A high-altitude lightning arrester

A lightning arrester and high-altitude technology, applied in the direction of resistors, resistor components, non-adjustable metal resistors, etc., can solve problems such as abnormal explosion-proof devices and excessive internal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

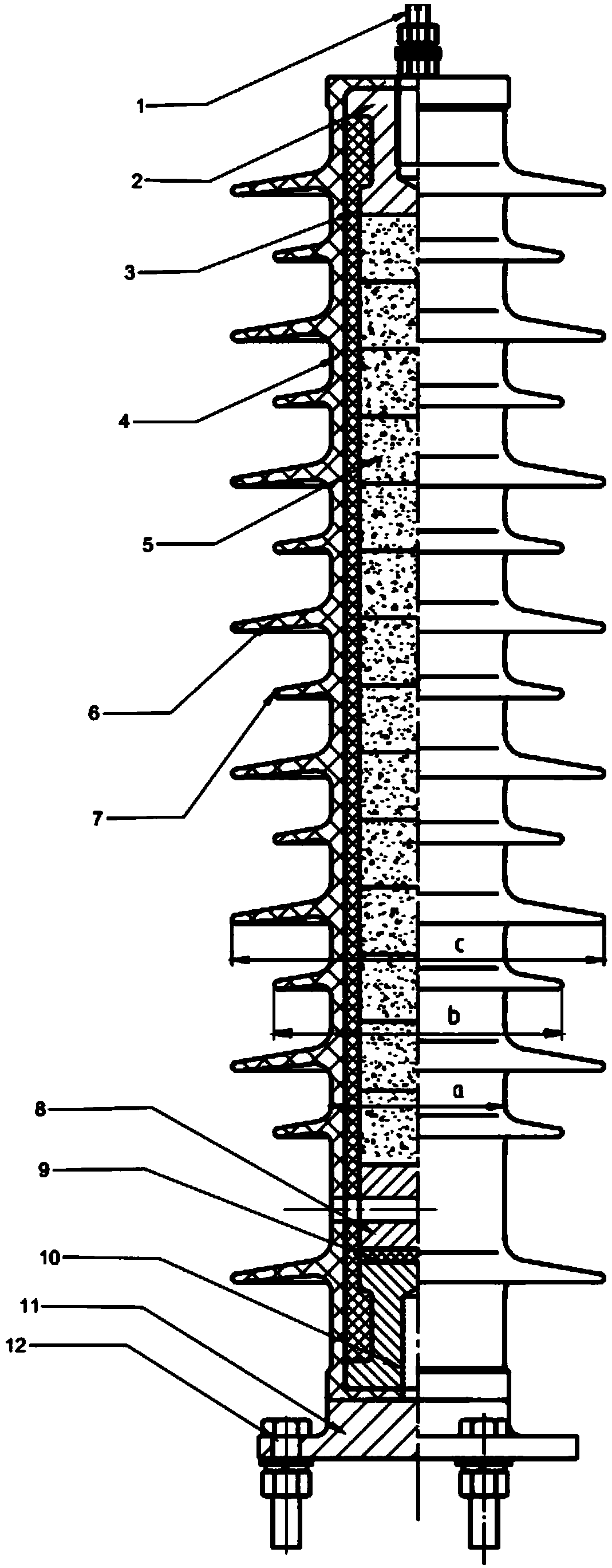

[0026] This embodiment provides a high-altitude arrester, the arrester is a solid structure, such as figure 1 As shown, it includes a high-voltage terminal 1, a silicone rubber insulating jacket 4, a winding layer 3, several series-connected zinc oxide resistors 5, an upper electrode 2, a lower electrode 10, and a grounding electrode 8. The resistors are stacked on the arrester The middle position of the winding layer covers the outer periphery of the resistor sheet and extends along the stacking direction of the resistor sheet; the silicone rubber insulating jacket covers the outer periphery of the winding layer; the upper electrode is arranged on the laminated resistor sheet The upper end of the ground electrode is arranged at the lower end of the laminated resistor sheet, the lower electrode is arranged at the lower end of the ground electrode, and the high voltage connection terminal is arranged at the upper end of the upper electrode.

[0027] Wherein, the winding layer p...

Embodiment 2

[0035] The diameter of the base of the arrester is 60mm; the diameter of the large shed is 136mm; the diameter of the small shed is 100mm.

[0036] The silicone rubber insulating jacket is made of the following raw materials in parts by weight: 0.994 parts of silicone gum, 0.0015 parts of toner, 0.0015 parts of silicone oil, and 0.0025 parts of dispersant.

[0037] Other content is identical with embodiment 1.

Embodiment 3

[0039] The diameter of the base of the arrester is 64mm; the diameter of the large shed is 130mm; the diameter of the small shed is 106mm.

[0040] The silicone rubber insulating jacket is made of the following raw materials in parts by weight: 0.996 parts of silicone gum, 0.0005 parts of toner, 0.0025 parts of silicone oil, and 0.0015 parts of dispersant.

[0041] Other content is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com