embodiment 3

[0056] Timber is the processing object, and it is processed according to the following steps:

[0057] (1) Prepare zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] growth solution, the pH value of regulating solution with ammonia water is controlled at 6.8;

[0058] (2) Under the condition of room temperature, the growth liquid is immersed into the inside of the sample by vacuum pressurization method, so that the wet weight gain rate after treatment is about 120%.

[0059] (3) Treat the treated wood in an oven at 95° C. for 6 hours after taking it out. Finally, balance to the desired moisture content.

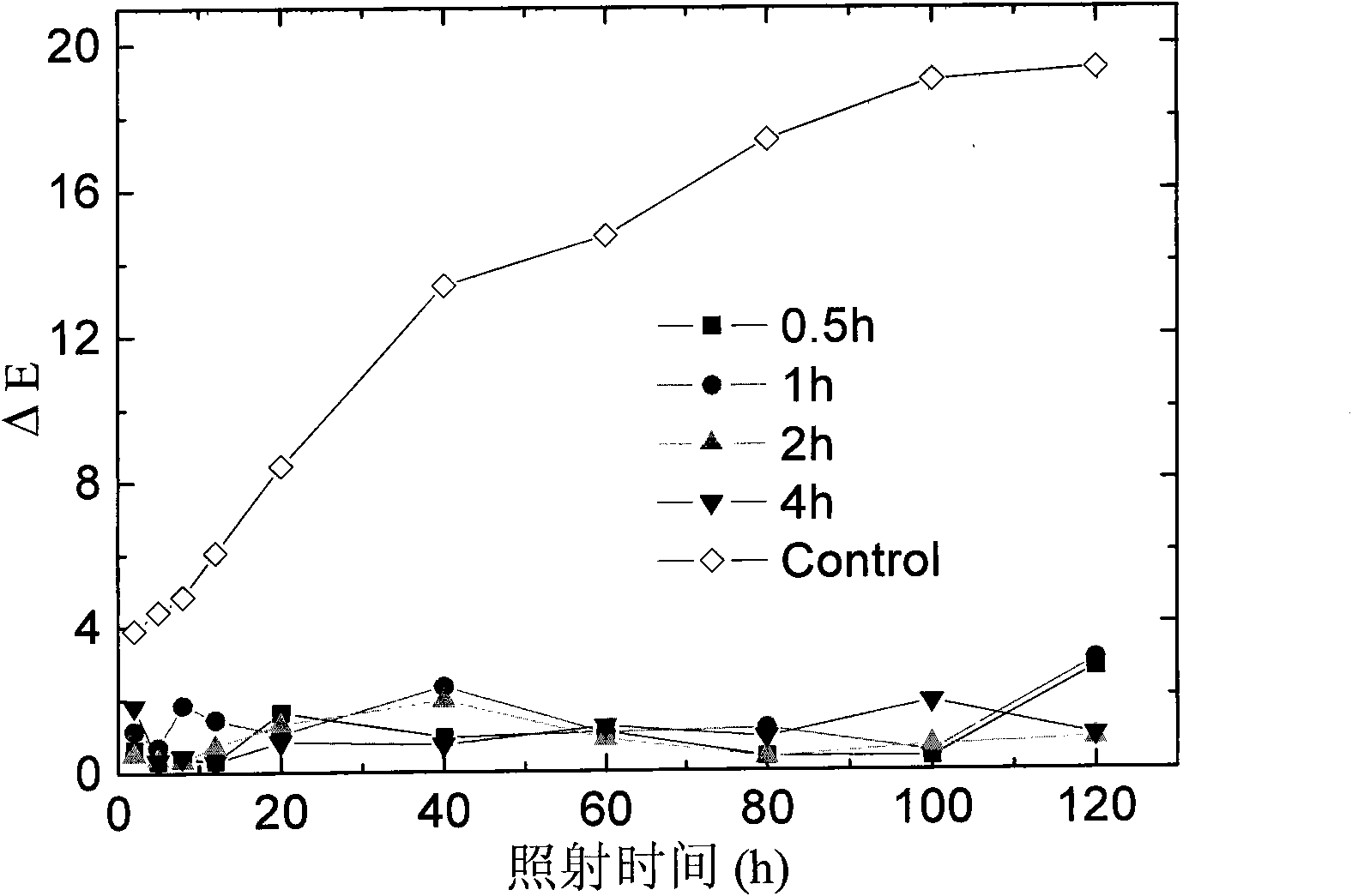

[0060] The treated wood and the untreated same wood were all placed in a high-humidity airtight environment with a relative humidity of 95%. The treated wood was placed for 30 days without mold growth, and the untreated wood began to appear mold spots after being placed for 1 day. Apparently, the anti-mold performance of the material is significantly improved after nano-zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com